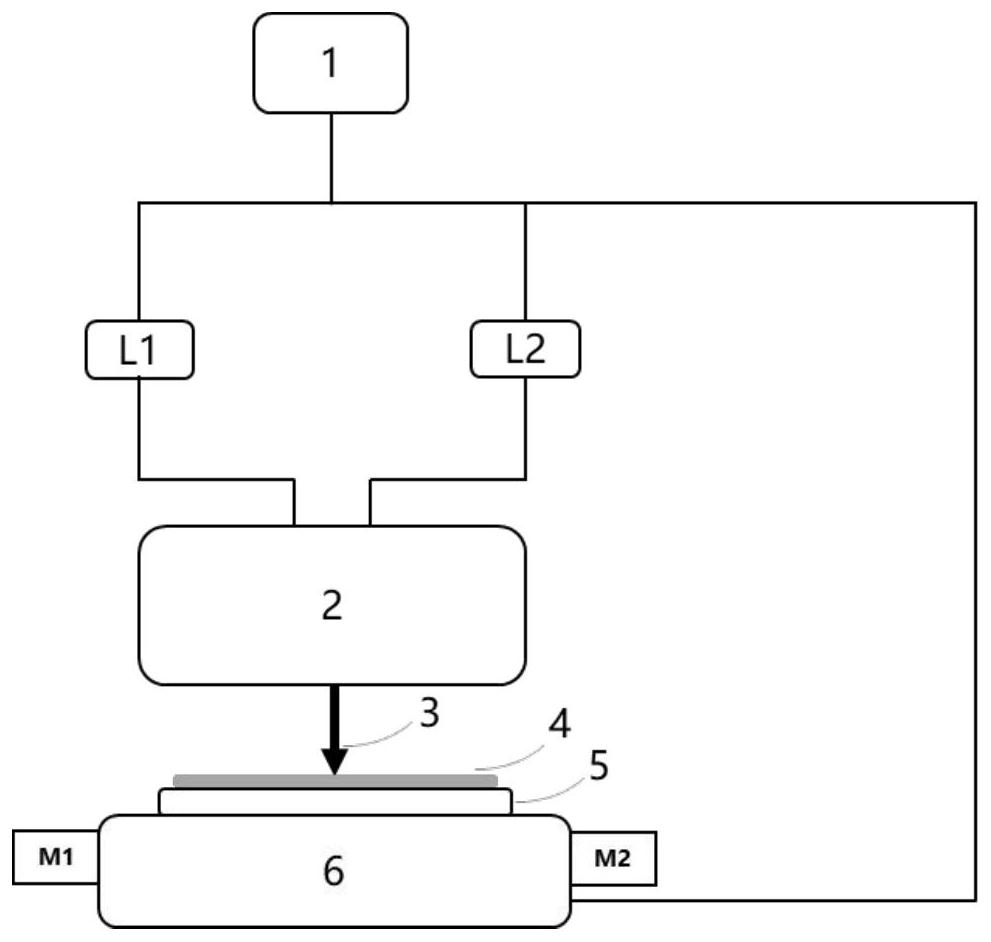

Laser annealing method and laser annealing system for power device

A power device, laser annealing technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

