Auxiliary paint spraying device for front cover of sedan

An auxiliary device and front cover technology, which is applied to spray devices, devices that apply liquid to the surface, coatings, etc., can solve the problems of increasing production costs, easily bruised paint film, and the weight of the front cover of the car body, and saves money. The effect of production cost, labor intensity reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

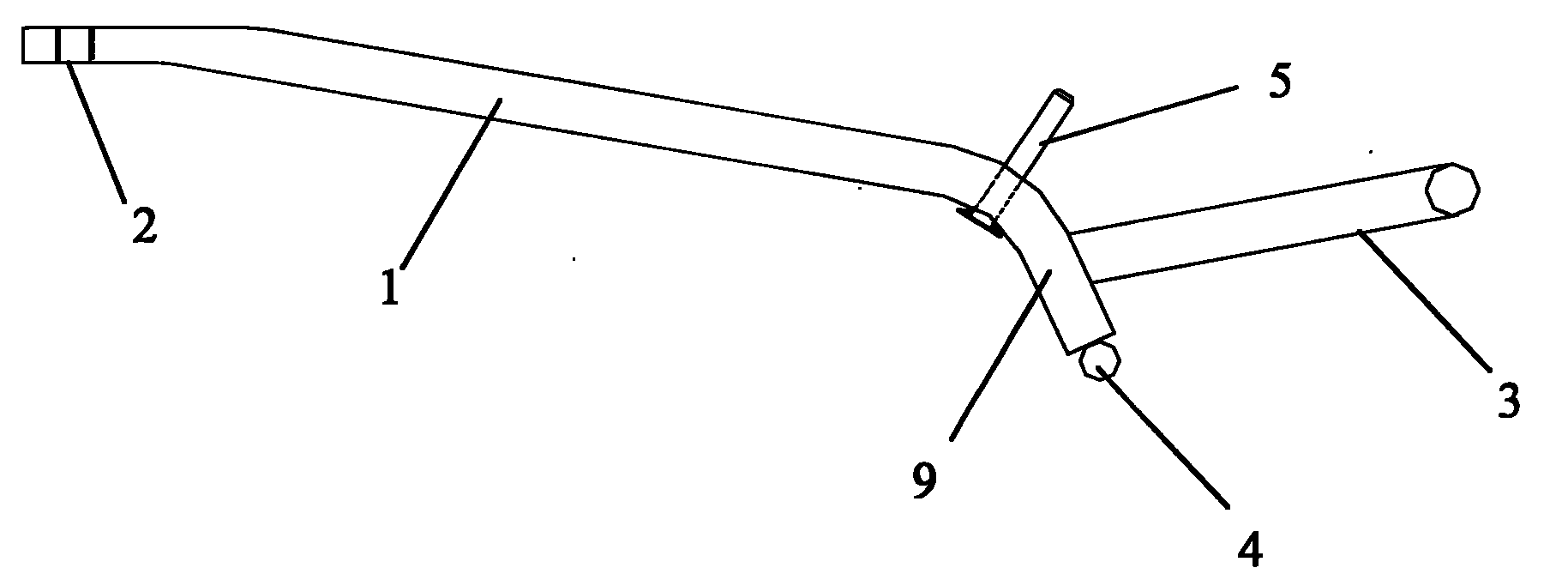

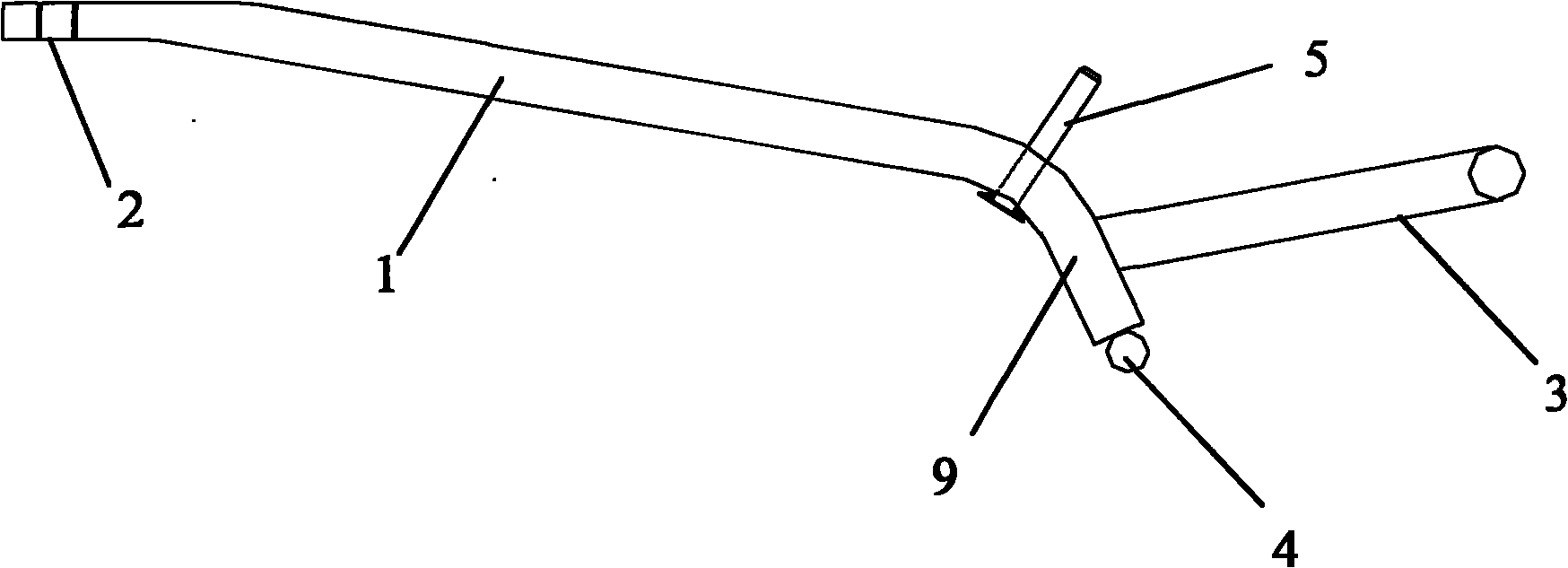

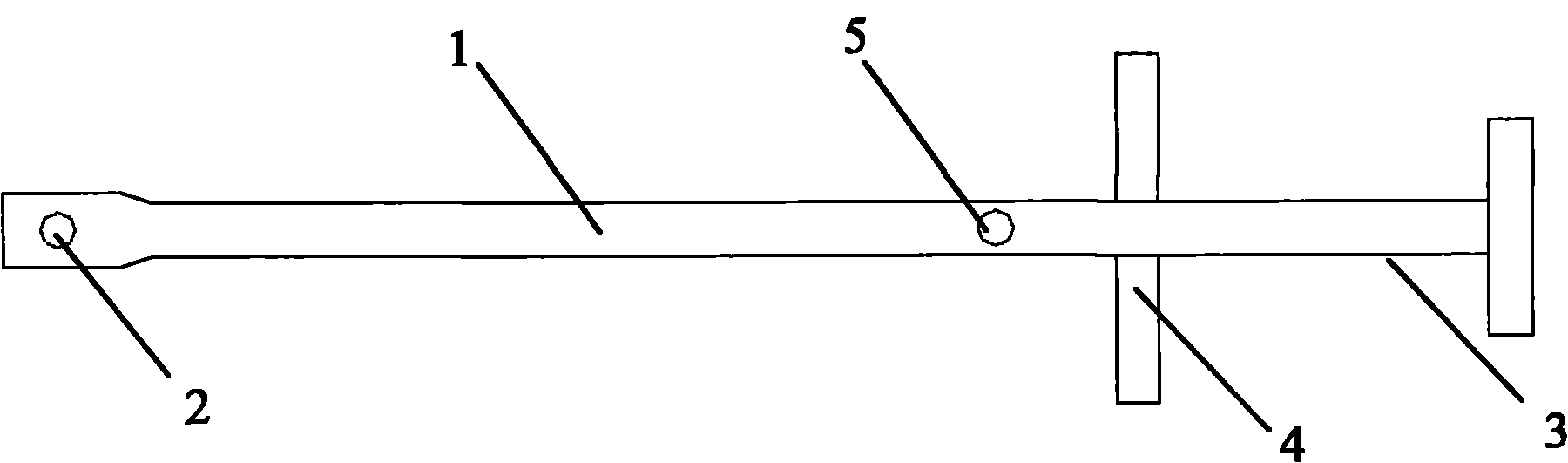

[0019] As shown in Figures 1 and 2, the car front cover painting auxiliary device of the present embodiment includes a main rod 1, the front end of the main rod 1 is provided with a screw hole 2 cooperating with the round hole at the rear end of the car front cover, A handle 3 extending backward is provided on the upper part, the rear end of the main rod 1 is bent downward to form a support part 9, and the bottom end of the support part 9 is provided with a horizontal support rod 4, and the main rod 1 is also provided with an upwardly protruding positioning screw. Column 5.

[0020] As shown in Figures 3 and 4, when painting the front cover of a car, first use the handle 3 to lift the front cover 6, and align the round hole 2 at the front end of the main rod with the round hole at the rear end of the front cover 6 to ensure that the two are aligned. Concentric state, then screw in a bolt 8 to fix the main rod 1 and the front cover 6 of the vehicle body as a whole, and start pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com