Plasma flat light source driving method

A flat-panel light source and plasma technology, which can be applied to light sources, electric light sources, lighting devices, etc., can solve the problems of uneven lighting, environmental pollution, and low luminous efficiency, and achieve the effects of reducing power consumption and improving luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further explained below in conjunction with the drawings.

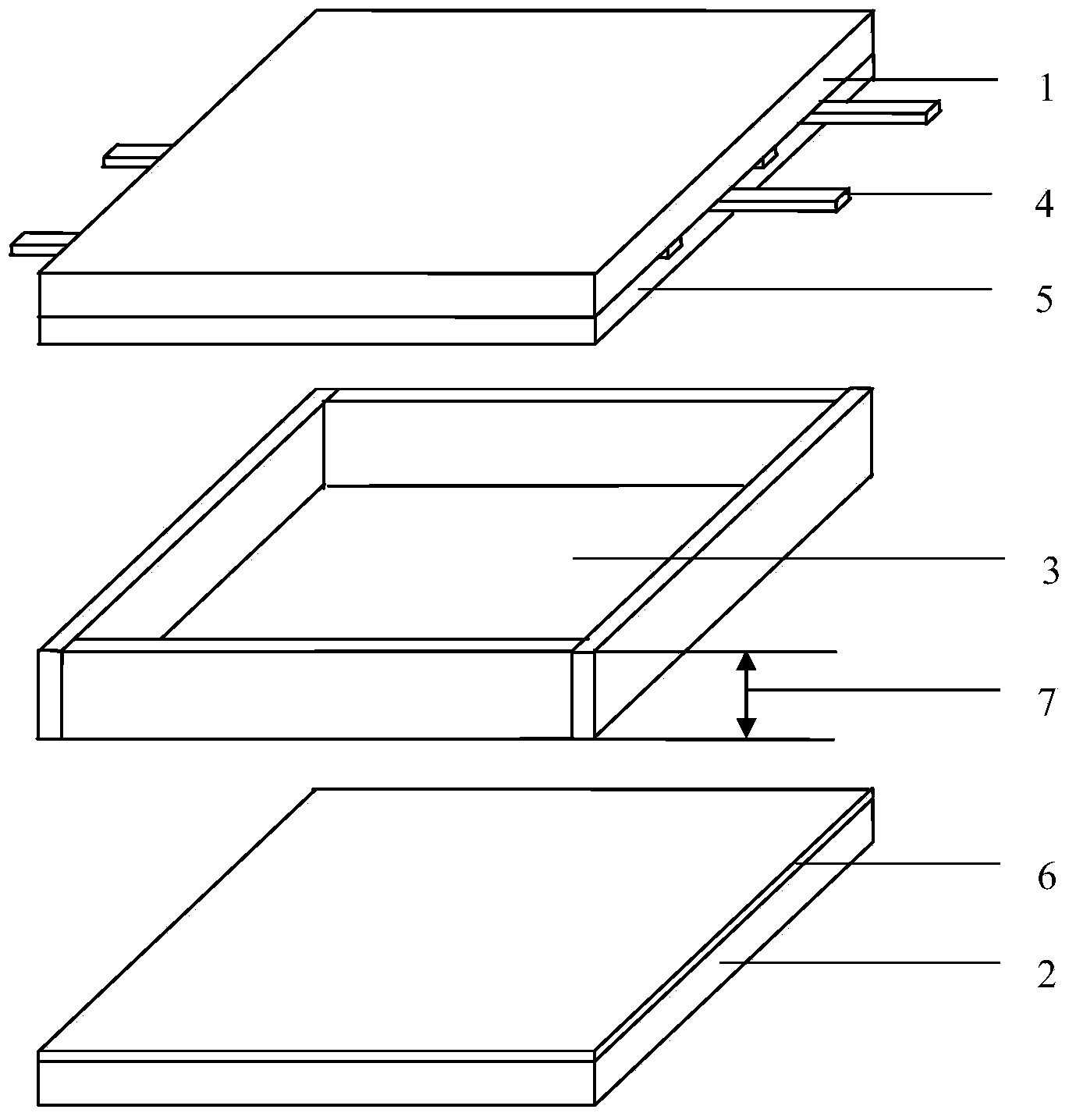

[0019] Such as figure 1 As shown, a preferred plasma flat light source of the present invention includes a front substrate 1, a rear substrate 2, and a discharge cavity 3. The discharge cavity 3 is arranged between the front substrate 1 and the rear substrate 2, and the front substrate 1 is close to one side of the discharge cavity. A transparent medium layer and a protective film 5 are arranged on the side, and a number of parallel electrodes 4 driven by square wave pulses are arranged between the front substrate 1 and the transparent medium layer and the protective film 5; the back substrate 2 is coated with three parallel electrodes on the side close to the discharge cavity 3 Mixing layer of color phosphor 6.

[0020] The distance between two adjacent parallel electrodes of this type of plasma flat light source is greater than or equal to 3 mm.

[0021] The discharge cavity of this ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com