Patents

Literature

31results about How to "Realize the cooling process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

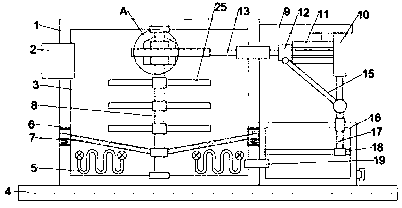

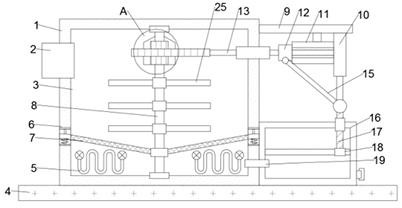

Continuous burning furnace

ActiveCN101265021AEven contactUniform treatmentGas discharge electrodesMaintainance of heating chambersCooling chamberEngineering

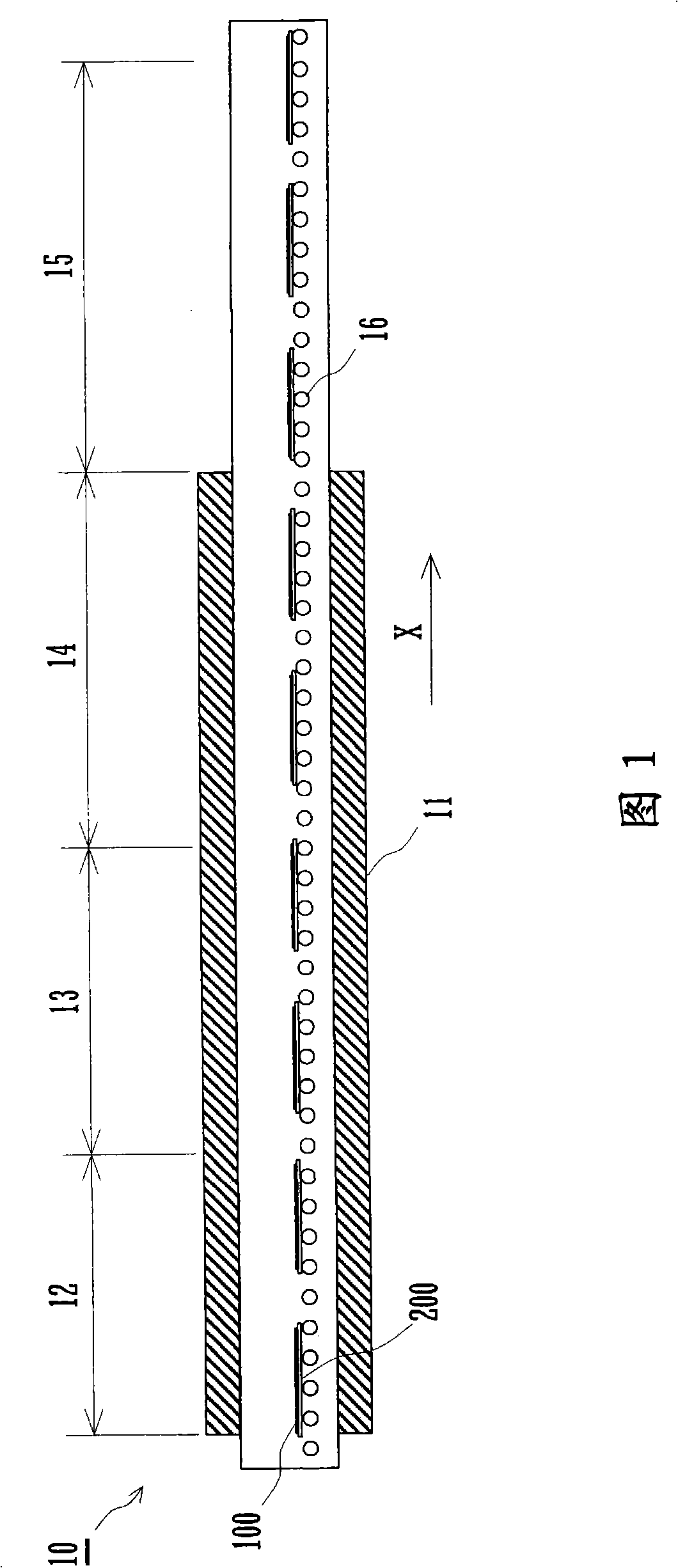

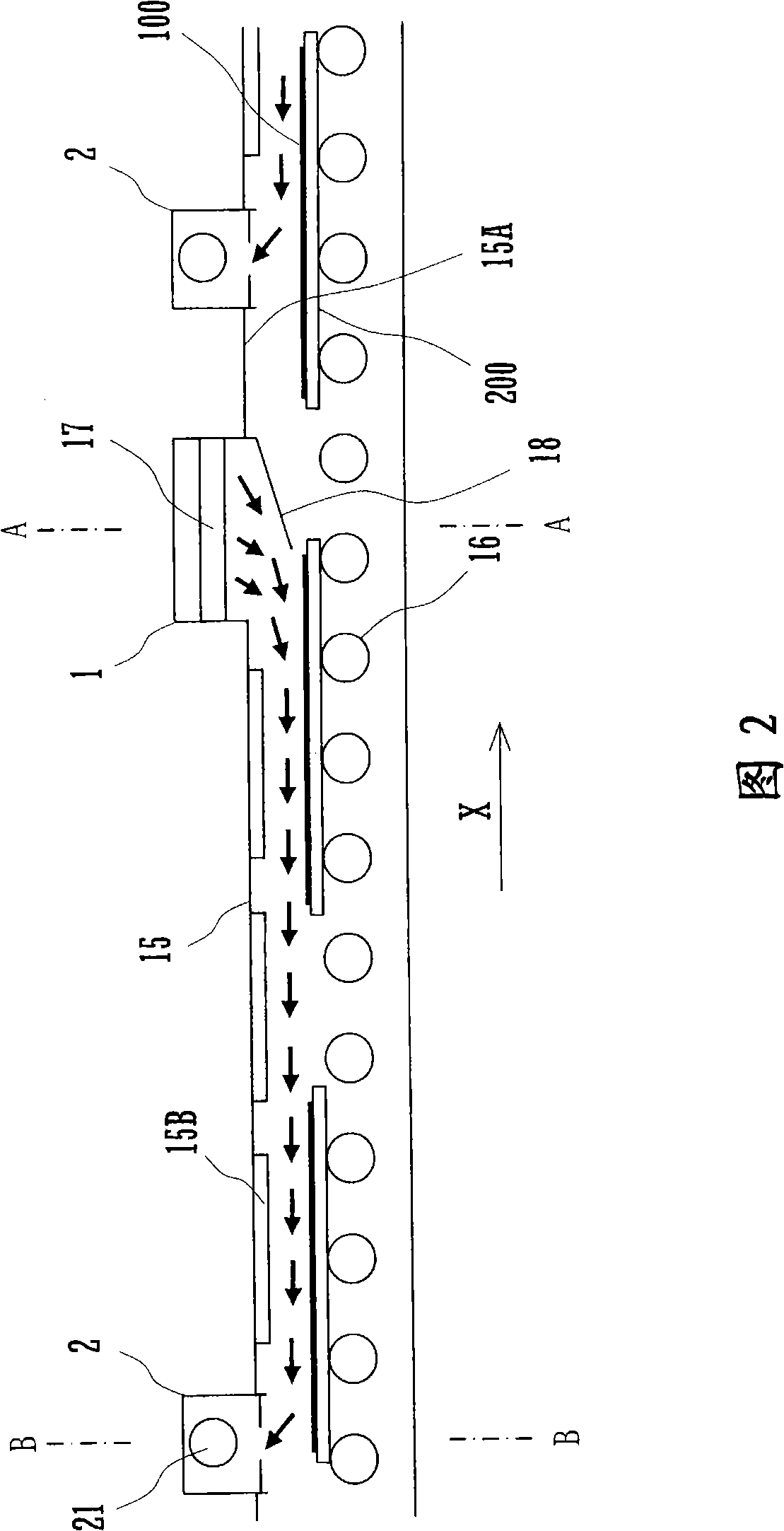

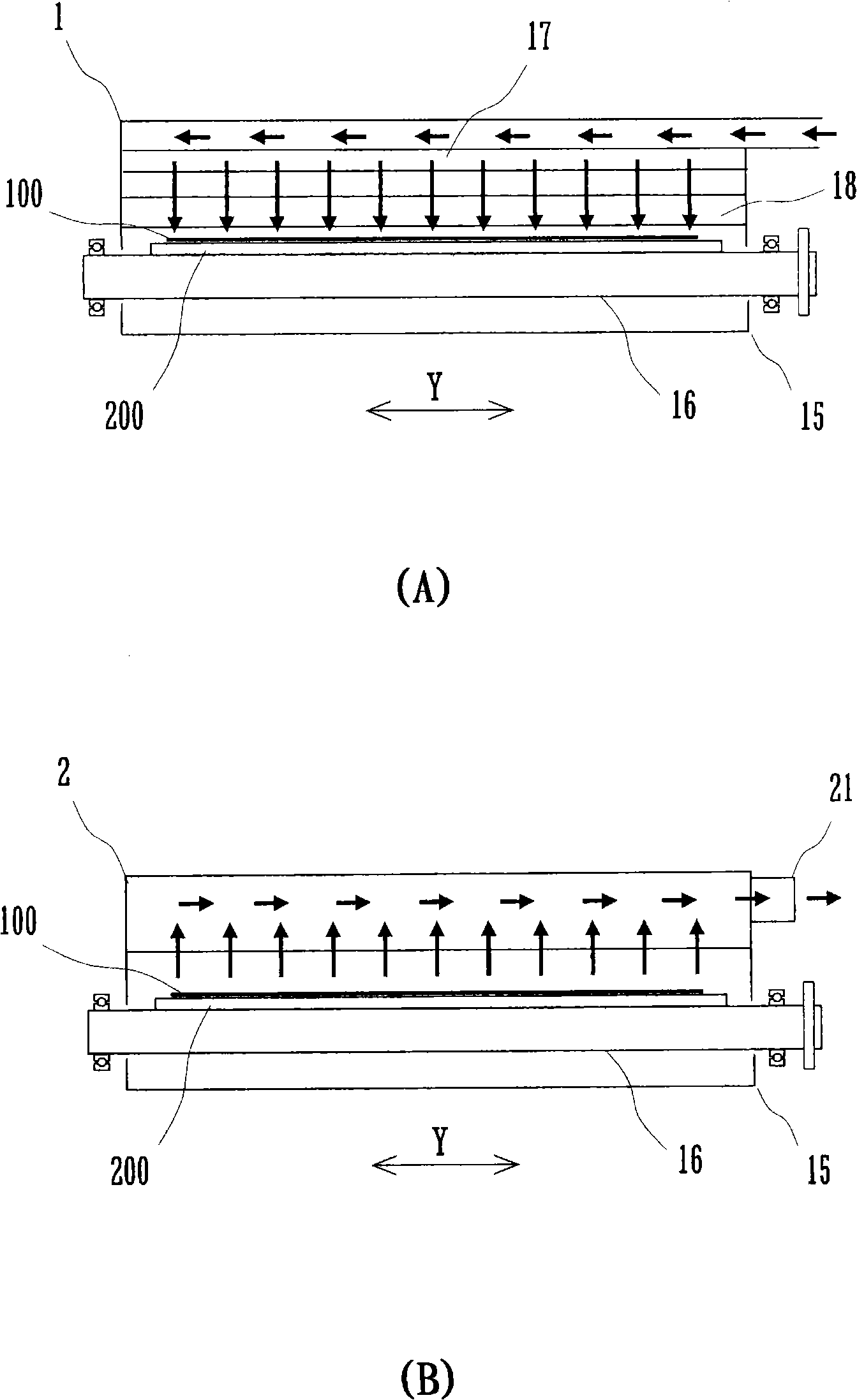

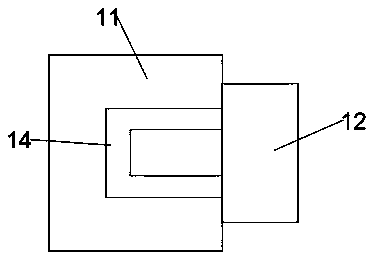

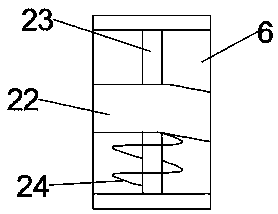

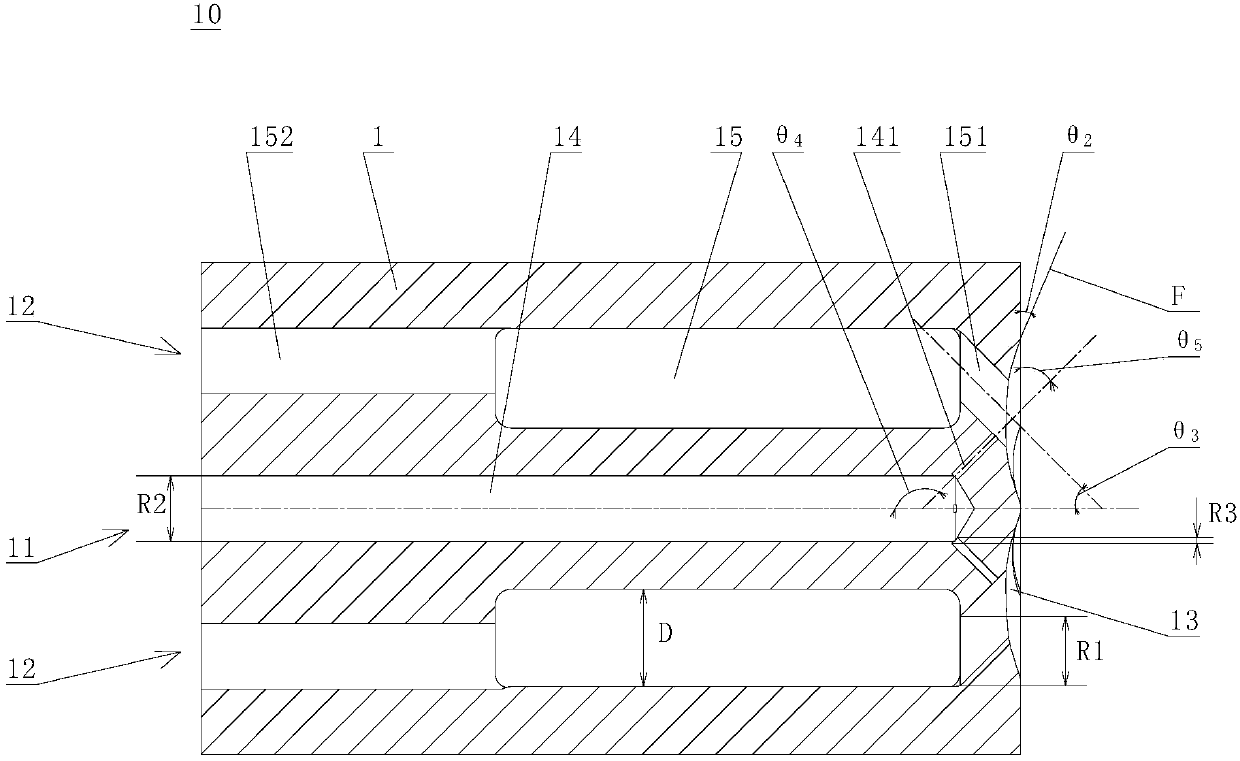

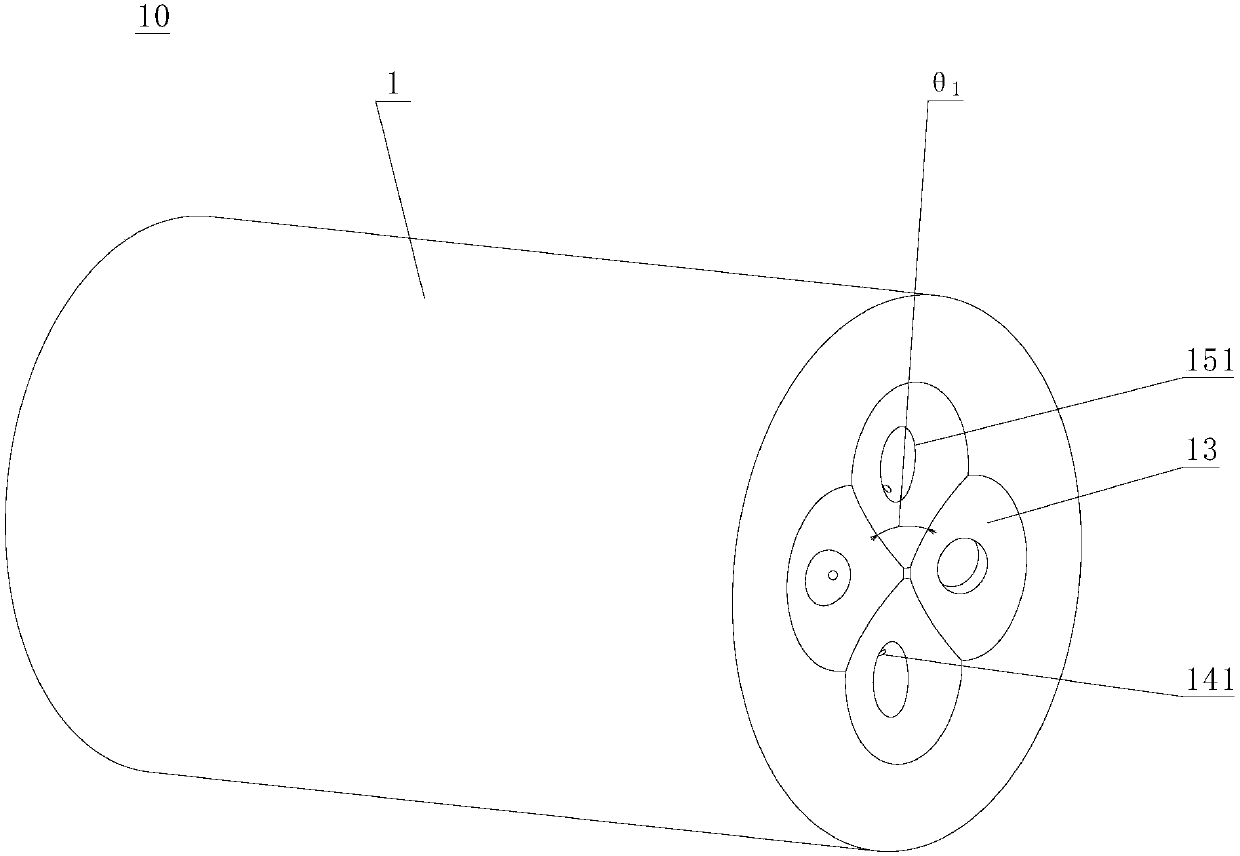

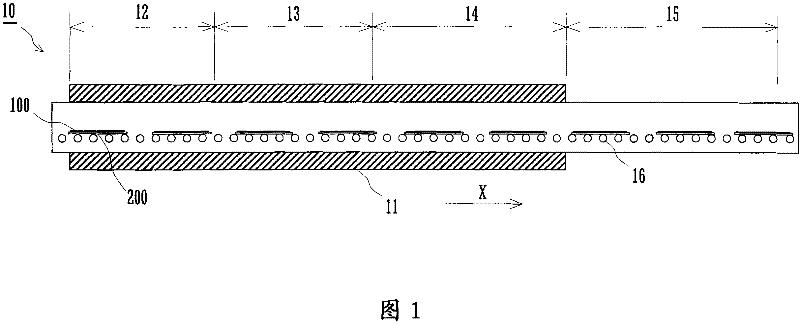

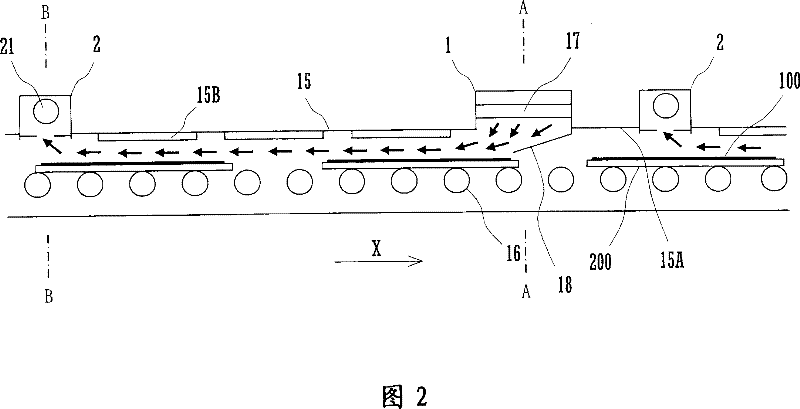

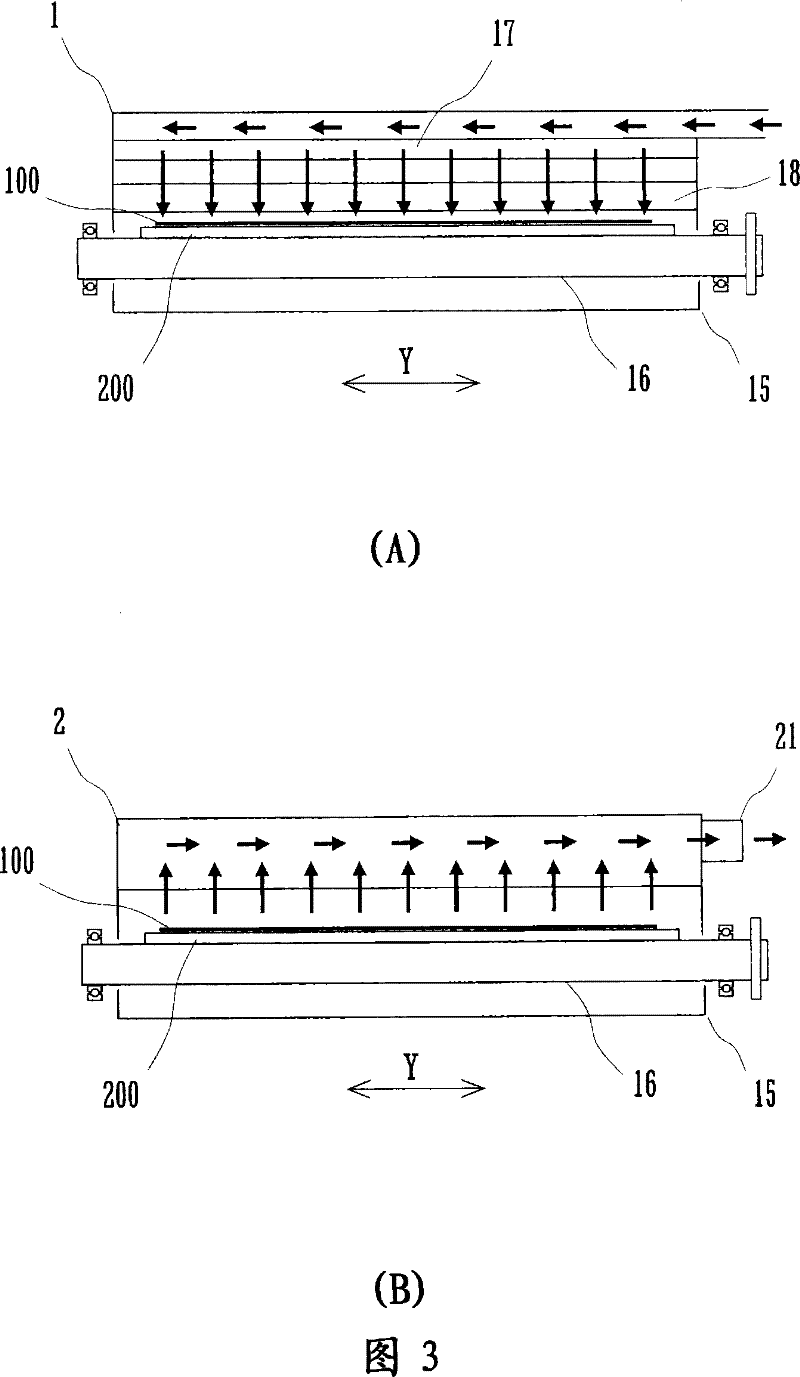

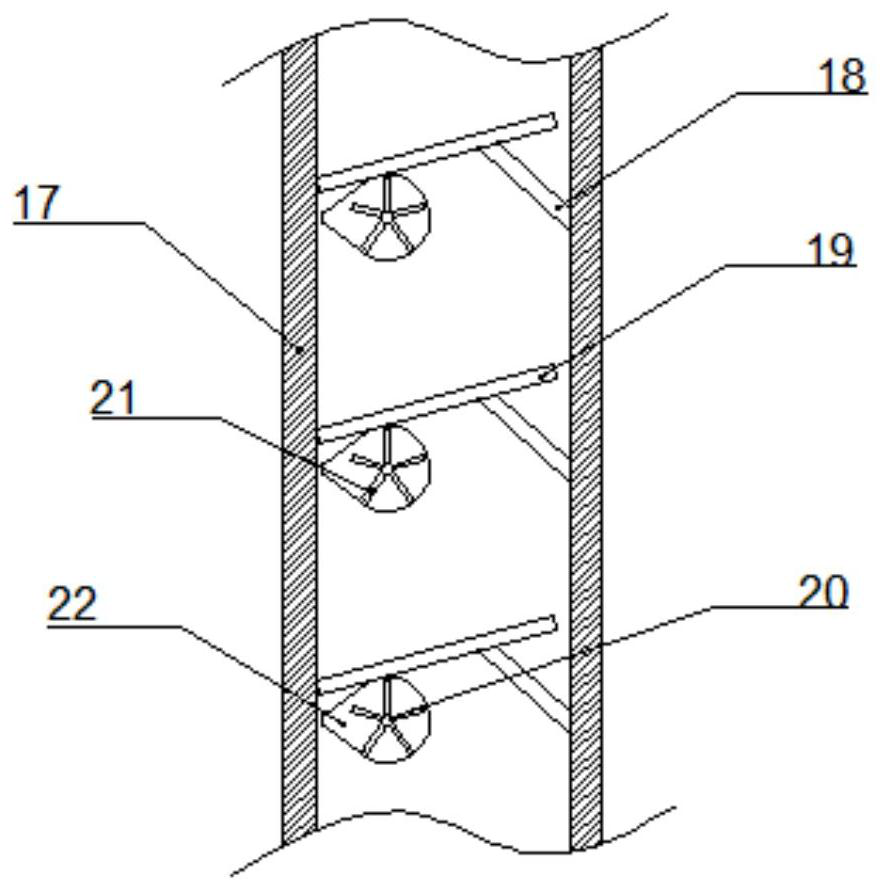

The present invention provides a continuous firing furnace. The continuous firing furnace is able to effectively cool the whole outer surface of the processing objects such as glass substrate etc., does not generate partial warpage or deformation on the processing object and reduces the cooling processing time. The cooling chamber (15) of the continuous firing furnace (10) is installed with guiding passage (1) and exhaust passage (2). The guiding passage and exhaust passage open at the almost whole area in the furnace-width direction (Y) on the inner furnace wall (15A) at the upper side of the cooling chamber. The guiding passage ejects the air by the mode of facing to the upper reach side of the moving direction (X). The exhaust passage exhausts the air of the cooling chamber at the upper reach along the moving direction (X) of the guiding passage. On the upper part of the processing object moved on the roller (16), the flow path with cooled external gas is uniformly formed in the almost whole area on the furnace-width direction (Y). The whole upper surface of the processing object is uniformly contacted with the air.

