Oversize heat recovery-type push disc-type wire continuously and isothermally-balling and annealing furnace

A heat recovery type, isothermal spheroidization technology, applied in the direction of heat treatment furnaces, furnaces, furnace types, etc., can solve the problems of short preheating and cooling zones, lower workpiece pass rate, and inapplicability of annealing of large workpieces, and achieve high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

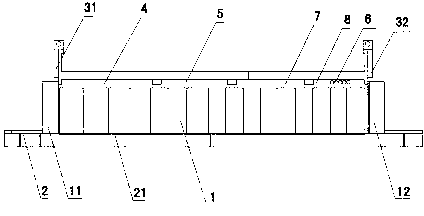

[0015] Extra-large heat recovery pusher type continuous isothermal spheroidizing annealing furnace for wire, such as figure 1 As shown, a furnace body 1 is included, the front end of the furnace body 1 is provided with a front door 31 for workpiece entry, the rear end of the furnace body 1 is provided with a rear door 32 for discharging workpieces, and the outlet end of the rear door 32 is provided with There is a discharge platform 12, and the furnace body 1 is provided with a furnace charge studio with a size of 19000mm in length, 1800mm in width and 2000mm in height, and 18 furnace charge chambers with a size of 1700mm in length, 1700mm in width and 120mm in height are arranged in the furnace body 1. There are four temperature control zones in the charging working room, which are sequentially set as a preheating zone, a heating zone, and a cooling zone. The furnace body is sequentially set with a preheating zone 4, a heating zone 5, and a cooling zone 8. An isothermal zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com