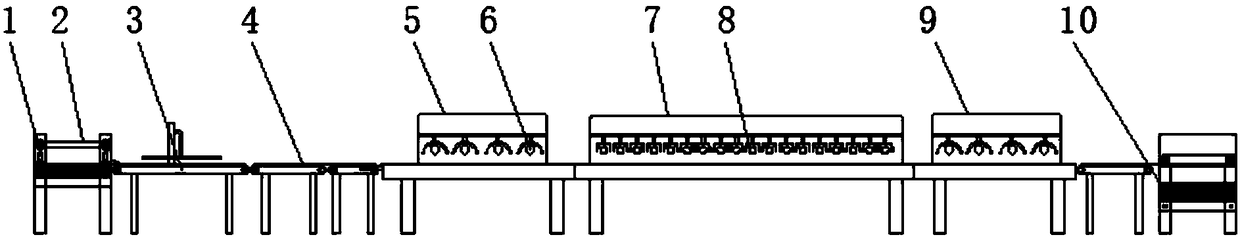

Integrated screen printing device for tinplates and screen printing technology

A technology of tinplate and screen printing, applied in the direction of printing process, screen printing, screen printing machine, etc., can solve the problems of scratches on the surface of tinplate, scratches on the printing surface, and heavy tinplate, so as to reduce the scrap rate and avoid scratches. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

