Oil-water separation device for vacuum pump

A technology of oil-water separation device and vacuum pump, which is applied to the components, separation methods, and separation of dispersed particles of elastic fluid pumping devices, and can solve problems such as poor cooling effect, polluted air, and insufficient separation, and achieve structural Simple and practical, avoiding pollution, ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

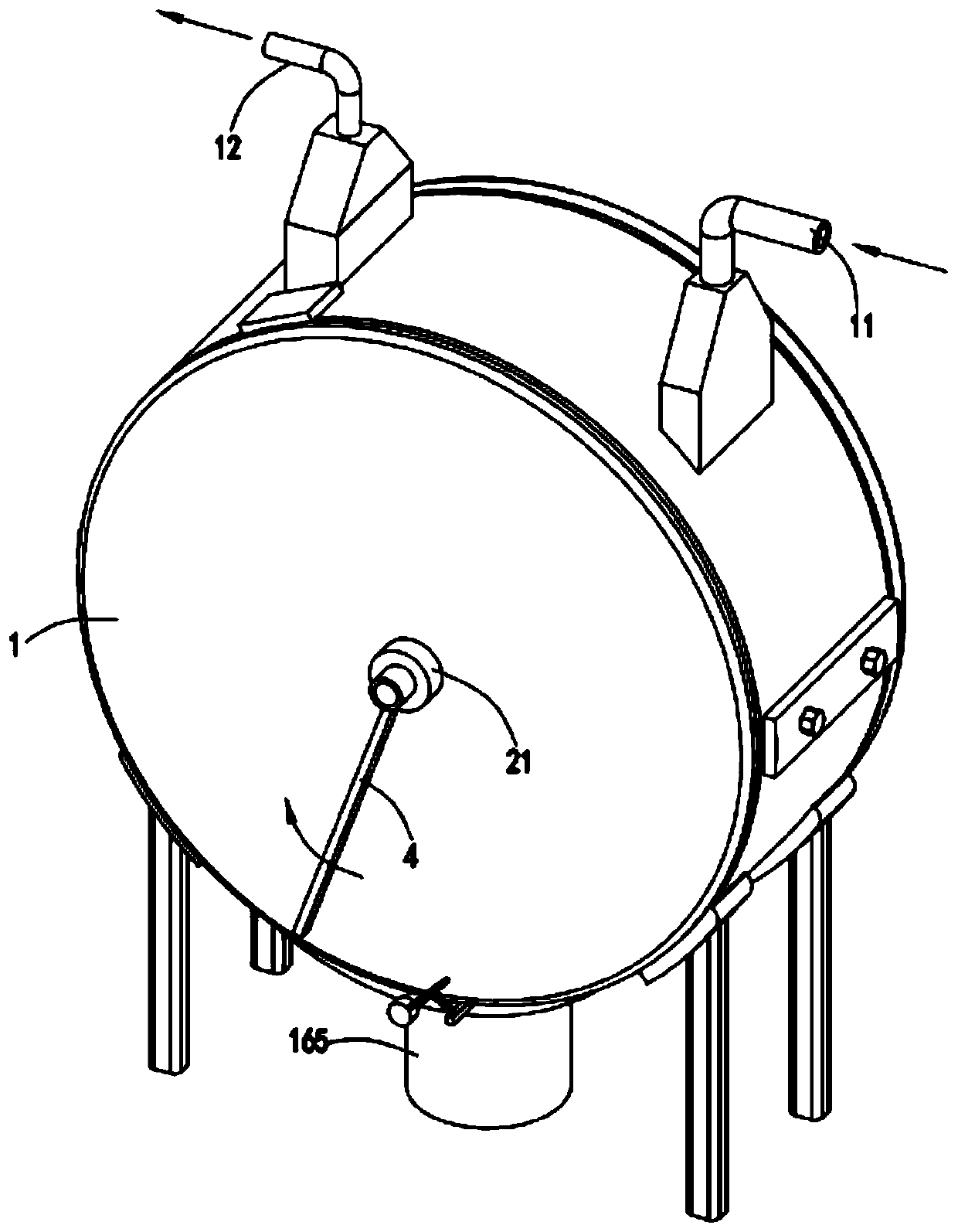

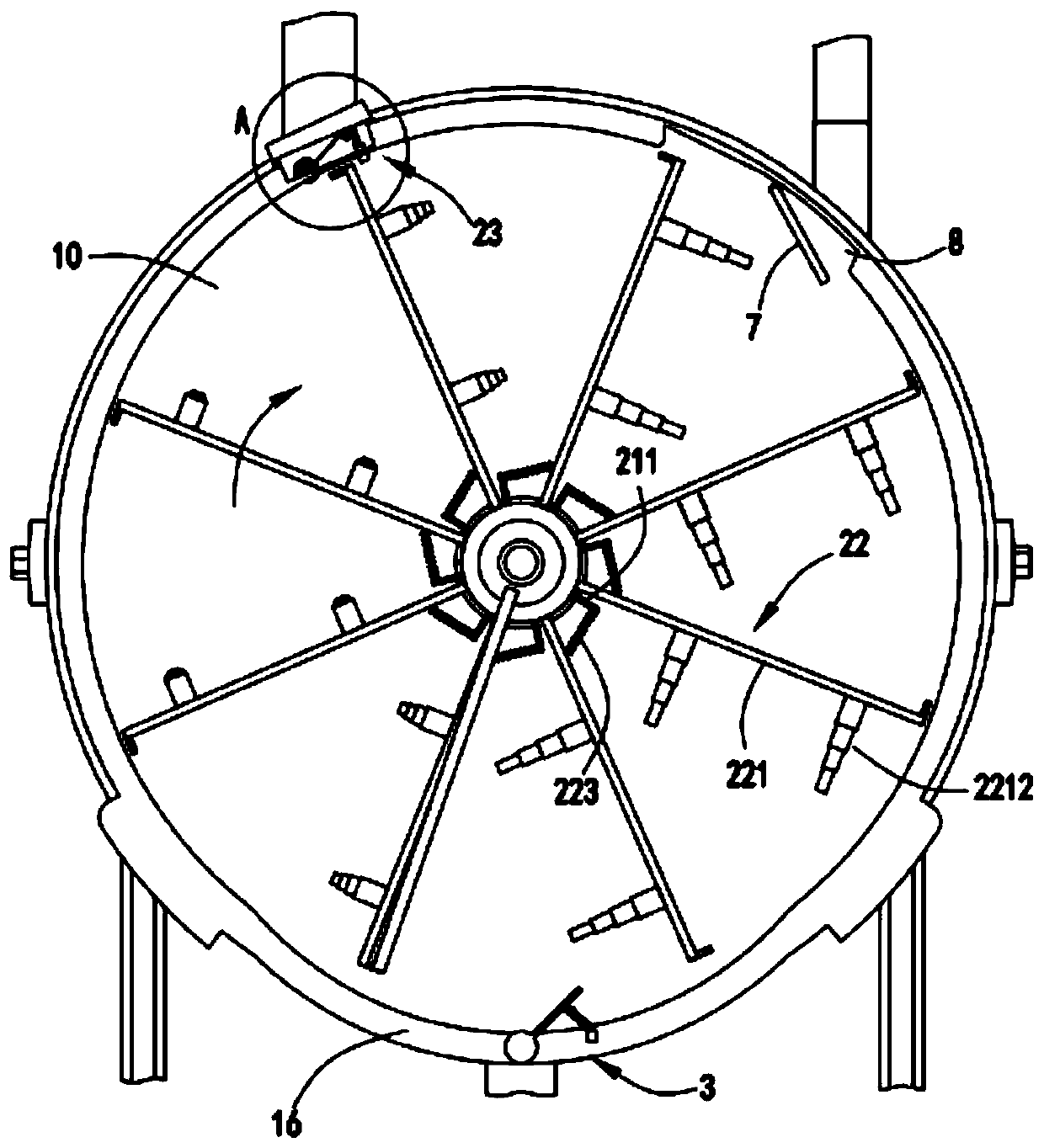

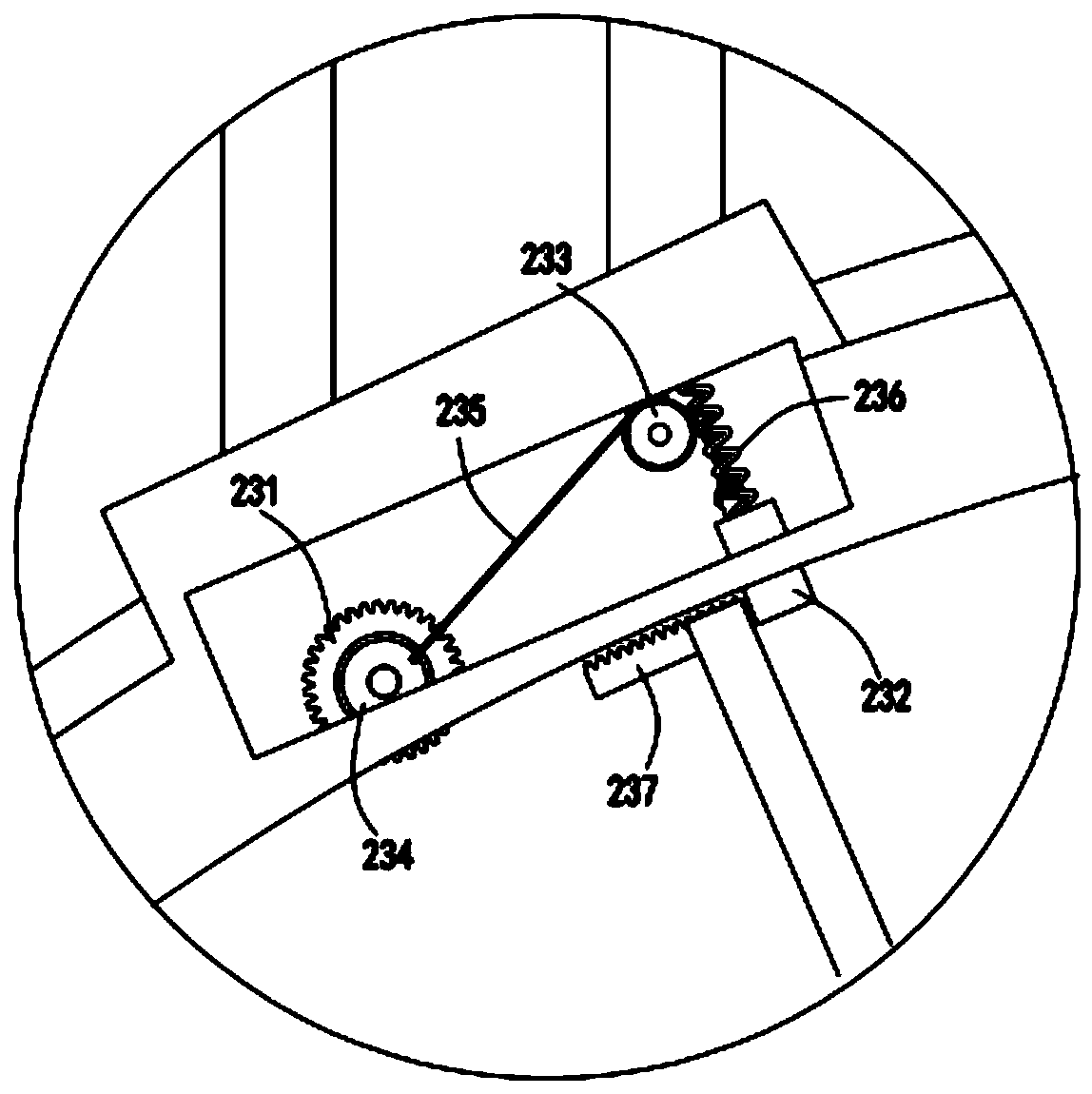

[0038] Such as Figure 1 to Figure 11 As shown, an oil-water separation device for a vacuum pump includes a separation box 1, the separation box 1 is connected with an air inlet pipe 11 and an air