Three-dimensional positioning tool of vehicle base plate welding assembly

A positioning tooling, three-dimensional technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of carrier plate damage, affecting welding quality and welding efficiency, affecting service life, etc. , the effect of shortening the processing time and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

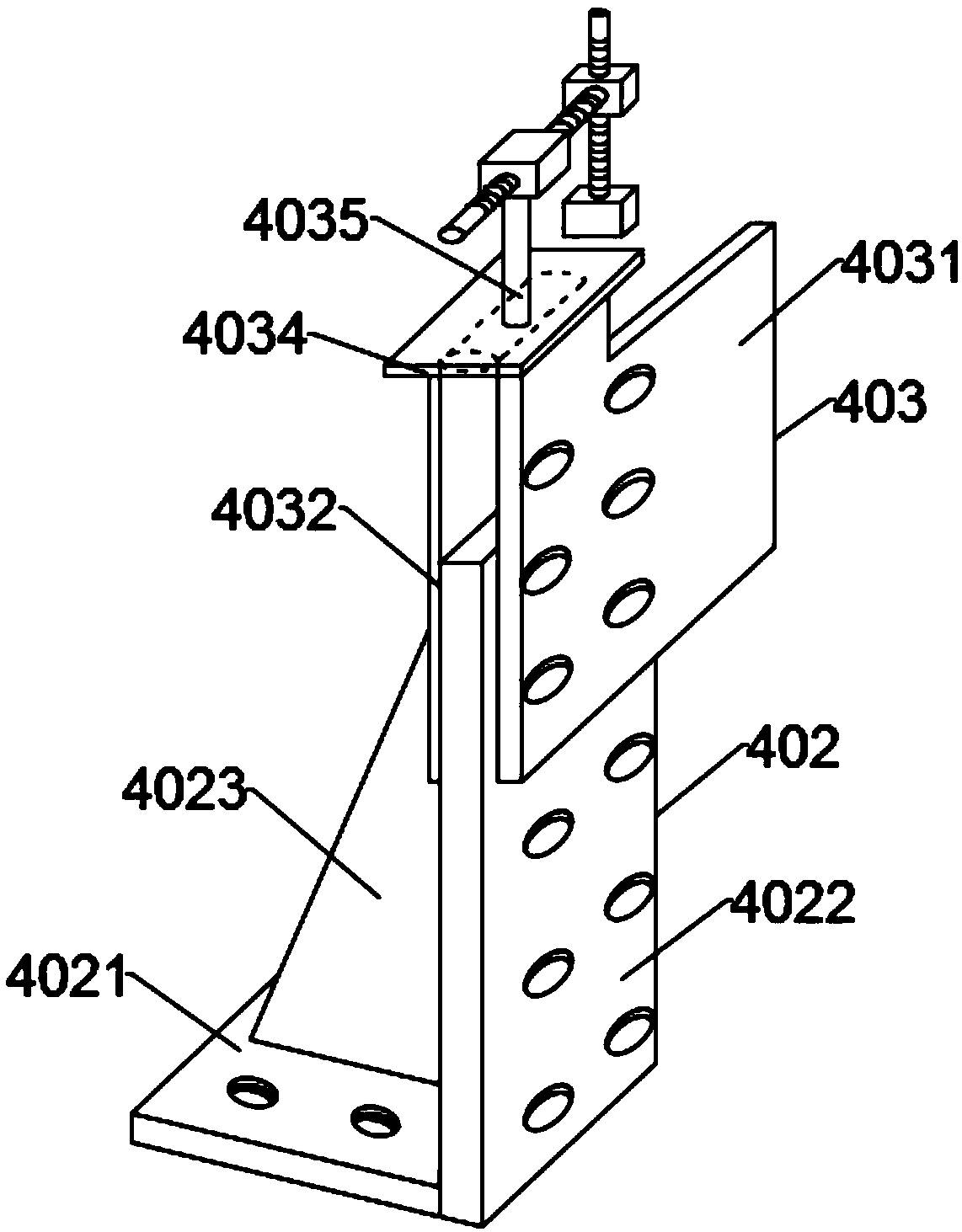

[0046] Embodiment 1: The upper mounting clamping plate 403 is used in combination with the lower fixed support plate 402;

