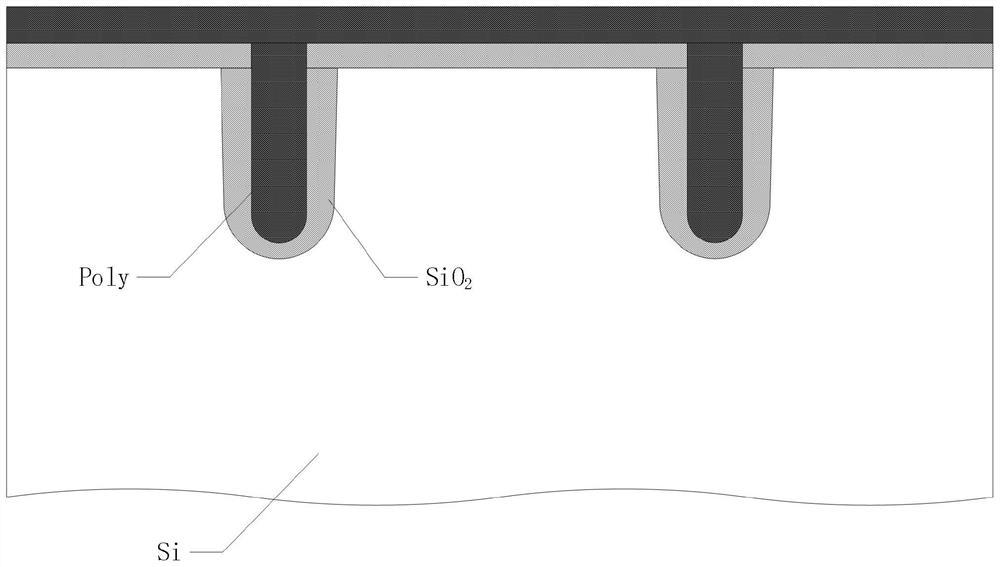

Process method for improving performance of Schottky diode with groove MOS structure

A Schottky diode and MOS structure technology, applied in the mechanical field, can solve the problems of hidden dangers of use reliability and reduced device performance, and achieve the effects of reducing difficulty, reducing charge density, and improving reverse breakdown voltage and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

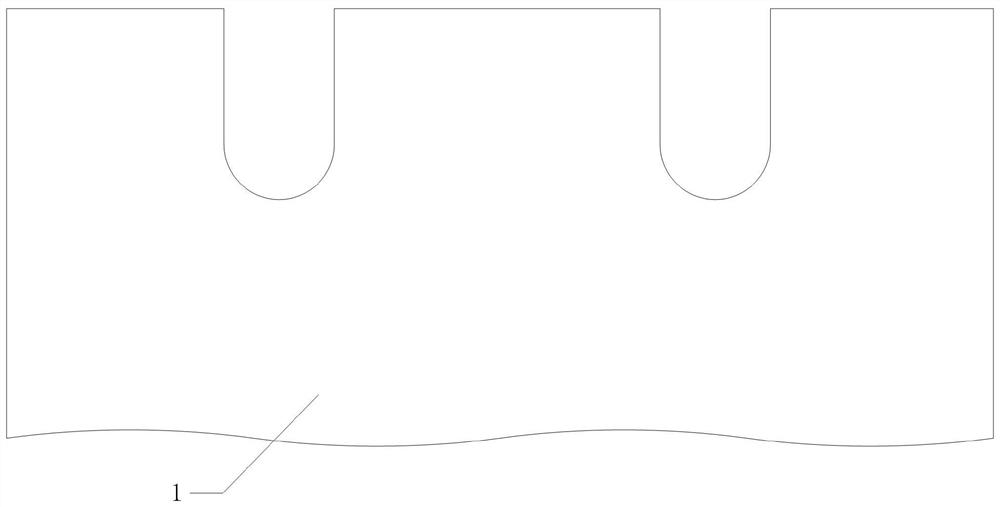

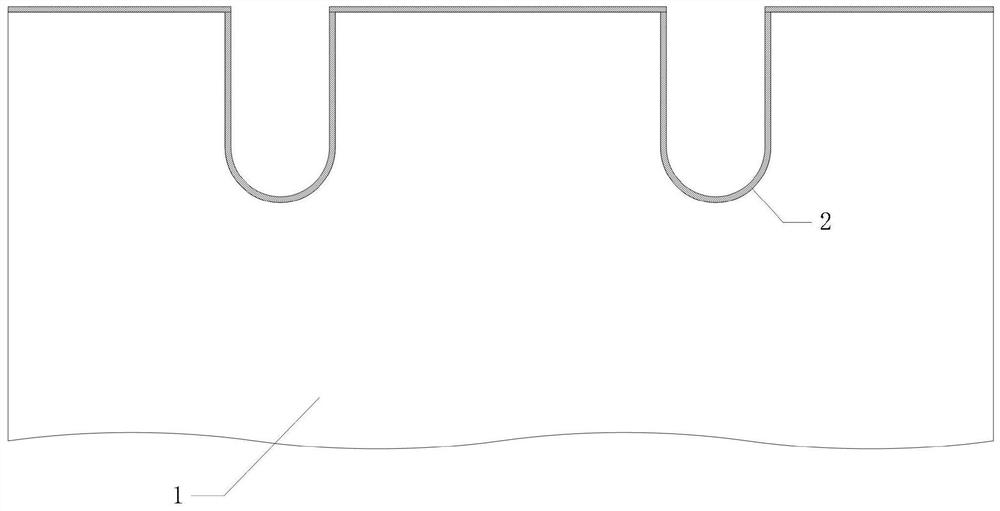

[0046] Specific embodiment 1, see Figure 2 to Figure 7 , a process method for improving the performance of a trench MOS structure Schottky diode. The oxide dielectric layer (oxygen-doped polysilicon layer 2, silicon nitride layer 3 and undoped polysilicon layer) required in the trench MOS structure is thermally oxidized and grown The silicon dioxide layer three) total thickness in Taking the left and right products as an example, the method includes the following steps:

[0047] Step 1: Take the silicon substrate 1 that has undergone groove etching, the depth of the groove is 2.5 μm-4.5 μm, and use hydrofluoric acid etching solution wet process to remove the silicon dioxide on the front side of the silicon substrate as a mask layer for silicon groove etching. silicon. See figure 1 .

[0048] Step 2: Deposit and grow a thin layer of oxygen-doped polysilicon layer 2 on the aforementioned silicon substrate 1 by LPCVD process; during the process of film deposition, the chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com