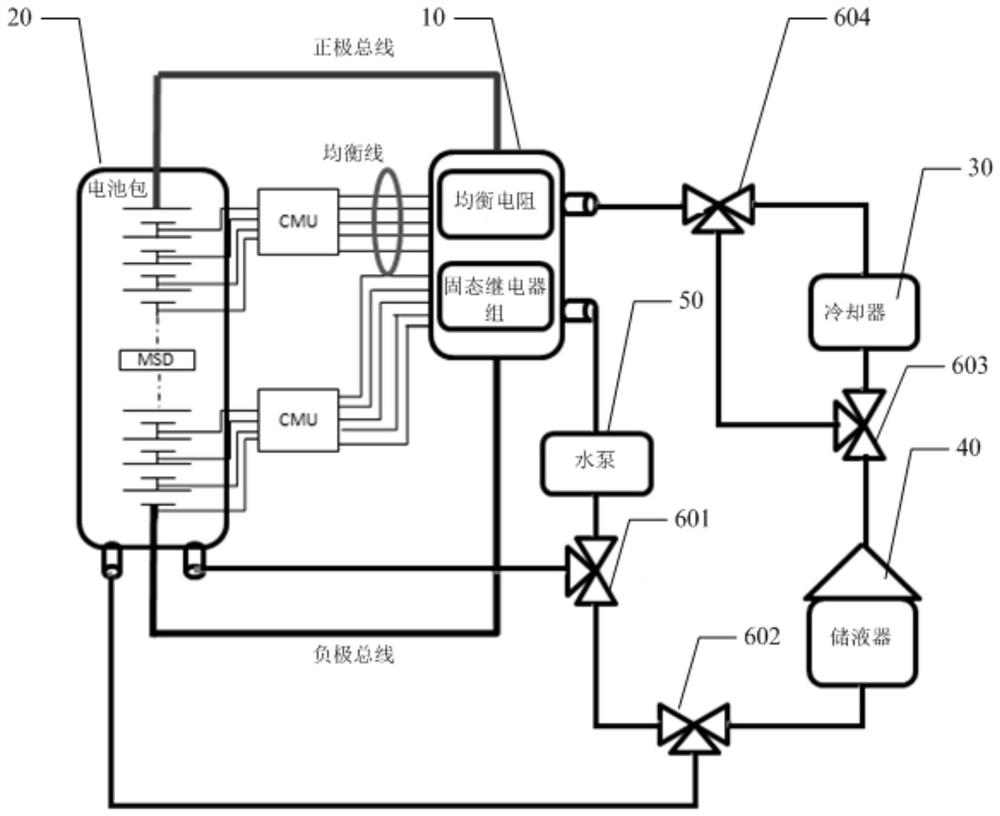

Temperature regulation system and control method for power battery

A power battery and temperature regulation technology, which is applied in battery/fuel cell control devices, secondary batteries, circuits, etc., can solve the problems of increasing system cost and low energy utilization rate, and achieves improved equilibrium efficiency, improved energy utilization rate, The effect of increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

