High-efficiency rice processing method

A rice processing and high-efficiency technology, applied in applications, grain processing, agriculture, etc., can solve the problems of difficult cleaning of various impurities and slow rice processing efficiency, so as to reduce production quality, improve work efficiency, and speed up separation and filtration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

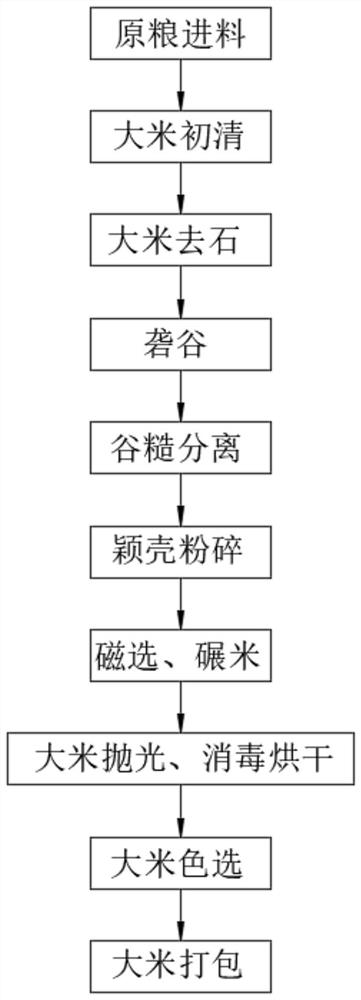

Image

Examples

Embodiment 1

[0028] A kind of high-efficiency rice processing method, comprises the following steps:

[0029] Step 1. Push the raw rice grain into the raw material storage box with a cart, and pour it down evenly, and regularly clean and filter some weeds on the raw grain sieve. The rice spilled on the ground of the raw material storage box should be cleaned frequently to avoid rolling back and forth by the transport truck pressure, affecting the yield;

[0030] Step 2. Clean and sieve the raw rice grains, feed the raw materials after the vibrating screen operates normally, and gradually increase the feeding amount to the normal load until the impurities inside the raw rice grains are screened out;

[0031] Step 3. Check whether the stone removal equipment is in good condition, whether there are foreign objects in the screen surface of the stone removal equipment and the discharge port, and then pour the raw rice grains that have been cleared into the stone removal equipment, and first adj...

Embodiment 2

[0041]The rest of the steps are the same as in Example 1, wherein the hole diameter of the vibrating screen in step 2 is 15MM, pay attention to observe and adjust the feed flow rate, which not only meets the flow requirements of the sieve, but also makes the material evenly distributed along the width direction of the screen surface, and clears the material in the feed hopper in time. Grass, twine, plastic bags and other sundries, regularly clean the sieve surface to keep the sieve holes unblocked. The first stone-removing sieve in step 3 is specifically a stainless steel stone-removing sieve. The hole diameter of the stainless steel stone-removing sieve is 14MM. The stone-removing sieve is specifically a stainless steel fine-mesh sieve, and the hole diameter of the stainless-steel fine-mesh sieve is 6MM. The husker in step 4 is specifically a centrifugal husker. After the centrifugal husker operates normally, pour the stone-removed rice into it. The rice accelerates in the inn...

Embodiment 3

[0043] The rest of the steps are the same as in Example 1. In Step 2, the hole diameter of the vibrating screen is 14.5MM. Pay attention to observe and adjust the feed flow rate, which not only meets the flow requirements of the sieve, but also makes the material evenly distributed along the width of the screen surface, and clears the feed hopper in time. Grass, twine, plastic bags and other sundries inside, clean the sieve surface regularly to keep the sieve holes unblocked. The first stone-removing sieve in step 3 is specifically a stainless steel stone-removing sieve. The hole diameter of the stainless steel stone-removing sieve is 13MM. The stone-removing sieve is specifically a stainless steel fine-mesh sieve, and the hole diameter of the stainless-steel fine-mesh sieve is 5.6MM. The husker in step 4 is specifically a centrifugal husker. After the centrifugal husker operates normally, pour the stone-removed rice After entering, the rice accelerates in the inner turntable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com