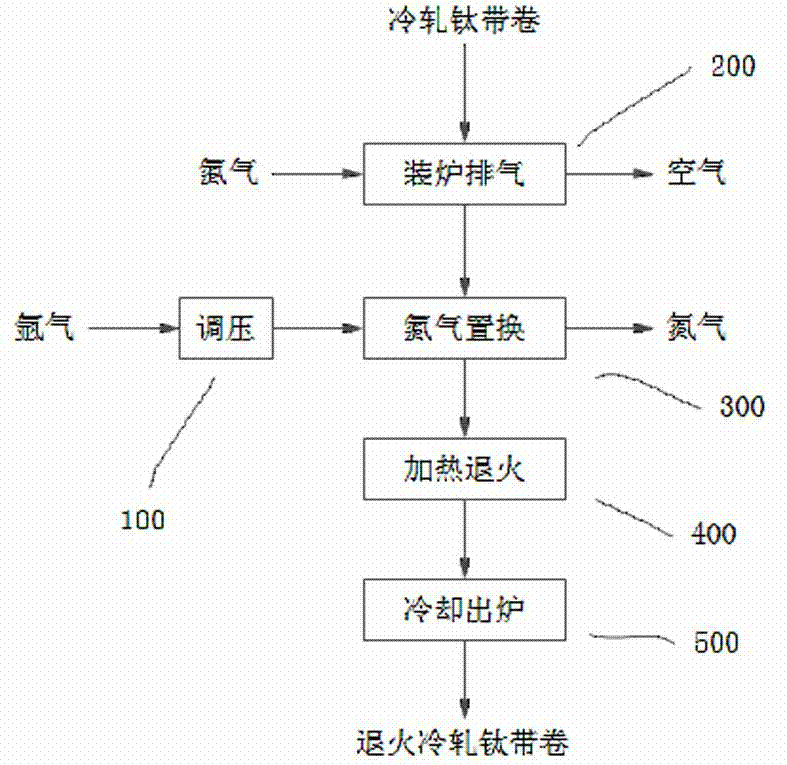

Method and device for performing inert gas protective cover type annealing on cold-rolled titanium strip coils

A bell-type annealing and bell-type annealing furnace technology, which is applied in the direction of furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as the unclear way of supplying argon, achieve remote real-time display and automatic control, facilitate transformation, and process The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