Owner:KOYO THERMO SYST CO LTD

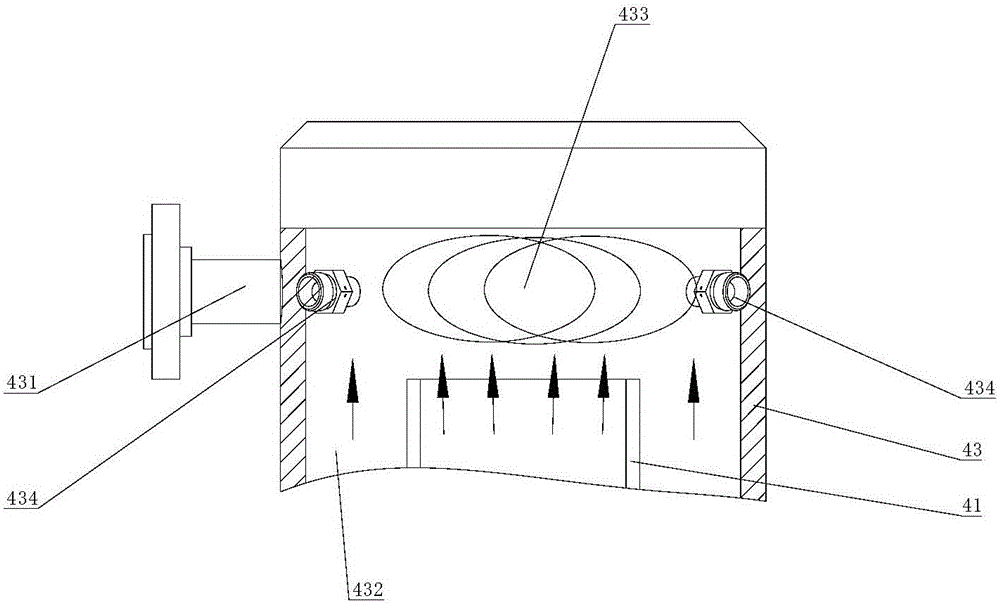

Generator for pure oxygen compound heat carrier and production method for compound heat carrier

ActiveCN105889888AReduce nitrogen contentRealize high-pressure sealed combustionFluid removalSteam generation plantsHeat carrierCombustion chamber

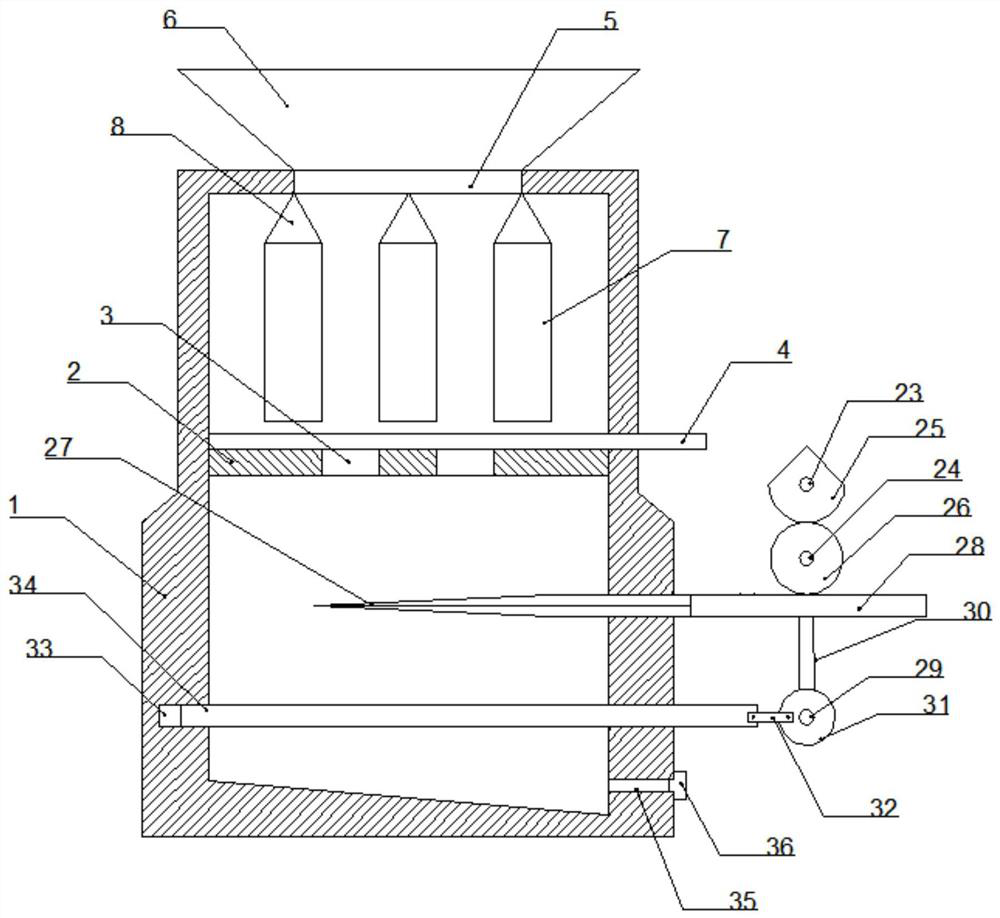

The invention provides a generator for a pure oxygen compound heat carrier and a production method for a compound heat carrier. The generator comprises a generator body and a generator head structure, wherein the generator body comprises a combustion chamber and a steam chamber arranged outside the combustion chamber in a sleeving manner; the generator head structure is provided with a head body, a combustion nozzle and an ignition electrode; the combustion nozzle is provided with a nozzle body, and a plurality of diaphragm outer cavities are formed on one end part of the nozzle body; a fuel channel and a pure oxygen channel are arranged in the nozzle body, the fuel channel communicates with the plurality of diaphragm outer cavities through a plurality of fuel inclined holes, and the fuel inclined holes are radially arranged outwards and slantwise along an injection direction of a fuel; and the pure oxygen channel communicates with the plurality of diaphragm outer cavities through a plurality of pure oxygen inclined holes, and the pure oxygen inclined holes are radially arranged inwards and slantwise along an injection direction of pure oxygen. The generator and the production method, which are provided by the invention, are capable of uniformly atomizing the pure oxygen and natural gas, realizing high-temperature sufficient combustion for the pure oxygen and the natural gas, and finally forming a high-temperature compound heat carrier containing carbon dioxide and steam.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

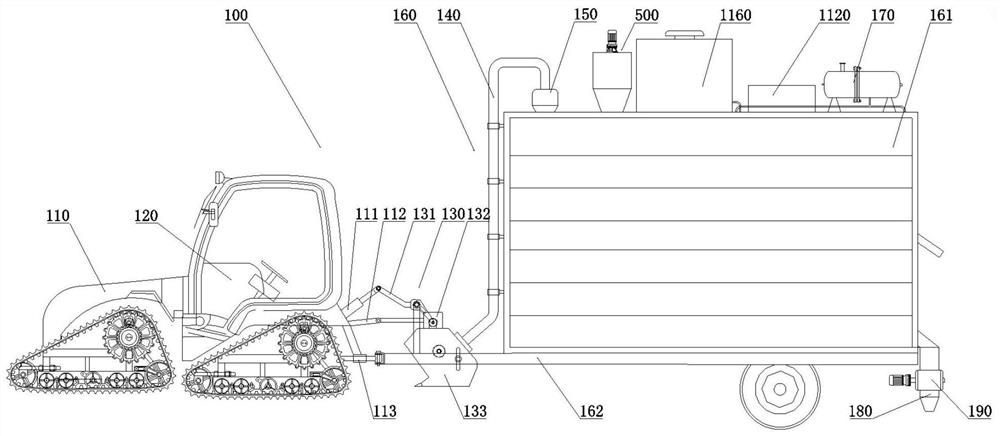

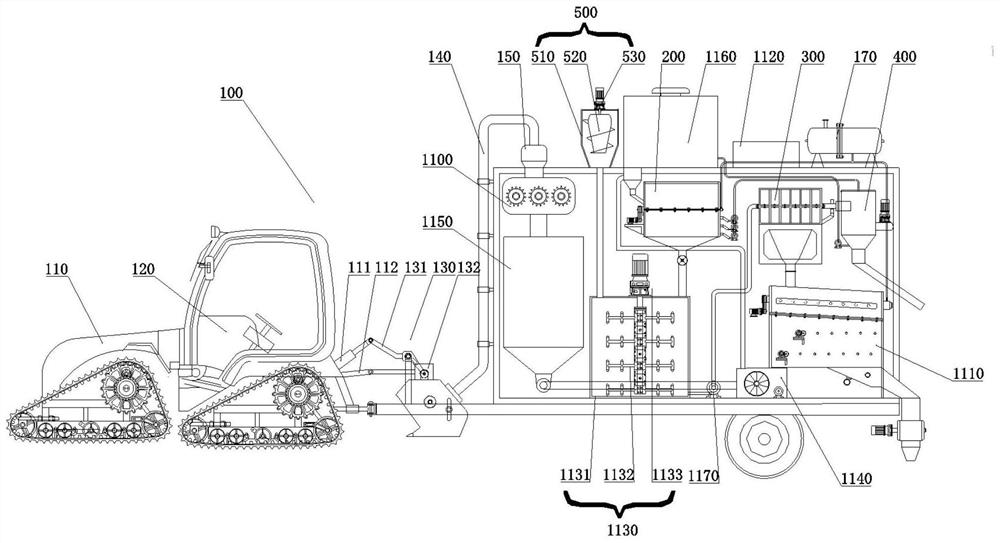

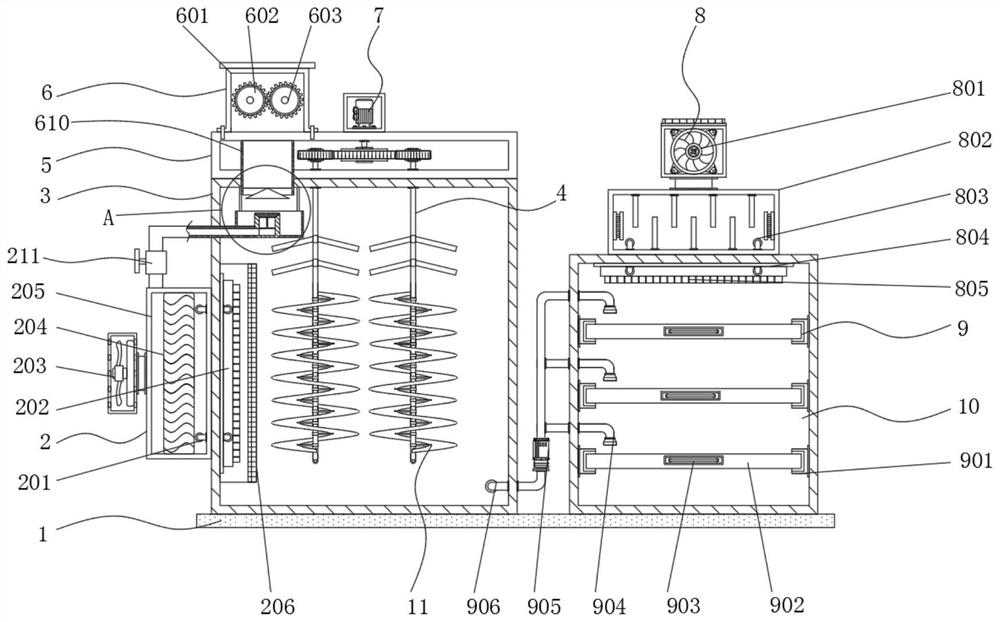

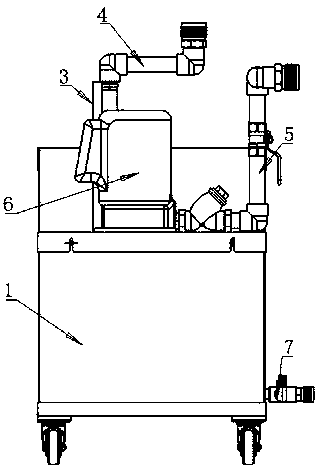

Vehicle-mounted skid-mounted soil leaching system

PendingCN112108508ARealize the collectionRealize harmless treatmentSievingScreeningVehicle frameSoil science

The invention relates to the technical field of soil remediation, in particular to a vehicle-mounted skid-mounted soil leaching system, which comprises a milling tunneling device arranged at the frontend of a frame chassis. A crushing device communicated with the milling tunneling device is arranged in a container body; the crushing device is arranged corresponding to the middle stock bin, the middle stock bin is communicated with a negative-pressure air inducing device, the other side of the negative-pressure air inducing device is communicated with a multi-stage rotary leaching device, andthe multi-stage rotary leaching device separates mud and pumps the mud into the centrifugal spin-drying device; tail pulp screened by the multi-stage rotary leaching device enters a purification treatment device; an outlet of the purification treatment device is communicated with slurry of a horizontal cake pressing device, and the horizontal cake pressing device is communicated with a feeding hole of the low-temperature carbonization furnace; a discharge hole of the low-temperature carbonization furnace is communicated with a discharge pipe arranged at the tail part of the container body. Thesystem is reasonable and novel in design and high in automation degree, collection and harmless treatment of contaminated soil and in-situ backfilling of most contaminated soil are achieved, and theadaptability and treatment efficiency of the device are greatly improved.

Owner:丁莹

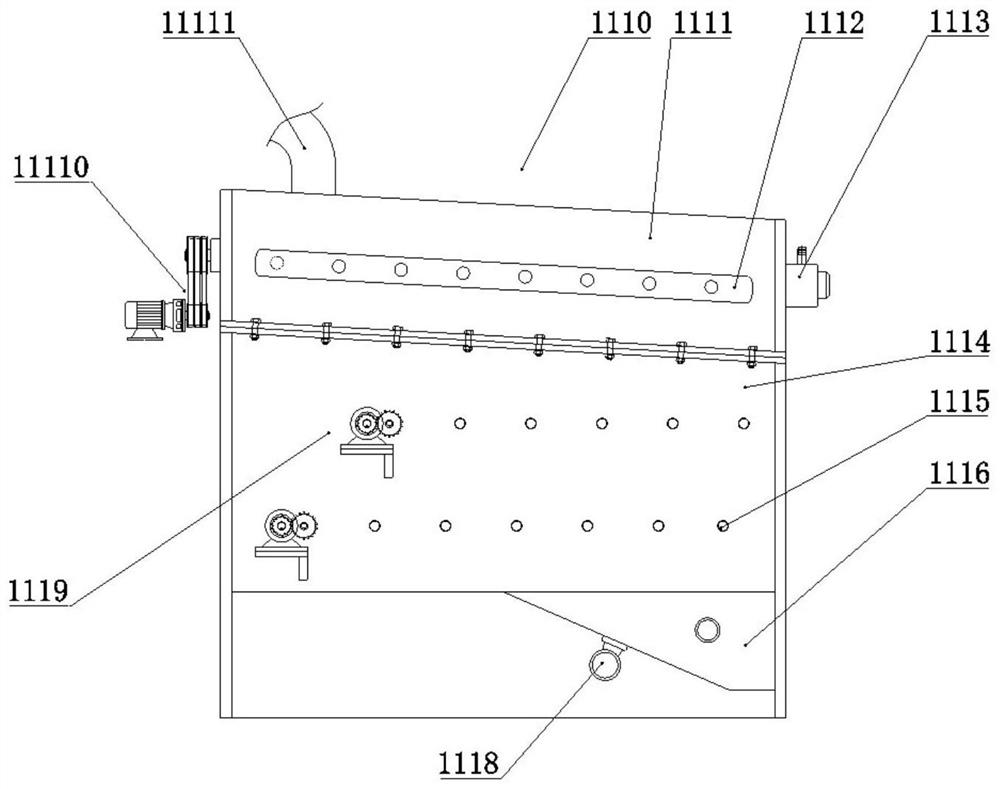

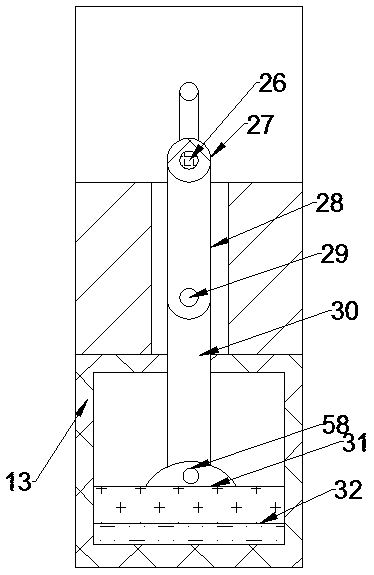

Cooling device used for wine brewing

InactiveCN108913412AAvoid bondingAvoid repeated hitsAlcoholic beverage preparationControl engineeringChain conveyor

The invention relates to the technical field of wine brewing, and discloses a cooling device used for wine brewing. The cooling device comprises a cooling tank and a pushing mechanism used for controlling the cooling tank to rotate, wherein the cooling tank is connected with a cooling mechanism, the pushing mechanism comprises a fixed eccentric gear which is rotatably arranged, lead screws are rotatably arranged on the outer side of the fixed eccentric gear, each lead screw is sleeved with a sliding sleeve, a rack is fixedly connected to the sliding sleeves, annular sliding rails are arrangedon the rack, the cooling tank is fixedly connected with telescopic support rods, the support rods are connected in the sliding rails in a sliding manner, shaft rods are fixedly arranged on the coolingtank, the shaft rods are rotatably connected to the circle center parts of the sliding rails, and torsional springs are connected between the shaft rods and the rack; and a movable eccentric gear meshed with the fixed eccentric gear is further rotatably arranged on the rack, one end of each lead screw is fixedly provided with a reel, a steel wire rope winds each reel, a spool is fixedly arrangedon the cooling tank, and one end, far away from each reel, of the corresponding steel wire rope is fixed to the spool. With the cooling device used for wine brewing, the problem that the cooling of the existing chain conveyer for rice is nonuniform and insufficient is solved.

Owner:遵义市永胜金属设备有限公司

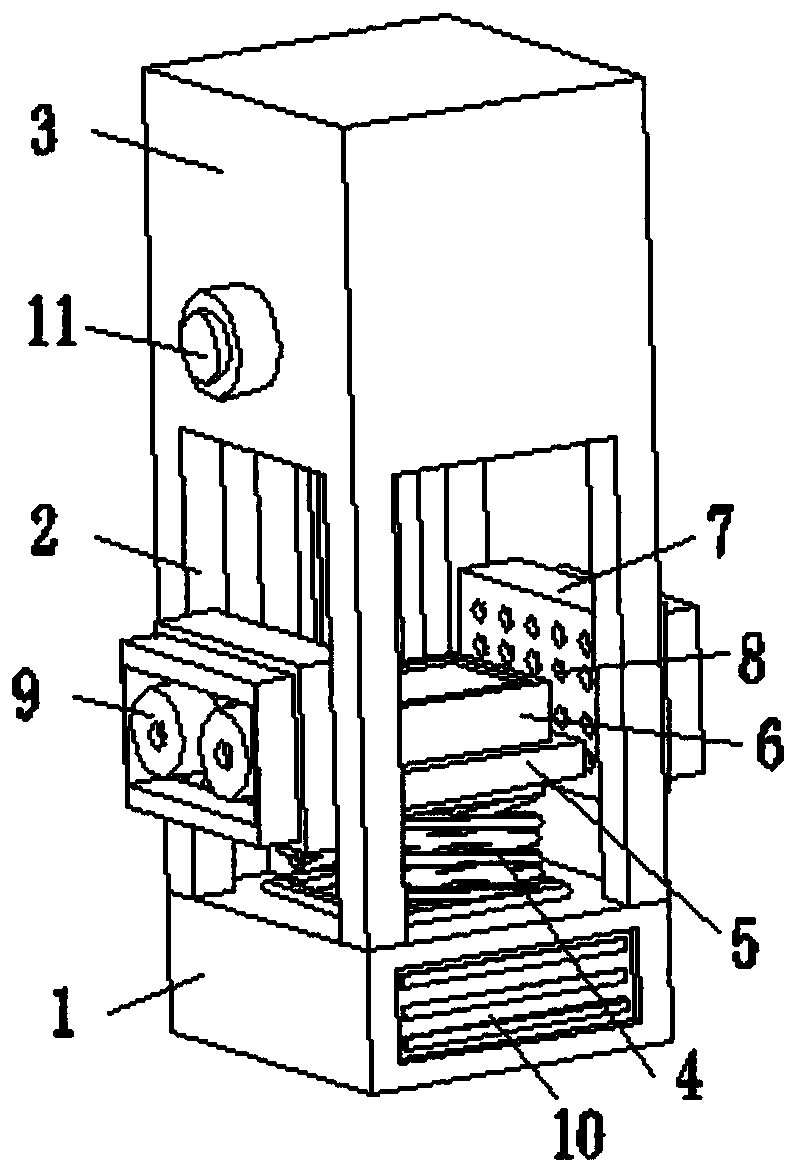

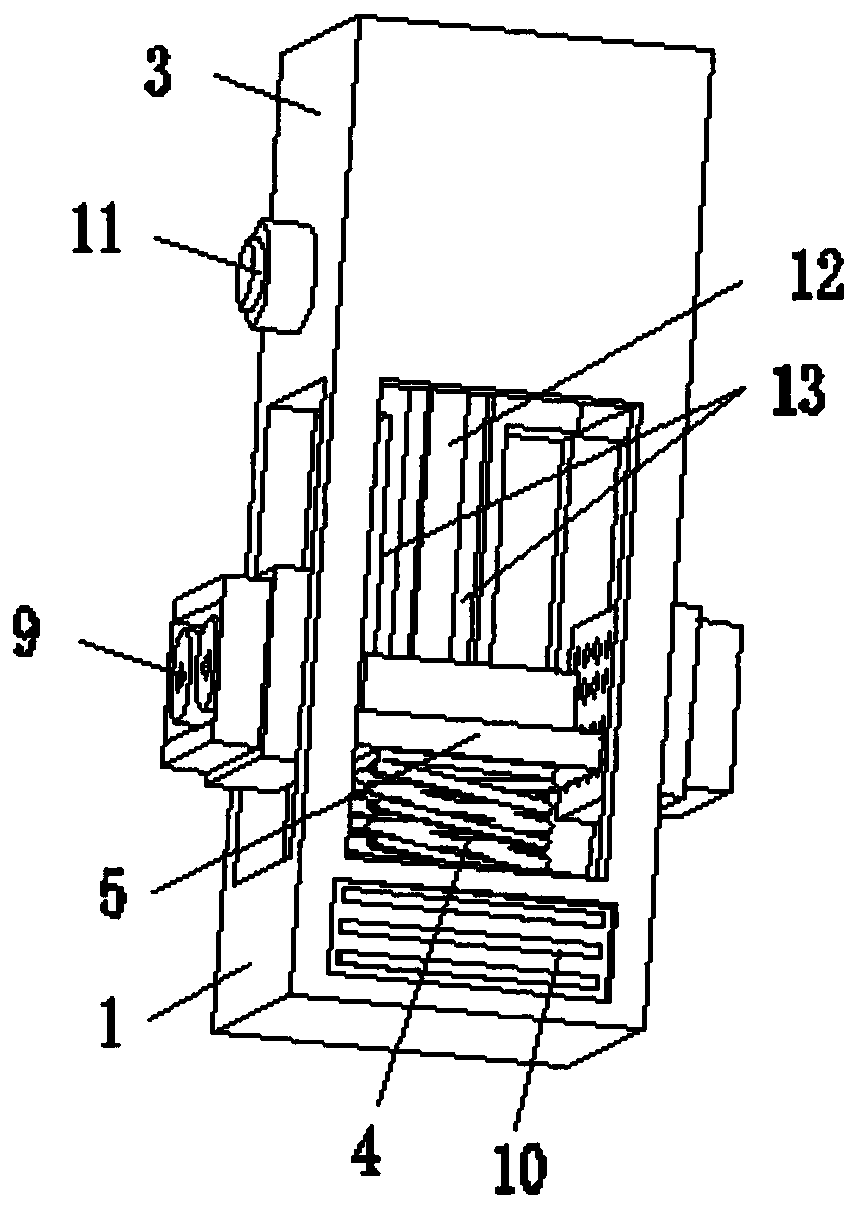

Open-air distribution box protection device

InactiveCN110880707AAchieve protectionRealize the shock absorption effectSubstation/switching arrangement cooling/ventilationAnti-seismic devicesElectric machineryMachine

The invention discloses an open-air distribution box protection device. The device comprises a machine shell. A machine body is arranged in the machine shell. The right side of the machine body is provided with a placement cavity for accommodating a distribution box. The outer surface of the right end of the machine shell is provided with a ventilation hole communicating with the outside and the containing cavity. A temperature sensor capable of sensing the temperature of the distribution box is fixedly arranged on the outer surface of the distribution box. The temperature sensor senses the temperature change of the outer surface of the distribution box. A starting or closing signal is transmitted to the motor. The spring is arranged in the machine body. A first water tank is arranged below the motor. According to the open-air distribution box protection device, protection of the power distribution box which is arranged in the open air can be achieved. Meanwhile, damping of the power distribution box which vibrates due to work is achieved through the buffering effect of the third connecting rod and the sliding rail, and therefore the noise reduction effect is achieved.

Owner:YIWU WANJU ELECTRONICS CO LTD

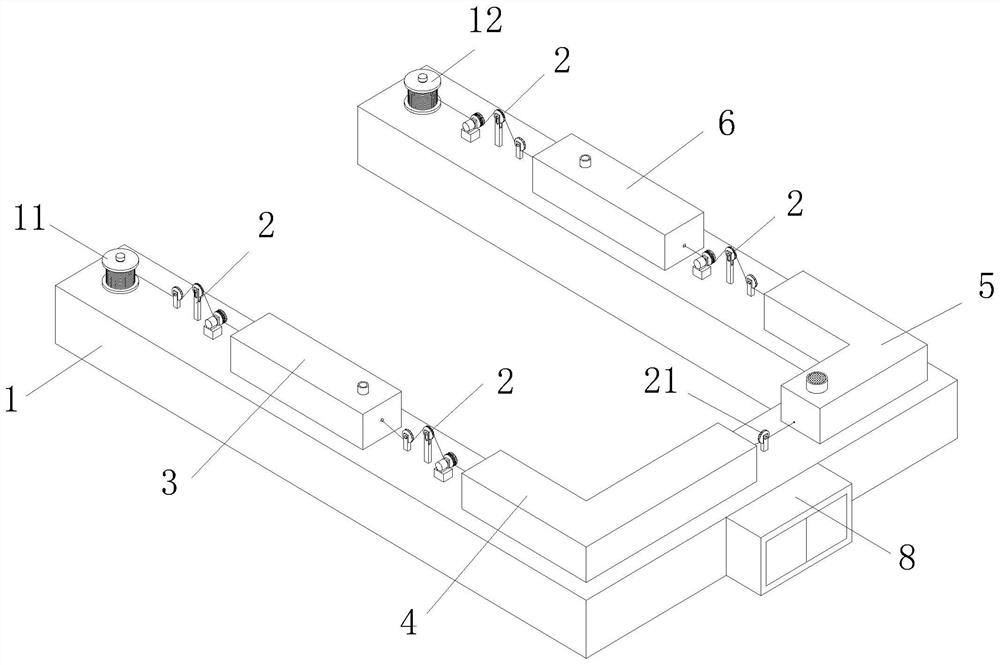

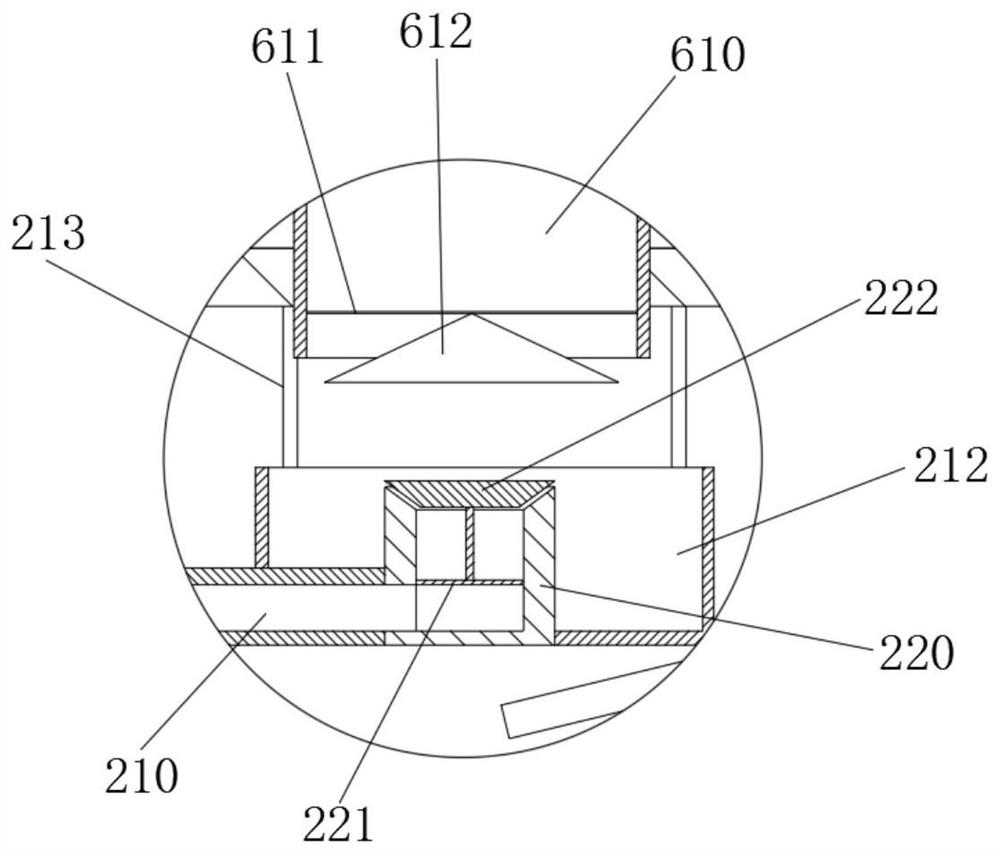

Automatic production line for producing enameled wires

InactiveCN114121376ASimple structureSmall footprintApparatus for feeding conductors/cablesApparatus for heat treatmentManufacturing engineeringIndustrial engineering

The invention provides an automatic production line for producing enameled wires. The automatic production line comprises a base, a conveying assembly, an annealing device, a painting device, a baking device, a cooling device, a wire drawing assembly and a control device. A pay-off roller and a take-up roller are movably arranged on the base, the conveying assembly sequentially conveys an enameled wire to the annealing device, the painting device, the baking device, the cooling device and the take-up roller from the pay-off roller, the annealing device conducts annealing processing on the enameled wire, the painting device conducts multi-layer painting processing on the enameled wire, and the baking device conducts evaporation and curing processing on paint liquid of the enameled wire. The cooling box is used for carrying out cooling processing on the enameled wire, the wire drawing assemblies are installed in the heating bin, the annealing bin, the first painting bin, the second painting bin, the baking bin, the evaporation bin, the cooling bin and the cooling bin correspondingly, and the control device controls the pay-off roller, the take-up roller, the conveying assembly, the annealing device, the painting device, the baking device and the cooling device to work normally. The automation degree and the production efficiency are high.

