Head structure for generator and assembly method for head structure

A generator and head technology, which is applied in the field of generator head structure and assembly, can solve the problems of unstable combustion, low temperature resistance, and easy burning of nozzles, so as to avoid directly facing the combustion chamber and prevent high temperature burning. Erosion, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

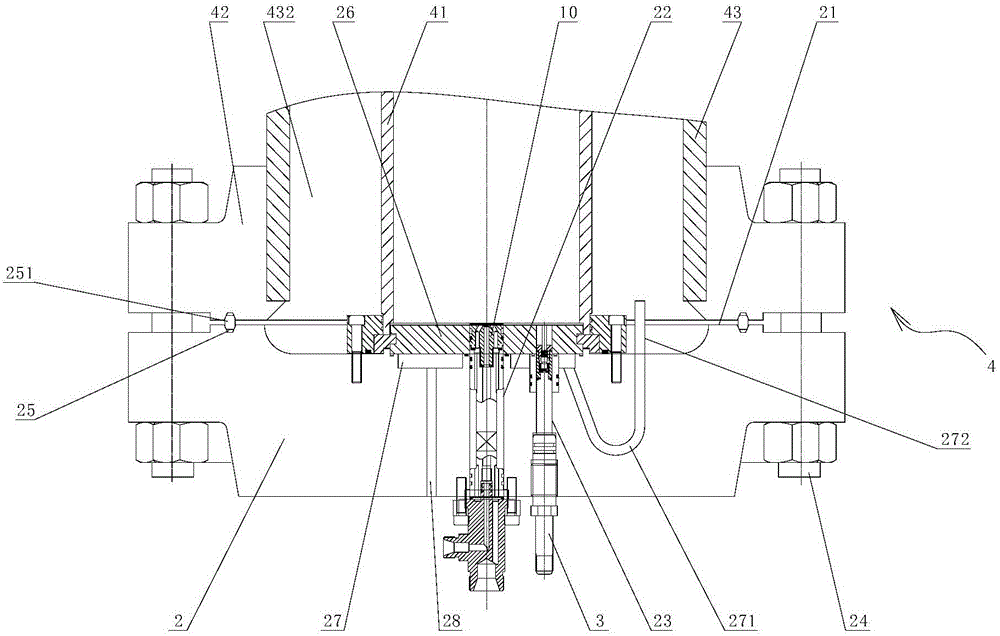

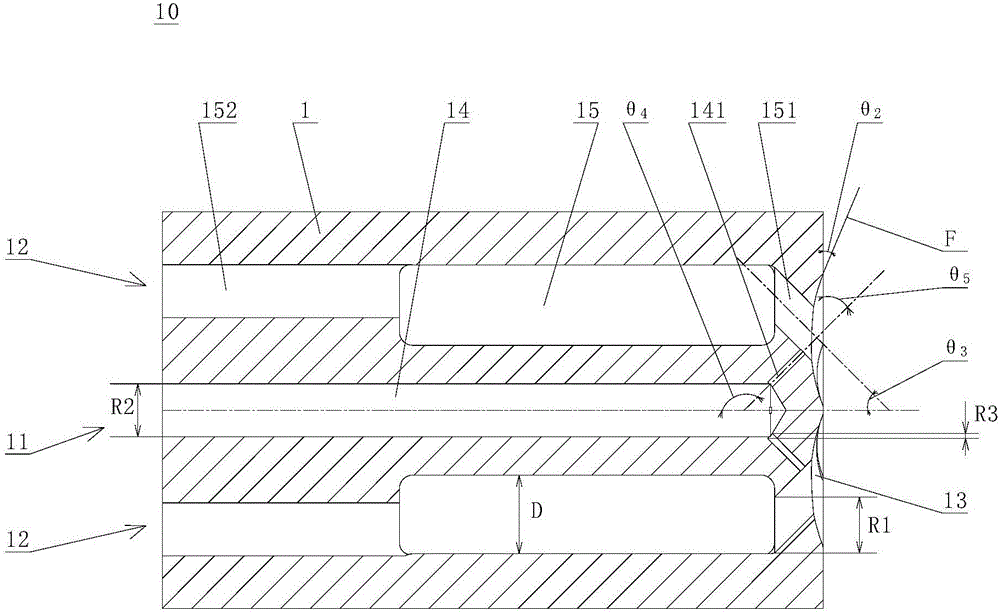

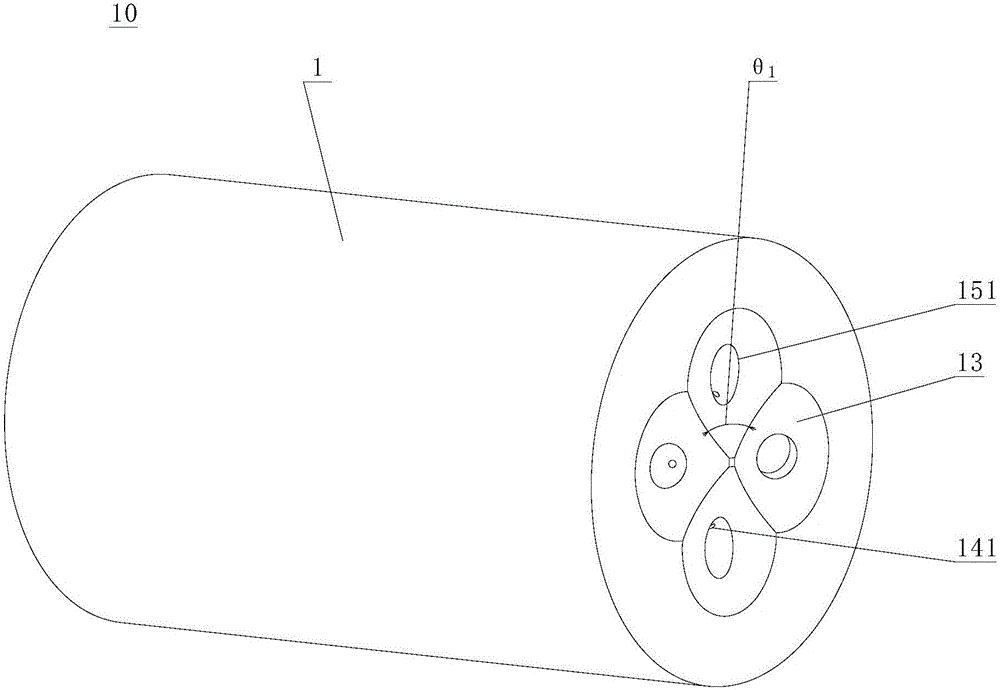

[0040] Such as Figure 1 to Figure 4 As shown, the present invention provides a generator head structure, which includes a head body 2, a combustion nozzle 10 and an ignition electrode 3, wherein: the head body 2 has an inner end surface 21 opposite to the combustion chamber 41 of the generator 4 , the head body 2 is provided with a nozzle channel 22 and an ignition electrode channel 23; the combustion nozzle 10 is located in the nozzle channel 22; the combustion nozzle 10 has a nozzle body 1, and one end of the nozzle body 1 has a fuel inlet 11 and pure oxygen inlet 12, the other end of which is formed with a plurality of diaphragm outer cavities 13, and a plurality of the diaphragm outer cavities 13 are arranged opposite to the combustion chamber 41 of the generator 4; wherein, the nozzle body 1 is provided with A fuel channel 14, one end of the fuel channel 14 communicates with the fuel inlet 11, and the other end of the fuel channel 14 communicates with a plurality of the ...

Embodiment approach 2

[0066] Such as Figure 1 to Figure 4 As shown, the present invention also provides an assembly method of the generator head structure, the assembly method is the generator head structure assembly method of Embodiment 1, the structure, working principle and The beneficial effect is the same as that of the first embodiment, and will not be repeated here. Described assembly method comprises the steps:

[0067] a) The combustion nozzle 10 is installed in the nozzle channel 22 of the head body 2, and the ignition electrode 3 is installed in the ignition electrode channel 23 of the head body 2;

[0068] b) The head body 2 is sealed and installed at the bottom of the combustion chamber 41 of the generator 4 , and the combustion nozzle 10 and the ignition electrode 3 are both arranged opposite to the combustion chamber 41 .

[0069] Specifically, in step a), after the combustion nozzle 10 and the ignition electrode 3 are installed in the head body 2, step b) is carried out, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com