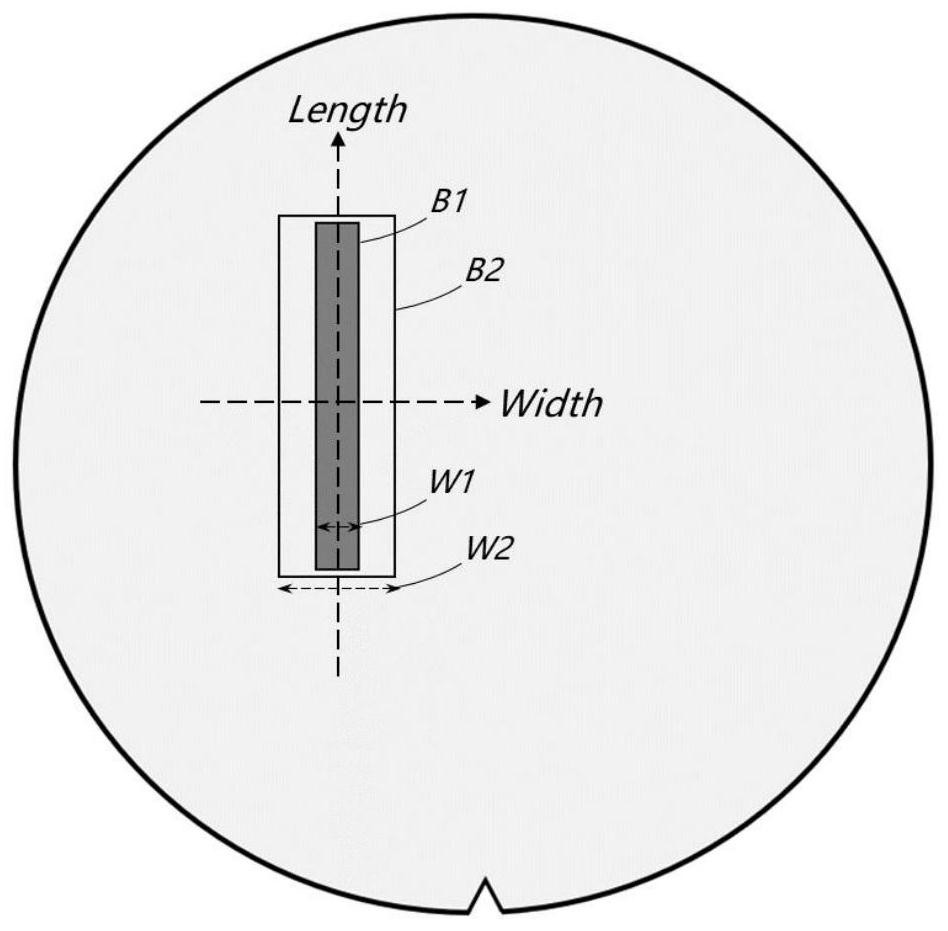

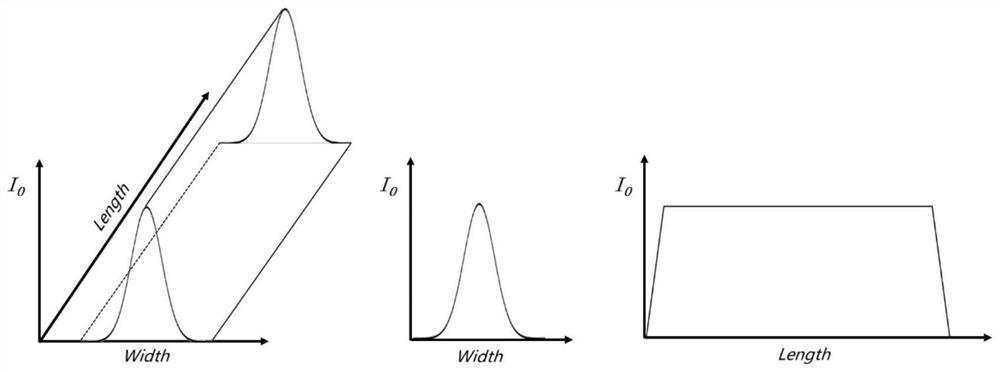

Method used

Image

Examples

Embodiment 1

[0113] (a) Implant N-stop. In order to achieve a relatively deep distribution of N-stop, the method of implanting N-type impurities at a small angle (>100kev, tilt 0°) with medium and high energy is usually used to form a near-Gaussian distribution of impurity body concentration along the depth direction. curve, the dotted line indicates the distribution of implanted impurities.

[0114] (b) The laser activates the N-stop, which generally has a lower concentration and a deeper depth, and the depth range is generally 0-10um. The laser emitted by the aforementioned laser annealing system is used to provide a temperature field, so that the required depth is above and the temperature is greater than 1100K, which can satisfy the activation in the full depth range. The solid line indicates the distribution of activated impurities.

[0115] (c) Inject P+ into the collector region. In order to achieve a relatively shallow distribution of P+ in the collector region, a method of implant...

Embodiment 2

[0118] (a) Implant N-stop. In order to achieve a relatively deep distribution of N-stop, the method of implanting (>100kev) N-type impurities is usually used to form a curve of impurity body concentration near Gaussian distribution along the depth direction. The dotted line indicates the implanted impurities Distribution;

[0119] (b) Laser activates N-stop, which generally has a low concentration and deep depth, and the depth range is generally 0-10um. When the laser adjustable space is limited and the temperature field distribution is very steep, it is necessary to use the short-term laser annealing system The wavelength laser performs surface melting, and cooperates with long-wavelength laser to achieve a deeper temperature greater than 1100K, so as to realize activation. The melting depth a is the depth of solid phase to liquid phase transformation, and the solid line indicates the distribution of activated impurities;

[0120] (c) Inject P+ into the collector region. In o...

Embodiment 3

[0123] (a) N-stop implantation. Since the method of implanting N-type impurities with medium and high energy (>100kev) is costly, this embodiment adopts low-energy and high-density implantation of N-type impurities, and the impurities gather on the shallow surface. The dotted line indicates the implantation of impurities Distribution;

[0124] (b) Laser activates N-stop. According to the requirements of device design, the short-wavelength laser of the aforementioned laser annealing system is used to melt the surface of the wafer to the required depth, so as to realize the flat-top distribution of impurity concentration along the depth direction, and the melting depth c For the depth of solid phase to liquid phase transformation, the temperature in this depth range after melting is greater than 1685K in combination with long-wavelength laser, so that the impurities are completely activated, and the solid line indicates the distribution of activated impurities;

[0125] (c) Inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com