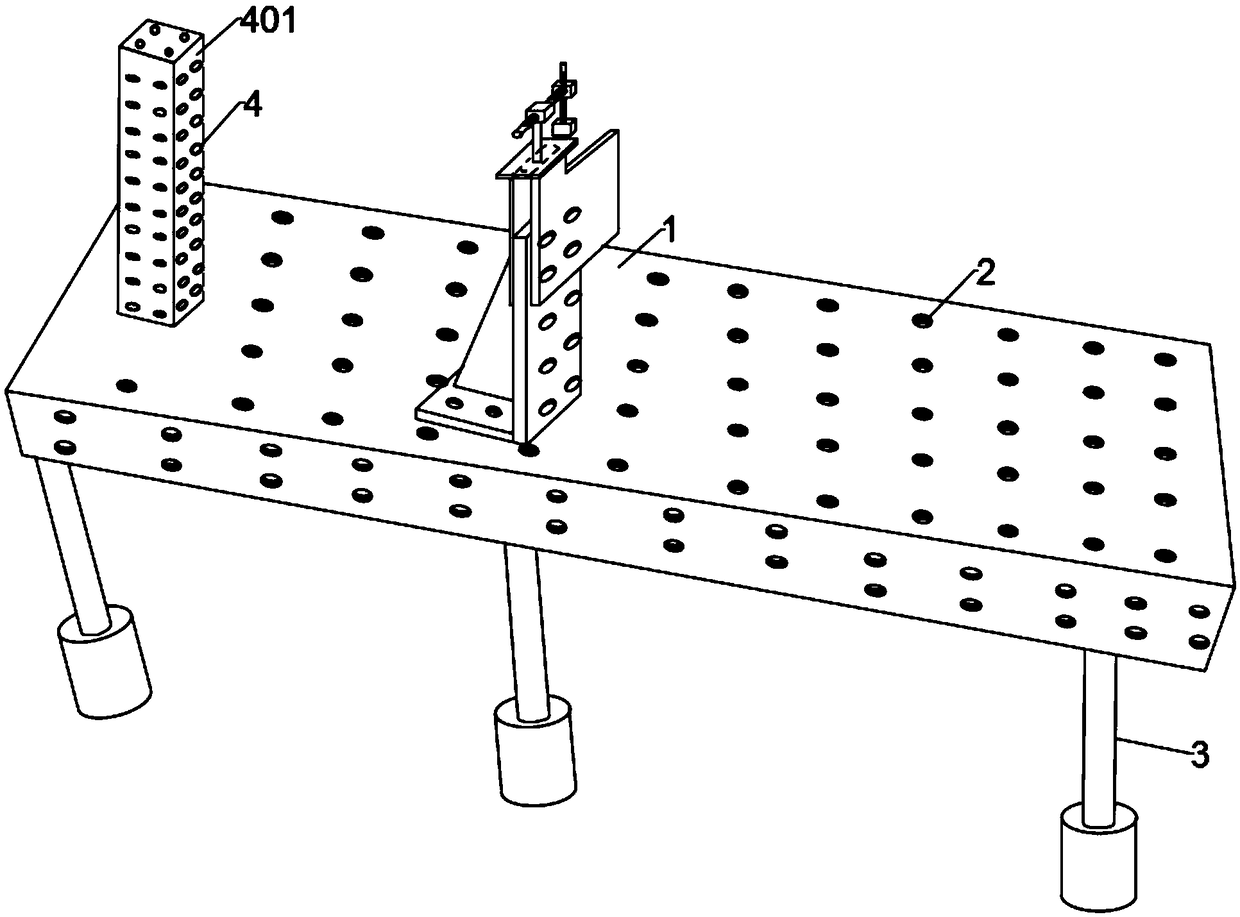

[0047] 1. The horizontal fixing plate 4021 in the lower fixing support plate 402 is fixed on the loading tooling plate 1 through the small threaded hole 2;