outlet pipe 12; the separation box 1 is provided with a separation mechanism 2, and the separation mechanism 2 It includes a rotating shaft 21 and a number of separation assemblies 22 arranged on the rotating shaft 21. A separation space 10 is formed between two adjacent separation assemblies 22. The air inlets 13 connected to the air inlet pipe 11 and the air outlet pipe 12 on the separation box 1 are respectively and the gas outlet 14 are respectively located on the left and right sides of the central axis of the separation box 1, the oil-containing gas enters the separation box 1 through the inlet pipe 11 and the air inlet 13, and the oil-containing gas acts on the separation assembly 22 located below the air inlet 13 to drive the rotating shaft 21 rotates so as to drive each sepa...

Embodiment 2

[0050] Such as Figure 8 and Figure 11 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the bottom of the separation box 1 is also provided with an oil discharge assembly 3, and the oily liquid condensed in the separation box 1 is collected to the oil discharge assembly 3, and the oil discharge assembly 3 The oil component 3 is intermittently communicated with the outside by means of the rotation of the rotating shaft 21 to discharge the oily liquid.

[0051] Further, the bottom of the separation box 1 is provided with an arc-shaped groove portion 16, and the middle bottom of the arc-shaped groove portion 16 is provided with a rotating groove 161, and the oil discharge assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com