Movable metal placing frame

A rack and metal technology, applied in the direction of tool storage devices, manufacturing tools, etc., can solve the problems affecting the service life of the rack, holding it in the hand, affecting work efficiency, etc., to save labor costs, easy to take and place , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

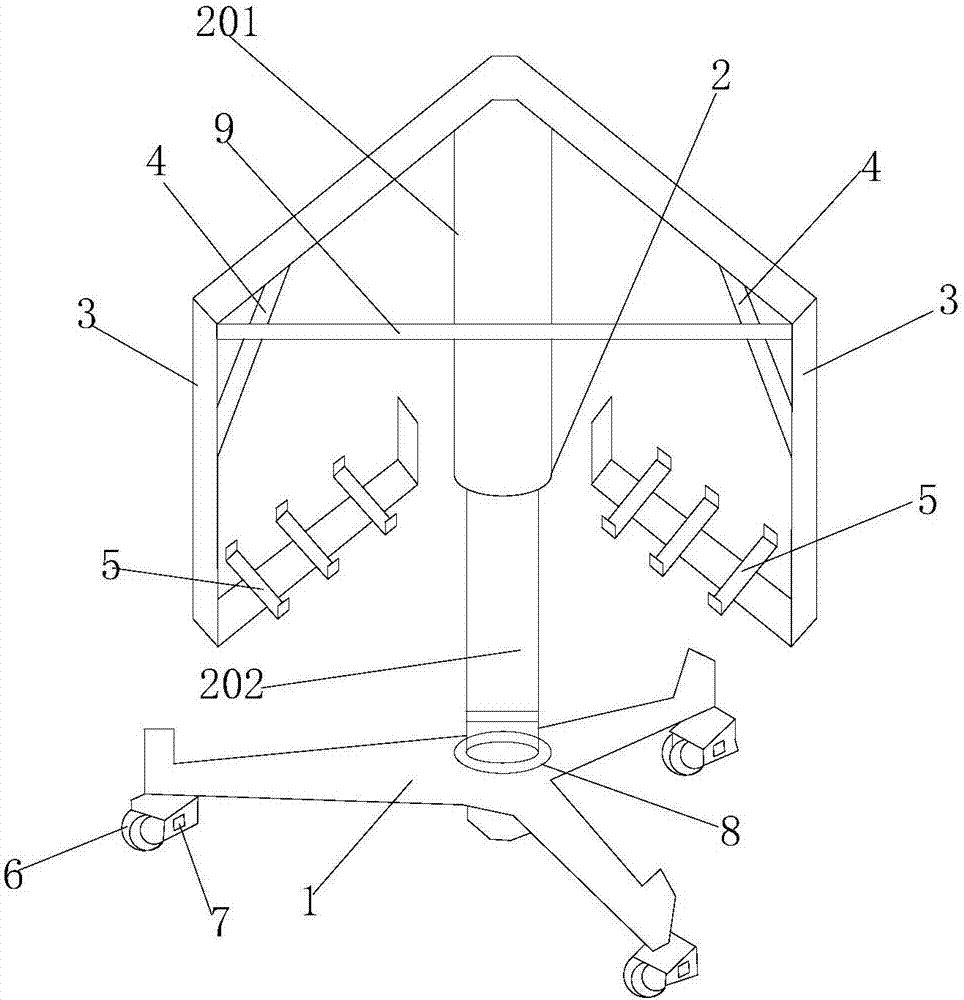

[0013] Such as figure 1 As shown, the movable metal placement frame includes a placement frame leg 1 and a telescopic support rod 2, the lower end of the telescopic support rod 2 is fixedly arranged on the placement frame leg 1, and the upper end of the telescopic support rod 2 is connected with a metal hook 3. The metal hooks 3 are provided with reinforcing ribs 4 that are left and right symmetrical about the longitudinal central section of the hooks. The reinforcing ribs 4 are fixedly connected to the metal hooks 3, and a plurality of U-shaped ribs are fixedly connected to the metal hooks 3. Pendant 5, universal wheel 6 is arranged below described placement frame leg 1, and brake 7 is arranged on described universal wheel 6; Described placement frame leg 1 is used as the support part of integral device, provides stable for device whole. For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com