Method for performing pretreatment and biotransformation by adding acidic reagent in lignocellulose raw material densification process

A technology for lignocellulose and densification treatment, applied in the field of biotransformation, can solve the problems of high transportation cost and large energy consumption for pretreatment, and achieve the effects of uniform specifications, reduced pretreatment cost, and convenient later operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This example illustrates the densification process of corn stalks with acid, the steps are as follows:

[0040] (1) Raw material preparation: After collecting the corn stalks in the farmland, dry them naturally and crush them into 1-4mm particles.

[0041] (2) DLA pretreatment: Spray the crushed corn stalks with dilute sulfuric acid solution. The content is 0.5g / g straw dry weight, and the corn straw evenly mixed with the acid reagent is used for densification operation. After the densification is completed, the straws with three acid concentrations are bagged and sealed respectively, and placed at room temperature for more than 1 day.

Embodiment 2

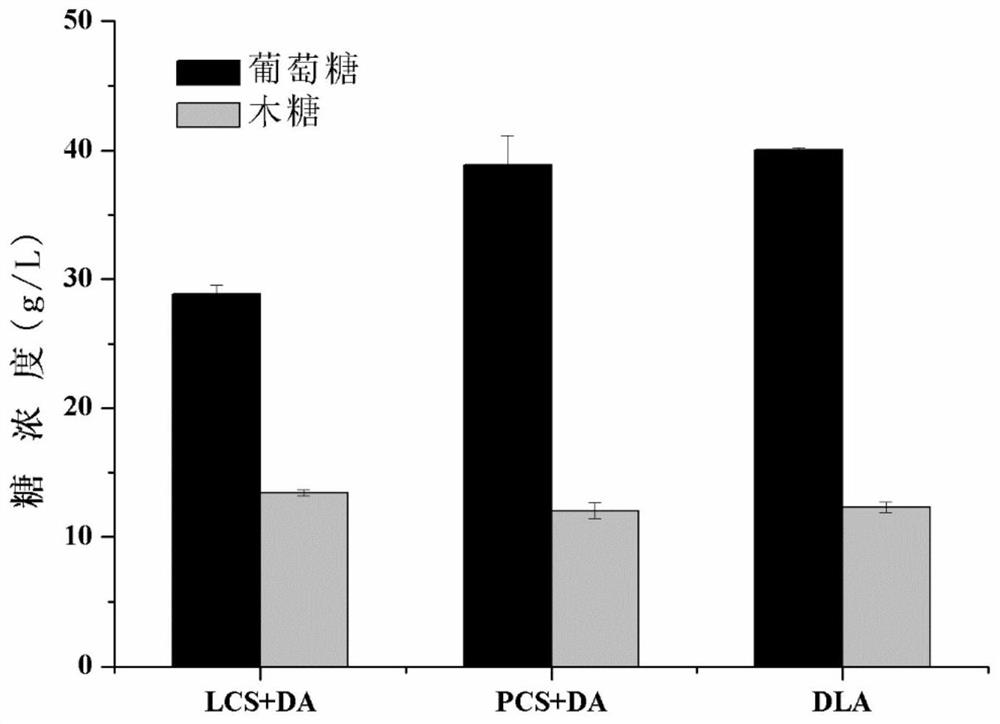

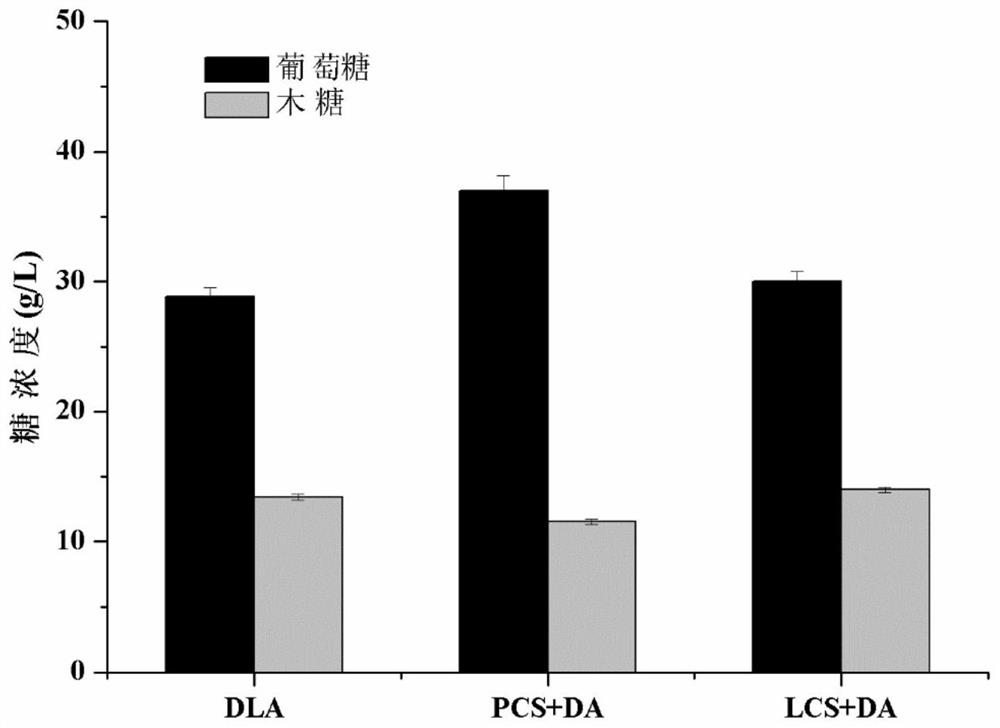

[0043] This example compares the pretreatment effects of DLA, PCS+DA, and LCS+DA hydrothermal pretreatment. Contains the following steps:

[0044] (1) DLA hydrothermal pretreatment process: the raw materials are selected from Example 1, the concentration of sulfuric acid is 0.1g / g dry weight of straw, and pure water is added to make the dry weight of straw: the total water content (including the moisture of the densified straw itself) is 1:9 ; Place it in a high-temperature and high-pressure reactor for heating, the heating temperature is 160° C., and the heating time is 10 minutes.

