Continuous burning furnace

A technology of firing furnace and cooling chamber, applied in the direction of furnace, furnace cooling, furnace type, etc., can solve the problems of warping, cooling chamber without exhaust mechanism, deformation, etc., to achieve the effect of cooling treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

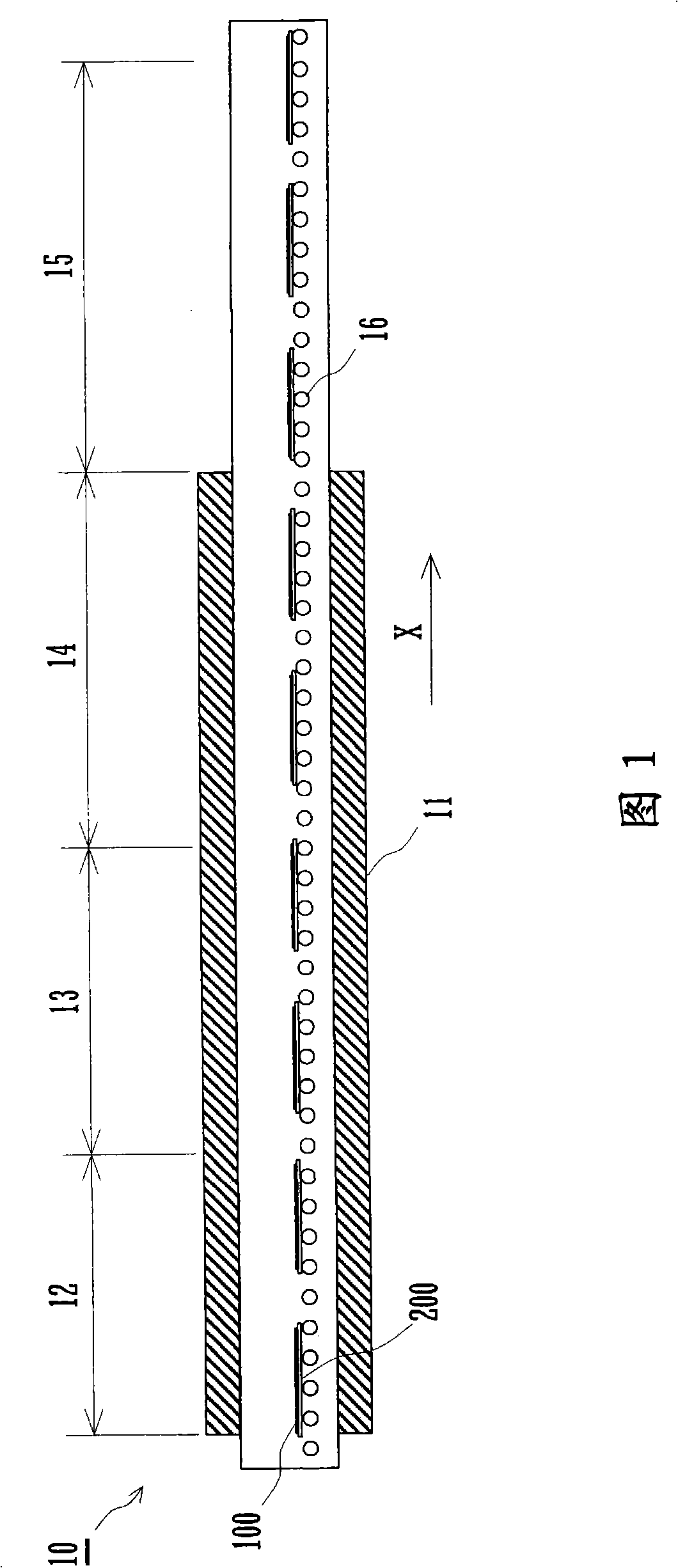

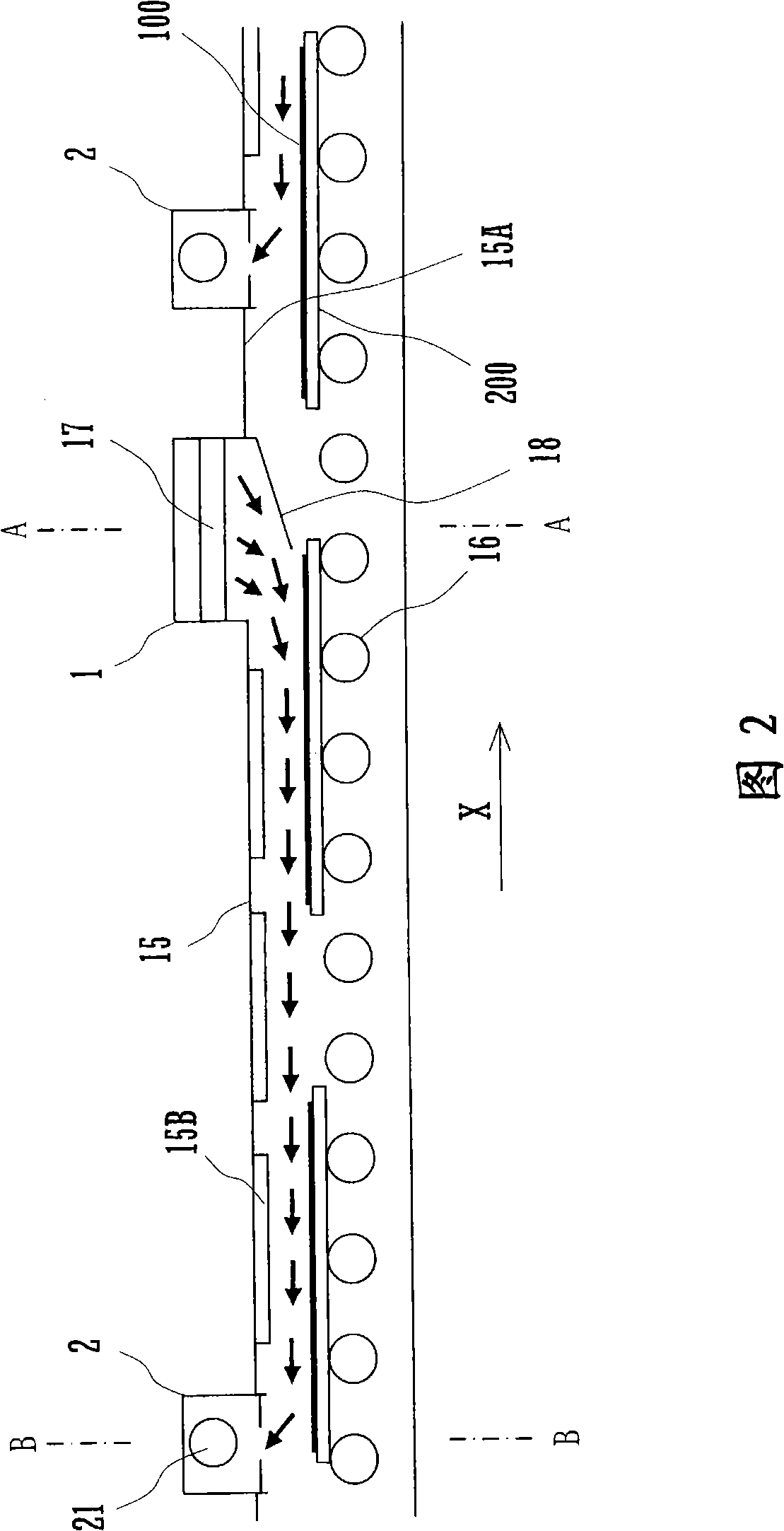

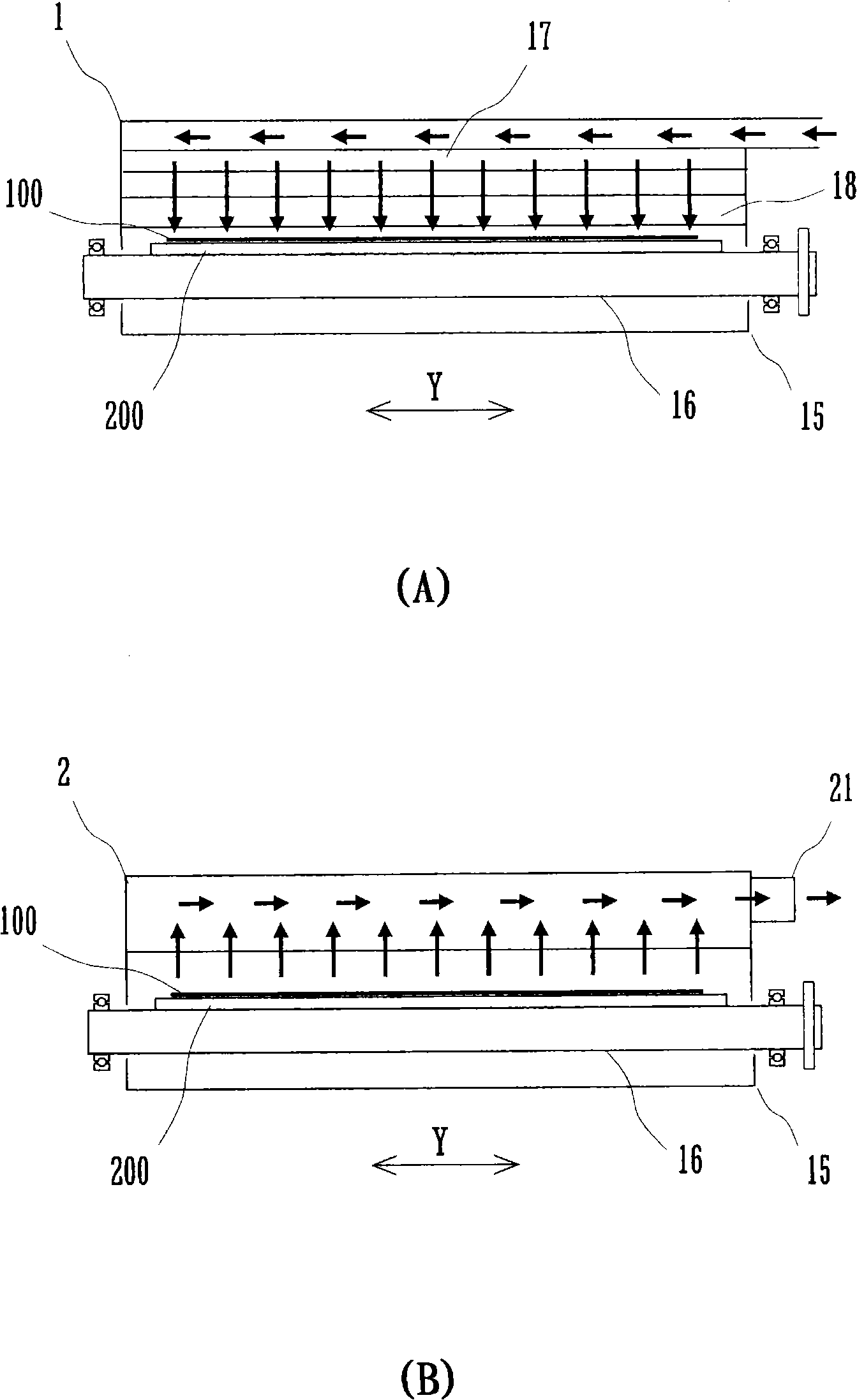

[0016] Hereinafter, specific embodiments of the present invention will be described in detail with reference to the drawings. Fig. 1 is a side sectional view showing an example of a continuous firing furnace according to an embodiment of the present invention. The continuous firing furnace 10 has a first heating chamber 12, a second heating chamber 13, and an annealing chamber 14 along the conveying direction X in the furnace 11, and the furnace 11 located on the downstream side of the annealing chamber 14 along the conveying direction X There is a cooling chamber 15 outside. In the first heating chamber 12 , the second heating chamber 13 , the annealing chamber 14 , and the cooling chamber 15 , a plurality of rotatable rollers 16 are arranged at equal intervals along the conveyance direction X.

[0017] The first heating chamber 12 performs the first temperature raising treatment and the first soaking treatment, for example, heating the treatment object to 350° C. to 400° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com