Automatic production line for producing enameled wires

An automatic production line and enameled wire technology, applied in the field of enameled wire, can solve the problems of low degree of automation and complex production line structure, and achieve the effect of high degree of automation, simple structure and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

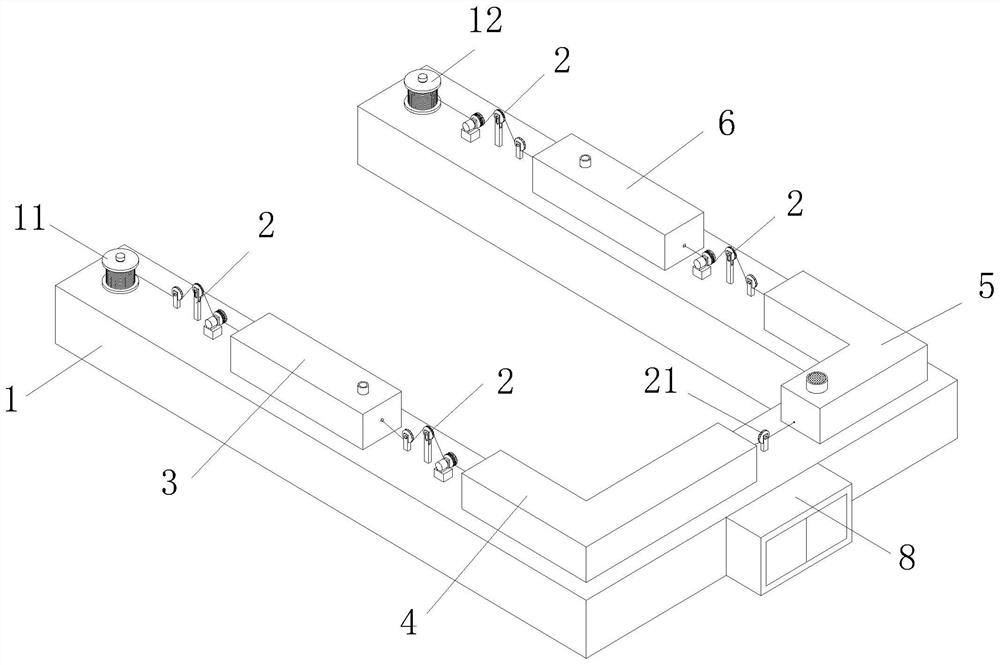

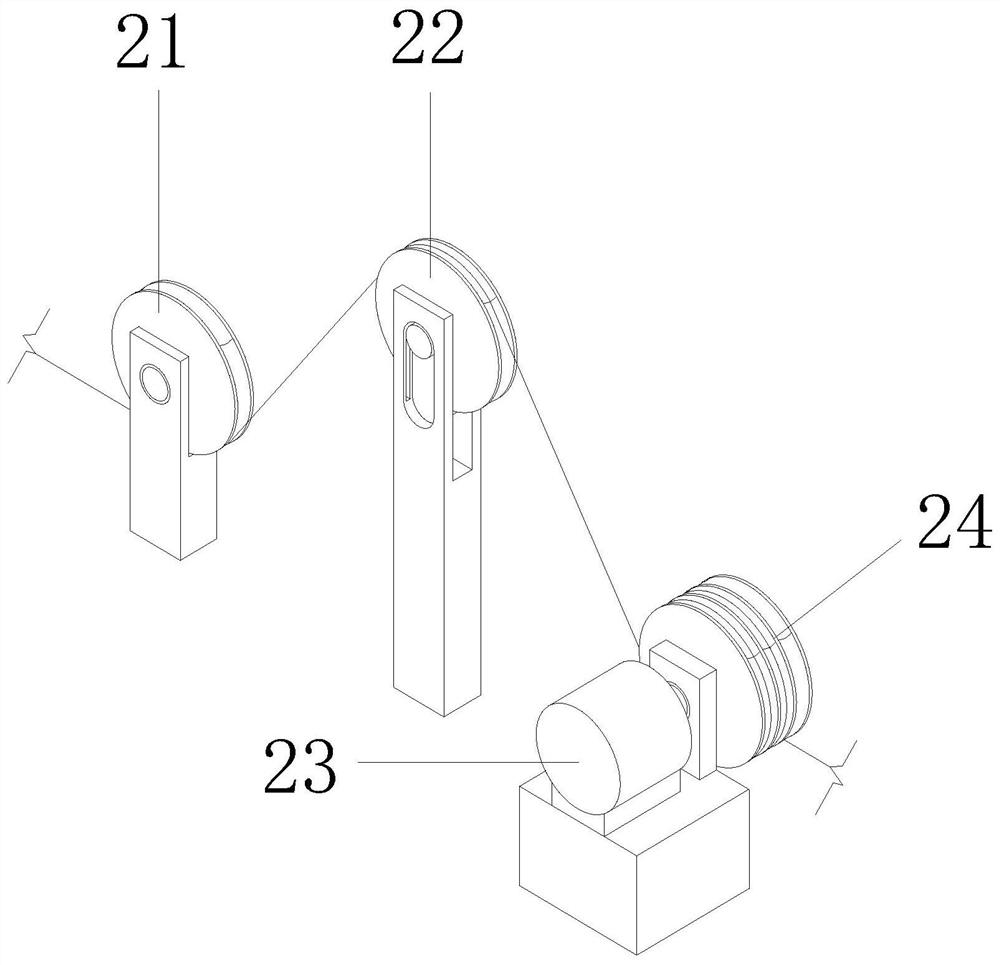

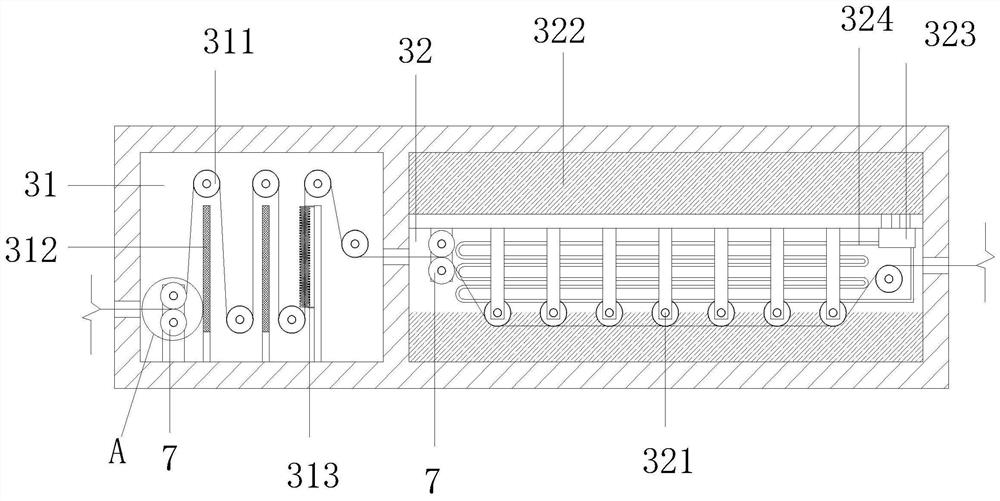

[0040] Please refer to the attached Figure 1-8 , an automatic production line for producing enameled wires: including a base 1, a conveying assembly 2, an annealing device 3, a painting device 4, a baking device 5, a cooling device 6, a wire drawing assembly 7 and a control device 8; the upper end of the base 1 is movable Wire roller 11, take-up roller 12, described pay-off roller 11 and described take-up roller 12 lower ends are all connected with stepping motor, described annealing device 3, painting device 4, baking device 5, cooling device 6 are all fixed The upper end surface of the base 1 is installed, the control device 8 is installed on the side end of the base 1, and the upper end surface of the base 1 is equipped with multiple sets of conveying assemblies 2, and the conveying assemblies 2 transport the enameled wire from the pay-off roller 11 are transported to the annealing device 3, painting device 4, baking device 5, cooling device 6, take-up roller 12 in turn, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com