[0045] (2) PCS+DA hydrothermal pretreatment process: the raw material is no acid-densified straw, the amount of sulfuric acid added to it is 0.1g / g dry weight of straw, and pure water is added to make the dry weight of straw: total water (including dense The moisture content of the straw itself) is 1:9; it is placed in a high-temperature and high-pressure reaction kettle for heating, and the hea...

Embodiment 3

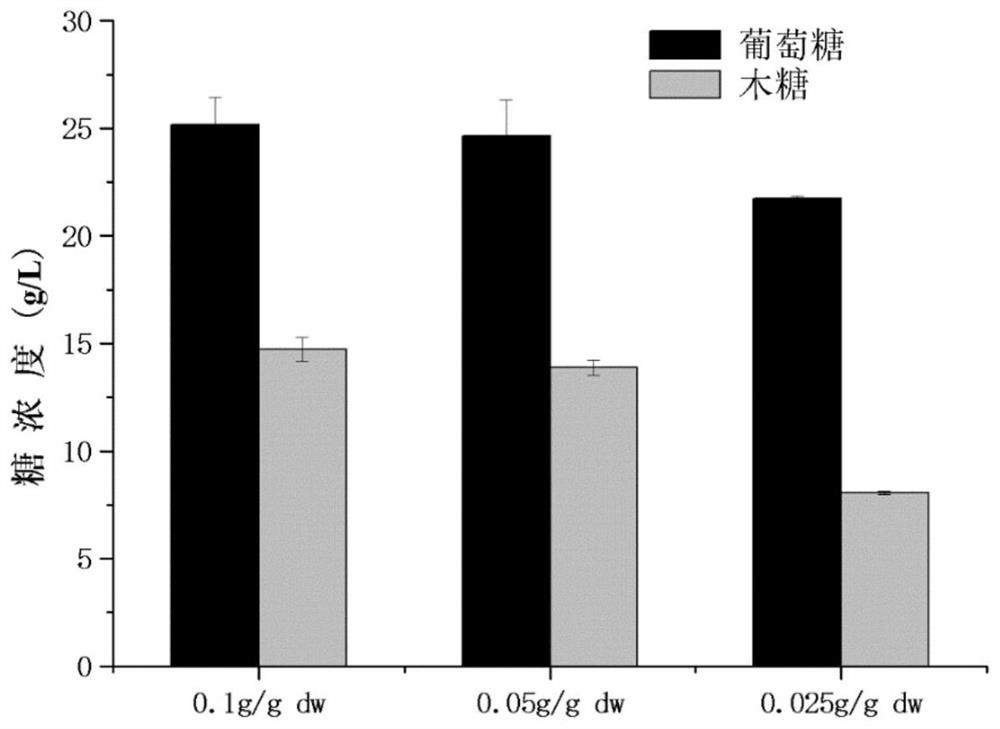

[0050] This example compares the hydrothermal pretreatment effect of DLA with different acid additions. Contains two steps:

[0051] (1) Pretreatment process: the raw materials are selected from Example 1, the concentration of sulfuric acid is 0.1g / g dry weight of straw, 0.05g / g dry weight of straw, and 0.025g / g dry weight of straw, and pure water is added to make the dry weight of straw : The total amount of water (including the moisture of the straw itself) is 1:5; it is placed in a high-temperature and high-pressure reactor for heating, the heating temperature is 120° C., and the heating time is 60 minutes.

[0052] (2) Enzyme hydrolysis process: the hydrolysis substrate concentration is 10% (based on the total mass), adding hydrolase and citric acid-sodium citrate buffer, and placing in a shaking incubator for cultivation (the setting speed is 250rpm, and the temperature is 50°C ) hydrolysis time is 72 hours.

[0053] according to figure 2 shown (Note: figure 2 Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com