Edible oil processing and discharging technology

A technology of edible oil and process, applied in the field of edible oil, can solve problems such as product inconsistency, waste of raw materials, and failure to achieve the same batch output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

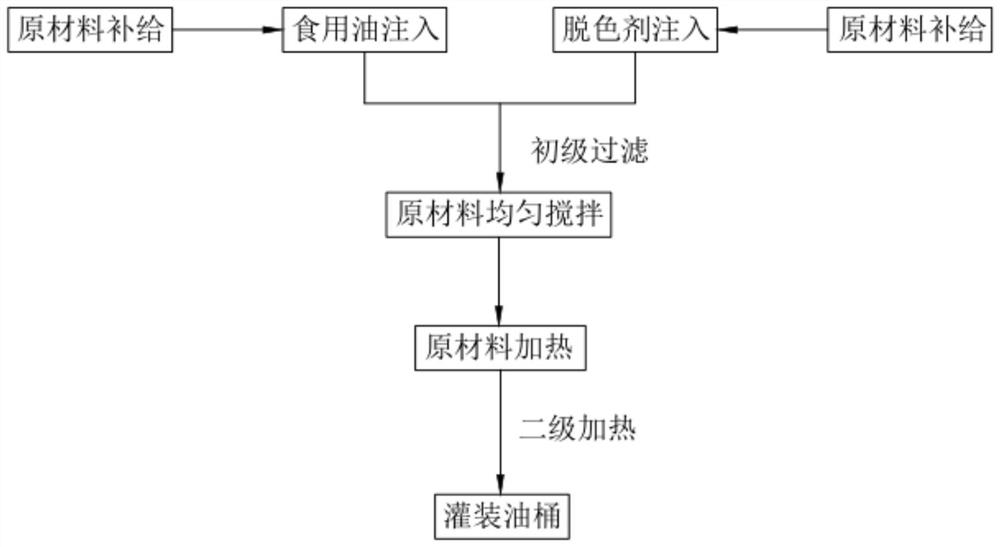

[0090] Such as figure 1 Shown, a kind of edible oil processing discharging process is characterized in that, comprises:

[0091] Step 1, raw material replenishment, the oil storage barrel in the previous process is transported by the oil pump from the feeding port b35 into the injection box a31 for temporary storage, and at the same time the decolorizing agent in the decolorizing agent storage box is pumped from the feeding port b35 into the injection Temporary storage in box b41;

[0092] Step 2, edible oil is injected, and the drive mechanism 2 is started to rotate. When meshing, the rotating fifth gear 63 drives the first rack 64 to move horizontally. When the first rack 64 moves, the first rack 64 drives the piston rod a32 to squeeze The air pressure of the injection box a31, during the movement, the baffle plate a36 blocks the feeding port b35, the piston rod a32 continues to move and squeezes the injection box a31, the edible oil enters the connecting pipe from the feed...