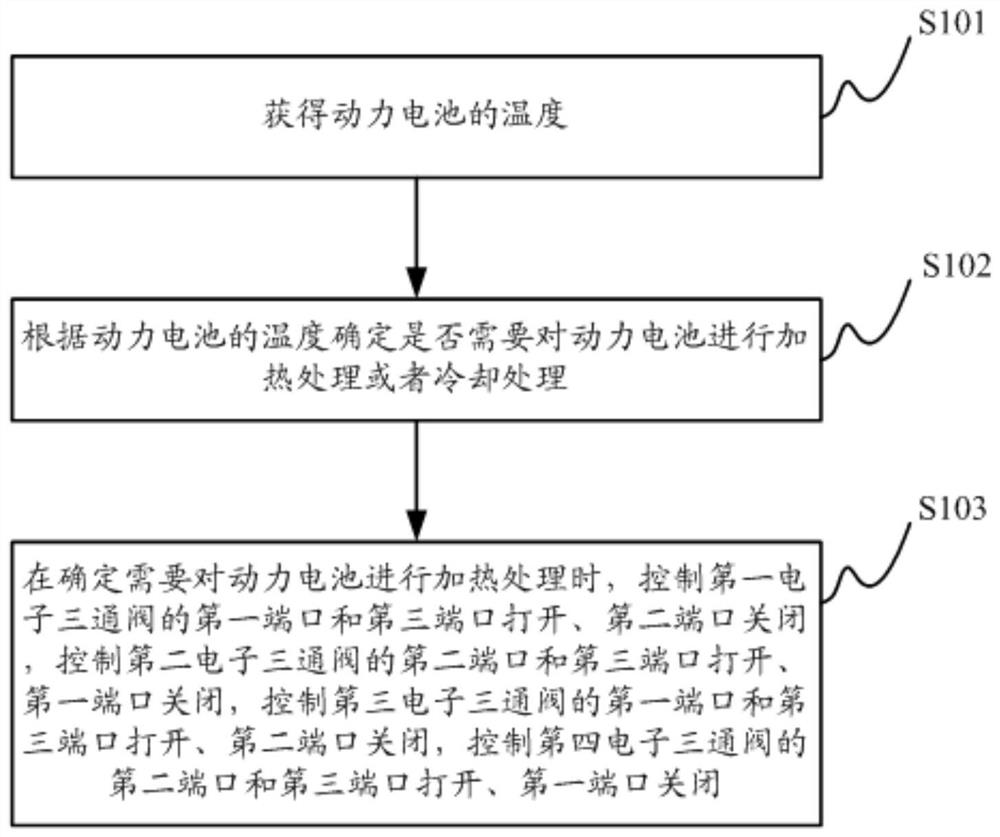

[0062] As an implementation, the control device compares the temperature of the power battery with the preset high temperature threshold and low temperature threshold, and if the temperature of the power battery is higher than the preset high temperature threshold, it is determined that the power battery needs to be cooled. If the temperature is lower than the preset low temperature threshold, it is determined that the power battery needs to be heated. Certainly, the control device may also use other methods to determine whether to perform heating or cooling treatment on the power battery.

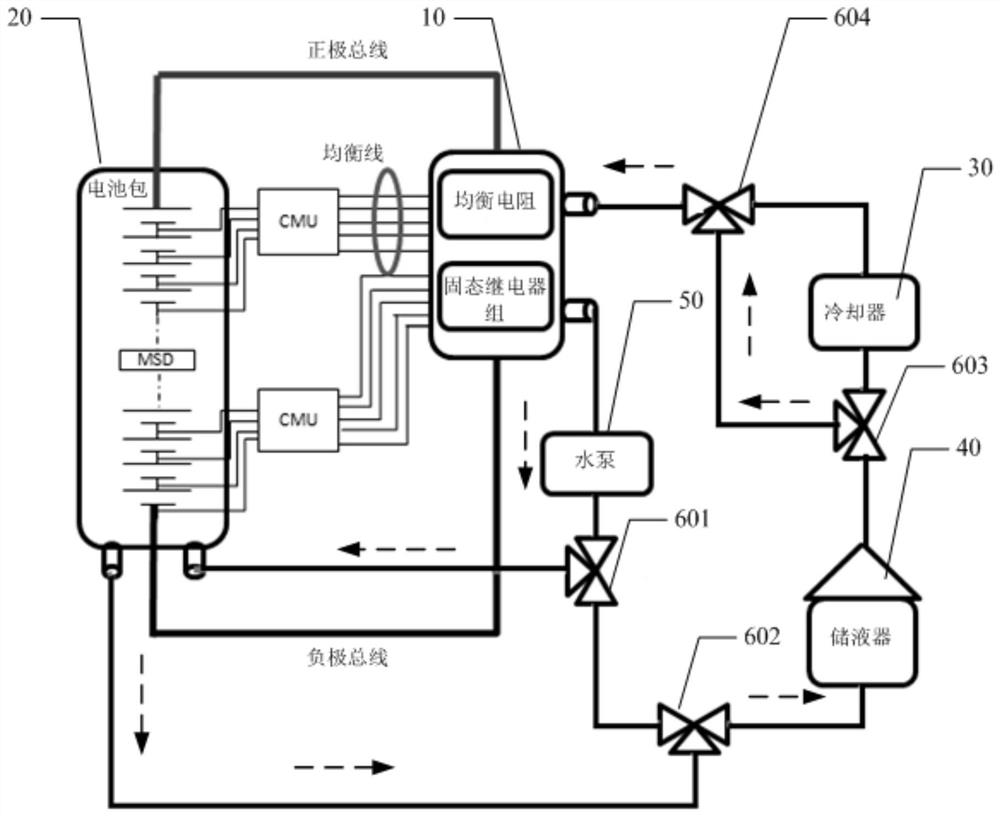

[0063] Step S103: When the control device determines that the power battery needs to be heated, it controls the opening of the first port and the third port of the first electronic three-way valve 601 and the closing of the second port, and controls the opening of the second electronic three-way valve 602. The second port and the third port are opened, the first port is closed, the first p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com