Tool for spreading for cooling of large-scale tea leaves

A tea, large-scale technology, applied in the field of large-scale tea cooling tools, can solve the problems of low work efficiency, poor cooling effect, high work intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

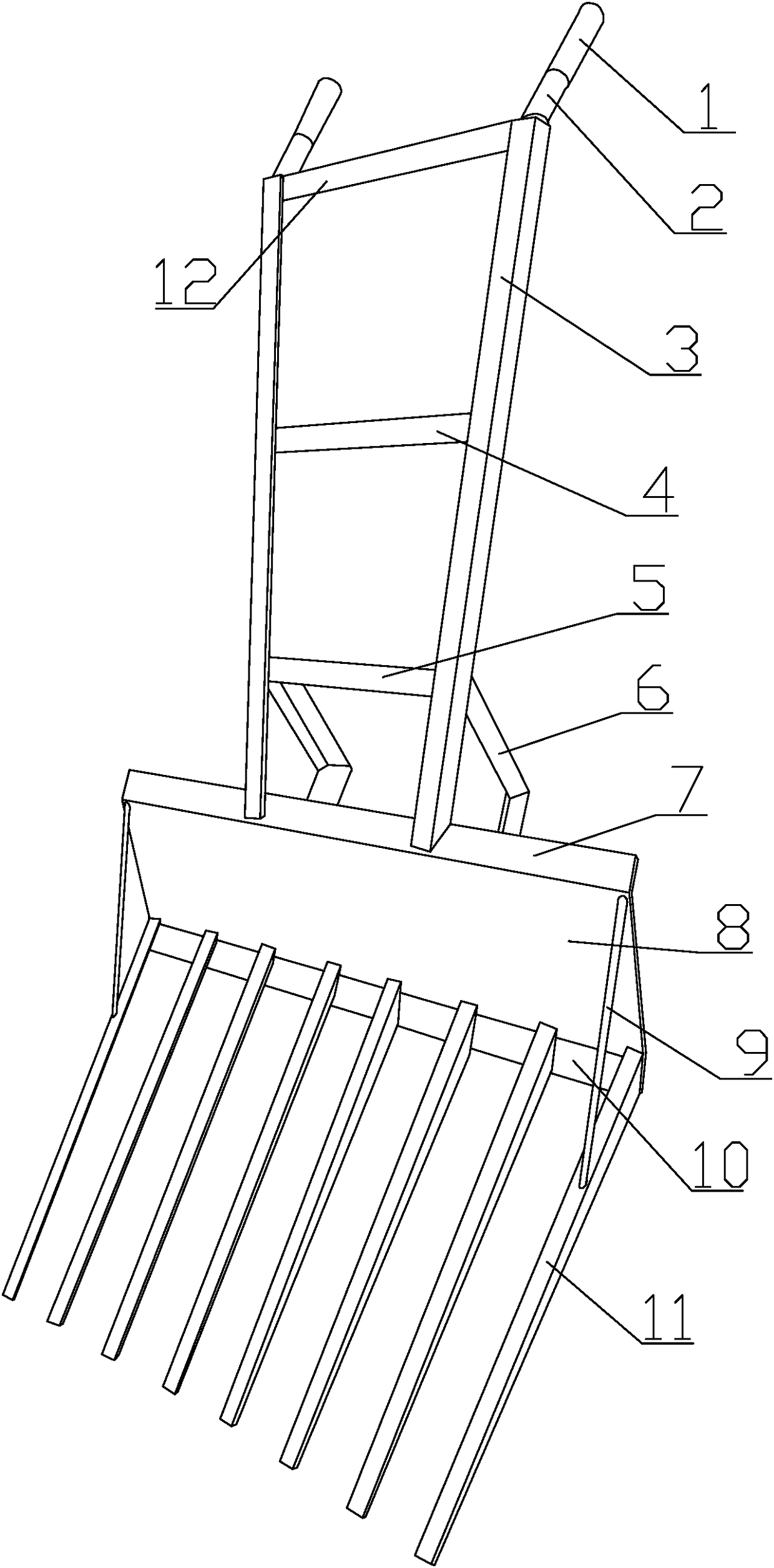

[0018] see figure 1 , a large-scale tea cooling tool, which includes an inclined push plate 8, the head of the inclined push plate 8 is provided with a fixed plate 10, and a plurality of tooth rods 11 are welded and fixed on the fixed plate 10 at equal intervals. The top of the inclined push plate 8 is bent with a top skirt 7, and two push rods 3 are installed in parallel on the top skirt 7, and a handle 2 is installed at the end of the push rod 3.

[0019] Further, the end of the handle 2 is fitted with a wear-resistant rubber handle 1 . The wear-resistant rubber handle 1 can ensure the stability of holding.

[0020] Further, a first crossbar 12, a second crossbar 4 and a third crossbar 5 are installed between the push rods 3, and the three crossbars are all made of steel strips. Material costs can be reduced by using steel strips.

[0021] Further,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com