Embodiment 2

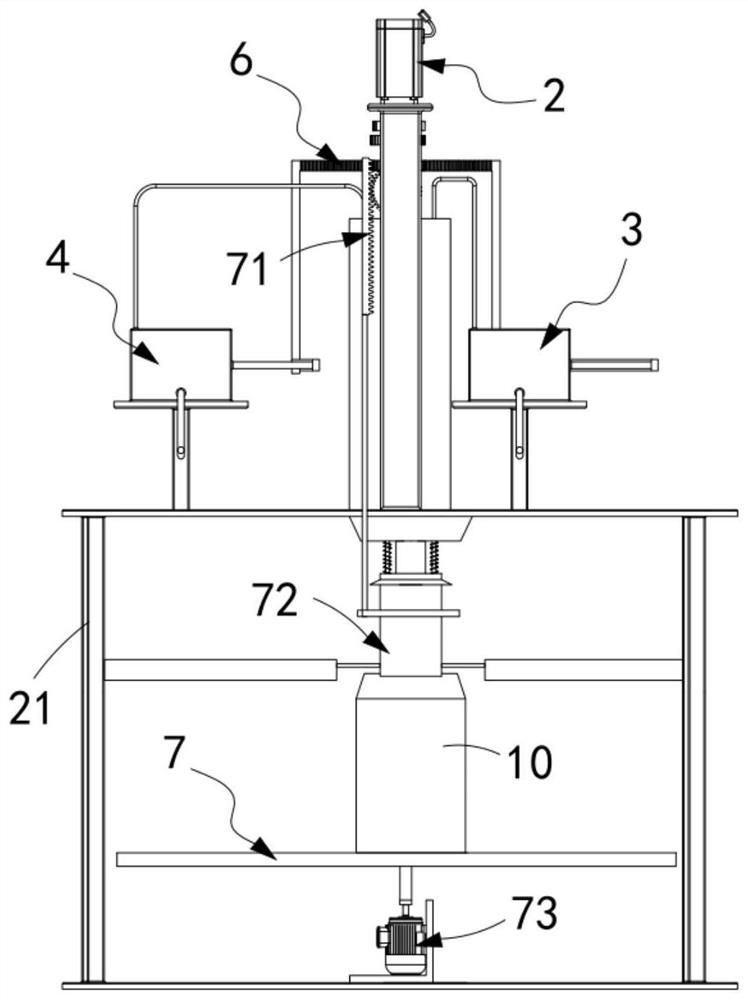

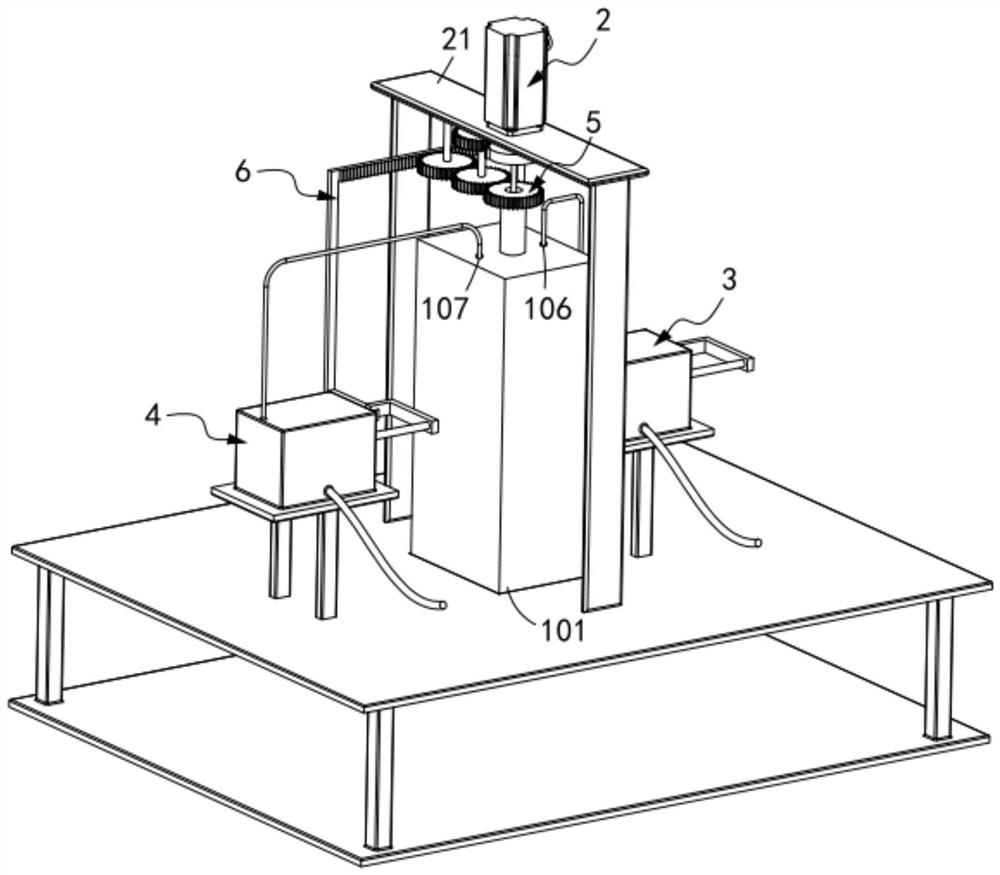

[0113] Such as figure 2 , image 3 and Figure 22 As shown, an edible oil processing and discharging device includes a tank body 101, an insulation layer 102 arranged around the outer periphery of the tank body 101, and a steam channel 103 arranged between the insulation layer 102 and the tank body 101 , the first filter screen 104 arranged at the input end of the tank body 101 and the second filter screen 105 arranged at the output end of the tank body 101, further comprising:

[0114] Drive mechanism 2, described drive mechanism 2 is installed on the frame 21, and described can body 101 is installed on the frame 21;

[0115] An edible oil feeding mechanism 3, the edible oil feeding mechanism 3 is arranged on one side of the tank body 101 and the output end of the edible oil feeding mechanism 3 communicates with the first feeding port 106 on the upper end of the tank body 101;

[0116] A decolorizing agent feeding mechanism 4, the decolorizing agent feeding mechanism 4 is...

Embodiment 3

[0160] Such as Figure 15 , Figure 13 and Figure 14 As shown, the parts that are the same as or corresponding to those in the second embodiment are marked with the corresponding reference numerals in the second embodiment. For the sake of simplicity, only the differences from the second embodiment will be described below. The difference between this embodiment three and embodiment two is:

[0161] Further, the bottom of the stirring mechanism 5 is provided with a draining mechanism 8 that cooperates with its rotation to drive. During the transmission process, the draining mechanism 8 fluctuates up and down in the vertical direction, and the mixed material flows along the draining mechanism 8 to the second filter screen 105 The drainage mechanism 8 includes several groups of first deflectors 81 and second deflectors 82 arranged along the height direction of the tank body 101, and the first deflectors 81 and second deflectors 82 are misaligned. relative settings;

[0162] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com