Owner:湖南奇洛电工器材有限公司

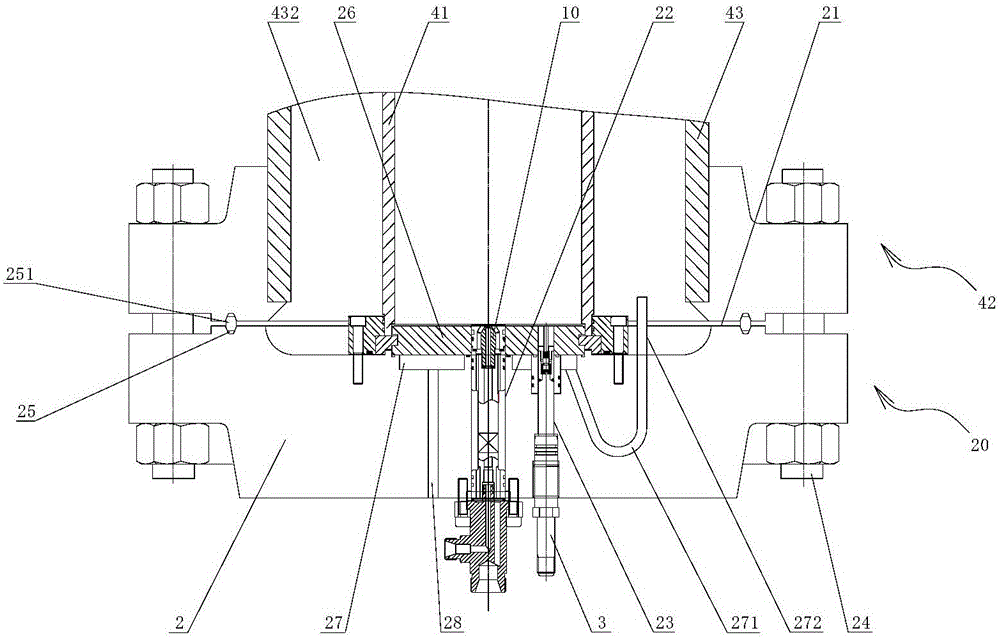

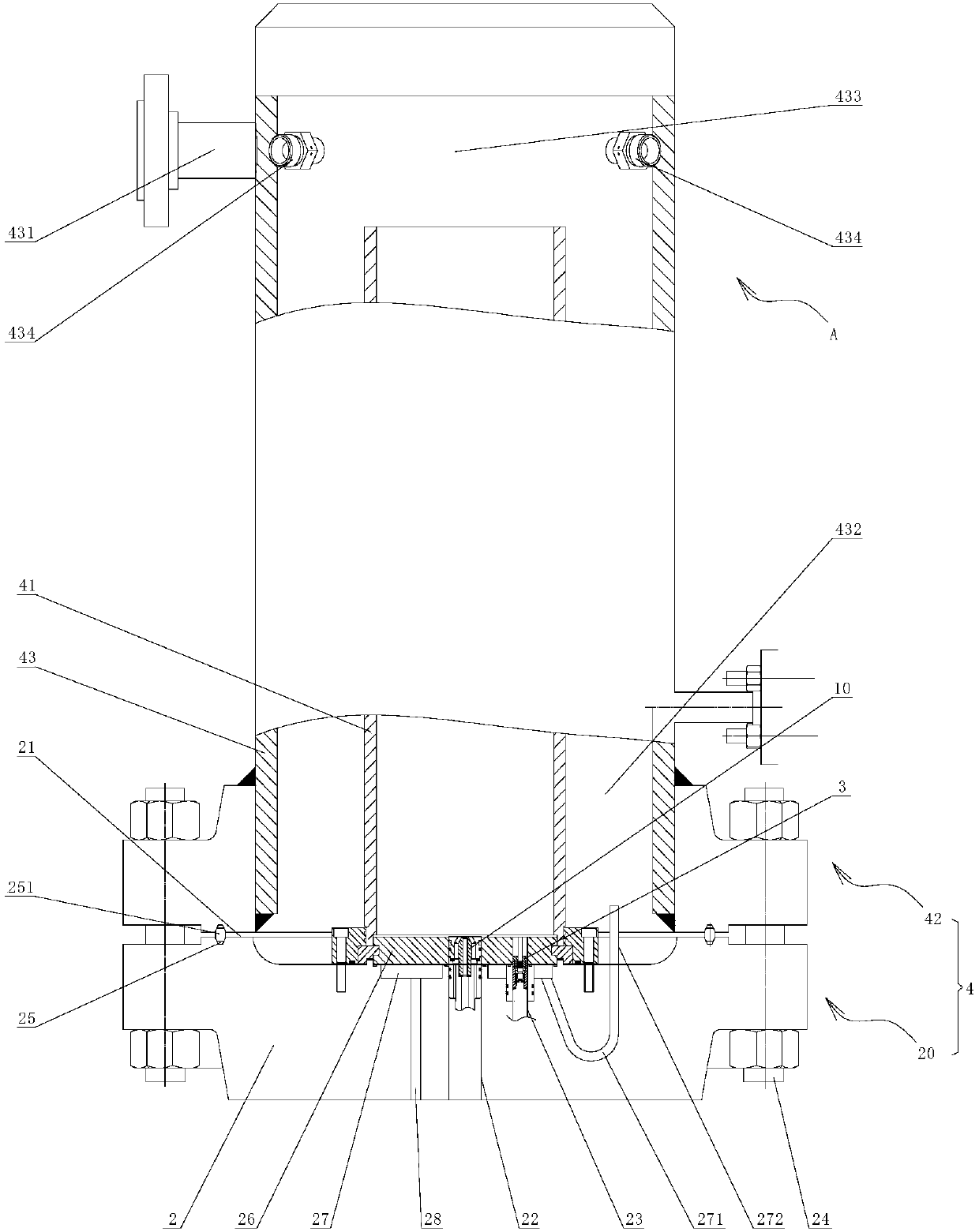

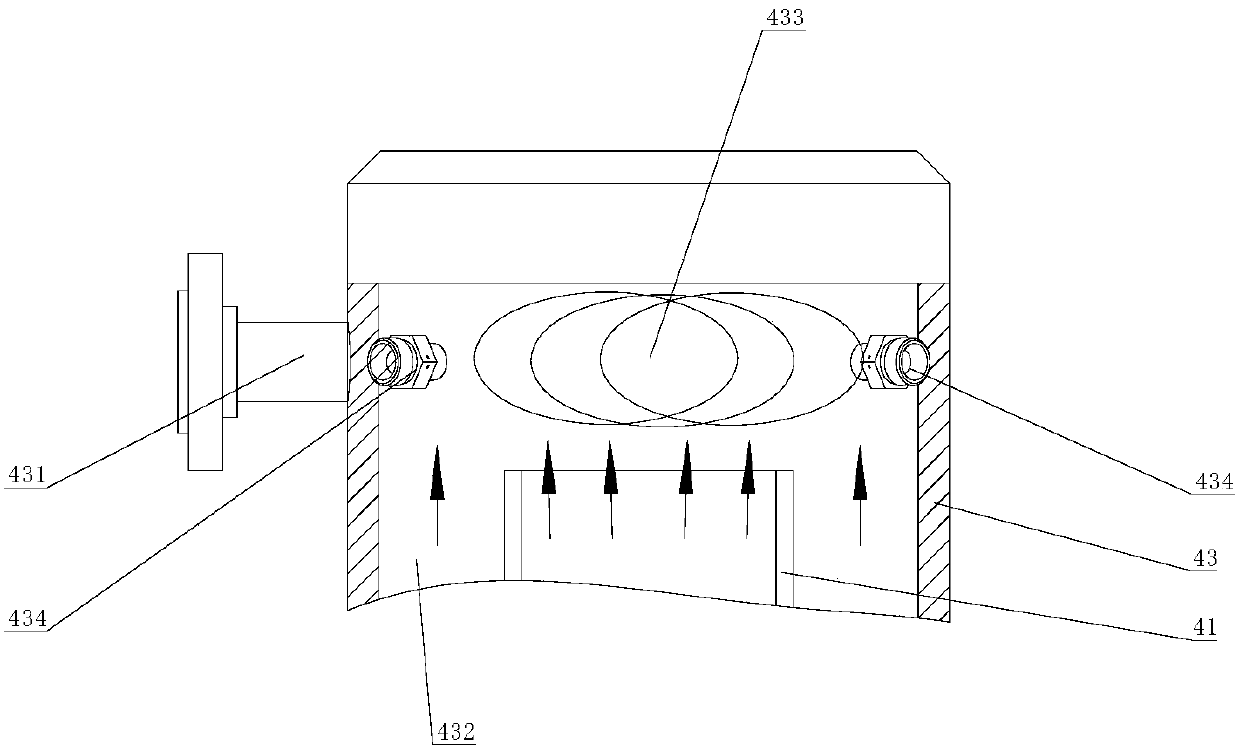

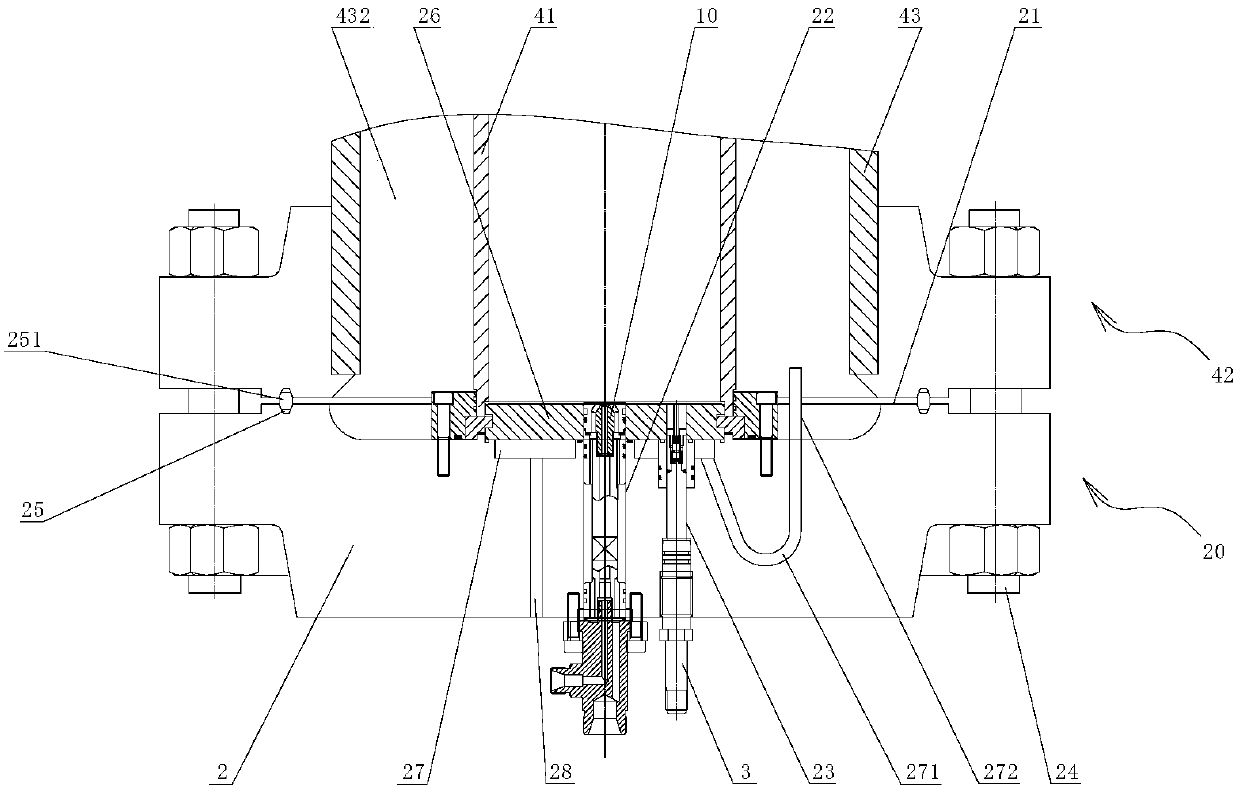

Waste water composite heat carrier generator and composite heat carrier generation method

ActiveCN105841129AHigh cost savingsExtended service lifeFluid removalSteam generation plantsCombustion chamberHeat carrier

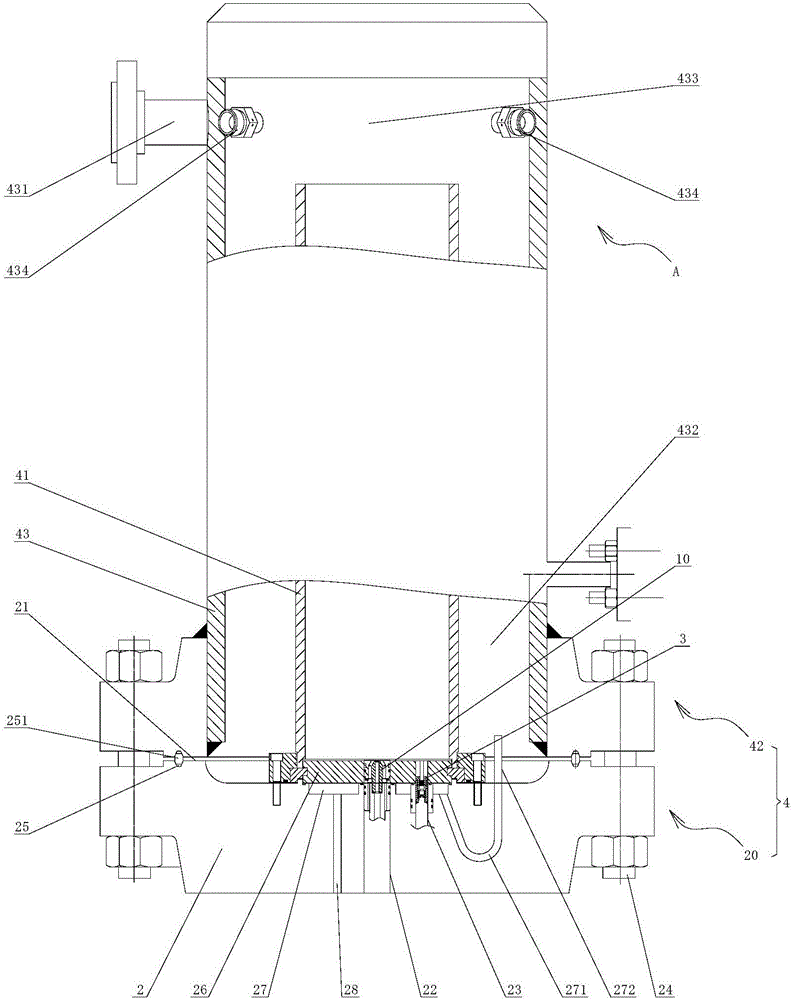

The invention provides a waste water composite heat carrier generator and a composite heat carrier generation method. The waste water composite heat carrier generator comprises a generator body, a generator head structure and a cooling gasifying device; the generator body comprises a combustion chamber and a steam chamber, the upper end of the combustion chamber is communicated with the steam chamber, and the upper end of the steam chamber is connected with an outlet pipeline; the generator head structure is connected to the lower end of the generator body, and is provided with a head body, a combustion nozzle and an ignition electrode, wherein the combustion nozzle and the ignition electrode are arranged in the head body and are arranged in a manner of being opposite to the combustion chamber, and a water inlet channel and a scale discharging channel are formed in the head body; the cooling gasifying device is connected to the upper end of the steam chamber; the generator can meet the requirements of high-pressure combustion and composite heat carrier safe output, meanwhile, waste water separated from crude oil is used as cooling water to be subject to cooling treatment through the lower portion and the upper portion of the generator, and steam needed by a composite heat carrier is generated; and clean water resources are saved, and the high cost of wastewater treatment can be reduced.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

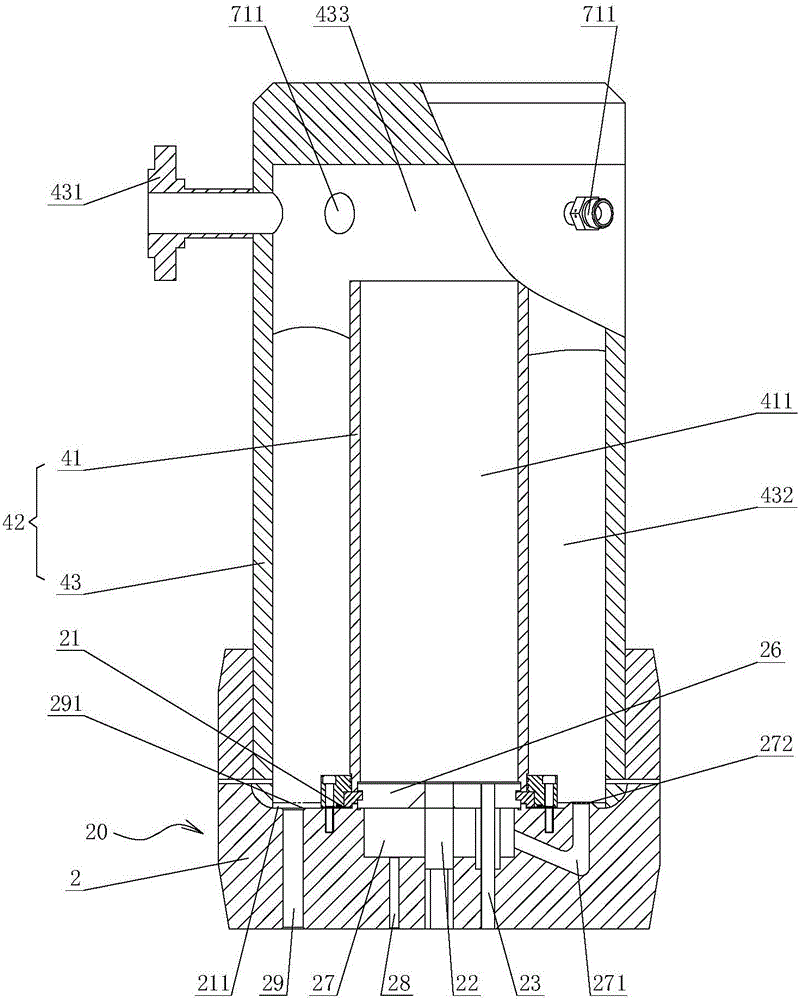

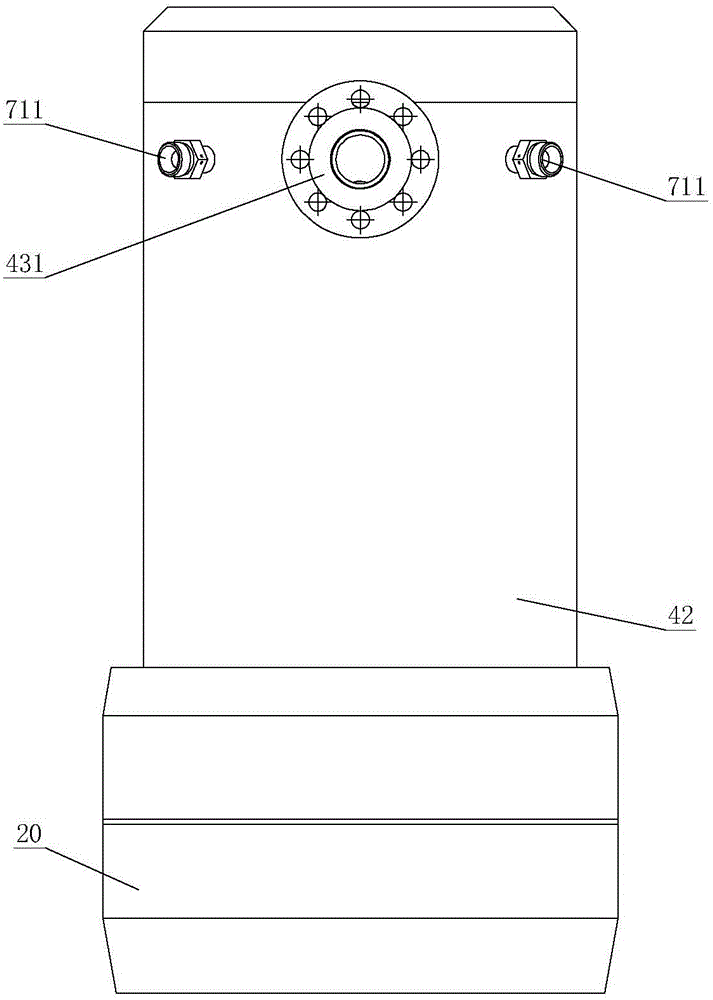

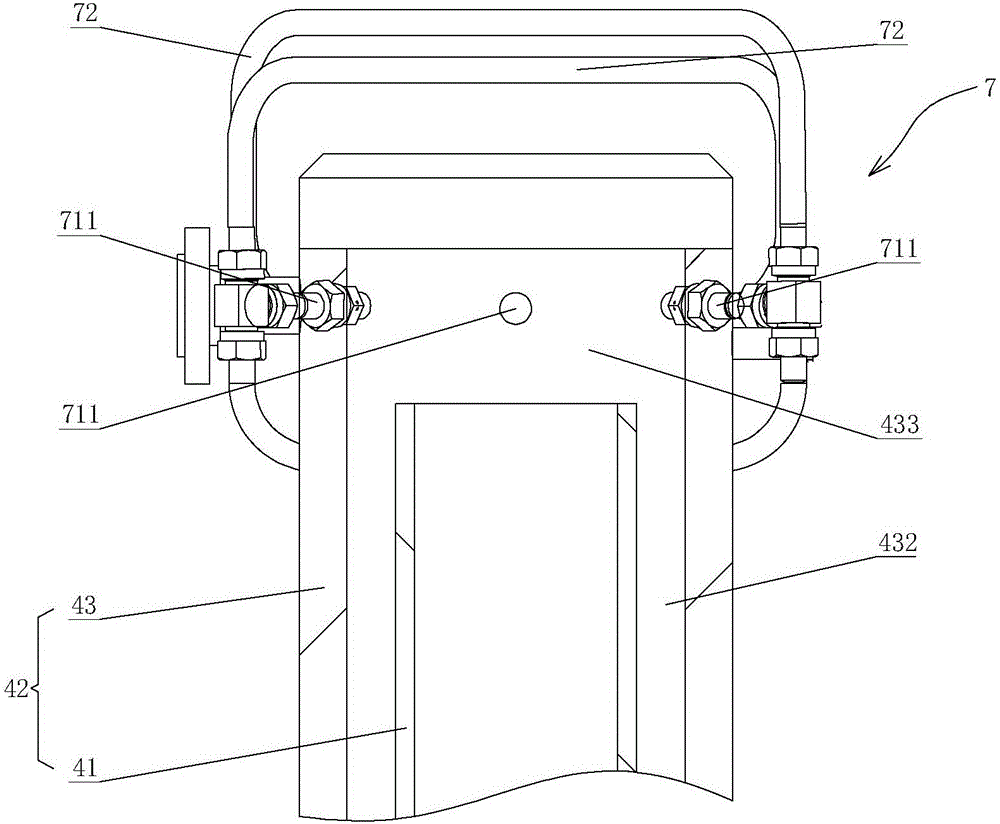

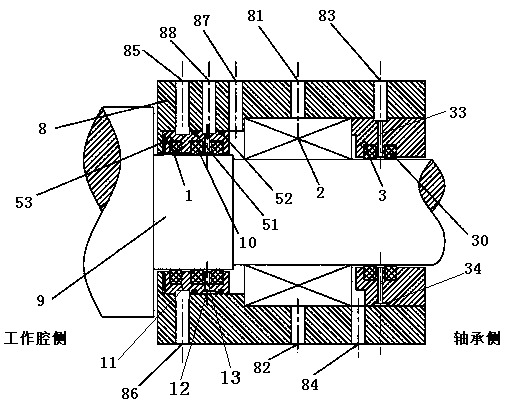

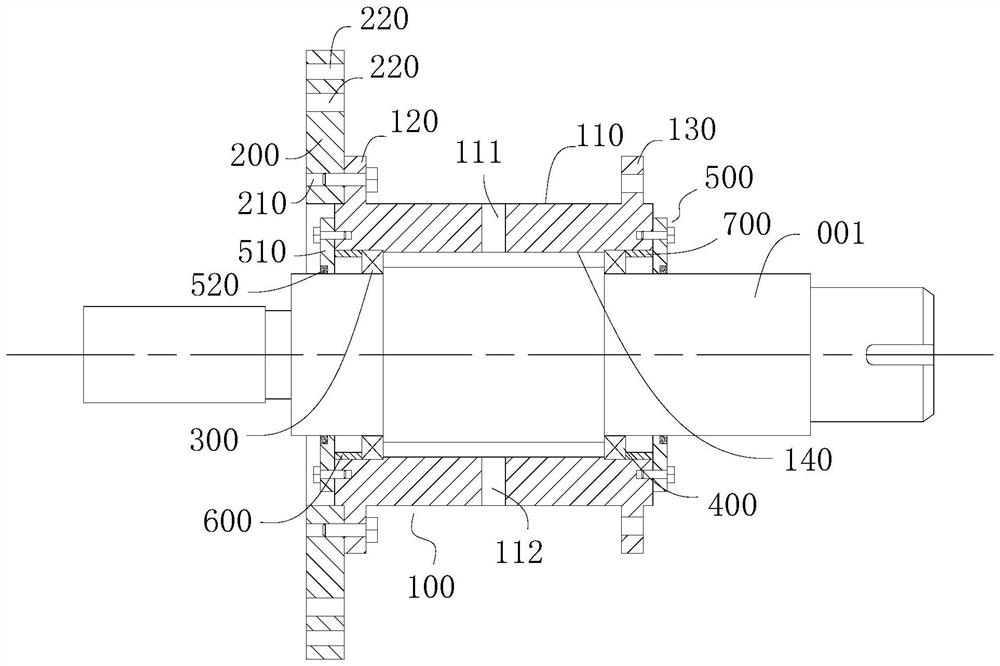

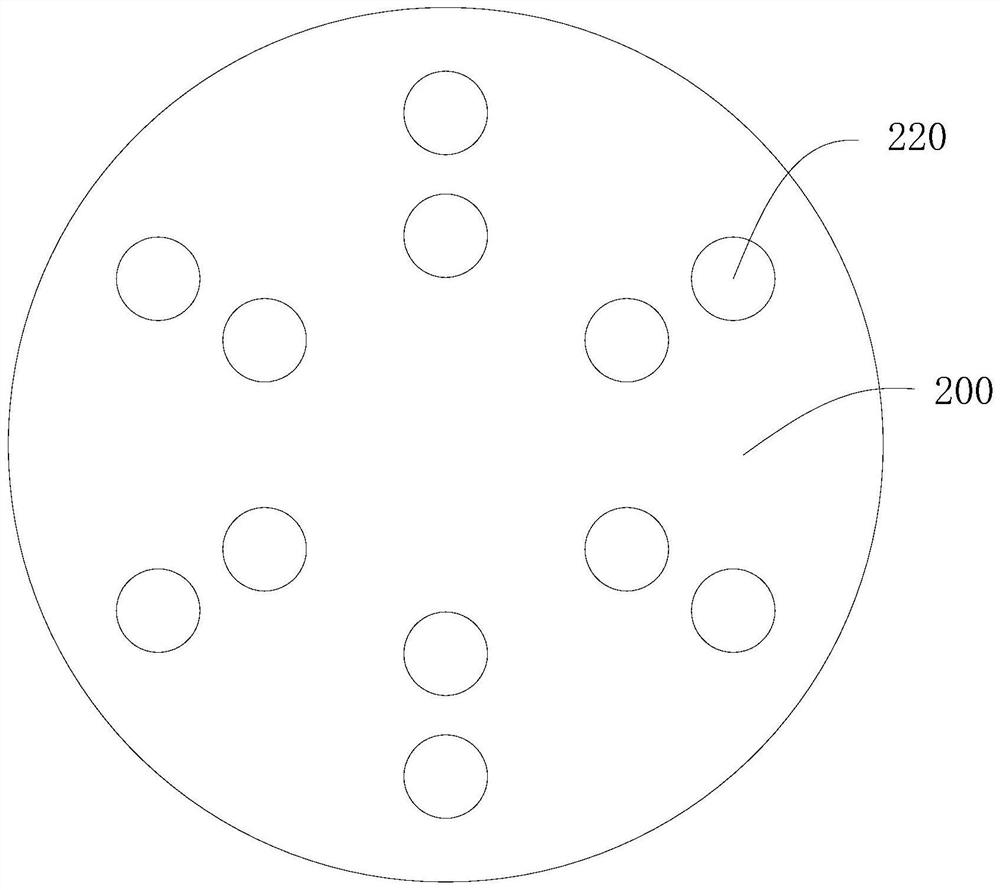

Shaft sealing device of oil-free screw machine

PendingCN107654377AAvoid pollutionAvoid contactSealing arrangement for pumpsSealing arrangements for enginesOil freeEngineering

Disclosed is a shaft sealing device of an oil-free screw machine. The shaft sealing device comprises a front sealing, a main sealing, an isolating air sealing and a bearing which are installed on a rotor of the oil-free screw machine. The main sealing is located between the front sealing and the bearing. The isolating air sealing is located between the main sealing and the bearing. The main sealing is a double-end-surface mechanical sealing. A water injecting hole and a backwater hole which penetrate through the side wall of a shell body are formed in the corresponding positions of the shell body of the oil-free screw machine and the double-end-surface mechanical sealing. Isolating air inlet holes penetrating through the side wall of the shell body are formed in the corresponding positionsof the shell body of the oil-free screw machine and the isolating air sealing. An isolating air guiding-in hole penetrating through the side wall of the isolating air sealing is formed in the side wall of the isolating air sealing. Isolating air injected into the isolating air inlet hole can enter the isolating air guiding-in hole. A sewage discharging hole penetrating through the side wall of the shell body is formed in the shell body of the oil-free screw machine between mechanical sealing and the isolating air sealing. The shaft sealing device cannot pollute working medium steam in a working cavity of the screw machine and cannot affect the service life of the rotor bearing.

