Electric power overhaul herringbone ladder

A technology of electric power maintenance and herringbone ladder, which is applied in the field of electric power, can solve problems such as easy sliding, low safety, easy accumulation, etc., and achieve the effects of stable air pressure, improved cleaning ability, and increased friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

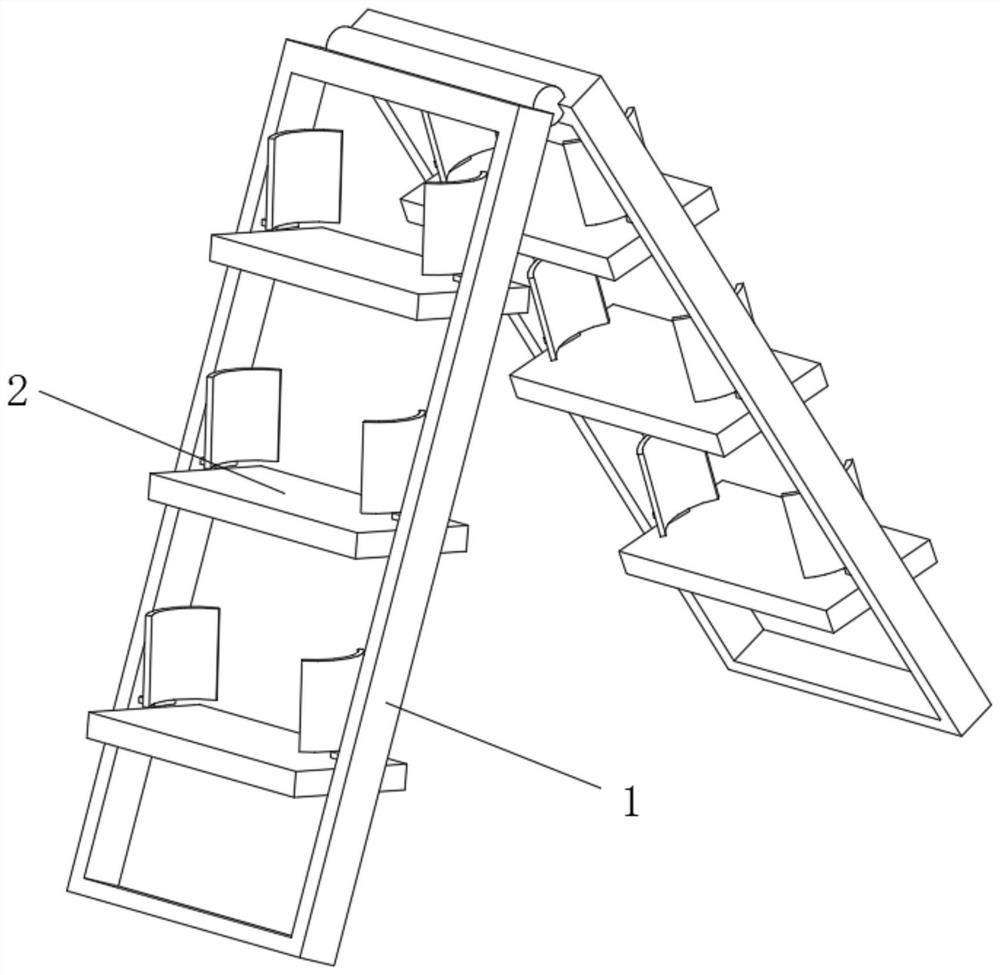

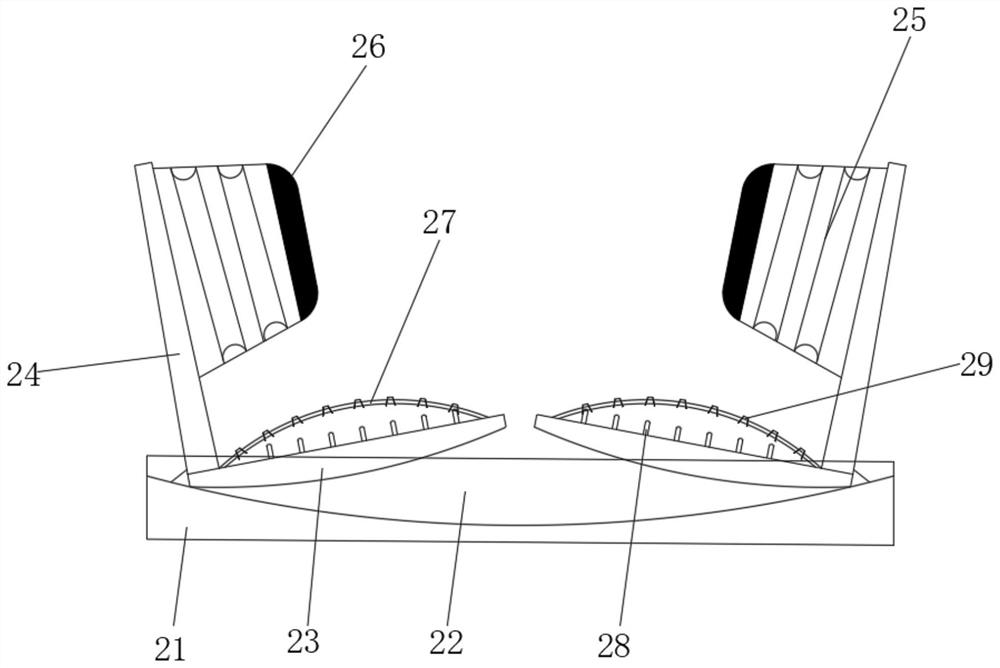

[0033] Such as Figure 1-3As shown, the present invention provides a technical solution: an electric power maintenance ladder, including a ladder frame 1, the lateral position of the ladder frame 1 is uniformly connected with a protective pedal mechanism 2, and the protective pedal mechanism 2 includes a load pedal 21, the middle position of the top of the load pedal 21 is provided with an adjustment storage groove 22, and the left and right sides of the adjustment storage groove 22 are connected with a support arc pressure plate 23 in rotation, and the top of the support arc pressure plate 23 and the position close to the outside are fixedly connected with a protective Clamping bar 24, the top of protective clamping bar 24 and close to the internal measurement position are all fixedly connected with corrugated cover frame 25, and one end of corrugated cover frame 25 away from protective clamping bar 24 is fixedly connected with magnet block 26, and the surface of supporting ar...

Embodiment 2

