Spandrel architectural construction of ballastless track wide-span high-speed railway arch bridge

A technology for high-speed railways and ballastless tracks, applied in the field of bridges, can solve problems such as excessive deformation of beam ends on arches, and achieve the effects of improving smoothness, saving materials, and improving comfort and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments.

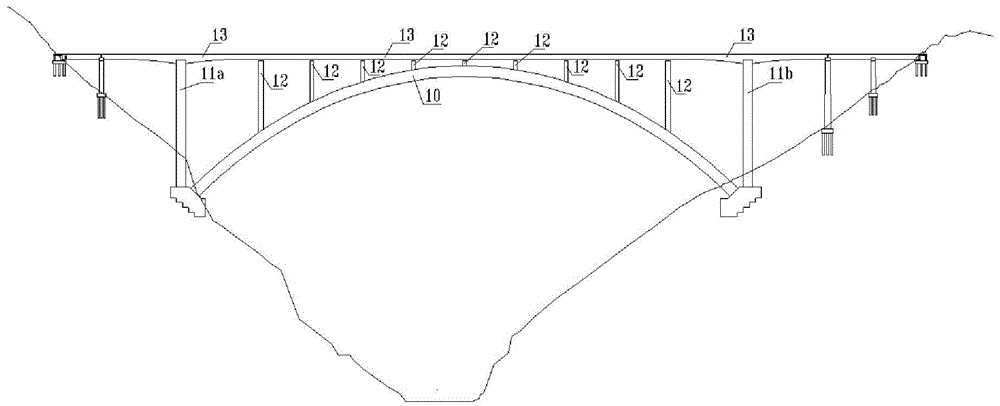

[0013] Reference figure 1 , The present invention is a ballastless track long-span high-speed railway arch bridge arch-over-arch structure, including a main arch 10, a left side junction pier 11a, a right side junction pier 11b, an upper arch pier column 12 and an upper arch beam 13, the left side The junction pier 11a and the right junction pier 11b are respectively arranged on both sides of the main arch 10, and the upper arch pier columns 12 fixed with the main arch 10 at the lower end are arranged at intervals along the bridge direction. The arch upper beam 13 is a continuous structure within the span of the main arch 10, and is consolidated with the upper ends of the left and right boundary piers 11a and 11b, and is connected to the upper ends of the upper piers 12 of each arch through supports.

[0014] Reference figure 1 , The upper arch beam 13 is a seamless co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com