Owner:SHANGHAI QIYAO SCREW MACHINERY +1

Waste water composite heat carrier generator and composite heat carrier generation method

ActiveCN105823032AMagnetization achievedLoose scalingBoiler cleaning apparatusFluid removalInlet channelCombustion chamber

The invention provides a waste water composite heat carrier generator and a composite heat carrier generation method. The waste water composite heat carrier generator comprises a generator body, a generator head structure and a magnetizing assembly. The generator body comprises a burning chamber and a steam chamber arranged outside the burning chamber in a sleeving manner, the upper end of the burning chamber is communicated with the steam chamber, and the upper end of the steam chamber is connected with an outlet pipe; the generator head structure is connected to the lower end of the generator body, and is provided with a head body, a burning spraying nozzle and an ignition electrode, the burning spraying nozzle and the ignition electrode are arranged in the head body and are arranged opposite to the burning chamber, and the head body is internally provided with a water inlet channel and a dirty discharging channel which are communicated with the steam chamber; and the magnetizing assembly is provided with a water inlet pipe, the exterior of the water inlet pipe is sleeved with a water magnetizer, and the water inlet pipe and the water inlet channel are connected. According to the waste water composite heat carrier generator and the composite heat carrier generation method, by means of the water magnetizing assembly, waste water led into the generator can be subject to water magnetizing treatment, scaling of the waste water is relatively loose, and the scaling is convenient to discharge.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

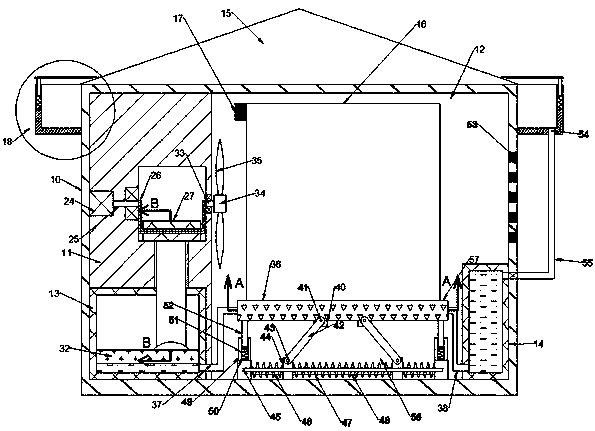

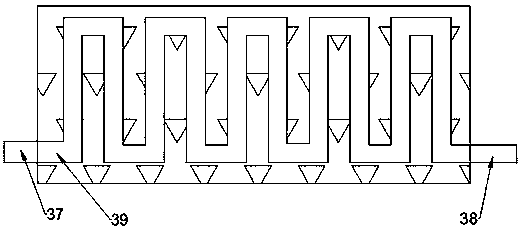

Rapid cooling device for hot galvanizing operation

ActiveCN109440043APlay the role of buffer protectionRealize the cooling processHot-dipping/immersion processesEngineeringMetal

The invention discloses a rapid cooling device for hot galvanizing operation, and belongs to the technical field of galvanization, so that the problem that an existing device cannot uniformly cool metal parts is solved, the outer surface of the metal parts have a chromatic aberration, and metal part beauty is influenced are solved. The device is technically characterized by comprising a shell, a feeding hole, a cooling cavity and a horizontal guide rail, a base is arranged at the lower part of the shell, the shell is fixed on the base, the feeding hole is formed in the top of the left side wall of the shell, the cooling cavity is formed in the shell, the feeding hole is communicated with the cooling cavity, a horizontal connecting cross rod is fixedly arranged on the top of the right sidewall of the shell, a horizontal guide rail is arranged below the horizontal connecting cross rod, the horizontal guide rails and the horizontal connecting cross rod are fixedly connected through bolts. According to the rapid cooling device, full cooling treatment can be carried out on the metal parts after hot galvanizing operation, and can ensure the rapid and high efficiency of the cooling process of the metal parts.

Owner:青岛豪迈永祥和环保科技有限公司

Generator head structure and its assembly method

ActiveCN105910086BLow running costUniform atomizationFluid removalSteam generation plantsCombustionEngineering

