Backlight module and liquid crystal display module

A backlight module, light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as LED temperature rise, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

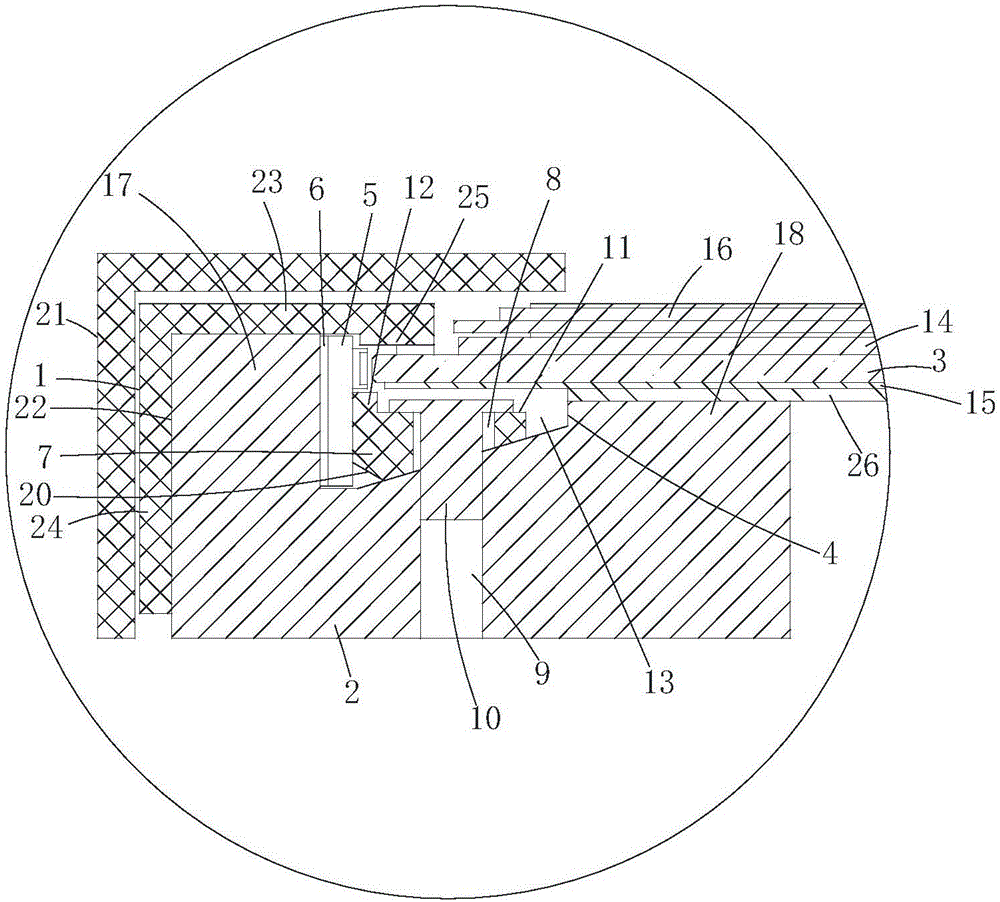

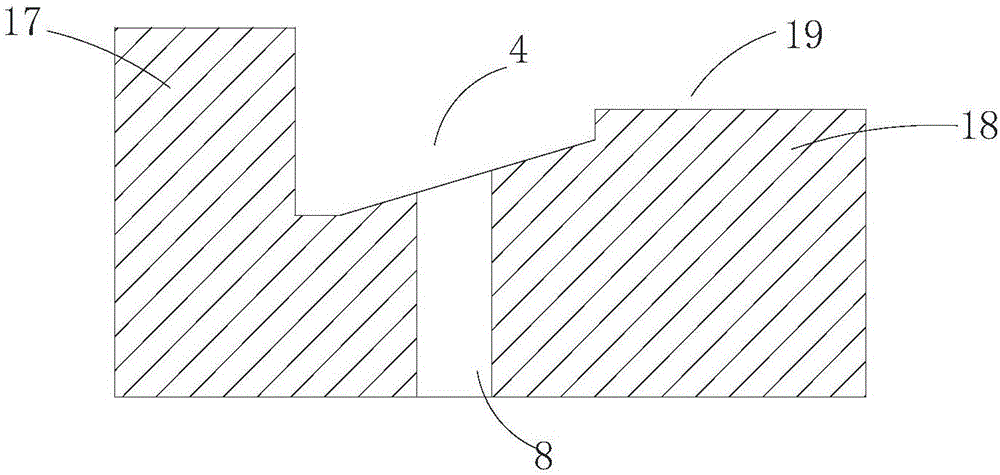

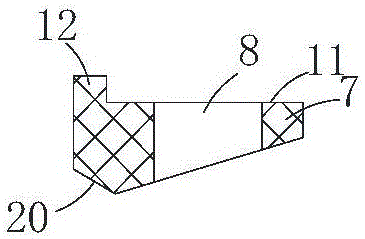

[0019] Such as figure 1 with figure 2 As shown, a backlight module of the present invention includes a middle frame 1, the middle frame 1 is L-shaped, from figure 1 It can be seen from the figure that it rotates 180 degrees clockwise. The middle frame 1 has a parallel portion 23 parallel to the surface of the light guide plate 3 and a vertical portion 24 perpendicular to the parallel portion 23. An accommodation portion 22 is formed between the parallel portion 23 and the vertical portion 24. The heat sink 2 is set in the housing portion 22, and the heat sink 2 carries the optical film 14, the light guide plate 3, the reflection sheet 15 and the back plate 26, and the side of the light guide plate 3 opposite to the heat sink 2 extends to the heat sink 2 Between the parallel part 23 of the middle frame 1, a liquid crystal panel 16 is carried...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com