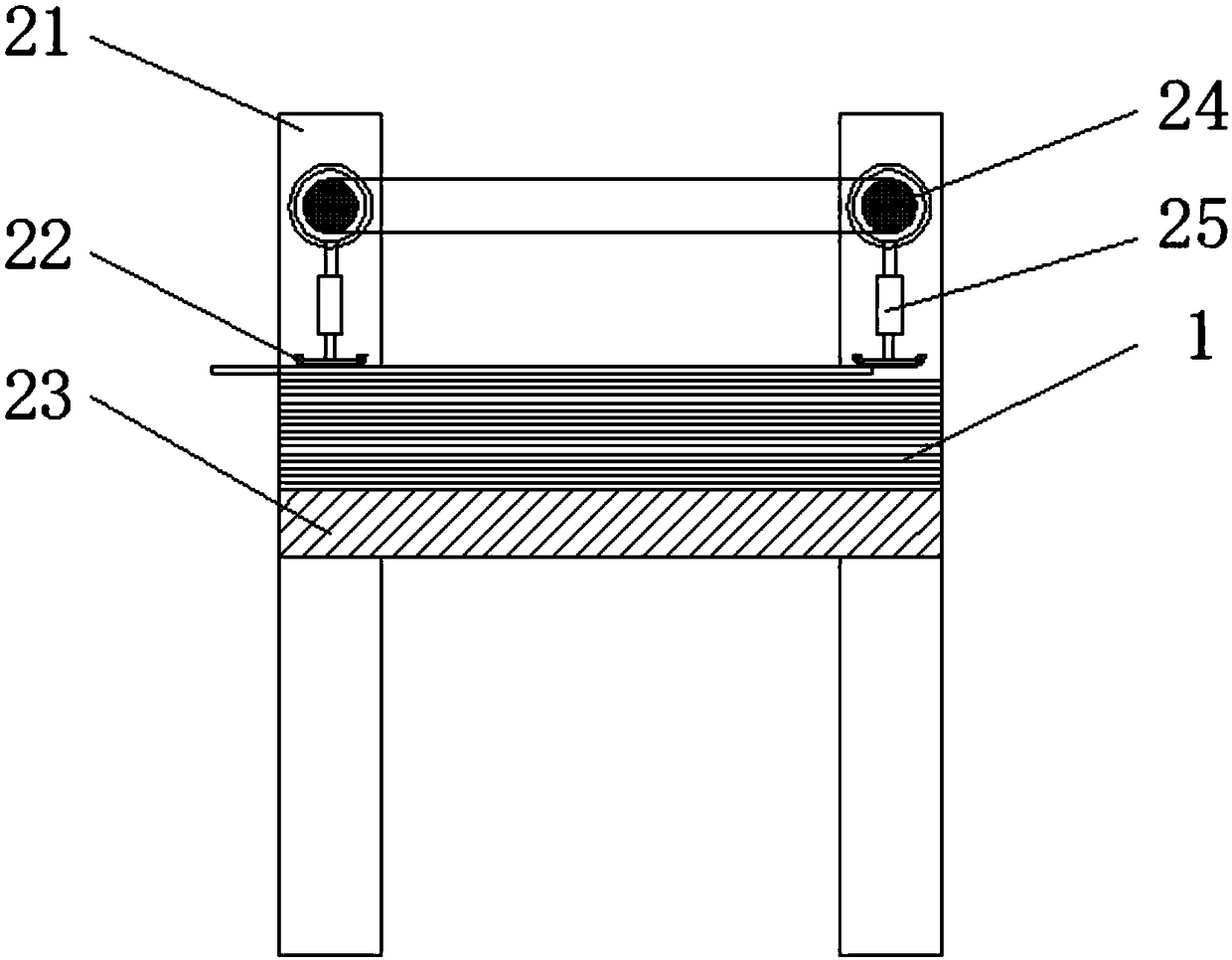

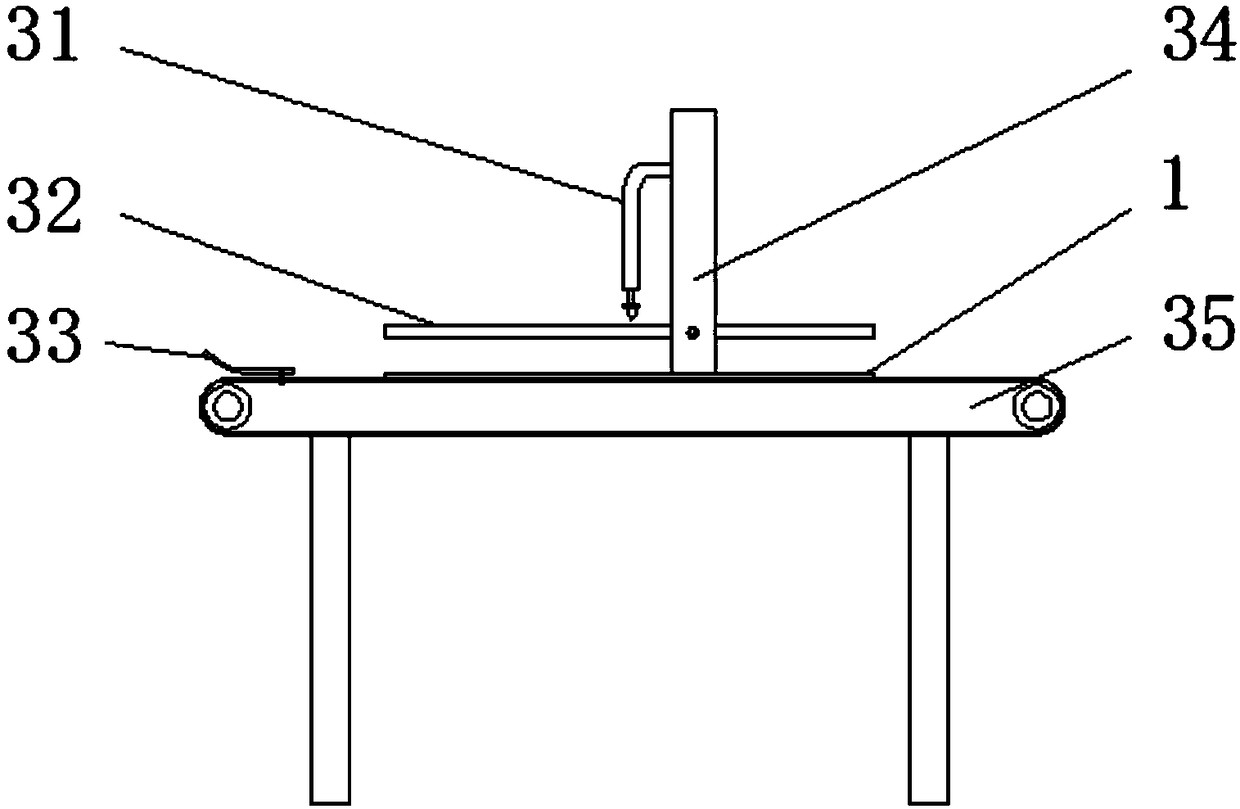

[0046] Place a stack of tinplate 1 on the feeding platform 23, start the suction gun conveyor belt 24 to make the electromagnetic suction gun 25 start to run, adjust the adsorption force of the electromagnetic suction gun 25 to make a tinplate 1 adsorb on the bottom of the fluffy cloth 22, and pass through the suction gun. The operation of the conveyor belt 24 transports the tinplate 1 to the silk screen assembly 3 on one side, so that all the tinplate 1 can be transported to the silk screen assembly 3 by such a reciprocating movement, and the tinplate 1 conveyed from the feeding assembly 2 passes through the limit The baffle 33 moves to the lower end of the screen printing mesh 32 through the screen printing platform 35, and starts the screen printing spray gun 31 to perform silk screen printing on the tinplate 1. According to the requirements of the screen printing, the variety of the screen printing mesh 32 can be changed, and the silk screen printed tinplate 1 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com