Raw material particle formula and production method of pe film

A production method and raw material technology, which can be applied to other household appliances, flat products, household appliances, etc., can solve the problems of PE film heat resistance, poor tensile strength, etc., and achieve industrialization with easy implementation, convenient operation, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

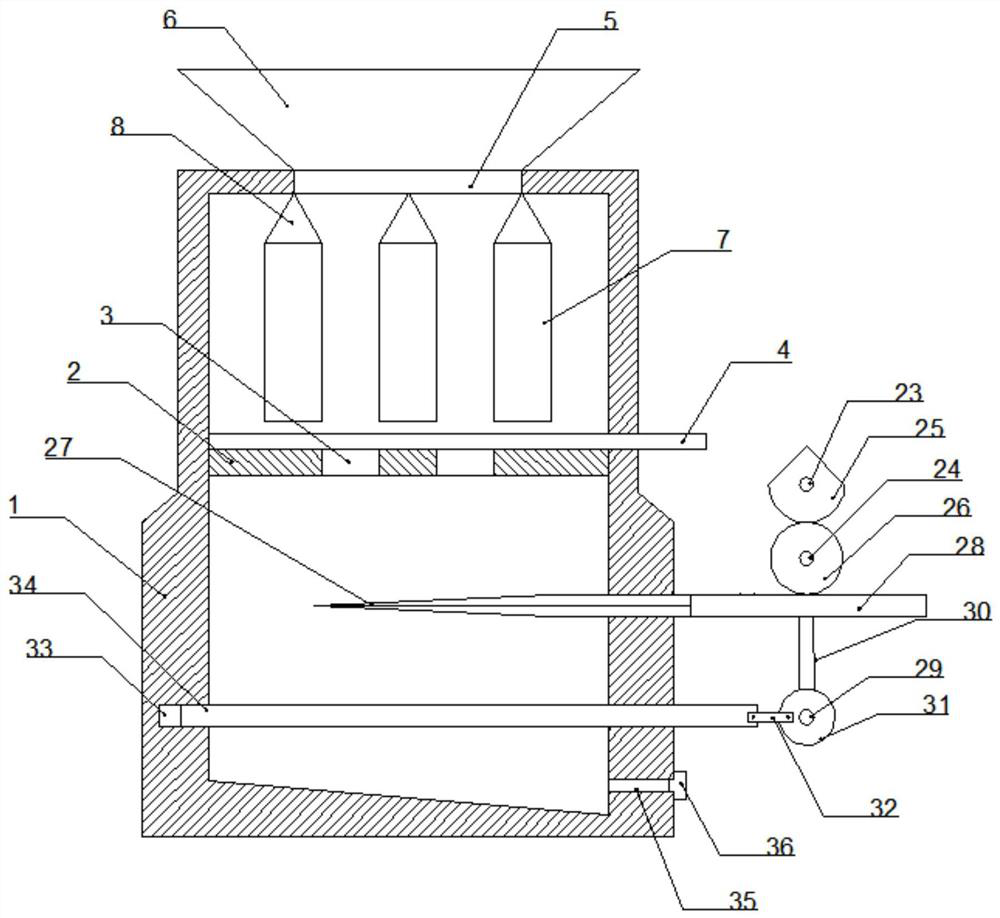

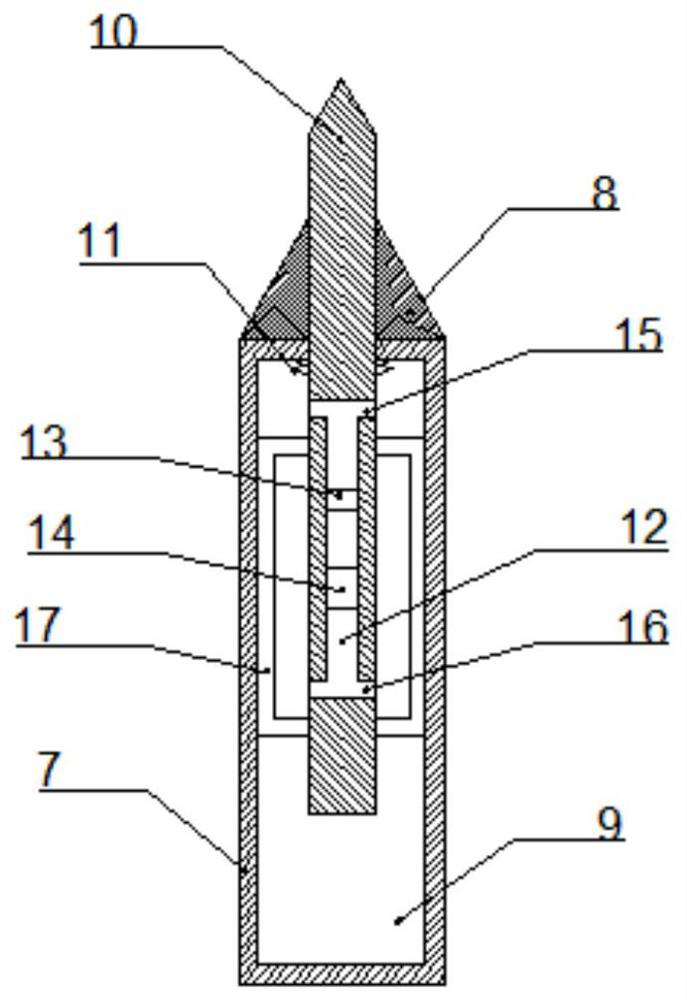

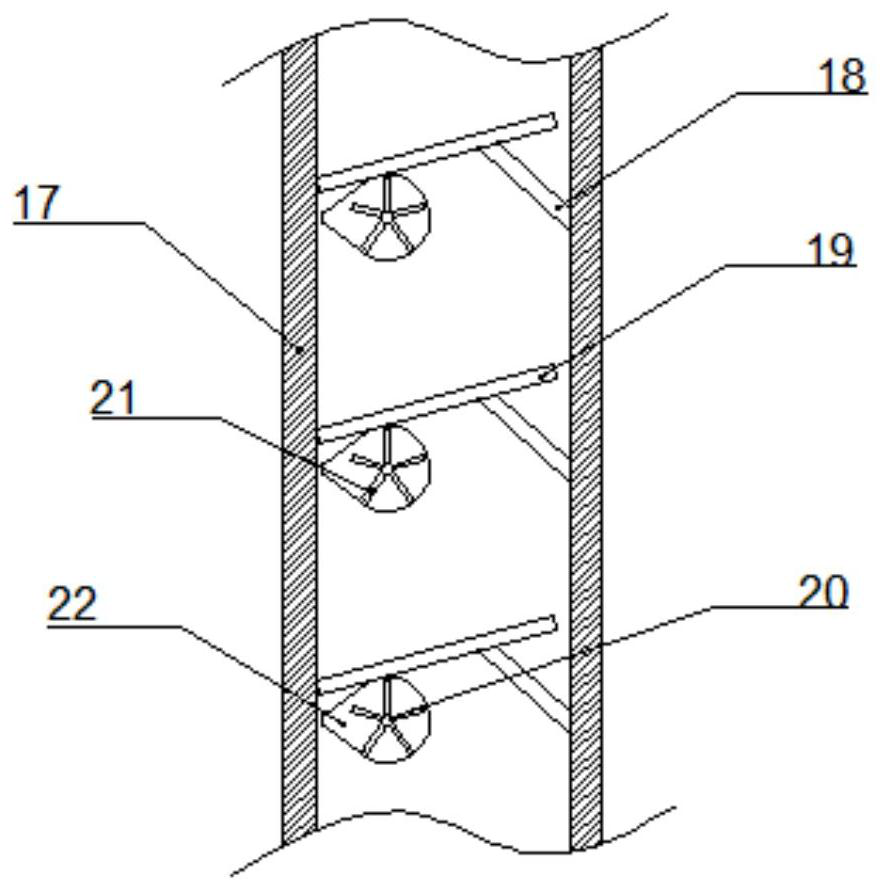

[0027] Basic as attached figure 1 , attached figure 2 And attached image 3 Shown: the production device of raw material granules, including a machine base, on which a box body 1 is installed; a partition plate 2 is welded in the middle of the box body 1, and a plurality of through holes 3 are opened on the partition plate 2 at equal distances in the horizontal direction; A shielding plate 4 is slidably connected to the side wall of the body 1 , and the shielding plate 4 is located above the partition plate 2 , and the shielding plate 4 can seal the through hole 3 .

[0028] The top of the box body 1 is provided with a feed port 5, and the feed port 5 is rectangular; a tapered feed pipe 6 is welded on the feed port 5, that is, the width of the feed pipe 6 gradually decreases from top to bottom . Several vertical blocks 7 are equidistantly arranged on the side wall of the box body 1, and the vertical block 7 is located above the partition plate 2; the through hole 3 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com