Ultraviolet cured color transfer screen printing fluorescent paint and preparation method thereof

A technology of color conversion and screen printing, applied in the direction of luminescent paint, coating, etc., can solve the problems of unsatisfactory color and brightness, and achieve the effect of high conversion rate, bright color and guaranteed efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

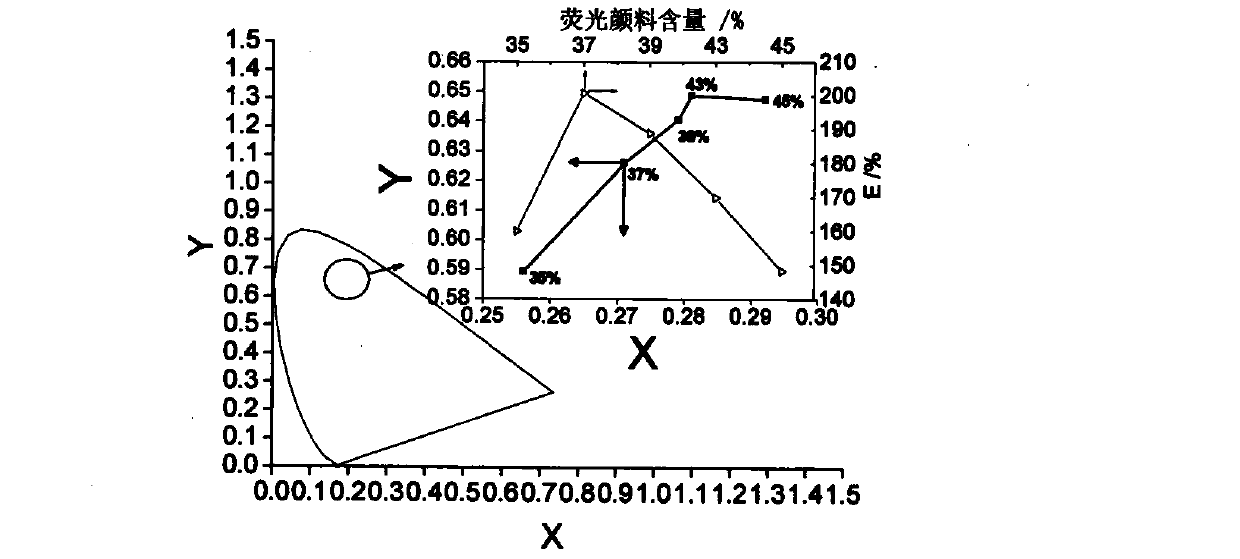

Examples

Embodiment 1-5

[0024] (1) Raw material formula:

[0025]

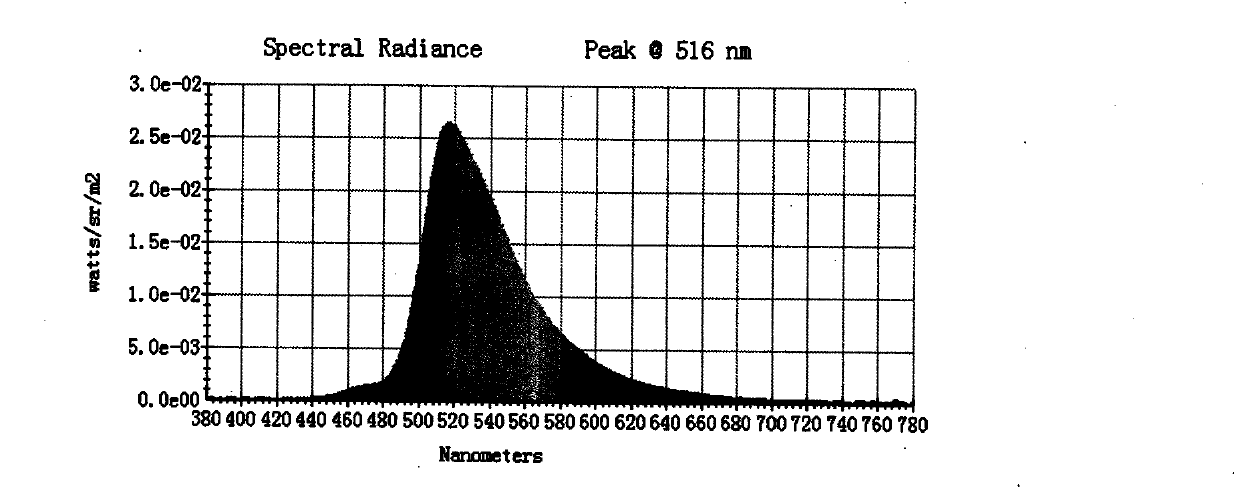

[0026] (2) Preparation method: weigh various raw materials according to the above formula and mix uniformly in proportion, then stir evenly with a stirring grinder, and then grind until the required fineness of the coating is below 50um. Print the prepared coating on a clean and dry glass sheet by screen printing, with a thickness of 20 μm, and then cure it on a UV curing machine (under a 5000W UV lamp, exposure for 2 seconds). An ultraviolet light-curable fluorescent color conversion film is obtained.

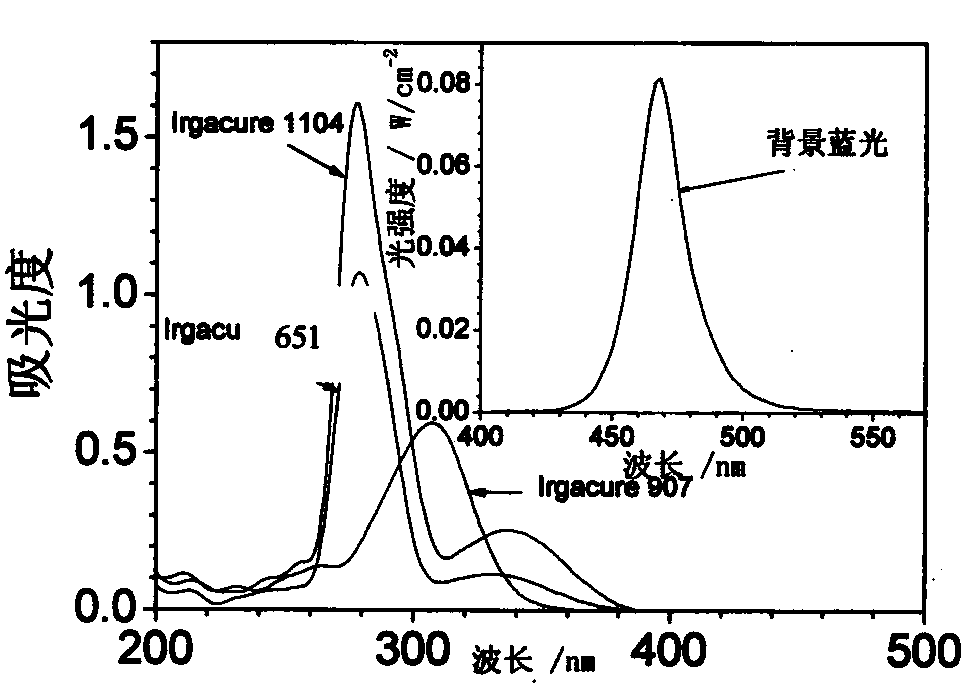

[0027] Photoinitiator selection:

[0028] The colorless and transparent varnish film should be the basis of the color conversion film. Since the photoinitiator generates a large number of free radicals during the curing process, the type and activity of the free radicals will inevitably affect the color and service life of the varnish film. Impact. Therefore, it is very necessary to study the initiator on the yellowness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com