Waste water composite heat carrier generator and composite heat carrier generation method

A composite heat carrier and generator technology, applied in steam generation, steam generation device, mining fluid, etc., to achieve the effect of saving water resources, improving service life, and avoiding the effect of directly facing the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

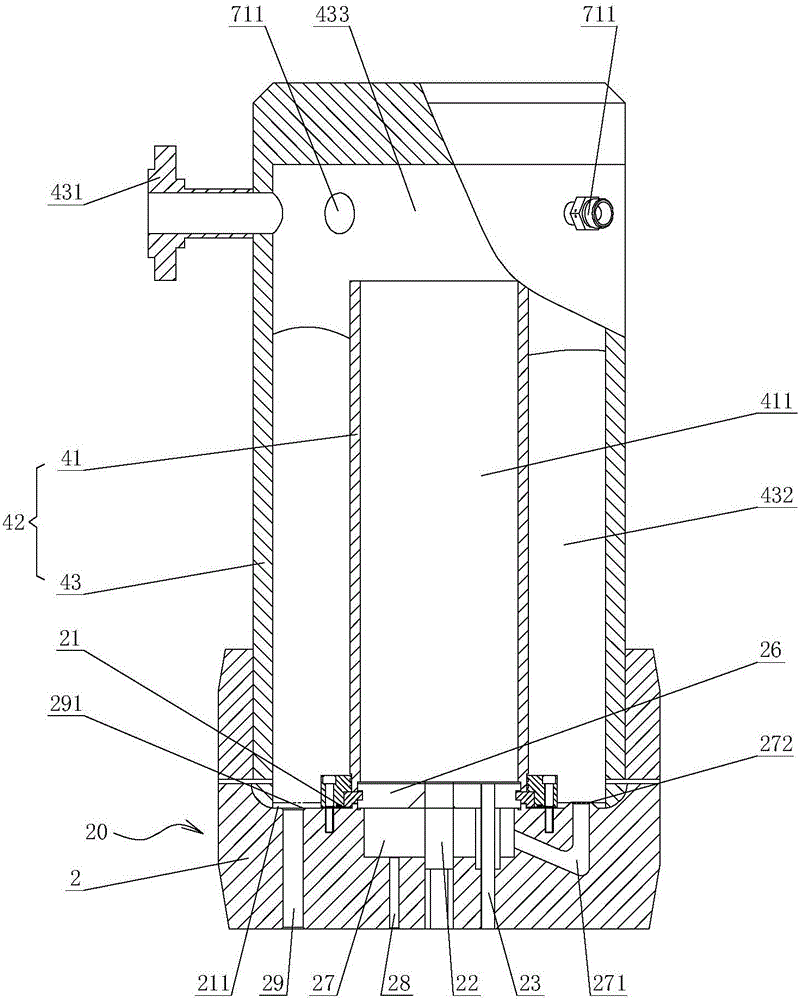

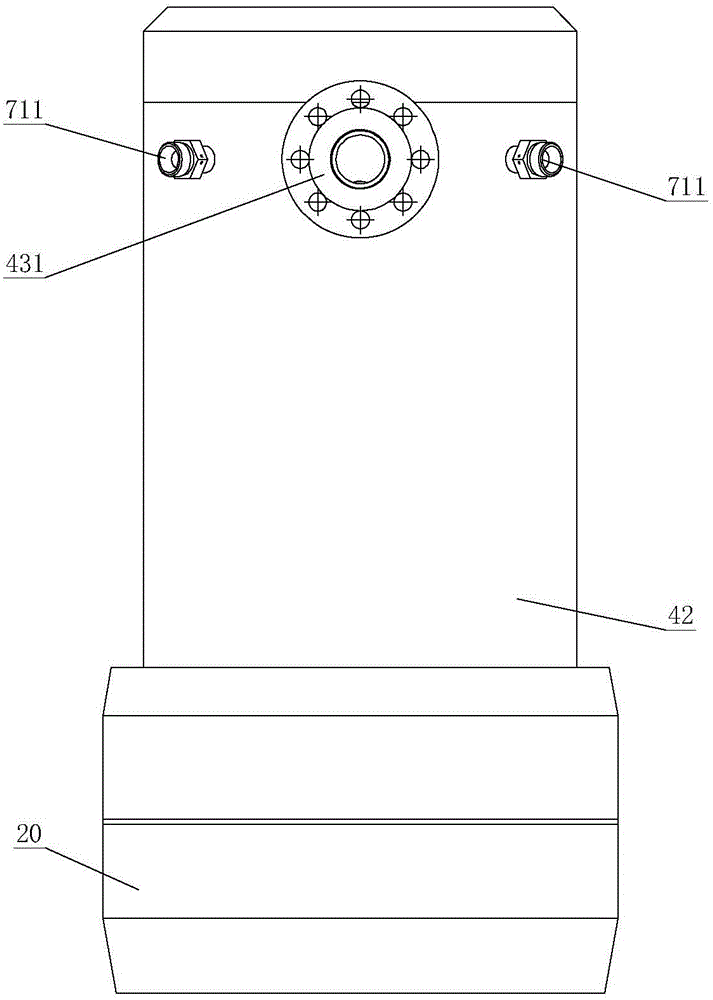

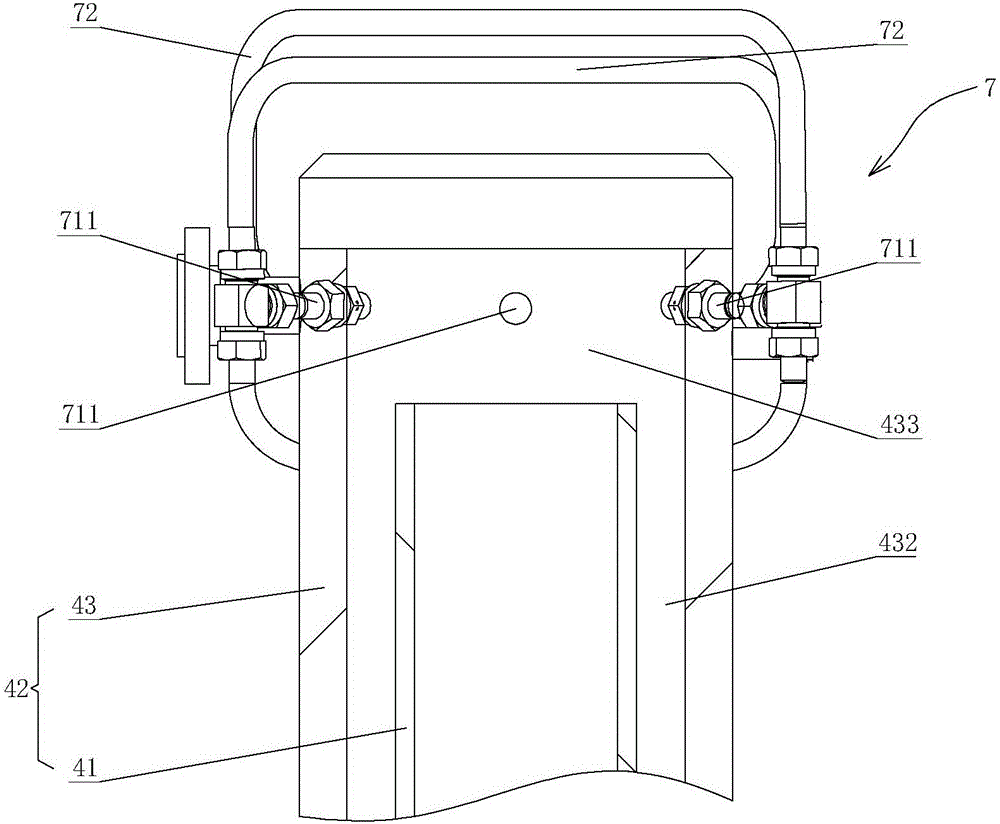

[0042] Such as Figure 1 to Figure 5As shown, the present invention provides a waste water composite heat carrier generator, which includes a generator body 42, a generator head structure 20 and a cooling gasification device 7, wherein: the generator body 42 includes a combustion chamber 41 and is sleeved in the The steam chamber 43 outside the combustion chamber 41, the upper end of the combustion chamber 41 communicates with the steam chamber 43, and the upper end of the steam chamber 43 is connected with an outlet pipe 431; the generator head structure 20 is connected to the generator The lower end of the generator body 42, the generator head structure 20 has a head body 2 and a combustion nozzle (not shown) and an ignition electrode (not shown) arranged in the head body 2, Both the combustion nozzle and the ignition electrode are arranged opposite to the combustion chamber 41, and the head body 2 is provided with a water inlet passage 28 and a scale removal passage 29 comm...

Embodiment approach 2

[0064] Such as Figure 1 to Figure 5 As shown, the present invention also provides a composite heat carrier production method of a wastewater composite heat carrier generator, the composite heat carrier production method is the composite heat carrier production method of the waste water composite heat carrier generator in Embodiment 1, and the The structure, working principle and beneficial effects of the waste water composite heat carrier generator are the same as those of Embodiment 1, and will not be repeated here. Described composite heat carrier production method comprises the steps:

[0065] a) Inject fuel into the combustion chamber 41 of the generator body 42 through the combustion nozzle, inject waste water into the steam chamber 43 of the generator body 42 through the water inlet channel 28 of the generator head structure 20, and pass through the cooling gasification device 7. Inject waste water into the steam chamber 43;

[0066] b) Open the ignition electrode, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com