Owner:CNPC GLOBAL SOLUTIONS LTD +1

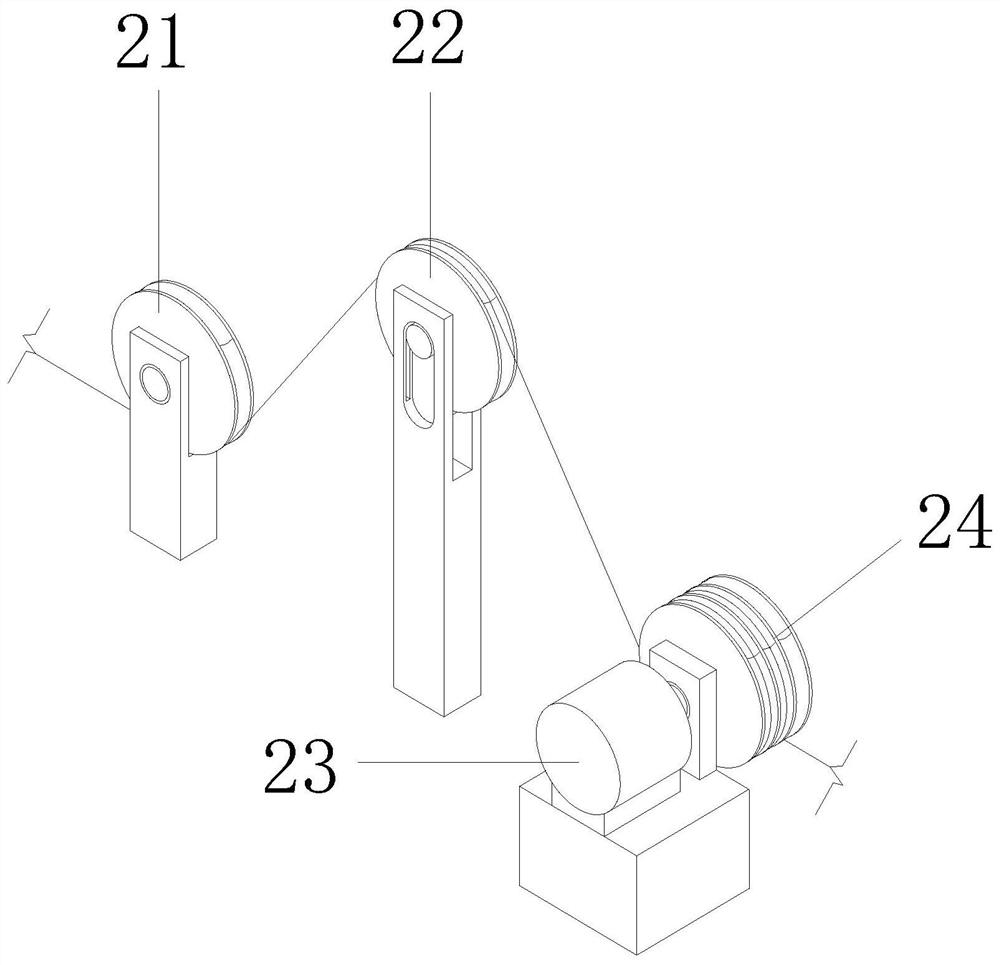

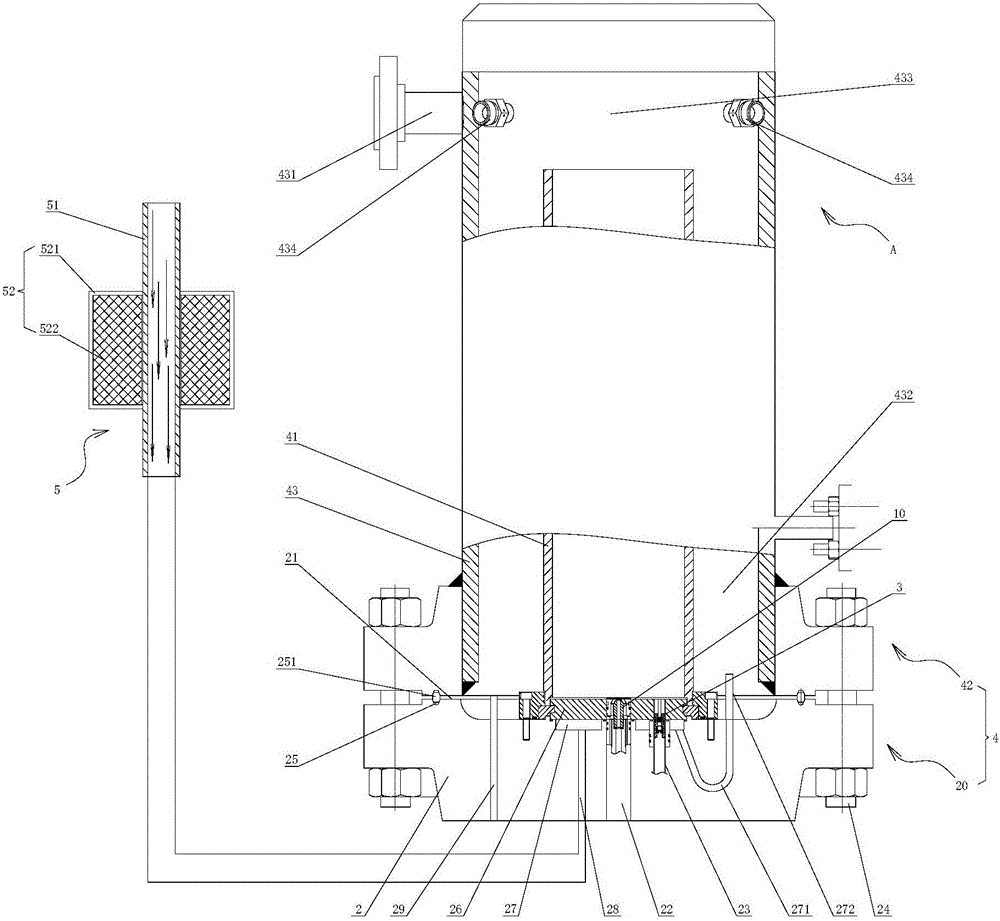

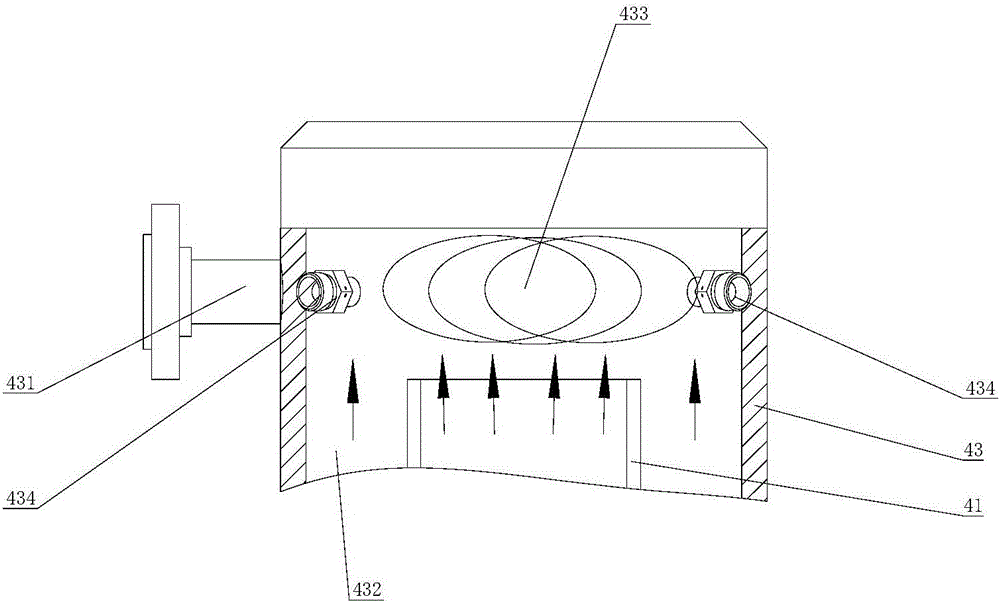

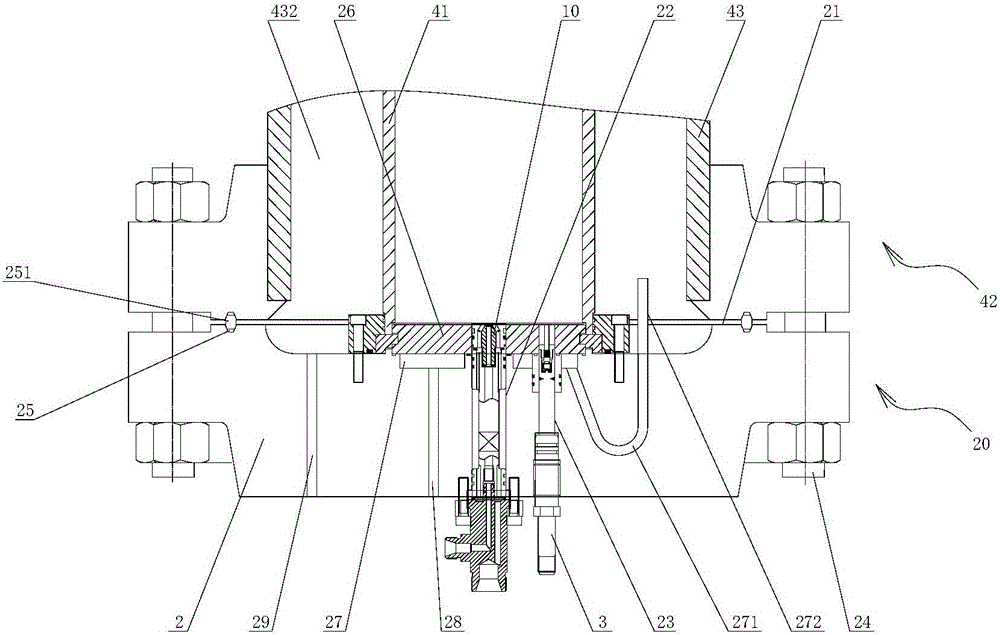

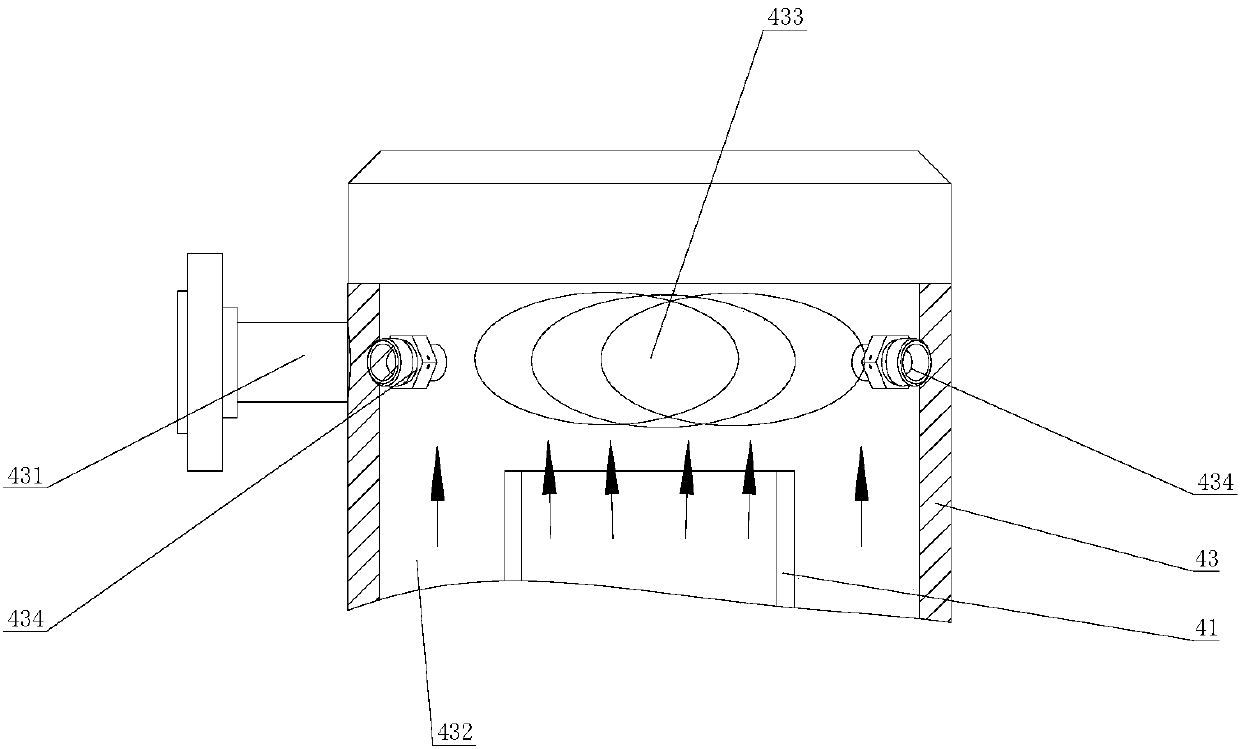

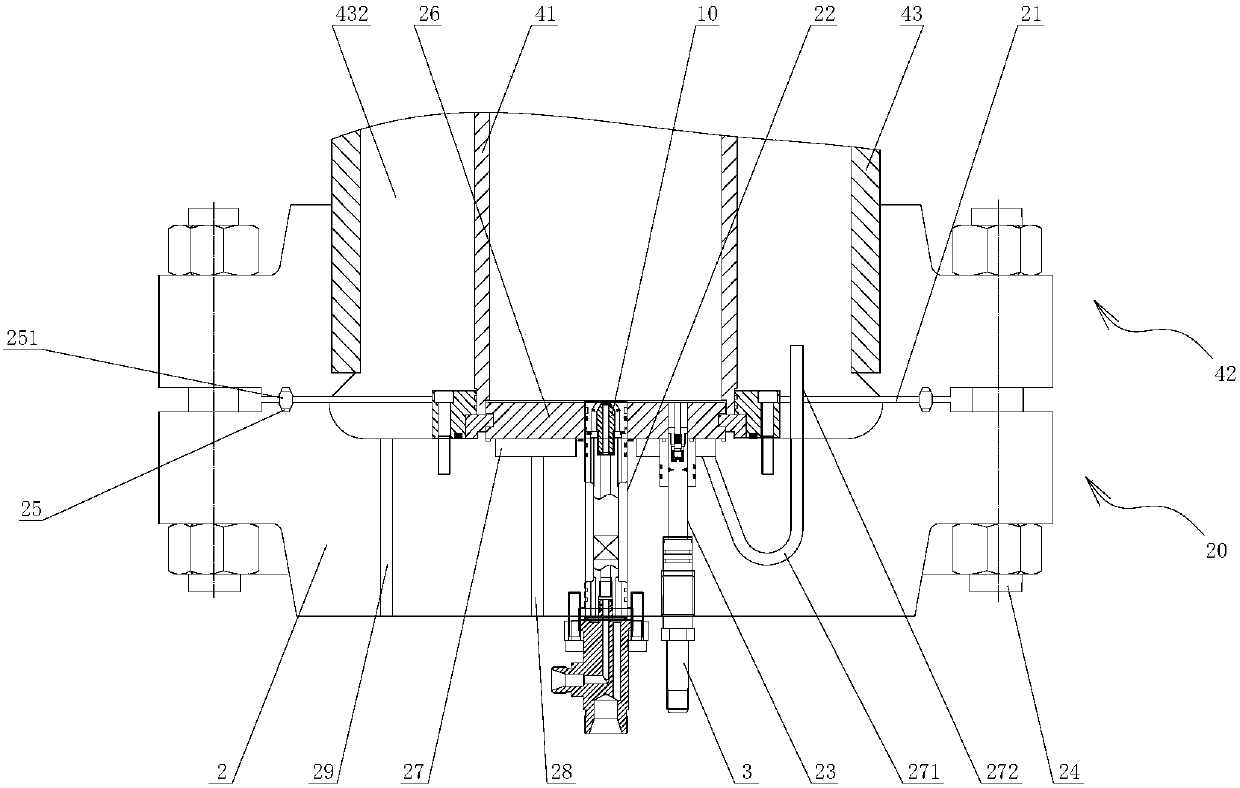

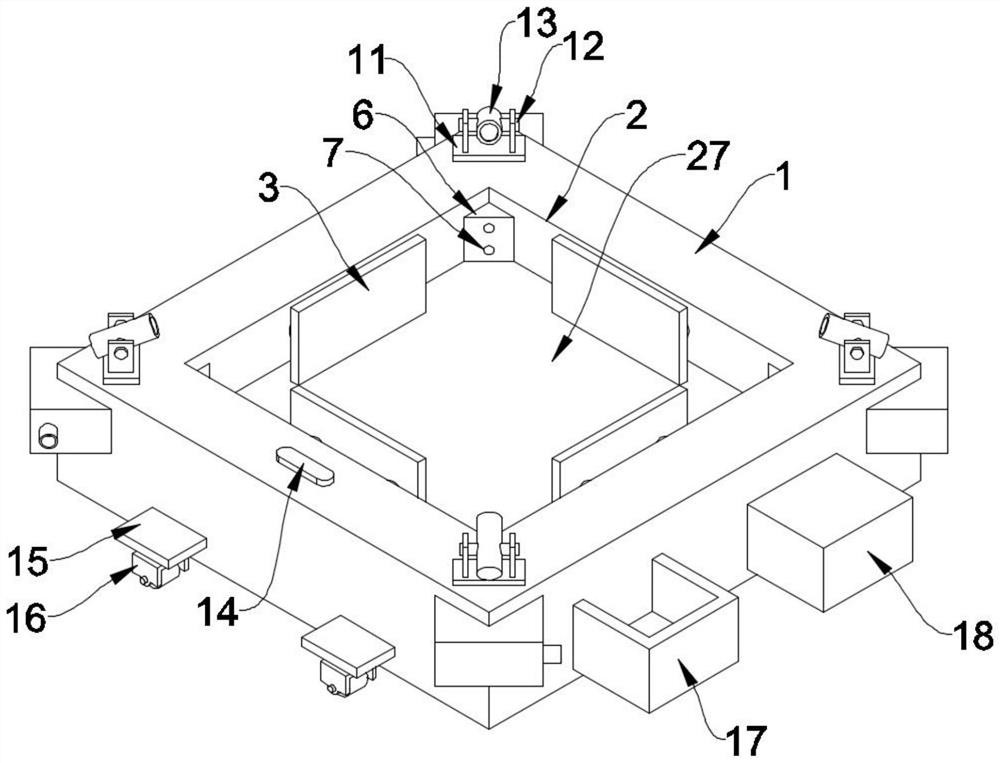

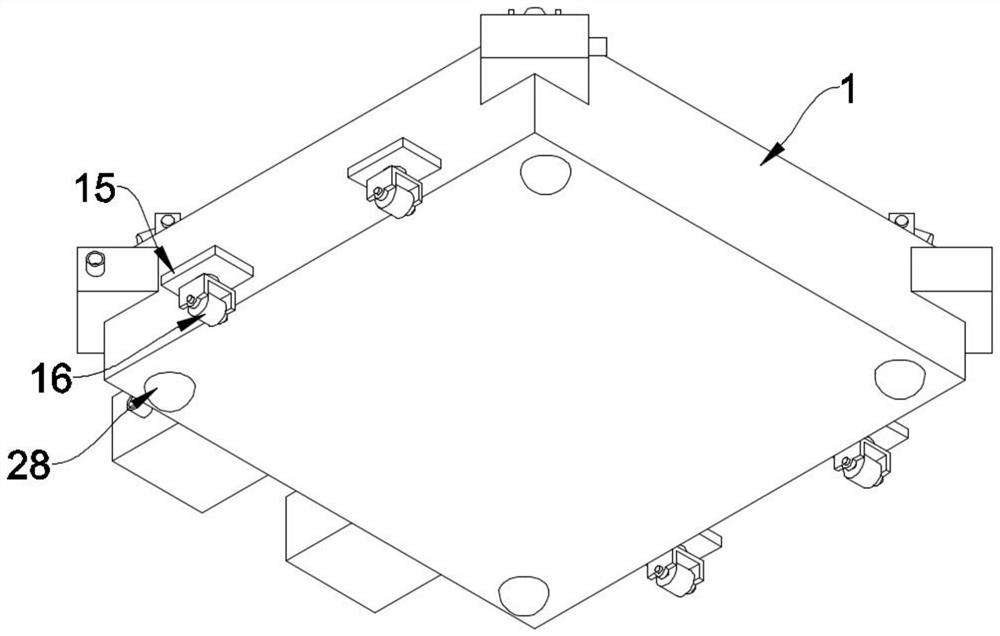

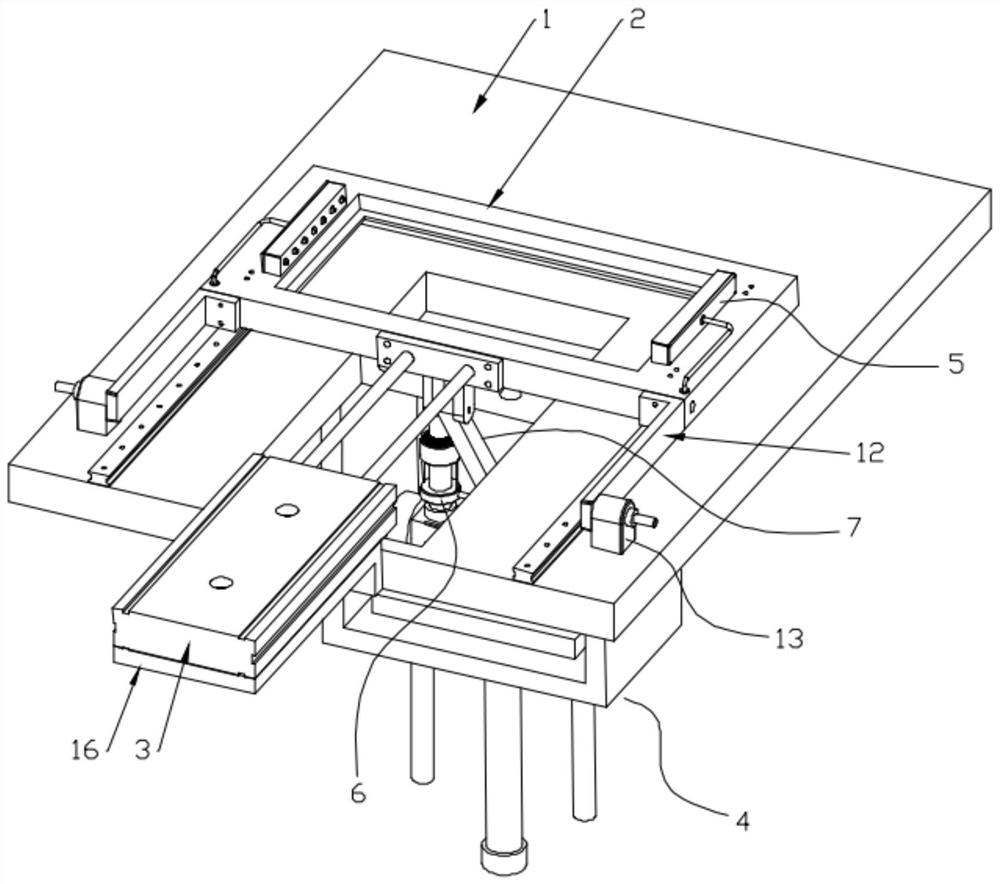

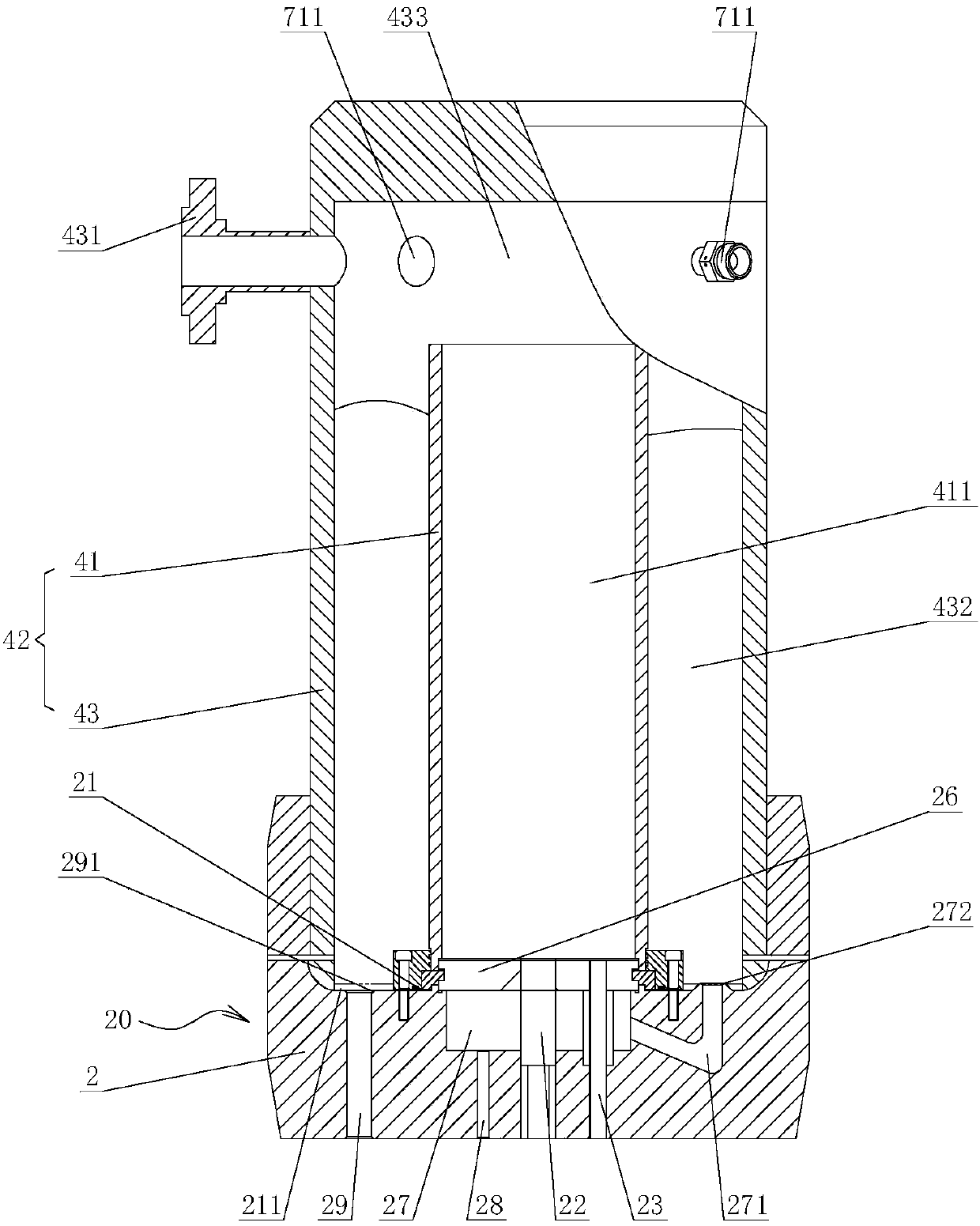

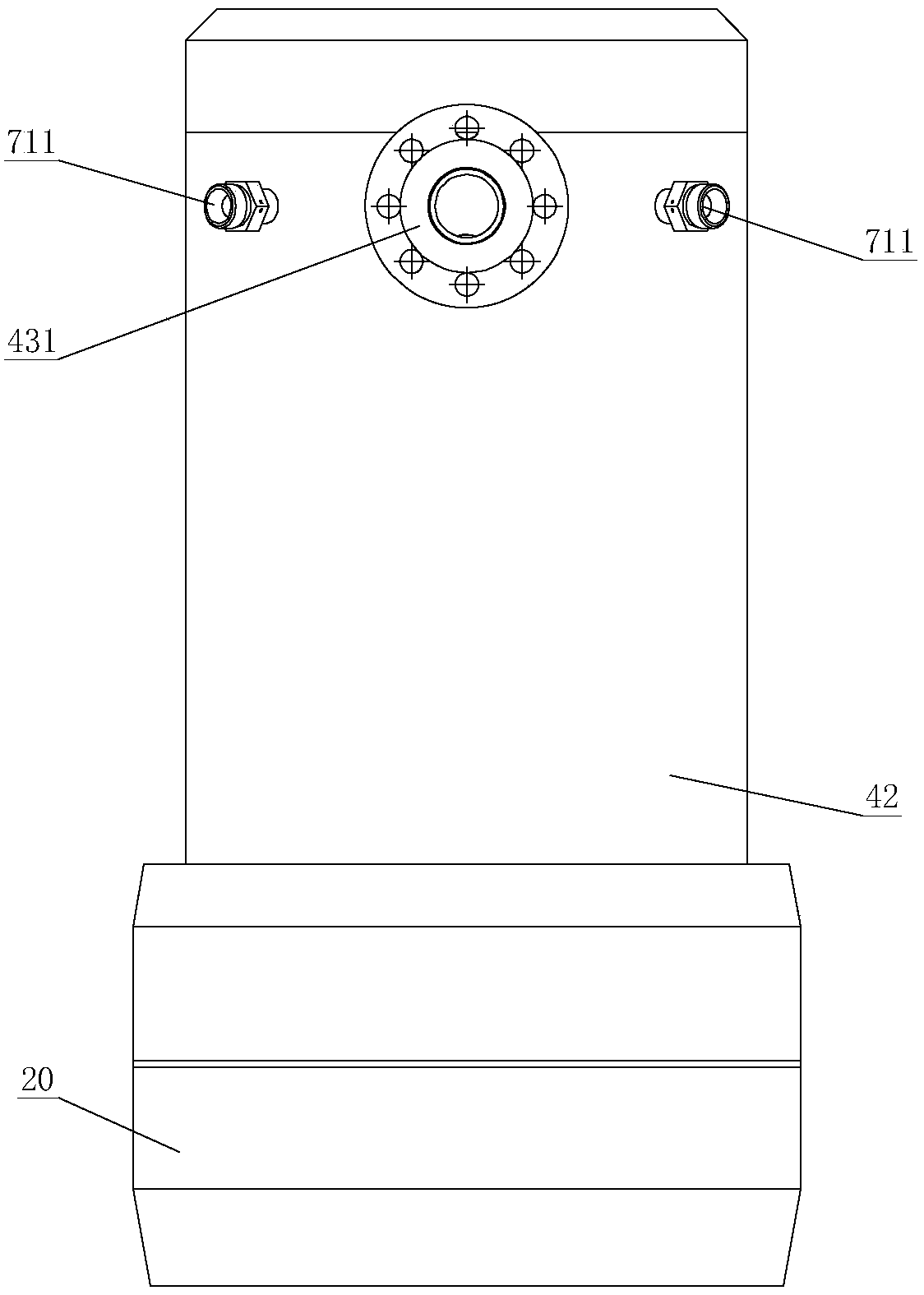

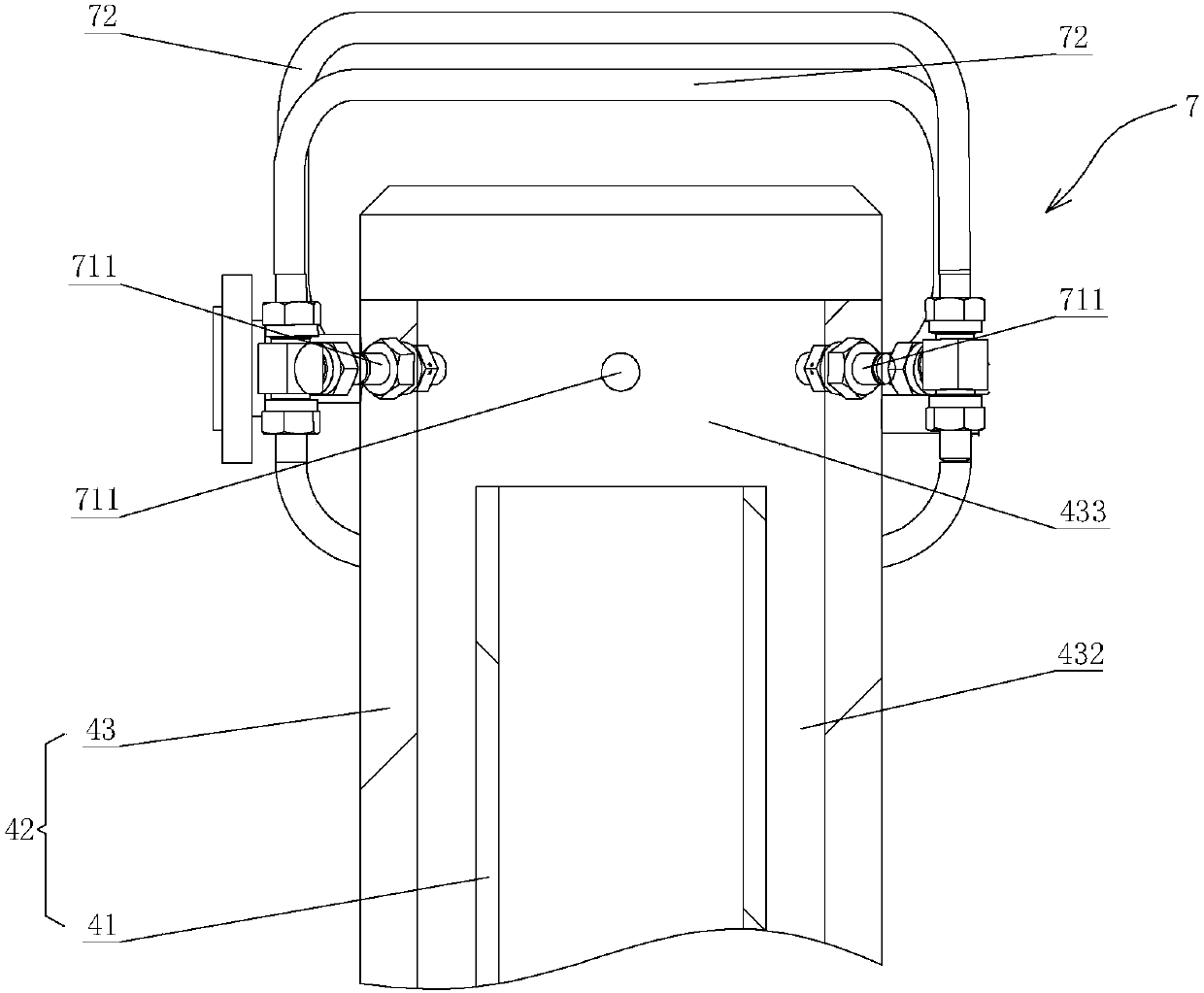

Head clamping spray cooling device

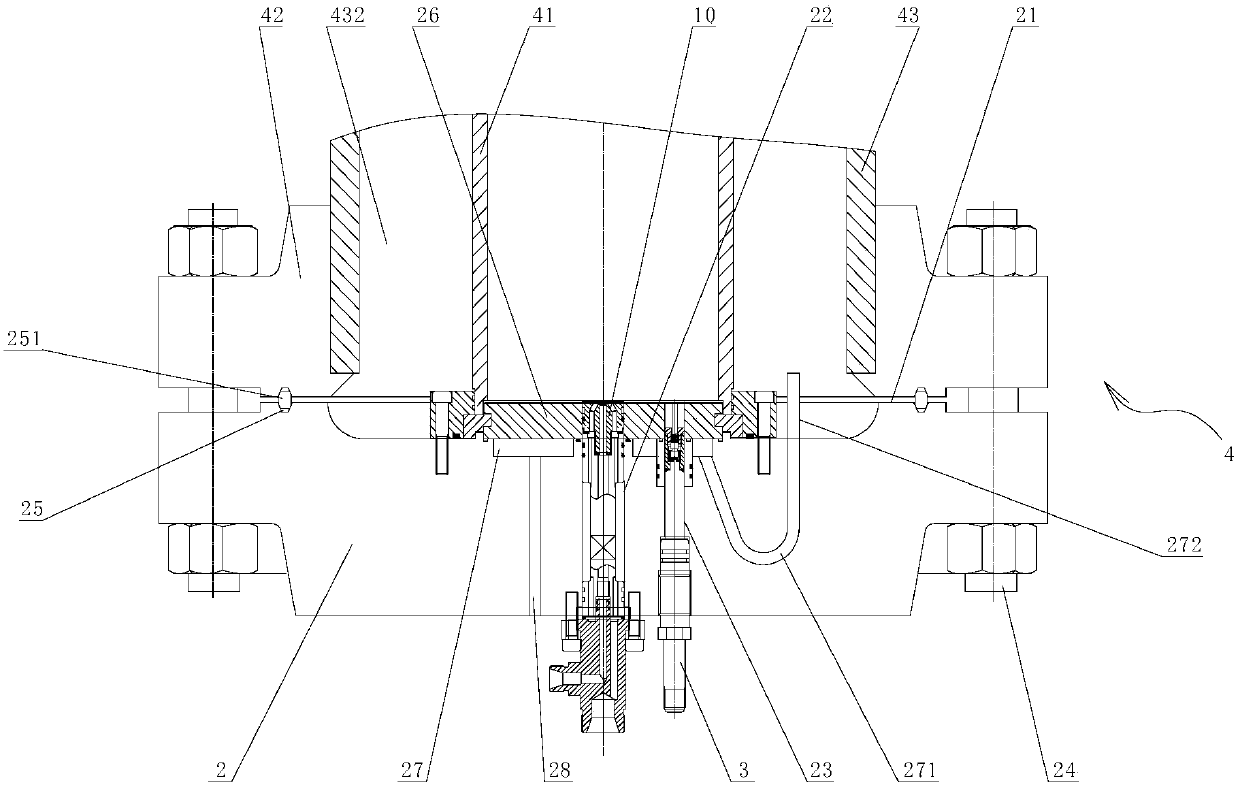

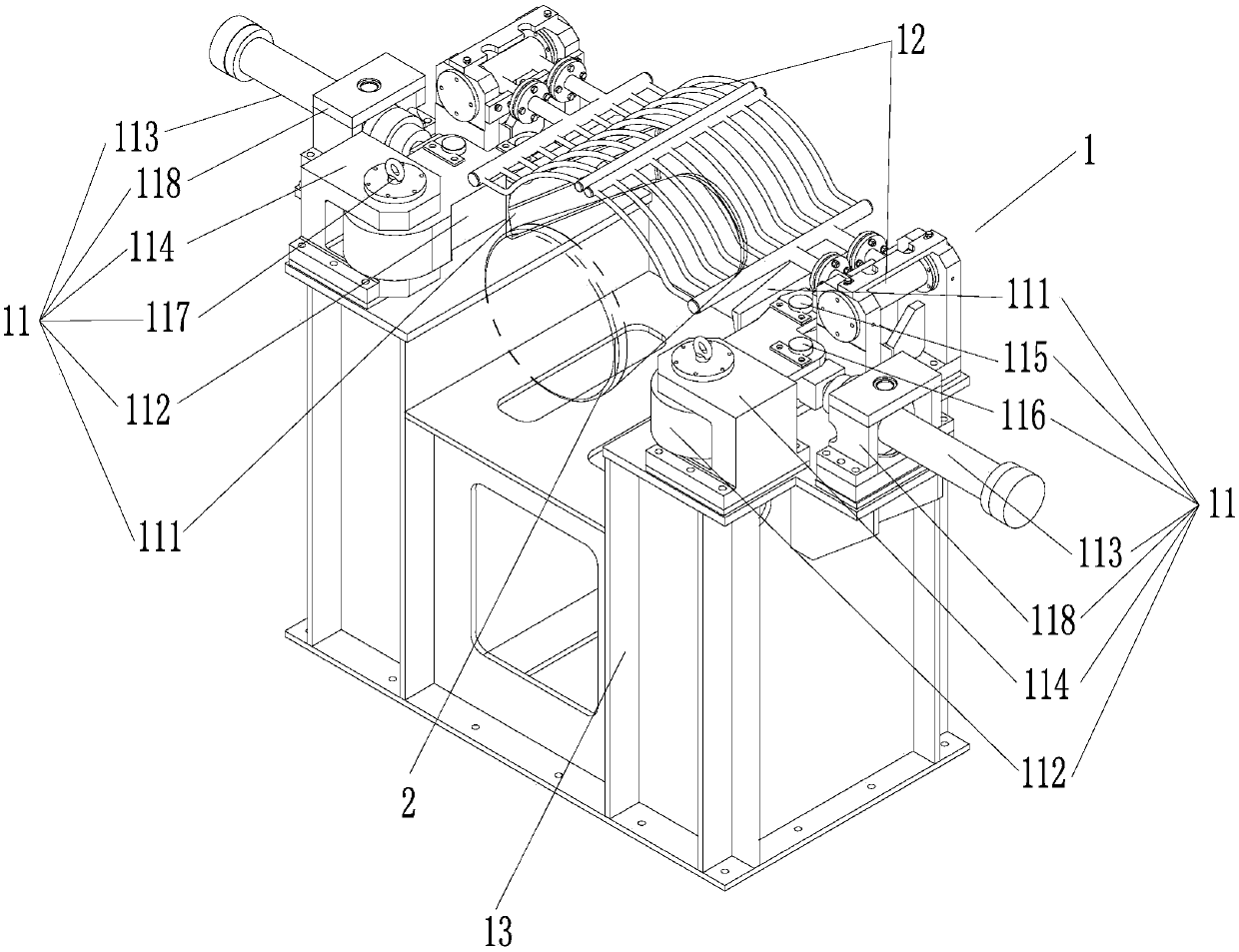

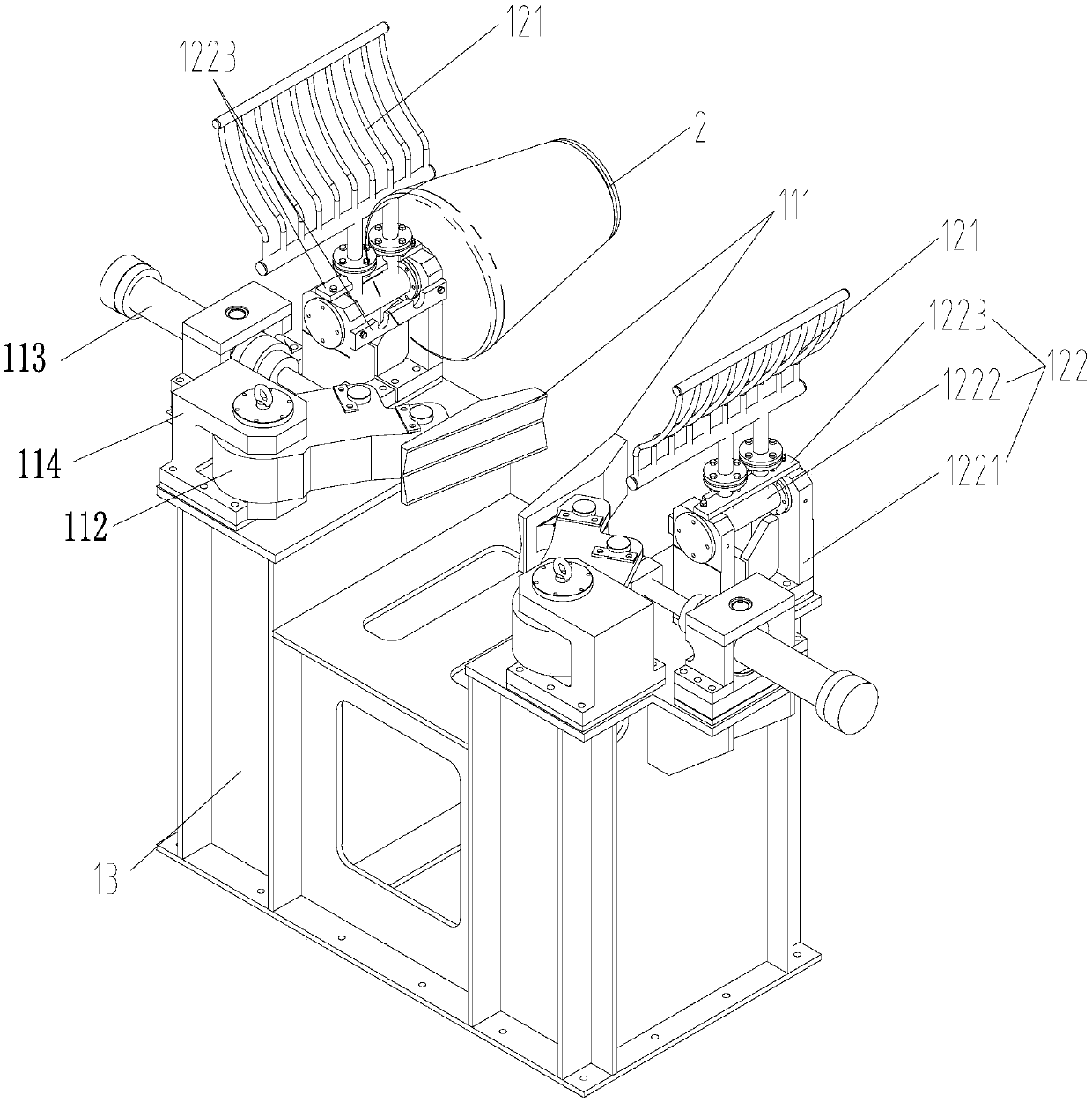

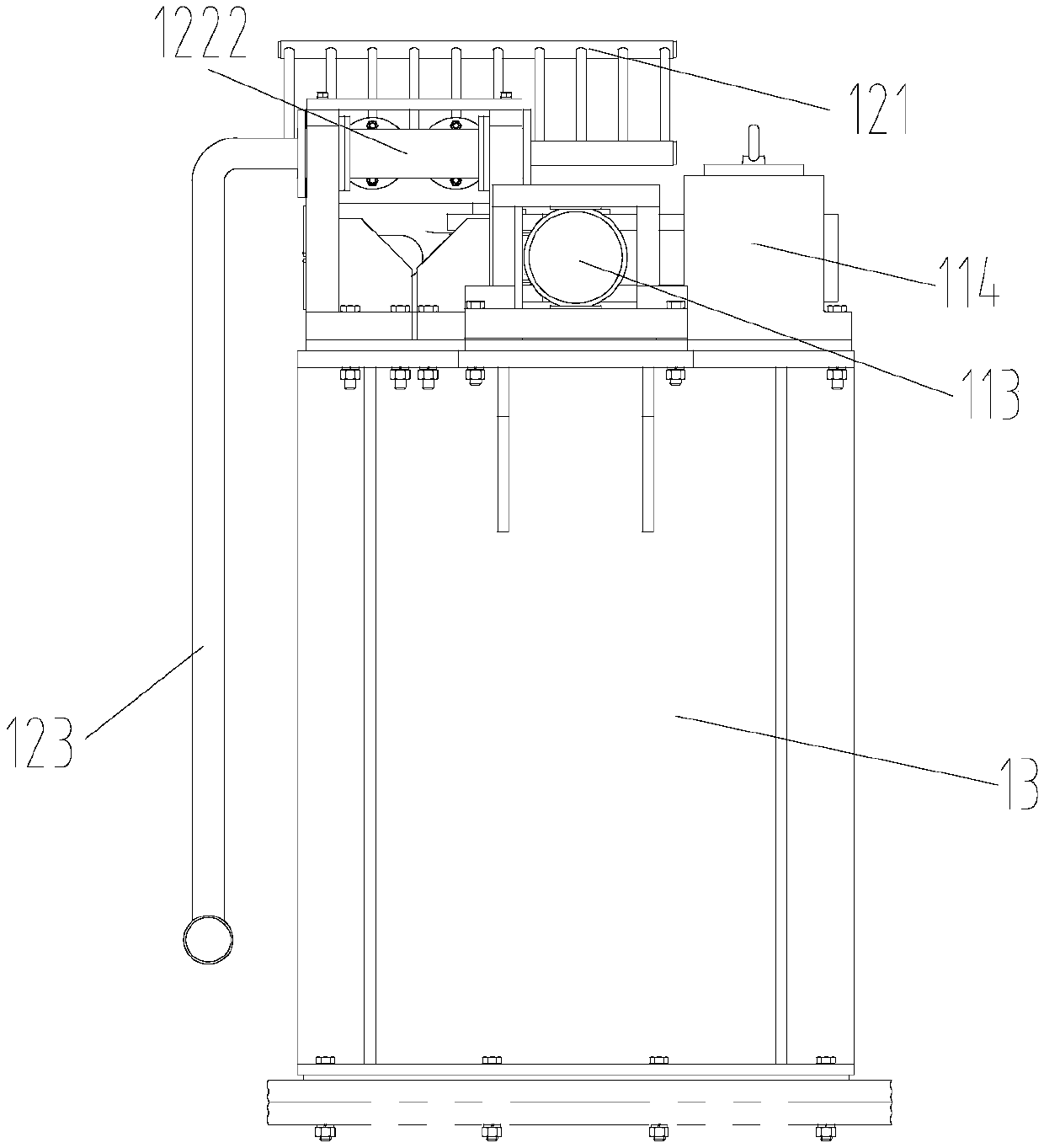

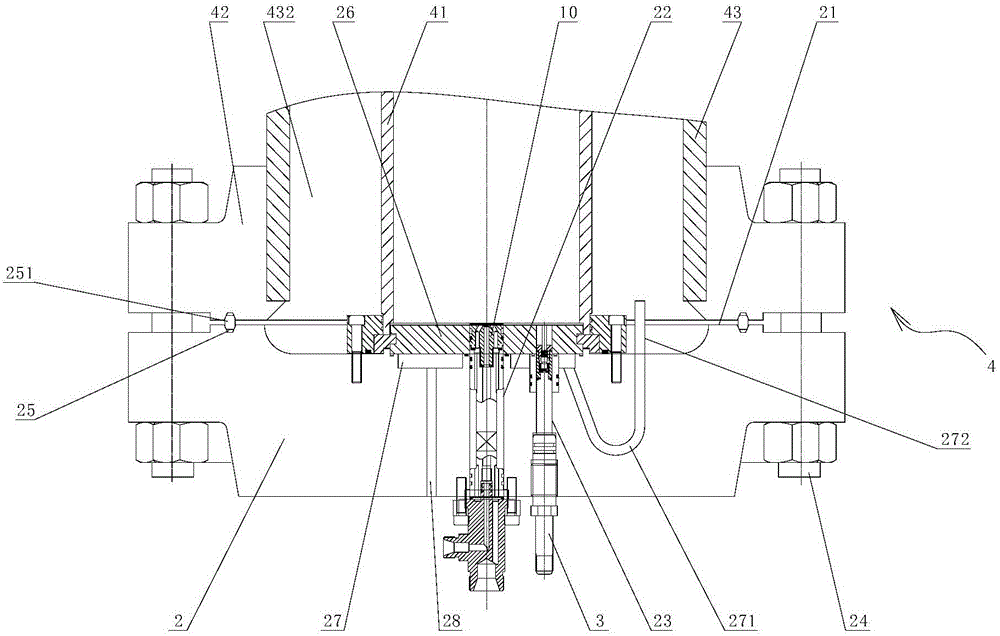

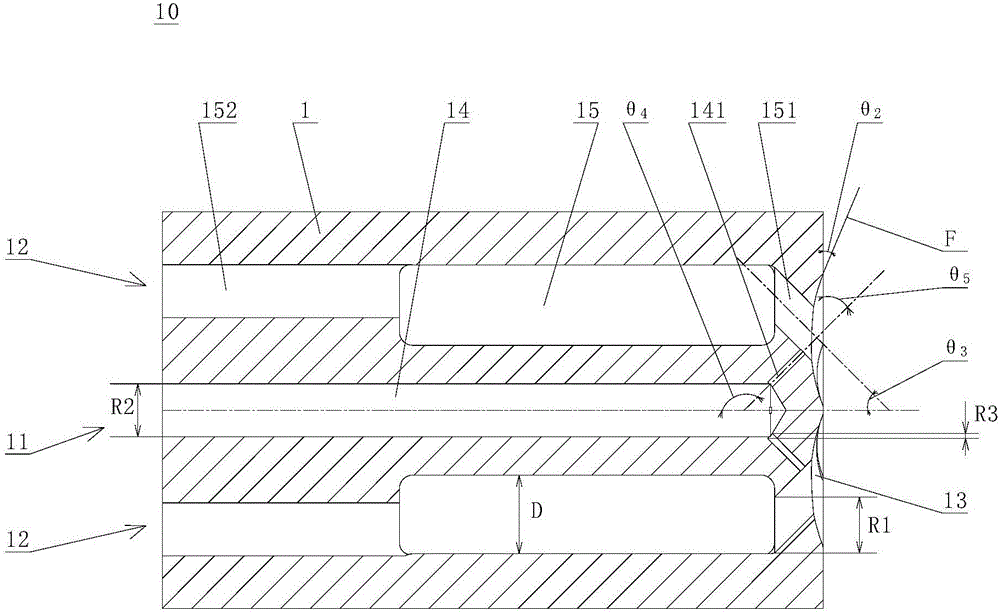

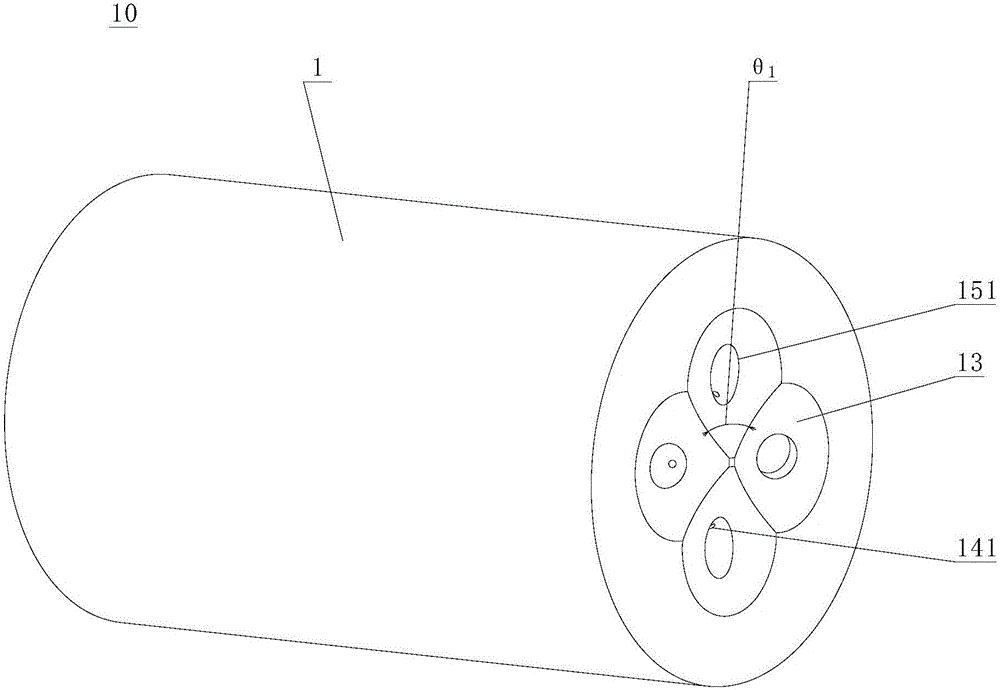

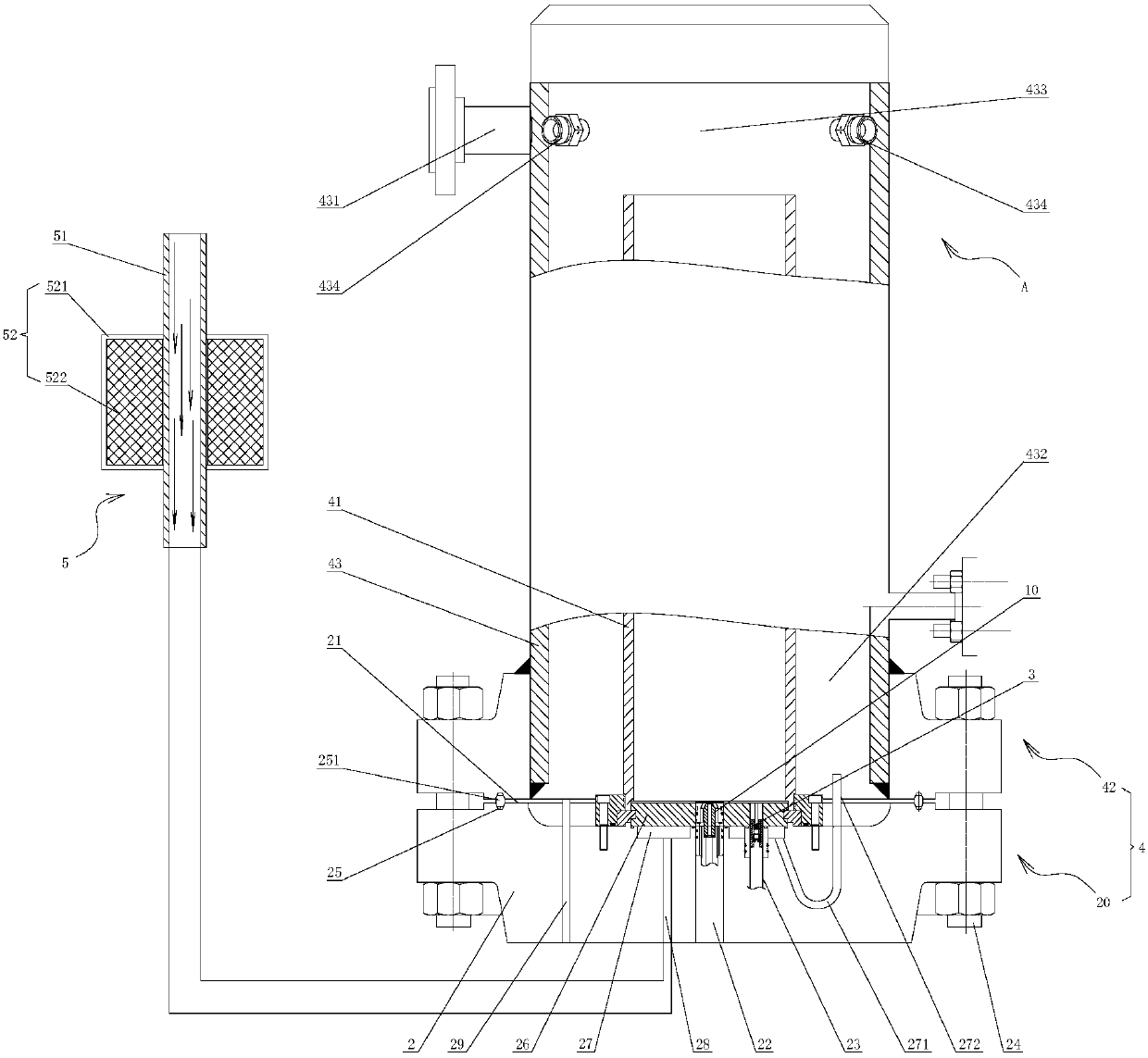

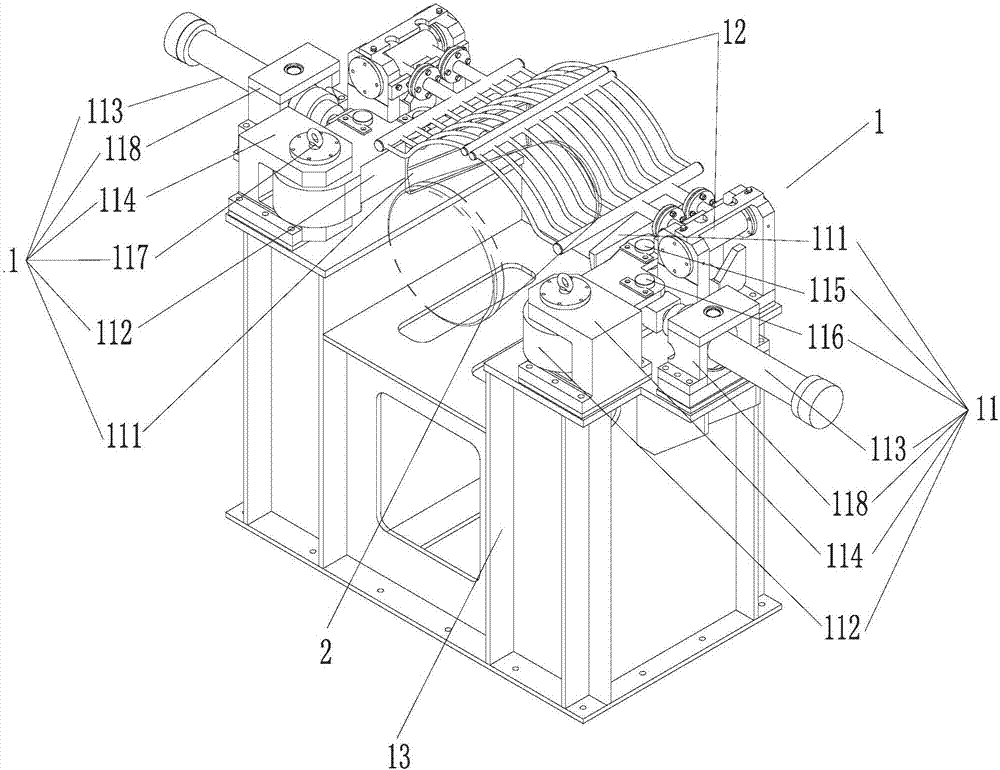

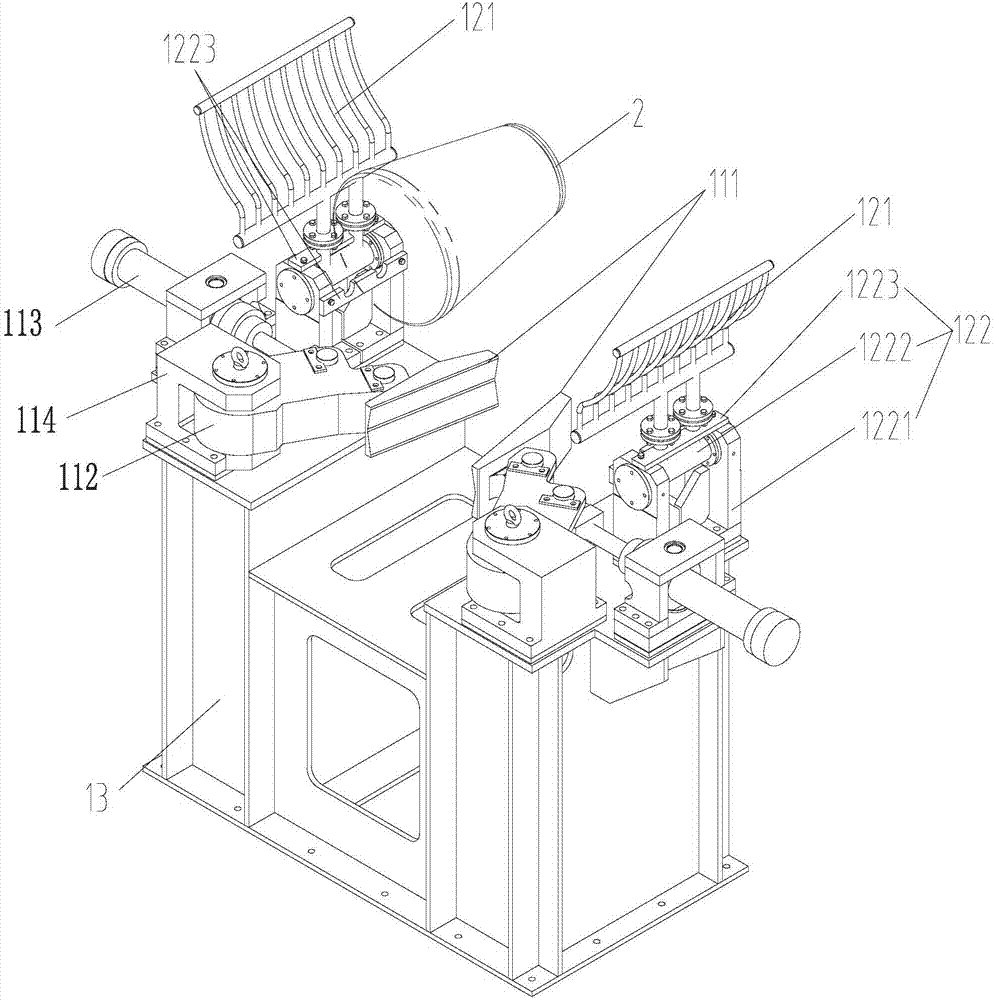

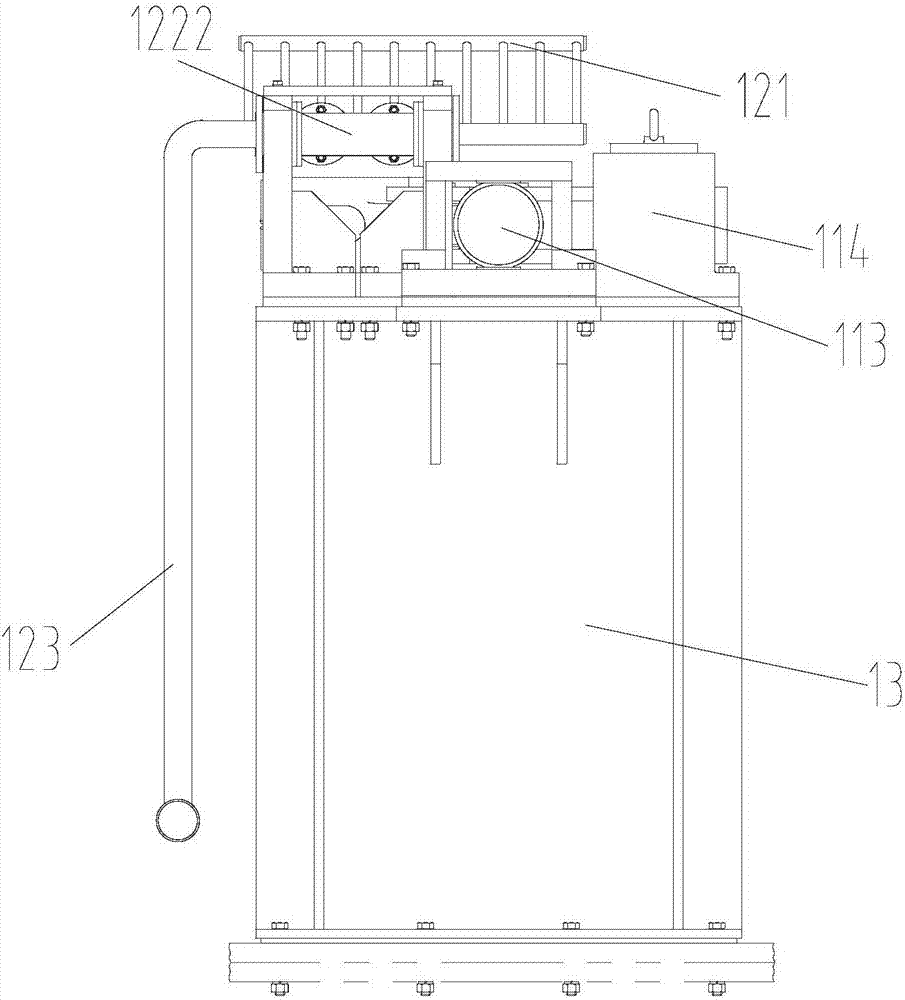

ActiveCN107282637BShorten production timeRealize the cooling processMandrelsMetal rolling arrangementsMechanical engineeringSpray cooling

The invention provides a top clamping spraying cooling device. The device comprises a clamping assembly and a spraying cooling assembly. The clamping assembly comprises paired clamping mechanisms which are symmetrically arranged about the axis of a clamped top. Each clamping assembly comprises a clamping claw, a rotating arm with the first end hinged to the clamping claw and a driving part with the telescopic movement end hinged to the second end of the rotating arm. Each clamping mechanism further comprises a rotating arm seat, wherein the third end of the rotating arm is hinged to the rotating arm seat. The paired clamping claws are converted between the clamping state that the top is clamped and the releasing state that clamping of the top is released under the drive of the respective rotating arms under the telescopic effect of the driving ends of the respective driving parts. By means of the top clamping spraying cooling device, three processes of top disengaging, top clamping and spraying cooling can be synchronously conducted at the same station and are seamlessly connected with the previous and posterior production work processes, and waste of invalid action time is avoided; and the production time of steel pipes is saved, and the production efficiency is improved.

Owner:TAIYUAN HEAVY MACHINERY GRP ENG TECH R & D CO LTD

Head structure for generator and assembly method for head structure

ActiveCN105910086ALow running costUniform atomizationFluid removalSteam generation plantsCombustionEngineering

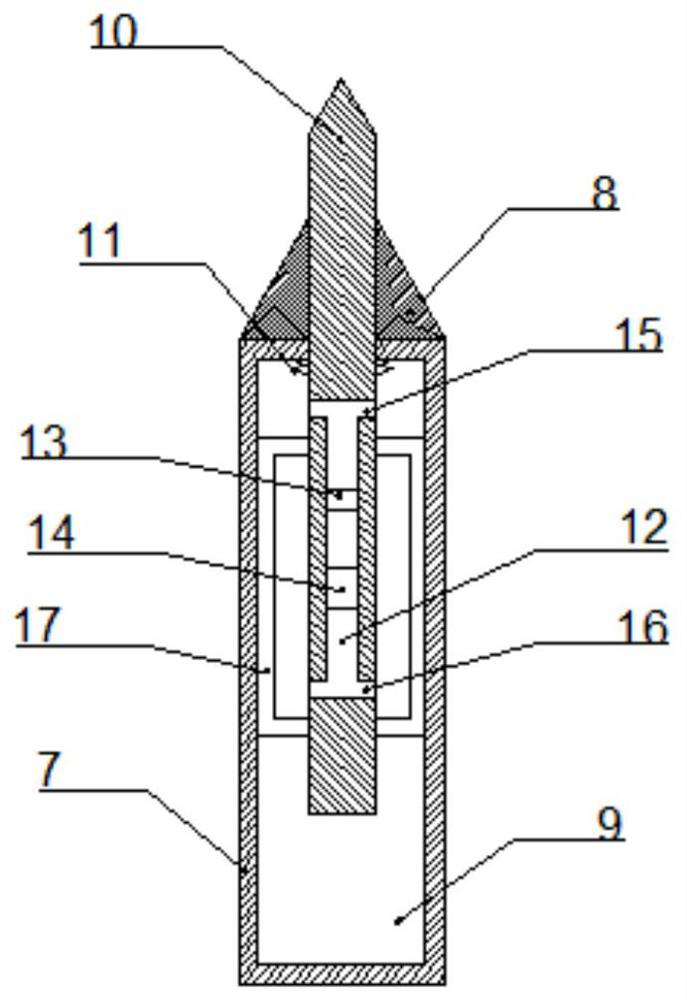

The invention provides a head structure for a generator and an assembly method for the head structure. The head structure for the generator comprises a head body, a combustion nozzle and an ignition electrode, wherein a nozzle channel and an ignition electrode channel are formed in the head body; the combustion nozzle is arranged in the nozzle channel and is provided with a nozzle body; a fuel inlet and a pure oxygen inlet are formed in one end of the nozzle body; a plurality of diaphragm outer cavities are formed in the other end of the nozzle body; a fuel channel which communicates with the fuel inlet is formed in the nozzle body; the other end of the fuel channel communicates with the plurality of diaphragm outer cavities through a plurality of fuel inclined holes; the fuel inclined holes are radially formed in an outward inclined manner in the spraying direction of fuel; a pure oxygen channel which communicates with the pure oxygen inlet is also formed in the nozzle body; the other end of the pure oxygen channel communicates with the plurality of diaphragm outer cavities through a plurality of pure oxygen inclined holes; the pure oxygen inclined holes are radially formed in an inward inclined manner in the spraying direction of pure oxygen; and the ignition electrode is arranged in the ignition electrode channel. The head structure for the generator resists high temperature and oxidation, has a safe and reliable structure and is long in service life.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

