Artificial ecological floating bed based on foamed polypropylene material

A foamed polypropylene, artificial ecology technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor impact energy and absorption capacity, low shape recovery stability, Use problems such as narrow temperature difference to achieve the effect of strong impact resistance, good shape recovery stability and wide temperature difference range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

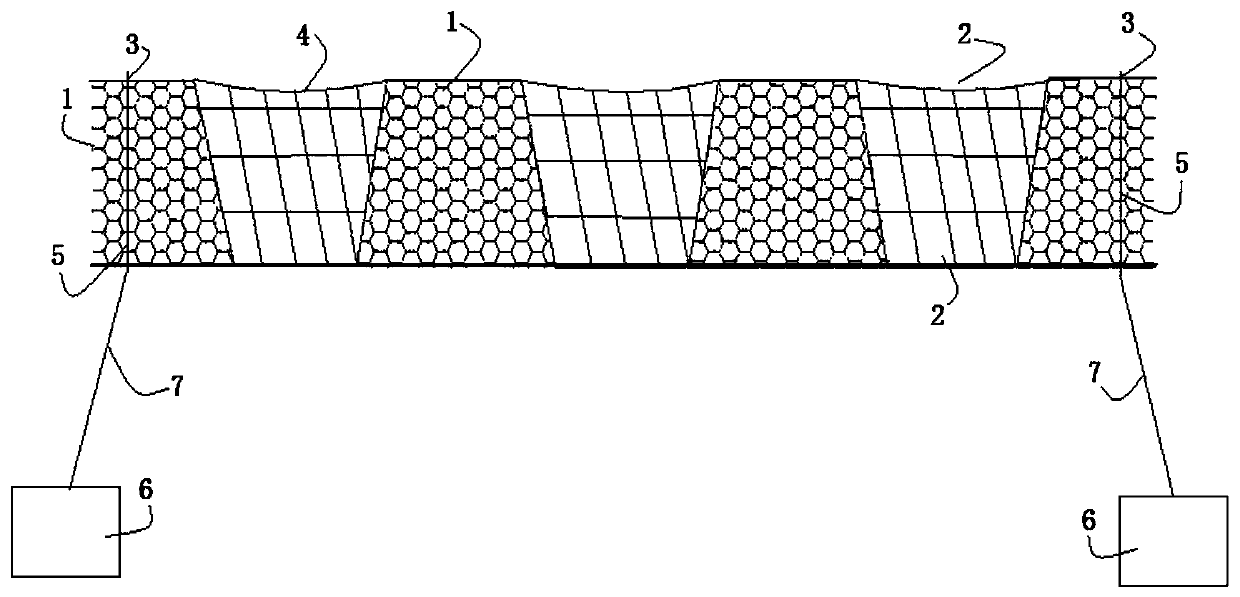

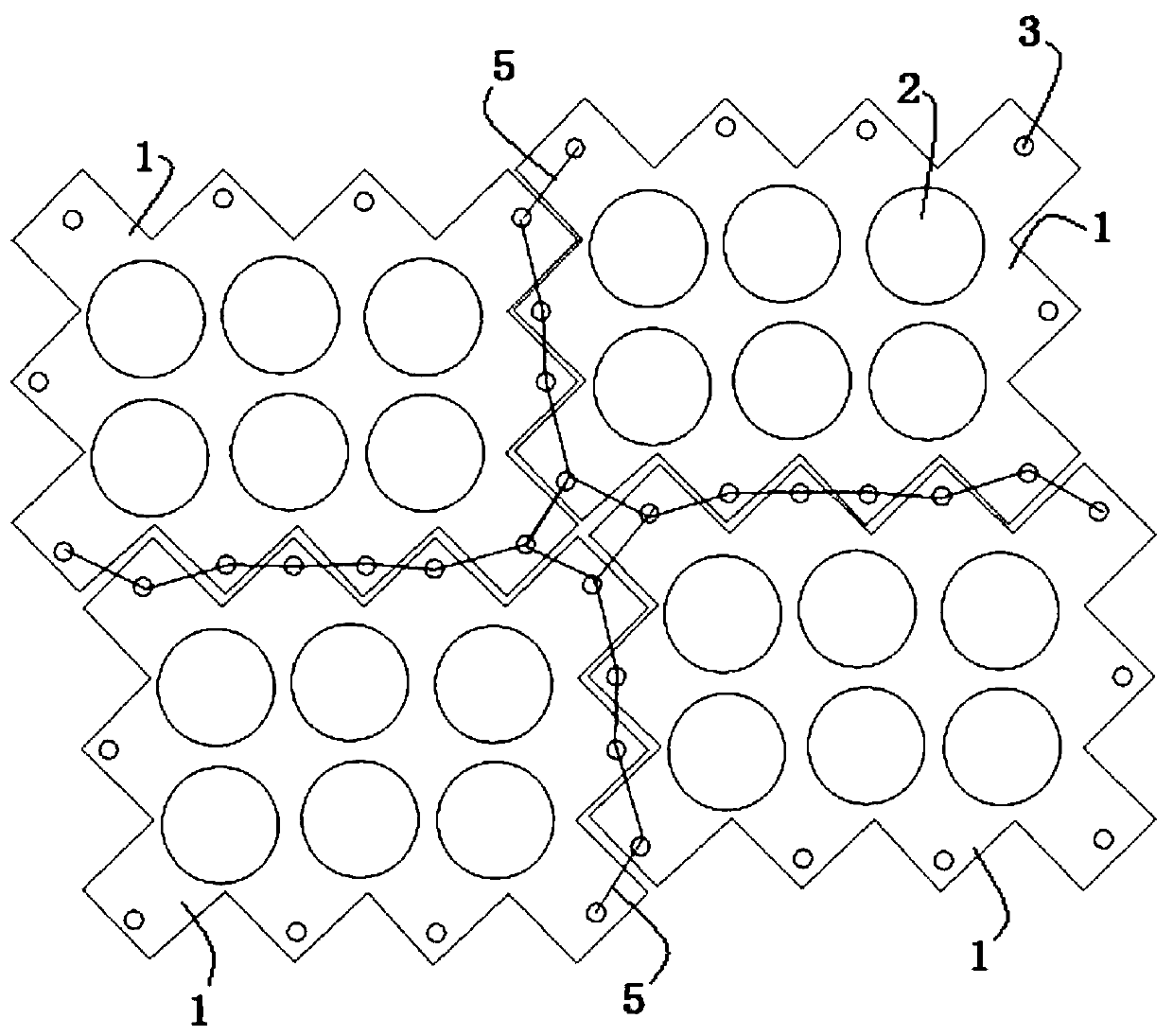

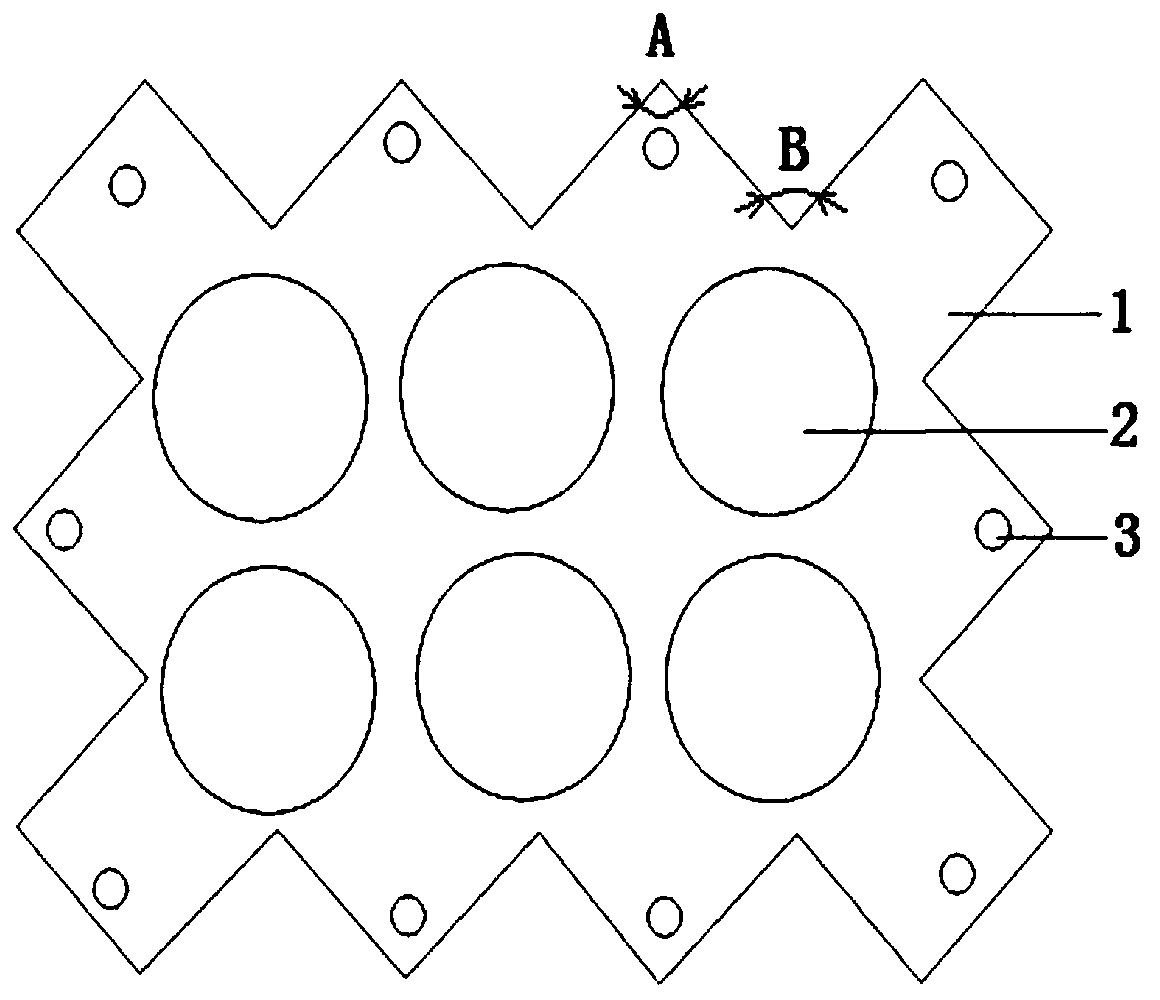

[0019] Below with the accompanying drawings ( Figure 1-Figure 3 ) to illustrate the present invention.

[0020] figure 1 It is a structural schematic diagram of an artificial ecological floating bed based on foamed polypropylene material for implementing the present invention. figure 2 Yes figure 1 Schematic diagram of the splicing structure of the four foamed polypropylene floating plates 1 in the middle. image 3 Yes figure 1 Schematic diagram of the unit structure of the medium-foamed polypropylene floating plate 1. like Figure 1 to Figure 3 As shown, an artificial ecological floating bed based on foamed polypropylene material includes a floating board, and the floating board is a foamed polypropylene floating board 1 . The foamed polypropylene floating plate 1 is made by foaming and pressing EPP foamed beads in the mold of the molding machine at one time, and the production density is 7-130kg / m 3 , The expansion ratio is between 8 and 45 times. The artificial ec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com