Floating pin positioning device for use in product processing

A technology of positioning device and floating pin, which is applied in the direction of positioning device, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high product defect rate, fatigue aging, processing fixture positioning and clamping failure, etc. Fast and convenient clamping, simple production and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

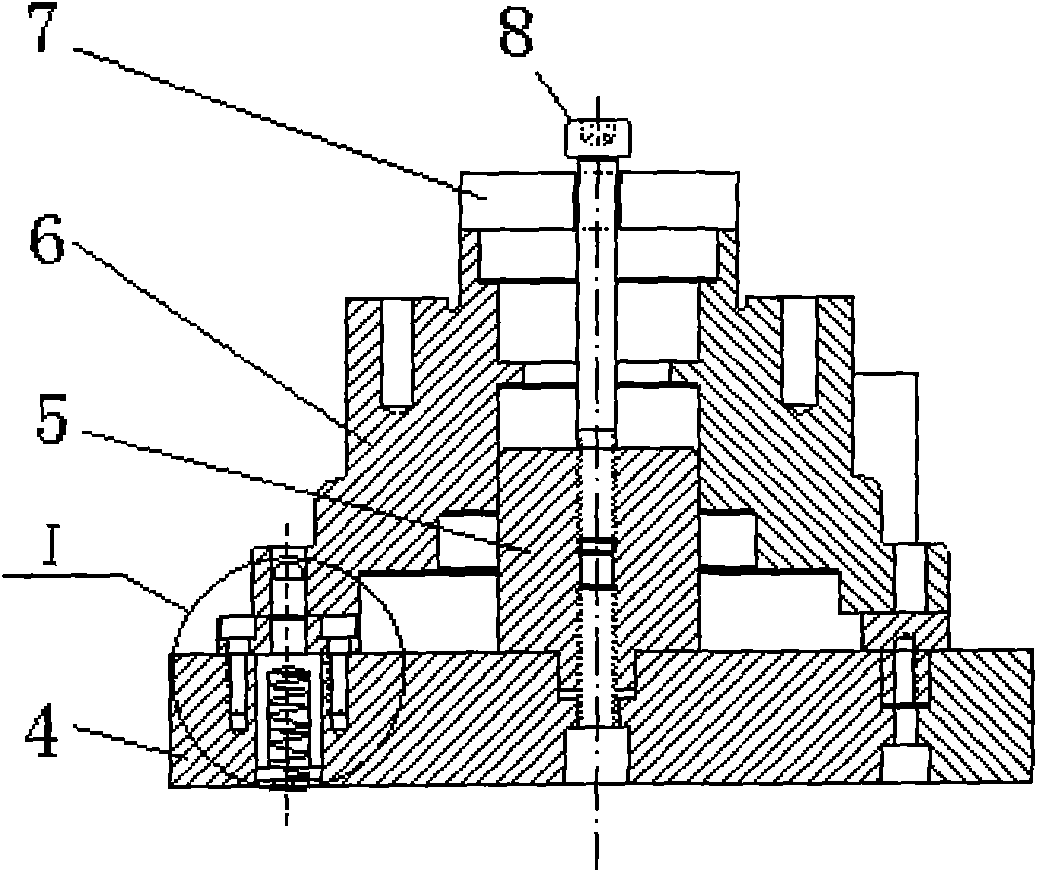

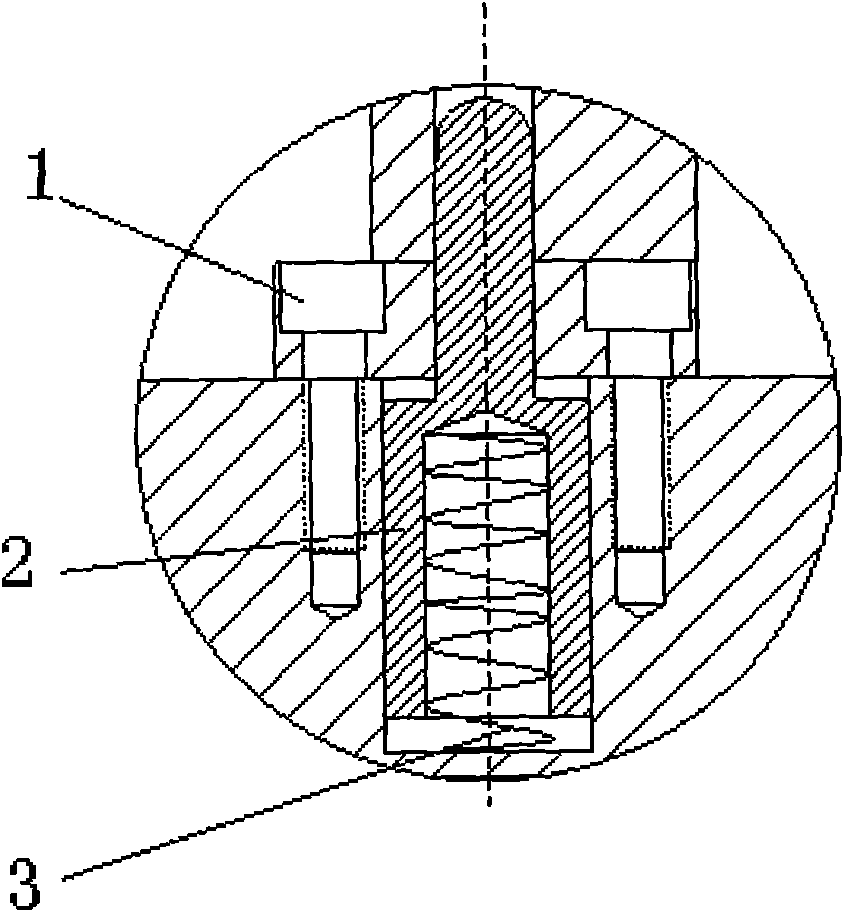

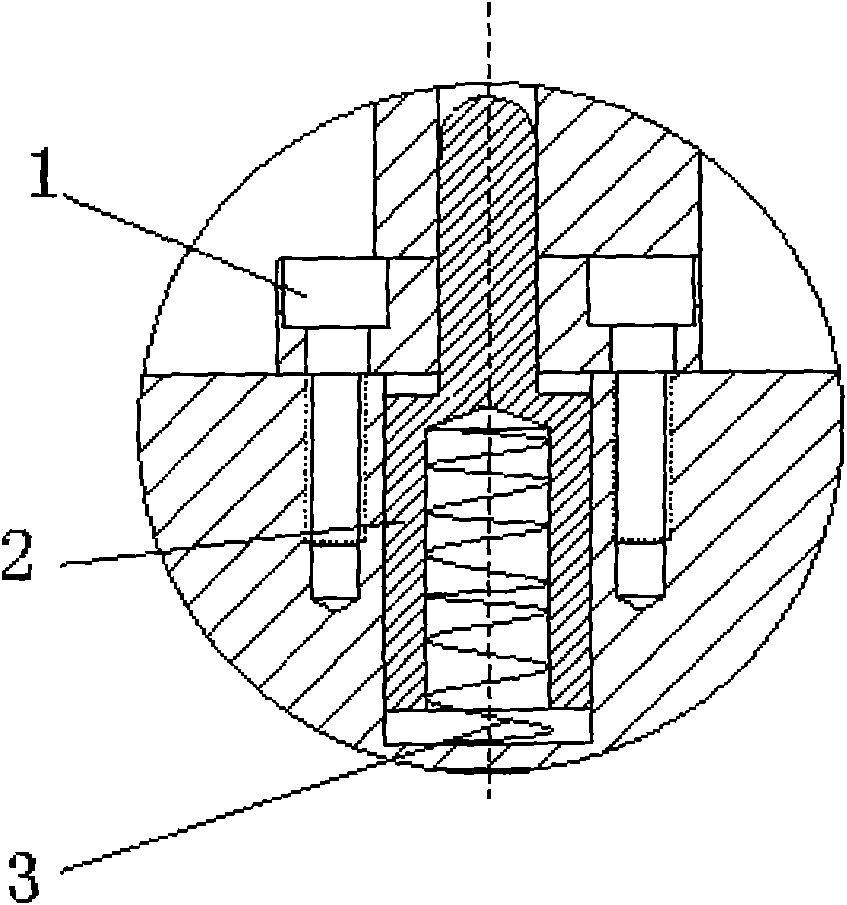

[0021] like Figure 1-2 As shown, a floating pin positioning device for product processing includes a gland 1, a positioning pin 2, a spring 3 and a processing tool reference hole, and the gland 1 is arranged on both shoulders of the positioning pin 2 to prevent The ejection of the positioning pin 2 can also be used as one of the plane references of the processing jig. The spring 3 is arranged in the positioning pin 2, and the positioning pin 2 is arranged in the reference hole of the processing jig. The positioning pin controls the positioning of the non-processing aperture of the product to achieve accurate positioning of the associated high-precision dimension processing parts. The tolerance of the sliding part of the jig template is: JIS B 0401 (1986) base shaft system / h6 .

[0022] The spring 3 controls the positioning pin 2 to maintain a directional force when the product is clamped. When the aperture position of the product deviates, it can be avoided or compensated a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com