Wastewater composite heat carrier generator and composite heat carrier generation method

ActiveCN105823032BMagnetization achievedLoose scalingBoiler cleaning apparatusFluid removalCombustion chamberInlet channel

The invention provides a waste water composite heat carrier generator and a composite heat carrier generation method. The waste water composite heat carrier generator comprises a generator body, a generator head structure and a magnetizing assembly. The generator body comprises a burning chamber and a steam chamber arranged outside the burning chamber in a sleeving manner, the upper end of the burning chamber is communicated with the steam chamber, and the upper end of the steam chamber is connected with an outlet pipe; the generator head structure is connected to the lower end of the generator body, and is provided with a head body, a burning spraying nozzle and an ignition electrode, the burning spraying nozzle and the ignition electrode are arranged in the head body and are arranged opposite to the burning chamber, and the head body is internally provided with a water inlet channel and a dirty discharging channel which are communicated with the steam chamber; and the magnetizing assembly is provided with a water inlet pipe, the exterior of the water inlet pipe is sleeved with a water magnetizer, and the water inlet pipe and the water inlet channel are connected. According to the waste water composite heat carrier generator and the composite heat carrier generation method, by means of the water magnetizing assembly, waste water led into the generator can be subject to water magnetizing treatment, scaling of the waste water is relatively loose, and the scaling is convenient to discharge.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

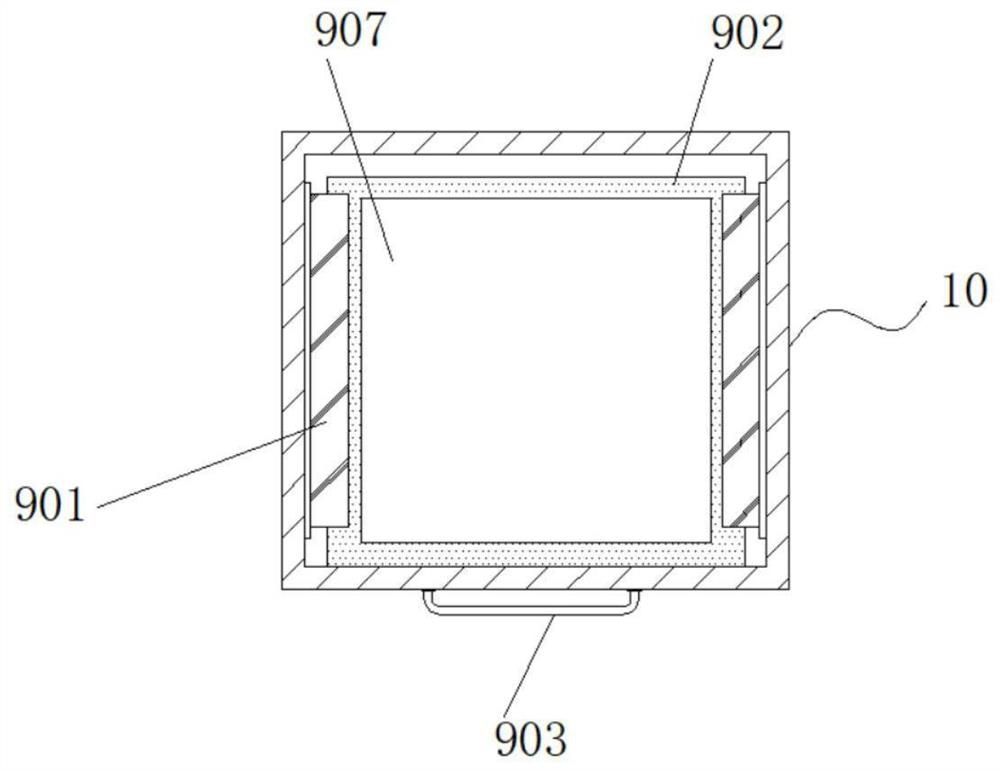

Placement box for 3D printing equipment

PendingCN112757640ARealize the cooling processSolve processing problemsManufacturing platforms/substratesDispersed particle filtrationEngineeringCooling pipe

The invention discloses a placement box for 3D printing equipment, relates to the related field of 3D printing equipment, and aims to solve the problem that heat accumulated at the bottom of the placement box cannot be treated in the prior art. The placement box is characterized in that a circulating cooling pipe is arranged in a box base, a three-way head is arranged on the circulating cooling pipe, the three-way head is fixedly connected with the circulating cooling pipe, a first electric valve is arranged on one side of the three-way head and fixedly connected with the circulating cooling pipe, a lifting pump is arranged on one side of the first electric valve and fixedly connected with the circulating cooling pipe, and a second electric valve is arranged at the rear end of the three-way head; and a water return pipe is arranged at the rear end of the second electric valve and fixedly connected with the second electric valve, a recooling machine is arranged on the water return pipe and fixedly connected with the water return pipe, the recooling machine is fixedly connected with the circulating cooling pipe, and a water pumping pipe is arranged at the rear end of the recooling machine.