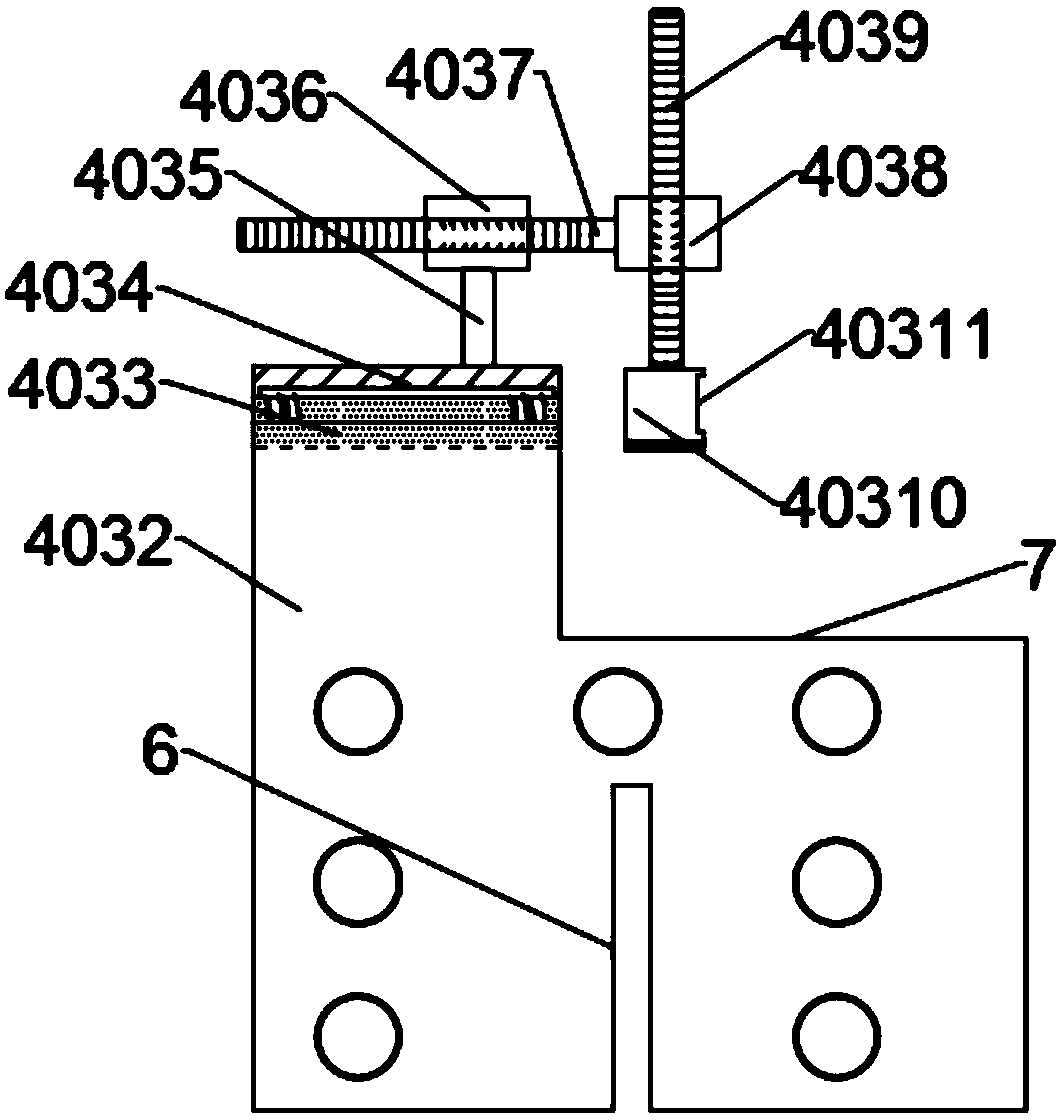

[0048] 2. The first threaded plate 4031 and the second threaded plate 4032 are fixed on both sides of the vertical positioning plate 4022 through the small threaded hole 2, and the car plate is placed on the load-bearing gap 7;

[0049] 3. Turn the horizontal displacement bolt 4037 to control the movement of the cube 40310 on the horizontal plane, and turn the vertical clamping bolt 4039 to control the movement of the cube 40310 in the vertical space until the cube 40310 is fixed and clamped on the car board of the upper surface.

Embodiment 2

[0050] Embodiment 2: The upper mounting clamping plate 403 acts on the loading tooling plate 1 alone;

[0051] 1. The first threaded plate 4031 and the second threaded plate 4032 are fully expanded, and the angle between the first threaded plate 4031 and the second threaded plate 4032 is 180°, and the first threaded plate 4031 and the second threaded plate 4032 pass through The small threaded hole 2 is fixed on the loading tooling plate 1;

[0052] 2. Remove the horizontal displacement bolt 4037, and install the vertical clamping bolt 4039 in the horizontal threaded hole penetration plate 4036;

[0053] 3. Turn the vertical clamping bolt 4039 to control the movement of the cube 40310 in the horizontal space until the support groove 40311 on the cube 40310 is fixedly clamped on the side of the car panel.

Embodiment 3

[0054] Embodiment 3: The upper assembly clamping plate 403 and the lower fixed support plate 402 are combined and installed on the assembled three-dimensional block 401 for use;

[0055] 1. Fix the horizontal fixing plate 4021 in the lower fixing support plate 402 on the assembled three-dimensional block 401 through the small threaded hole 2;

[0056] 2. Fix the cube 40310 on the assembled three-dimensional block 401 through fixing bolts, and fix the first threaded plate 4031 and the second threaded plate 4032 on both sides of the vertical positioning plate 4022 through the small threaded hole 2;

[0057] 3. Place the car plate in the support groove 40311 of the cube 40310,

[0058] 4. Turn the vertical clamping bolt 4039 to control the movement of the cube 40310 on the horizontal plane, and turn the horizontal displacement bolt 4037 to control the movement of the cube 40310 in the vertical space until the cube 40310 is fixedly clamped on the car board of the upper surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com