Deformation recovery device for deep underground plastic pipe, and use method thereof

A technology of reset device and plastic pipe, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of structural damage of engineering entities, unstable engineering quality, easy water leakage in deformed parts, etc., to improve engineering quality , The effect of ensuring normal water supply and drainage and avoiding noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

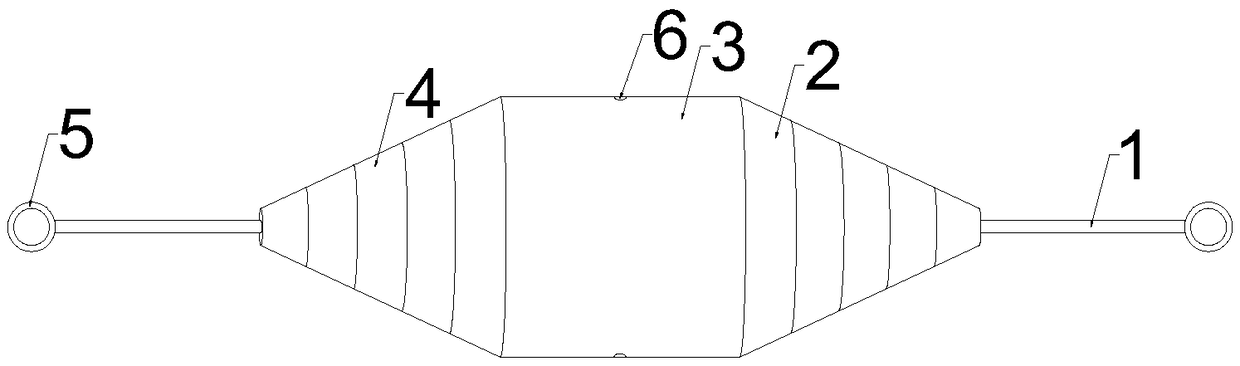

[0040] Example 1: Deformation Reset Device for Deeply Buried Underground Plastic Pipes

[0041] The present invention provides a deep-buried underground plastic pipe deformation reset device, which includes a screw-in cone and a hanging ring 5. The screw-in cone includes a front screw-in cone 2, a middle column 3 and a rear-end screw-in cone 4. The middle part of the screw-in cone is set A round steel 1 is arranged, and the two ends of the round steel 1 are provided with hanging rings 5 .

[0042] In the present invention, the hanging ring 5 is a circular hanging ring.

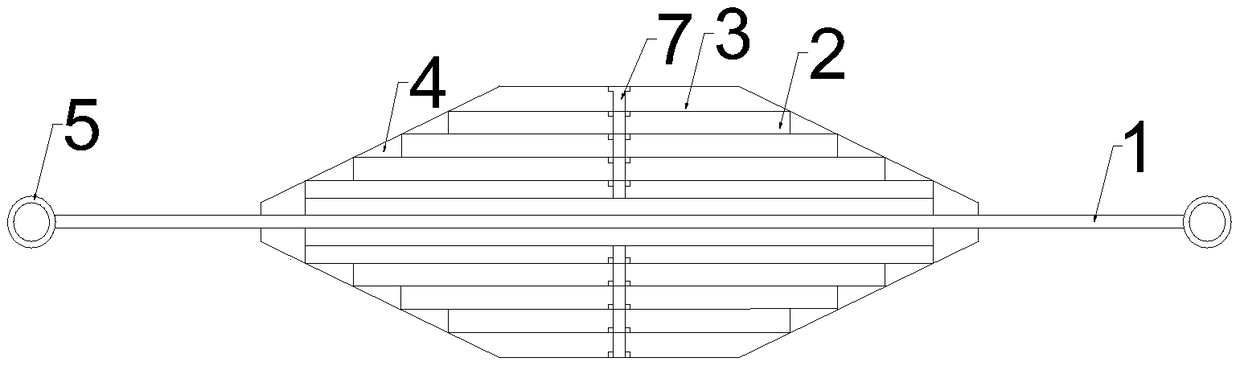

[0043] In the present invention, the precession cone is formed by socketing several layers, and a circular hole 7 is provided in the middle of the middle cylinder 3, and an internal thread is provided in the circular hole 7.

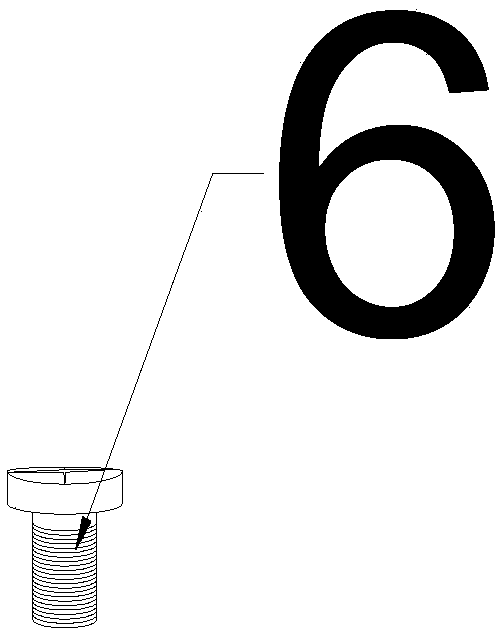

[0044] In the present invention, the surface of the round hole 7 of each layer is provided with a screw counterbore.

[0045] In the present invention, a screw 6 is arranged in the r...

Embodiment 2

[0047] Example 2: Preparation method of deep-buried underground plastic pipe deformation reset device

[0048] The preparation method of the deep-buried underground plastic pipe deformation reset device of the present invention comprises the following steps:

[0049] (1) Use a lathe to process several sets of concentric cylinders with socket diameters that are compatible with each other, and the two ends of each cylinder are processed into cones with the same inclination angle.

[0050] (2) two circular holes 7 are punched in the middle of each cylinder, and the drill bit larger than the diameter of the circular holes is punched out of the screw countersink on the circular hole 7 upper ends, and the internal thread is punched out with a tap in the circular holes 7.

[0051] (3) Through holes are drilled on the cones at both ends of the most central cylinder, and a round steel 1 is inserted in the through holes, and circular hanging rings 5 are welded at both ends of the round ...

Embodiment 3

[0053] Embodiment 3: The method of using the deep buried underground plastic pipe deformation reset device

[0054] The use method of the deep buried underground plastic pipe deformation reset device of the present invention comprises the following steps:

[0055] (1) Insert one end of the threader into a plastic pipe buried deep in the ground, and pull out the wire rope introduced by the threader.

[0056] (2) The steel wire rope is closely connected to the circular hanging ring 5 at one end of the deeply buried underground plastic pipe deformation reset device, and the circular hanging ring 5 at the other end of the deeply buried underground plastic pipe deformation reset device is closely connected to another steel wire rope, which is connected to the two ends of the pipeline. Pull mechanism.

[0057] (3) Drag the steel wire rope back and forth from both ends of the pipe, so that the deep-buried underground plastic pipe deformation reset device repeatedly punches and expan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com