Owner:东莞市宏鑫三维科技有限公司

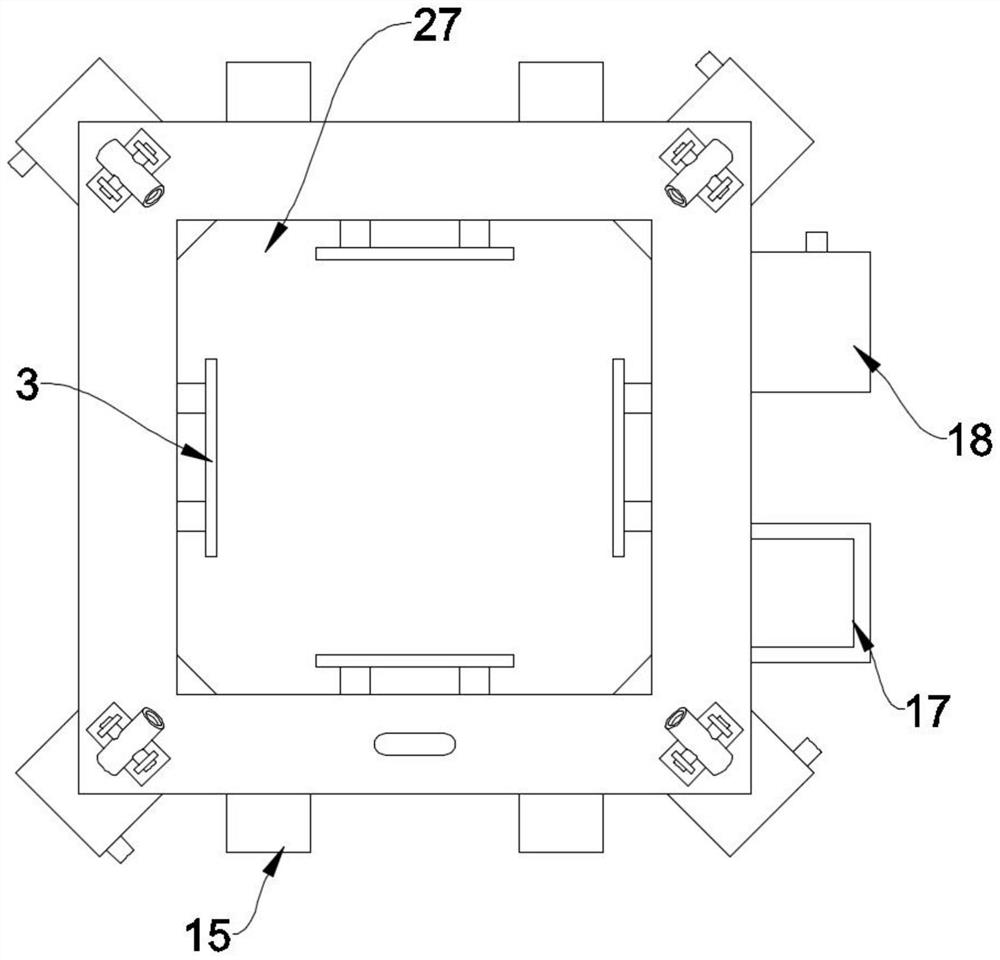

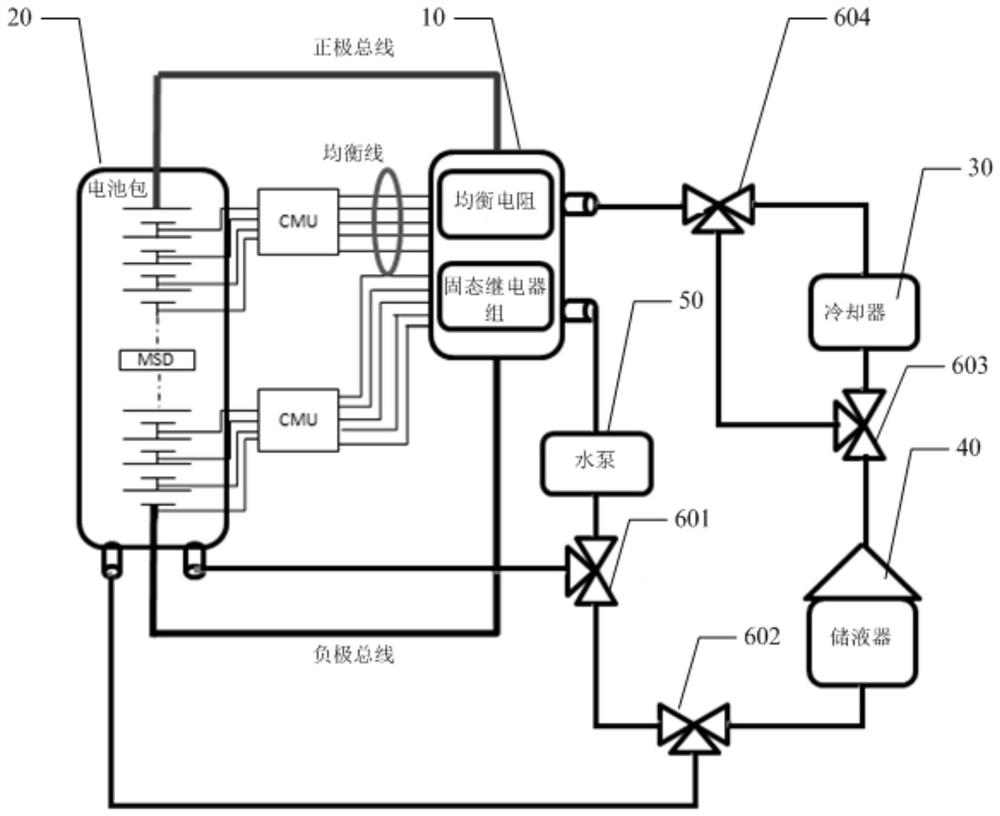

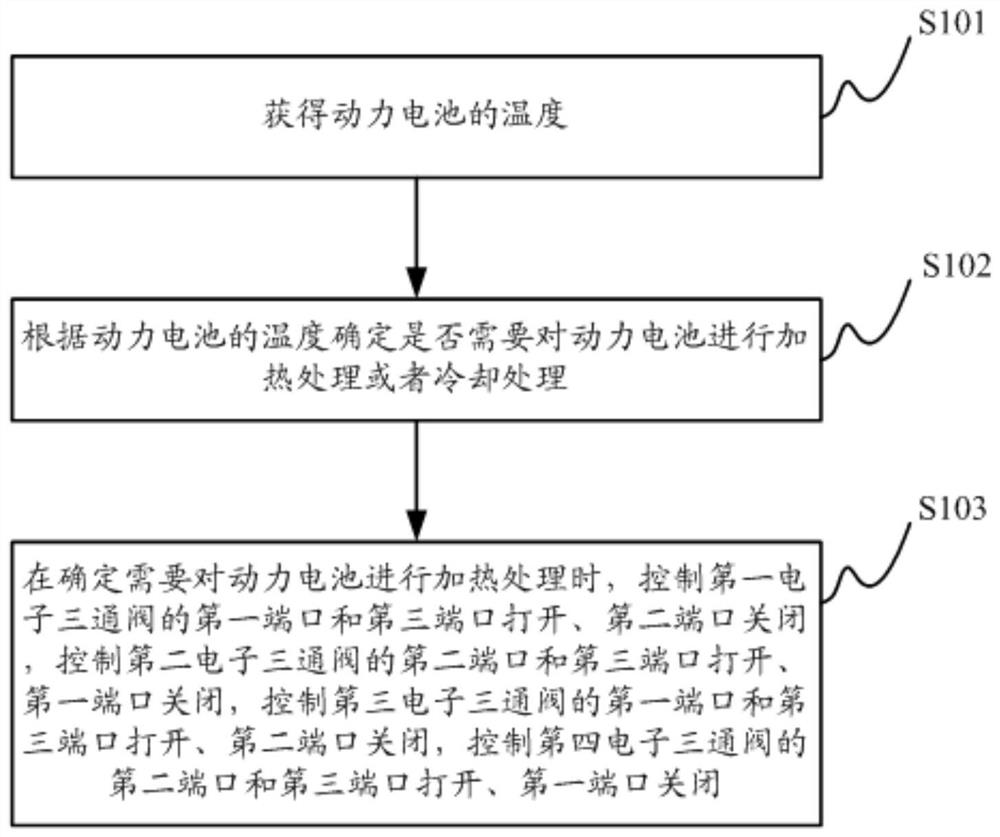

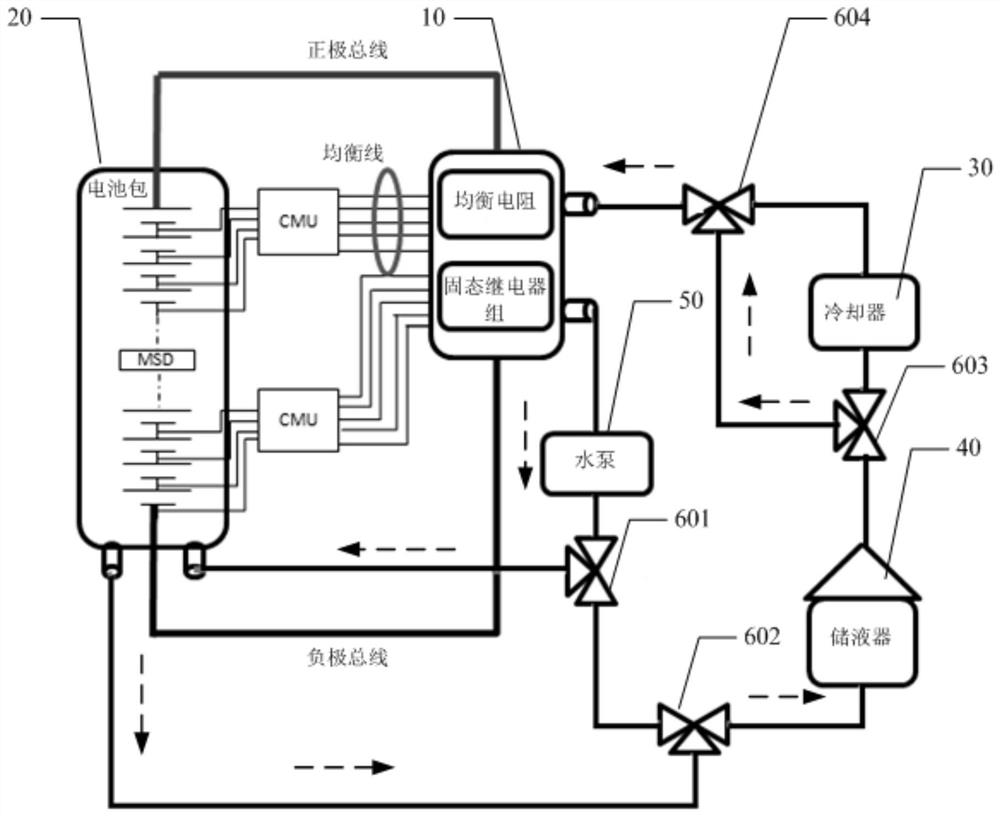

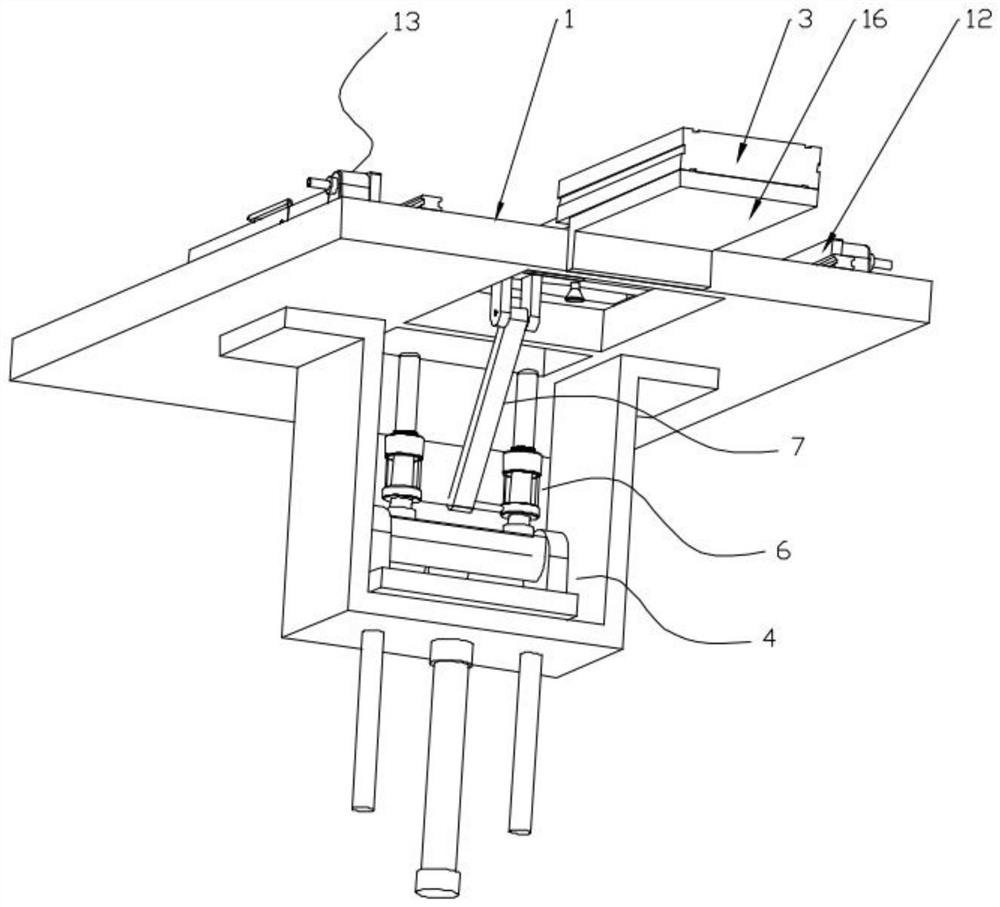

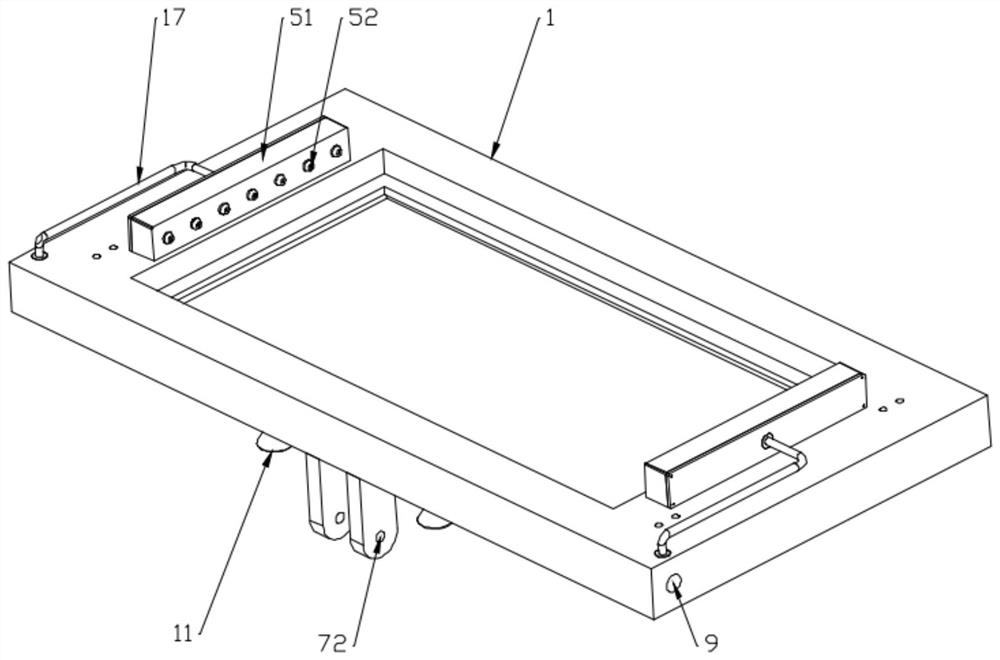

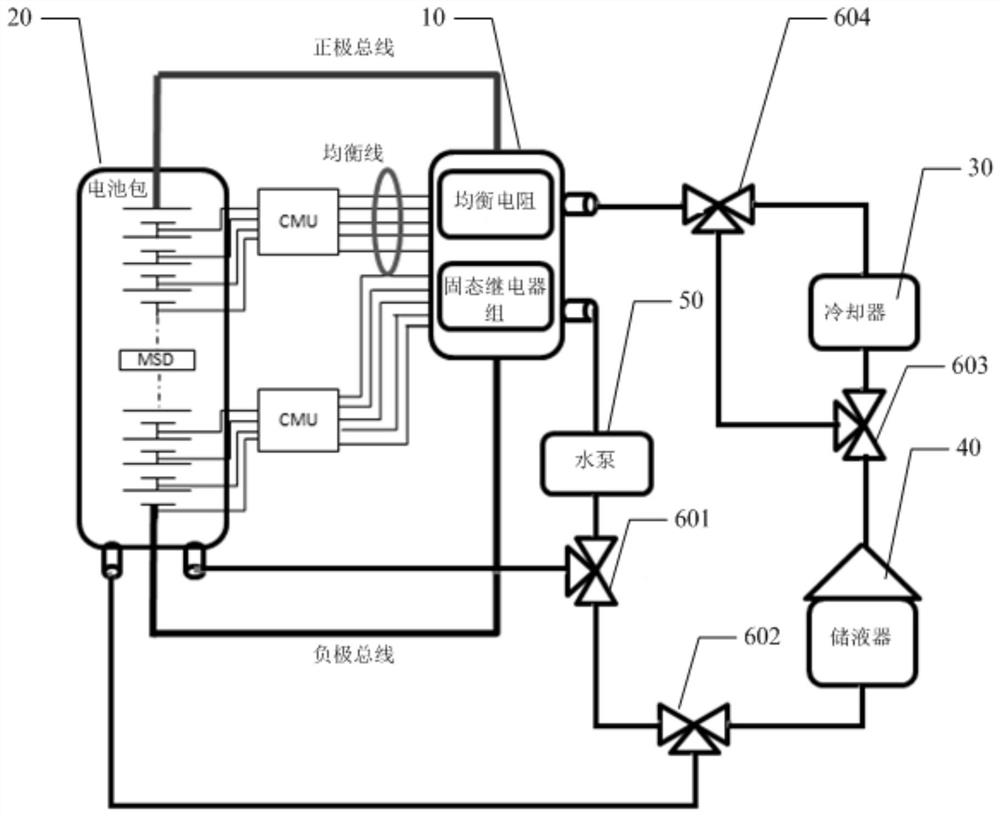

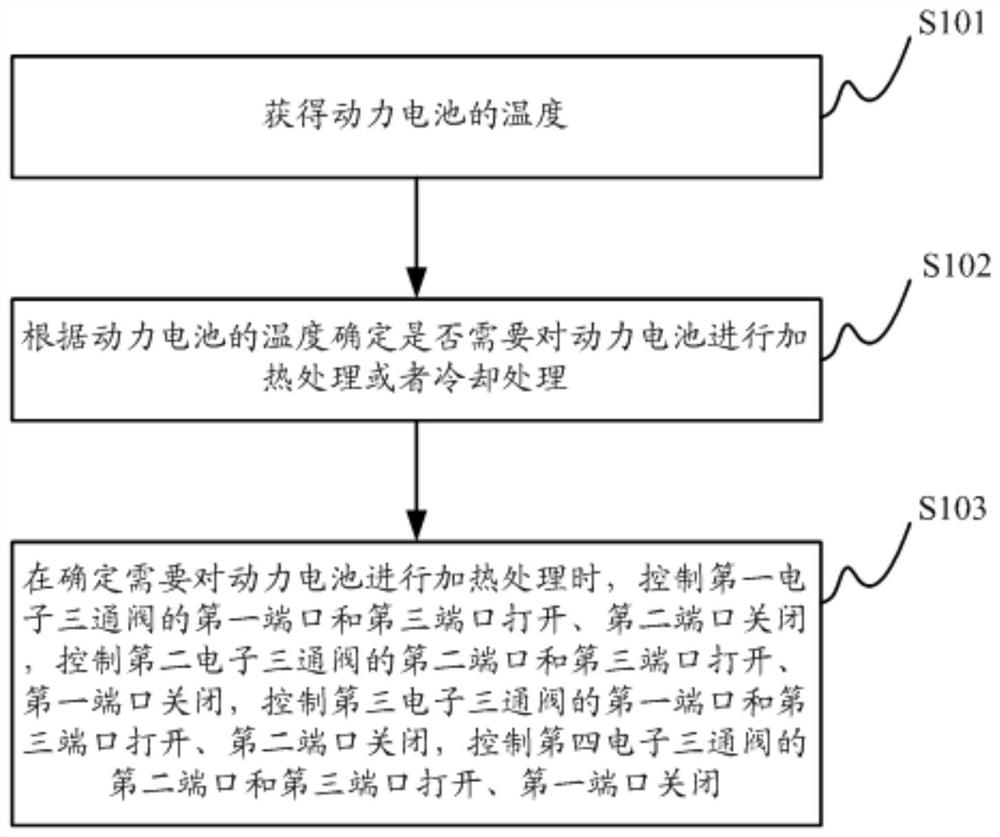

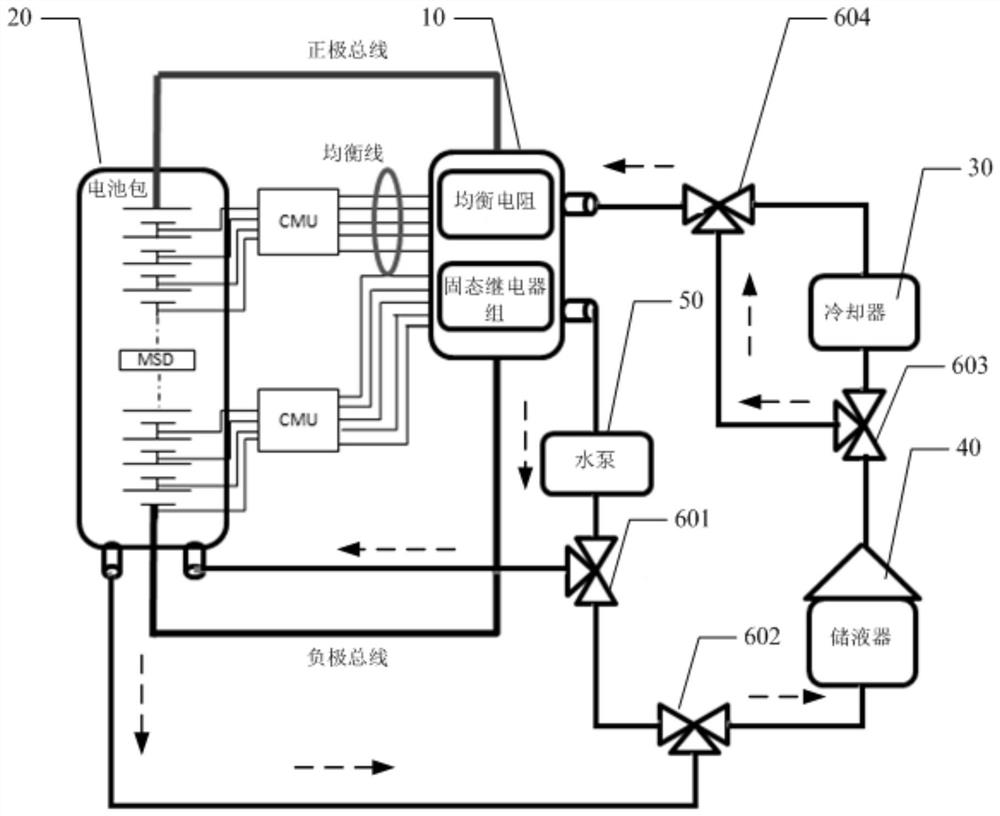

Temperature regulation system and control method for power battery

ActiveCN111725587BAchieve heatingImprove energy utilizationSecondary cellsVehicular energy storagePower batteryThermodynamics

The present application discloses a temperature adjustment system for a power battery, comprising: a first cooling device, a second cooling device, a cooler, a liquid accumulator, a water pump, a first electronic three-way valve, a second electronic three-way valve, a third The electronic three-way valve, the fourth electronic three-way valve and the control device; when the power battery needs to be heated, the control device adjusts the connection state of the four electronic three-way valves, in the first cooling device, the second cooling device and the storage device. A passage is formed between the liquid containers, and the power battery is heated by the heat generated by the equalizing resistance and the solid state relay group, and the cooling treatment of the equalizing resistance and the solid state relay group is realized at the same time. Based on the temperature regulation system disclosed in the present application, the power battery can be heated without setting a PTC resistor, the energy utilization rate is improved, and the balance efficiency of the power battery is improved.

Owner:SAIC MOTOR

Top clamping spraying cooling device

ActiveCN107282637AShorten production timeRealize the cooling processMandrelsMetal rolling arrangementsEngineeringSpray cooling

The invention provides a top clamping spraying cooling device. The device comprises a clamping assembly and a spraying cooling assembly. The clamping assembly comprises paired clamping mechanisms which are symmetrically arranged about the axis of a clamped top. Each clamping assembly comprises a clamping claw, a rotating arm with the first end hinged to the clamping claw and a driving part with the telescopic movement end hinged to the second end of the rotating arm. Each clamping mechanism further comprises a rotating arm seat, wherein the third end of the rotating arm is hinged to the rotating arm seat. The paired clamping claws are converted between the clamping state that the top is clamped and the releasing state that clamping of the top is released under the drive of the respective rotating arms under the telescopic effect of the driving ends of the respective driving parts. By means of the top clamping spraying cooling device, three processes of top disengaging, top clamping and spraying cooling can be synchronously conducted at the same station and are seamlessly connected with the previous and posterior production work processes, and waste of invalid action time is avoided; and the production time of steel pipes is saved, and the production efficiency is improved.

Owner:TAIYUAN HEAVY MACHINERY GRP ENG TECH R & D CO LTD

Continuous burning furnace

ActiveCN101265021BUniform treatmentEven contactGas discharge electrodesMaintainance of heating chambersCooling chamberEngineering

The present invention provides a continuous firing furnace. The continuous firing furnace is able to effectively cool the whole outer surface of the processing objects such as glass substrate etc., does not generate partial warpage or deformation on the processing object and reduces the cooling processing time. The cooling chamber (15) of the continuous firing furnace (10) is installed with guiding passage (1) and exhaust passage (2). The guiding passage and exhaust passage open at the almost whole area in the furnace-width direction (Y) on the inner furnace wall (15A) at the upper side of the cooling chamber. The guiding passage ejects the air by the mode of facing to the upper reach side of the moving direction (X). The exhaust passage exhausts the air of the cooling chamber at the upper reach along the moving direction (X) of the guiding passage. On the upper part of the processing object moved on the roller (16), the flow path with cooled external gas is uniformly formed in the almost whole area on the furnace-width direction (Y). The whole upper surface of the processing object is uniformly contacted with the air.