[0037] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a kind of electric power maintenance ladder, the protective conduction assembly 29 includes a conductive outer frame 291, and the outer side of the conductive outer frame 291 and the protective air bag 27 Fixed connection, conduction The position above the outer frame 291 is fixedly connected with an elastic plate 292 , and the outer surface of the elastic plate 292 is uniformly provided with air-conducting grooves 295 .

[0038] The output end outside the air guide channel 295 is fixedly connected with a conduction backing plate 293 , and the top outside of the elastic plate 292 is fixedly connected with an anti-skid bump 294 . Ensure that the exhaust port is not blocked by trampled impurities, and achieve targeted cleaning of impurities.

[0039] The top of the inner side of the conductive outer frame 291 is fixedly connected with an elastic baffle 296 , and...

Embodiment 3

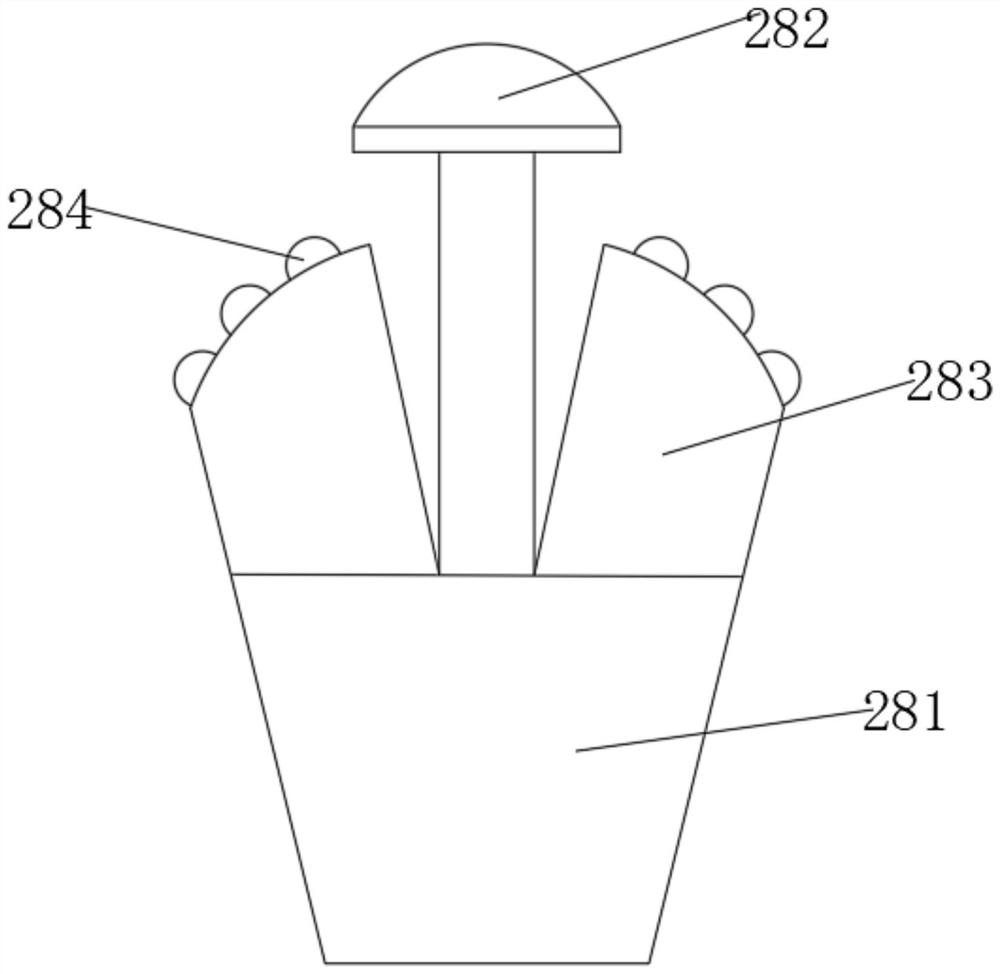

[0042] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: an electric maintenance ladder, the tension adjustment assembly 299 includes an auxiliary connecting rod a1, and the bottom of the auxiliary connecting rod a1 is connected to the The outer frame 291 is fixedly connected, the top end of the auxiliary link a1 is fixedly connected with a tension band a2 , and the bottom end of the tension band a2 is fixedly connected with the elastic plate 292 .

[0043] The top of the auxiliary connecting rod 1 is fixedly connected with a support bar a3, and the surface of the top of the tension band a2 is uniformly and fixedly connected with a tension bar a4. Further improve the friction force when stepping, avoid the phenomenon of stepping and sliding of workers, and protect the safety of workers when climbing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com