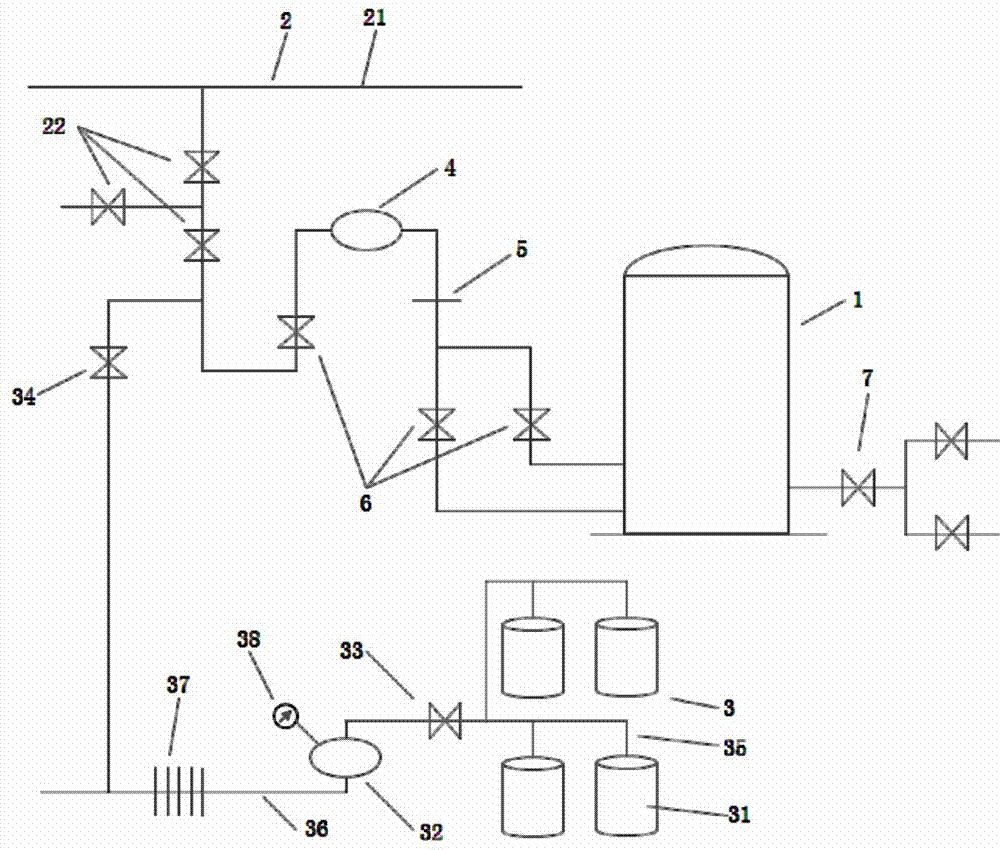

[0045] A, close the argon valve 34, open and regulate the connection regulating valve 33 between the liquid argon bottle 31 and the argon buffer device 32, so that the gas pressure in the argon buffer device 32 reaches 220mbar;

[0046] B. Put 2077kg of titanium strip coils into the furnace according to the furnace loading plan, press the inner cover of the annealing furnace and pass the cold seal test, open the nitrogen valve 22, the intake valve 6 and the exhaust valve 7, and use nitrogen to safely purge and replace the air 20 minutes;

[0047] C. After exhausting the air, close the nitrogen valve 22 and quickly open the argon valve 34, connect the argon gas in the bell annealing furnace, carry out argon purge and replace the nitrogen gas before ignition until the argon gas purity in the furnace atmosphere is 99.9%;

[0048]D. After replacing the nitrogen gas, adjust the argon gas valve 34 and the exhaust valve 7 and continue to feed argon gas and keep the pressure in the ma...

Embodiment 2

[0051] A, close the argon valve 34, open and adjust the connection regulating valve 33 between the liquid argon bottle 31 and the argon buffer device 32, so that the gas pressure in the argon buffer device 32 reaches 400mbar;

[0052] B. According to the furnace loading plan, stack 2342kg of titanium strip coils into the furnace, press the inner cover of the annealing furnace and pass the cold seal test, open the nitrogen valve 22, the intake valve 6 and the exhaust valve 7, and use nitrogen to safely purge and replace the air 30 minutes;

[0053] C. After exhausting the air, close the nitrogen valve 22 and quickly open the argon valve 34, connect the argon gas in the bell annealing furnace, carry out argon purge and replace the nitrogen gas before ignition until the argon gas purity in the furnace atmosphere is 99%;

[0054] D. After replacing the nitrogen gas, adjust the argon gas valve 34 and the exhaust valve 7 and continue to feed argon gas and keep the pressure of the ma...

Embodiment 3

[0057] A, close the argon valve 34, open and adjust the connection regulating valve 33 between the liquid argon bottle 31 and the argon buffer device 32, so that the gas pressure in the argon buffer device 32 reaches 300mbar;

[0058] B. According to the furnace loading plan, stack 1835kg of titanium strip coils into the furnace, press the inner cover of the annealing furnace and pass the cold seal test, open the nitrogen valve 22, the intake valve 6 and the exhaust valve 7, and use nitrogen to safely purge and replace the air 25 minutes;

[0059] C. After exhausting the air, close the nitrogen valve 22 and quickly open the argon valve 34, connect the argon gas in the bell annealing furnace, carry out argon purge and replace the nitrogen gas before ignition until the argon gas purity in the furnace atmosphere is 99.99%;

[0060] D. After replacing the nitrogen, adjust the argon valve 34 and the exhaust valve 7 and continue to feed argon and keep the annealing furnace table mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com