Owner:KOYO THERMO SYST CO LTD

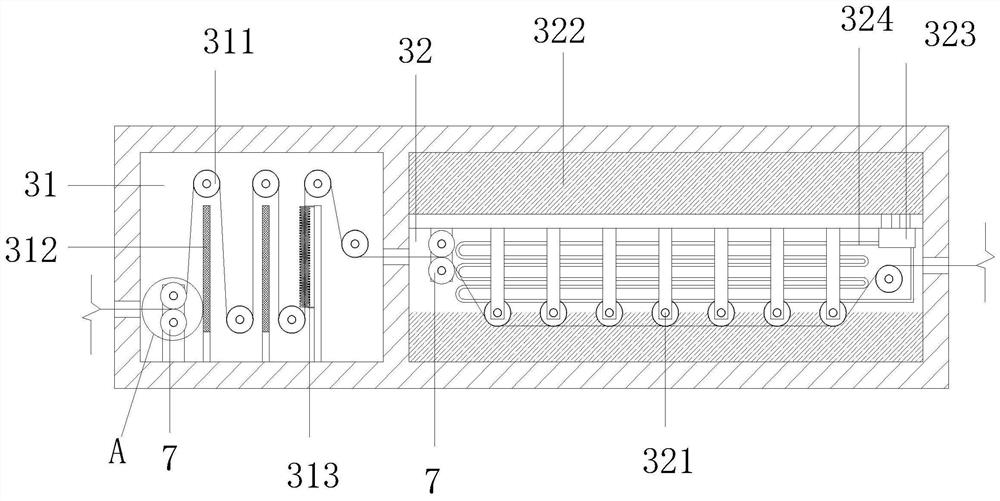

Raw material particle formula and production method of pe film

The invention relates to the technical field of polymer materials, and discloses a raw material particle formula of PE film, which is characterized in that it includes the following raw materials: PE, antioxidant, ceramic particles, ceramic particles, calcium carbonate, rutile particles, glycerin, glutaraldehyde; and A method for producing raw material granules of PE film, comprising the following steps: need to use a raw material granule production device, the raw material enters the box body from the feed port, the raw material is cut into raw material strips through the vertical block; through the circulating refrigeration system in the vertical block The raw material strip can be continuously cooled; the raw material strip can be cut intermittently with a cutter to obtain raw material particles; the raw material particles can be put into a plastic film blowing machine for production to obtain PE film. This solution mainly solves the problems of poor heat resistance and tensile strength of the current PE film and low production efficiency of the PE film.

Owner:CHONGQING RUITING PLASTIC

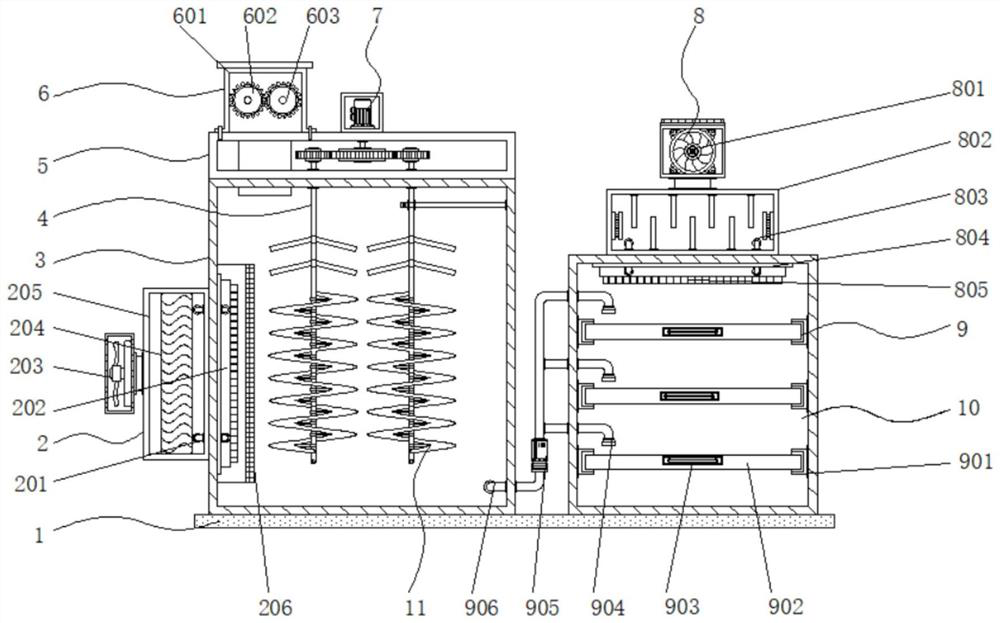

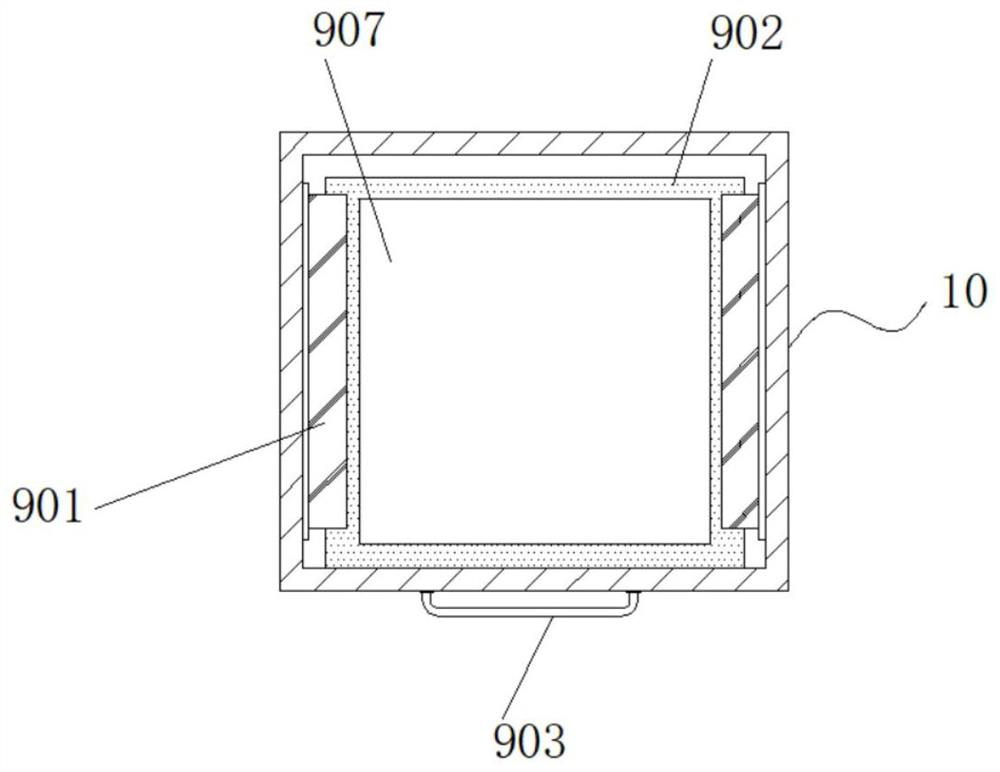

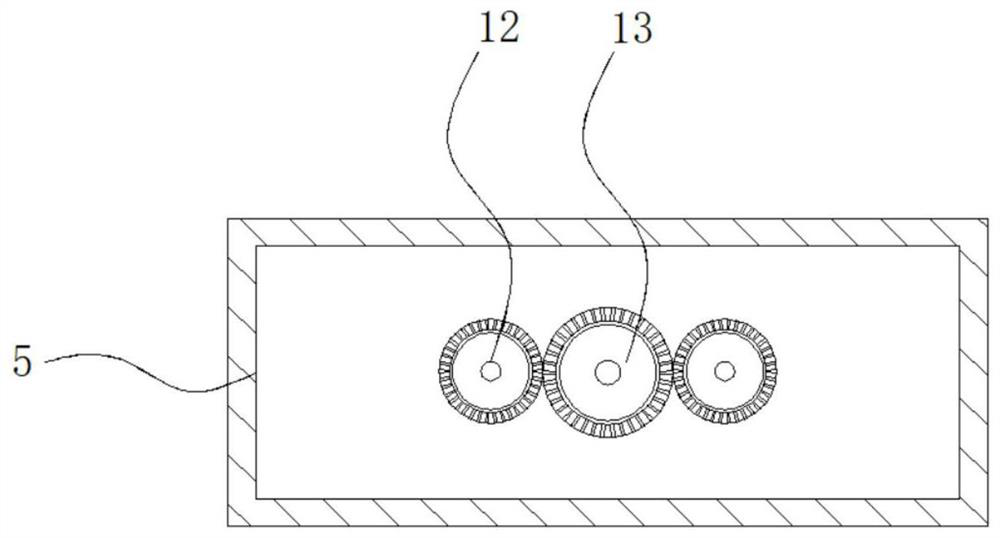

Stirring and mixing equipment for thin film raw materials

The invention discloses stirring and mixing equipment for thin film raw materials. The stirring and mixing equipment comprises a bottom plate, a barrel body is fixedly connected to one side of the top end of the bottom plate, a box body is fixedly connected to the other side of the top end of the bottom plate, a fixing seat is fixedly connected to the top end of the barrel body, and a smashing mechanism is arranged on one side of the top end of the fixing seat. A heating mechanism is arranged on one side of the barrel body, a material placing mechanism is arranged in the box body, a cooling mechanism is arranged at the top end of the box body, and a stirring mechanism is arranged in the barrel body; the smashing mechanism is connected with the barrel body through a feeding pipe, a separating mechanism is mounted in the barrel body at the feeding pipe, the separating mechanism is connected with the heating mechanism through a gas guide pipe, and a stop valve is mounted on the gas guide pipe. According to the stirring and mixing equipment for the thin film raw materials, the defects in the prior art are overcome, large-density particle impurities such as metal particles mixed after thin film raw material particles are smashed can be effectively removed.

Owner:张娟

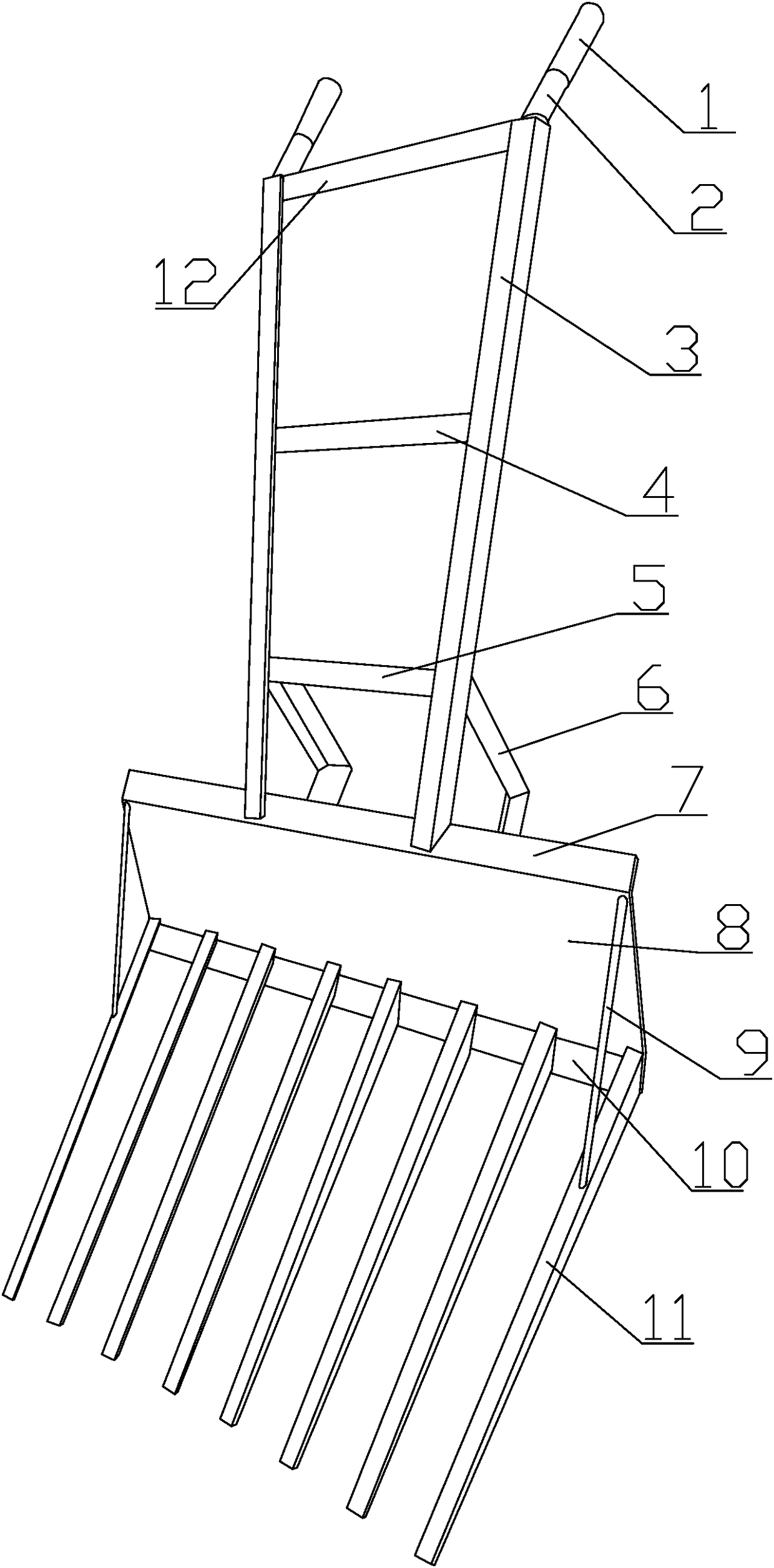

Tool for spreading for cooling of large-scale tea leaves

InactiveCN109463472ASpread cool evenlyRealize the cooling processPre-extraction tea treatmentDrying solid materialsWear resistantEngineering

The invention provides a tool for spreading for cooling of large-scale tea leaves. The tool comprises an oblique push plate, wherein a fixing plate is arranged at the head of the oblique push plate; aplurality of toothed rods are fixed to the fixing plate in an equal interval through welding; a top skirt is arranged at the top of the oblique push plate in a bending manner; two push rods are mounted on the top skirt in parallel; a handle is mounted at the tail end of each push rod; and a wear resistant rubber handle is mounted at the tail end of each handle in a sleeving manner. The tool for spreading for cooling disclosed by the invention can assist in performing the operation of spreading for cooling on massive new tea, so that the effect of spreading for cooling of the tea is improved,and the labor intensity of operation staff is reduced.

Owner:宜昌三峡原红茶业有限公司

Pure oxygen composite heat carrier generator and method for producing composite heat carrier

ActiveCN105889888BReduce nitrogen contentRealize high-pressure sealed combustionFluid removalSteam generation plantsHeat carrierCombustion chamber

The invention provides a generator for a pure oxygen compound heat carrier and a production method for a compound heat carrier. The generator comprises a generator body and a generator head structure, wherein the generator body comprises a combustion chamber and a steam chamber arranged outside the combustion chamber in a sleeving manner; the generator head structure is provided with a head body, a combustion nozzle and an ignition electrode; the combustion nozzle is provided with a nozzle body, and a plurality of diaphragm outer cavities are formed on one end part of the nozzle body; a fuel channel and a pure oxygen channel are arranged in the nozzle body, the fuel channel communicates with the plurality of diaphragm outer cavities through a plurality of fuel inclined holes, and the fuel inclined holes are radially arranged outwards and slantwise along an injection direction of a fuel; and the pure oxygen channel communicates with the plurality of diaphragm outer cavities through a plurality of pure oxygen inclined holes, and the pure oxygen inclined holes are radially arranged inwards and slantwise along an injection direction of pure oxygen. The generator and the production method, which are provided by the invention, are capable of uniformly atomizing the pure oxygen and natural gas, realizing high-temperature sufficient combustion for the pure oxygen and the natural gas, and finally forming a high-temperature compound heat carrier containing carbon dioxide and steam.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

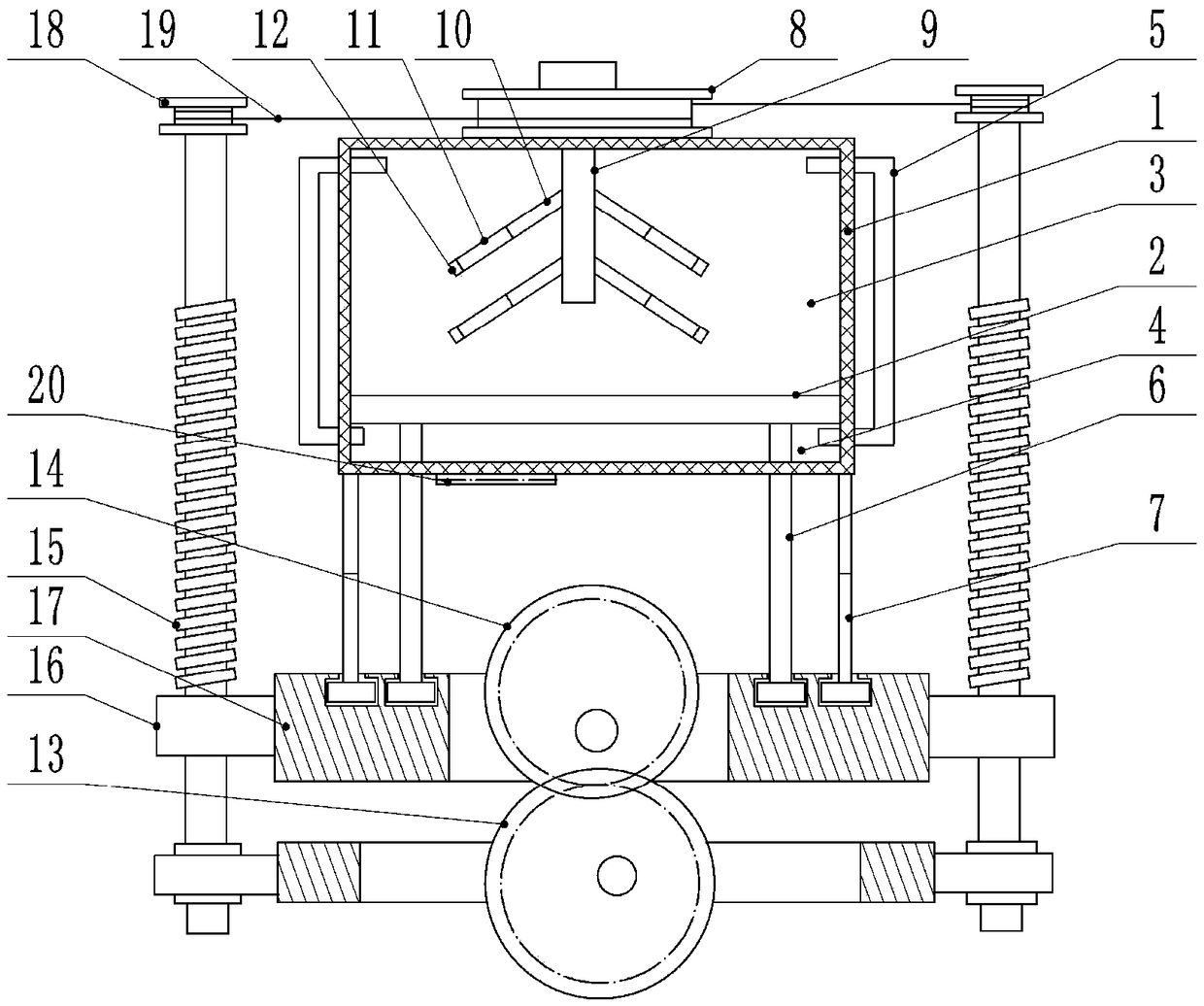

Heat treatment device capable of automatically lifting

InactiveCN109825676AEasy to useUse automationFurnace typesHeat treatment process controlSoftware engineeringAir blower

The invention relates to the technical field of heat treatment devices, in particular to a heat treatment device capable of automatically lifting. The heat treatment device comprises a control box bottom, four sets of pillars, a heat treatment box body, a shear-type lifting device, a lifting platform, a mounting table, a cooling box body, an air blower, and a control display screen, the control box bottom is arranged as a square box body, a device controller is arranged in the inner cavity of the control box bottom, a control display screen is fixedly mounted on the front side of the control box bottom, the four sets of pillars are fixedly mounted at the four corners of the upper surface side of the control box bottom, the heat treatment box body is fixedly mounted on the upper sides of the four sets of the pillars, and a rail limiting vertical plate is fixedly mounted at the back end of the bottom side of the heat treatment box body. According to the heat treatment device capable of automatically lifting, the automatic use of the heat treatment device is achieved, the risk of the artificial operation is reduced, the modern use of the device and the safe use performance of the device are improved, and the fast and convenient effect of the integrating use of heat treatment and cooling processes through shear-type lifting is achieved.

Owner:NINGGUO HUIHONG WEAR RESISTANT MATERIALS

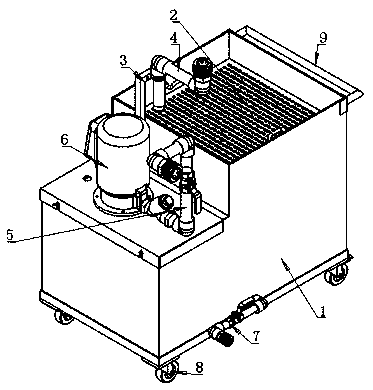

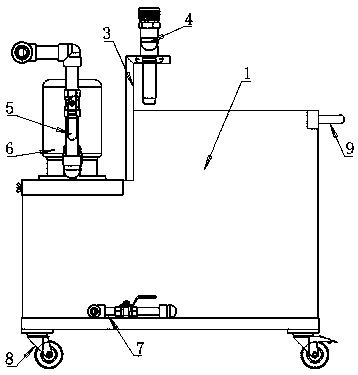

Simple movable cooler convenient to use

InactiveCN110260592ASimple structureLow costDomestic cooling apparatusLighting and heating apparatusEngineering

The invention relates to the technical field of coolers, in particular to a simple movable cooler convenient to use. According to the technical scheme, the simple movable cooler comprises a main body cooling protection shell with a cuboid shape; a separate cooling liquid containing cavity is formed in the main body cooling protection shell; a detachable rectangular input opening filter screen is arranged in the upper end of the right side of the main body cooling protection shell; the left side of the upper end of the input opening filter screen is provided with a main body input support connecting frame which is integrated with the main body cooling protection shell; the main body input support connecting frame is connected with a main body input connection stabilization connector; and the lower end of the main input connection stabilization connector is located above the input opening filter screen. The simple movable cooler convenient to use has the advantages that the simple movable cooler convenient to use is designed and produced by adopting a brand-new structure, the overall structure is relatively simple, the overall cost is lower during production, and the simple movable cooler can be moved to different positions according to needs in using processes and is more flexible and convenient to use.

Owner:江苏永盛传热科技有限公司

Bearing seat structure for shield tunneling machine gearbox test and shield tunneling machine gearbox test system

PendingCN114688170ARealize the cooling processImprove accuracyGear lubrication/coolingSecuring devicesClassical mechanicsStructural engineering

The invention provides a bearing seat structure for a shield tunneling machine gear box test and a shield tunneling machine gear box test system, and relates to the technical field of gear box test, the bearing seat structure comprises a bearing seat main body, an adapter plate, a positioning bearing and an oil seal assembly, the bearing seat main body is provided with an assembly hole, and an oil inlet hole and an oil return hole which are communicated with the assembly hole; the adapter plate is provided with a plurality of connecting parts used for being connected with a shield tunneling machine body, and the connecting parts are different in size so as to adapt to shield tunneling machines of different models. The adapter plate is connected with the bearing seat main body; the positioning bearing is embedded in the assembly hole; the oil seal assembly is used for blocking two ends of the assembly hole. The test result is high in reliability.

Owner:NANJING HIGH SPEED & ACCURATE GEAR GRP

Automobile part welding cooling device

InactiveCN113909658ARealize the cooling processQuality assuranceResistance electrode holdersWelding/cutting auxillary devicesMotor vehicle partWorkbench

The invention discloses an automobile part welding cooling device, and relates to the field of machines. The automobile part welding cooling device comprises a workbench, a sliding table, a driving air cylinder, a turnover type conductive assembly, a cooling assembly and a cleaning assembly. According to the automobile part welding cooling device, the cooling assembly, an exhaust port and an air inlet assembly can be used for communicating when the sliding table returns and resets, so that cooling treatment on a product and a conductive head is realized; the connection between the exhaust port and the air inlet assembly is interrupted in the welding process, so that the influence on the welding process is avoided; and when the sliding table returns and resets, the cleaning assembly can be driven to move by means of a driving assembly, so that oxide residues generated by welding on the conductive head are cleaned, and the welding quality and stability are guaranteed.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Temperature adjusting system of power battery and control method thereof

ActiveCN111725587AAchieve heatingImprove energy utilizationSecondary cellsVehicular energy storagePower batteryThermodynamics

The invention discloses a temperature adjusting system of a power battery. The temperature adjusting system comprises a first cooling device, a second cooling device, a cooler, a liquid storage device, a water pump, a first electronic three-way valve, a second electronic three-way valve, a third electronic three-way valve, a fourth electronic three-way valve and a control device. When the power battery needs to be subjected to heating treatment, the control device adjusts the communication states of the four electronic three-way valves to form a passage among the first cooling device, the second cooling device and the liquid storage device; and heat generated by the balance resistor and the solid-state relay set is used for heating the power battery, and meanwhile, cooling treatment on thebalance resistor and the solid-state relay set is achieved. Based on the temperature adjusting system disclosed by the invention, the heating treatment of the power battery is realized on the premiseof not arranging a PTC resistor, so that the energy utilization rate is improved, and the equalization efficiency of the power battery is improved.

Owner:SAIC MOTOR

Biodegradable plastic film preparation device

PendingCN113459318AStable stirringImprove the mixing effectPlastic recyclingBiodegradable plasticEngineering

The invention discloses a biodegradable plastic film preparation device, and particularly relates to the technical field of biodegradable plastic film processing. The biodegradable plastic film preparation device comprises a bottom plate, a cylinder is fixedly connected to one side of the top end of the bottom plate, a box is fixedly connected to the other side of the top end of the bottom plate, a fixing seat is fixedly connected to the top end of the cylinder, a smashing mechanism is arranged on one side of the top end of the fixing seat, and a heating mechanism is arranged on one side of the cylinder. By arranging a limiting block, a mold base, a handle, a material guiding pipe, a material pumping pump, a material conveying pipe and a mold groove, in the using process, the material pumping pump is started, mixed materials are conveyed into the material guiding pipe through the material conveying pipe and poured into the mold groove in the mold base through a nozzle at the bottom of the material guiding pipe, after a period of time, a worker pulls the handle, and the mold base is pulled out, materials in the mold groove are treated, the efficiency is higher than that of manually pouring out the materials, time and labor are saved, and the functionality of the device is improved.

Owner:张娟

Wastewater composite heat carrier generator and composite heat carrier generation method

ActiveCN105841129BHigh cost savingsExtended service lifeFluid removalSteam generation plantsHeat carrierCombustion chamber

The invention provides a waste water composite heat carrier generator and a composite heat carrier generation method. The waste water composite heat carrier generator comprises a generator body, a generator head structure and a cooling gasifying device; the generator body comprises a combustion chamber and a steam chamber, the upper end of the combustion chamber is communicated with the steam chamber, and the upper end of the steam chamber is connected with an outlet pipeline; the generator head structure is connected to the lower end of the generator body, and is provided with a head body, a combustion nozzle and an ignition electrode, wherein the combustion nozzle and the ignition electrode are arranged in the head body and are arranged in a manner of being opposite to the combustion chamber, and a water inlet channel and a scale discharging channel are formed in the head body; the cooling gasifying device is connected to the upper end of the steam chamber; the generator can meet the requirements of high-pressure combustion and composite heat carrier safe output, meanwhile, waste water separated from crude oil is used as cooling water to be subject to cooling treatment through the lower portion and the upper portion of the generator, and steam needed by a composite heat carrier is generated; and clean water resources are saved, and the high cost of wastewater treatment can be reduced.

Owner:CNPC GLOBAL SOLUTIONS LTD +1

A kind of rapid cooling equipment for hot-dip galvanizing

ActiveCN109440043BPlay the role of buffer protectionRealize the cooling processHot-dipping/immersion processesEngineeringMechanical engineering

The invention discloses a rapid cooling device for hot galvanizing operation, and belongs to the technical field of galvanization, so that the problem that an existing device cannot uniformly cool metal parts is solved, the outer surface of the metal parts have a chromatic aberration, and metal part beauty is influenced are solved. The device is technically characterized by comprising a shell, a feeding hole, a cooling cavity and a horizontal guide rail, a base is arranged at the lower part of the shell, the shell is fixed on the base, the feeding hole is formed in the top of the left side wall of the shell, the cooling cavity is formed in the shell, the feeding hole is communicated with the cooling cavity, a horizontal connecting cross rod is fixedly arranged on the top of the right sidewall of the shell, a horizontal guide rail is arranged below the horizontal connecting cross rod, the horizontal guide rails and the horizontal connecting cross rod are fixedly connected through bolts. According to the rapid cooling device, full cooling treatment can be carried out on the metal parts after hot galvanizing operation, and can ensure the rapid and high efficiency of the cooling process of the metal parts.

Owner:青岛豪迈永祥和环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com