Novel finned tube machining method without rotation of workpiece

A processing method and technology of finned tubes, which are applied in the field of processing finned tubes without rotation of coiled tubes, can solve problems such as low work efficiency, bruises on the inner wall, and complicated processing processes, so as to ensure no noise, improve the forming effect, and process high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

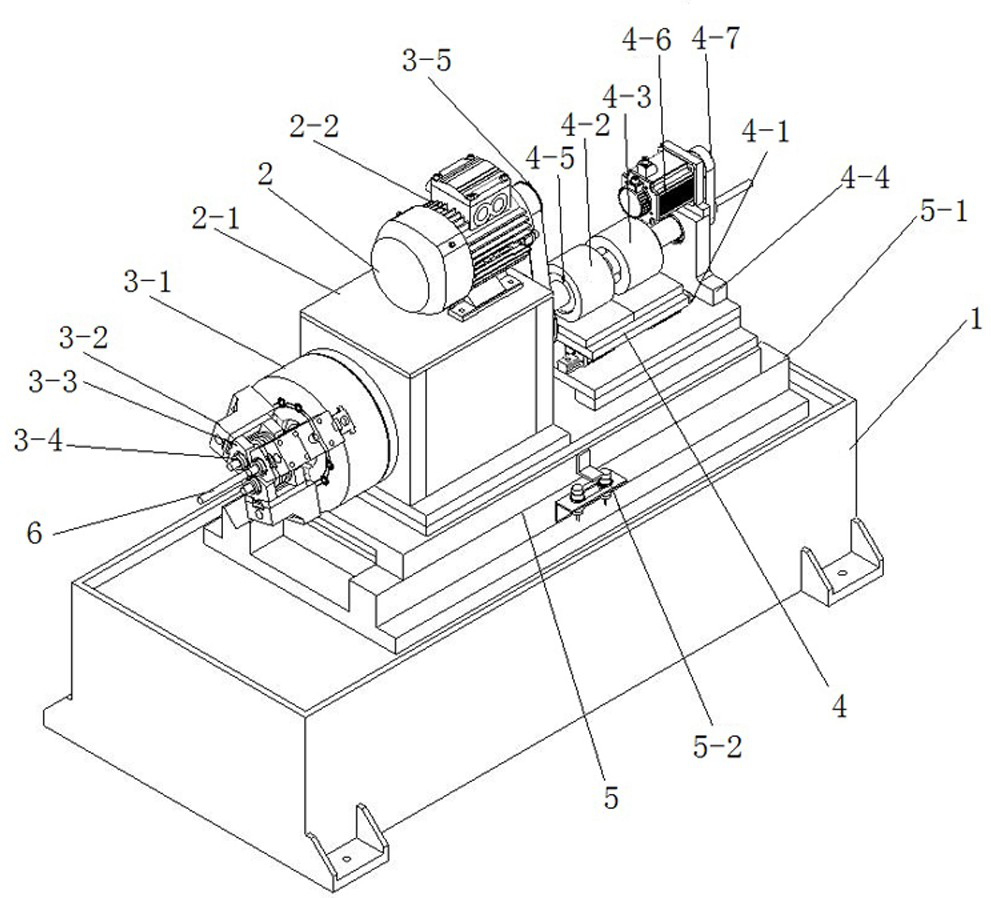

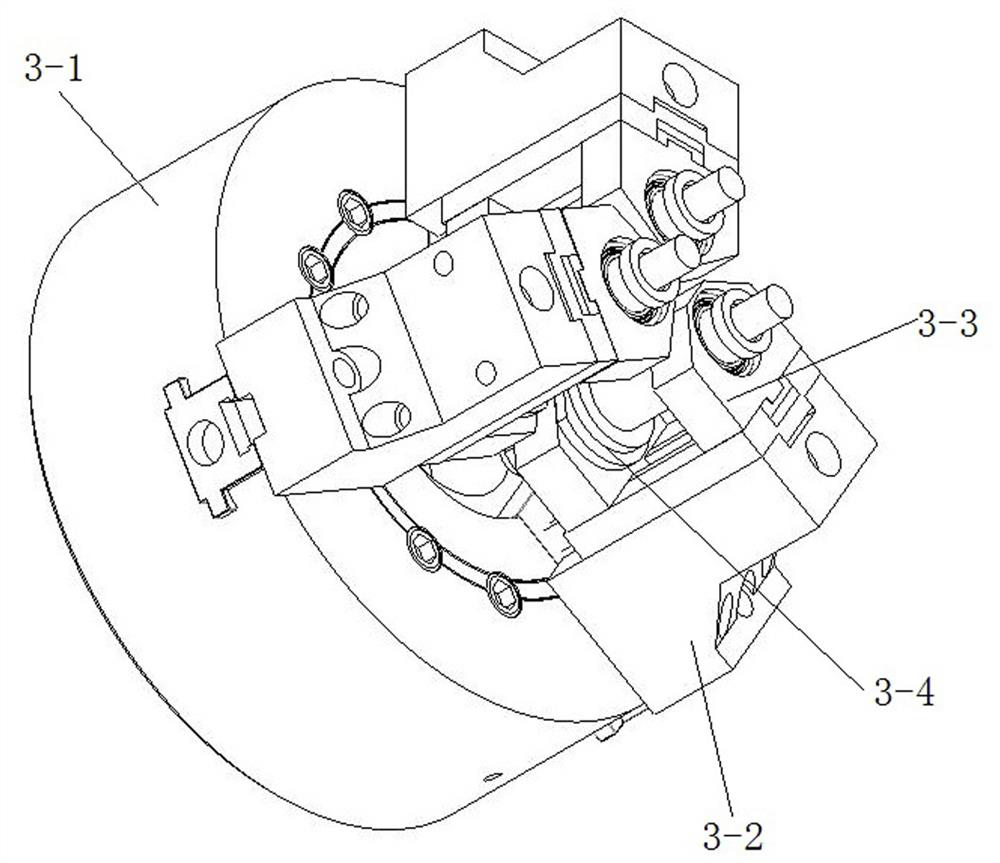

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

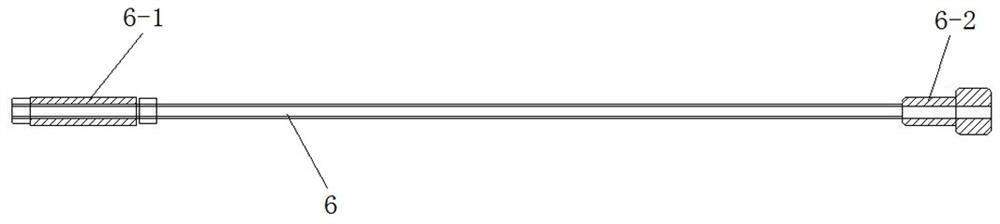

[0029] The straightening machine, chain type continuous drawing machine, fin forming mechanism, sawing trolley, etc. are arranged in sequence to form an integral fin tube production line for continuous processing of coil tubes. The novel workpiece is in particular a continuous coil of tubing.

[0030] Specifically, a novel method for processing finned tubes without rotation of workpieces of the present invention comprises the following steps,

[0031] Step 1: prefabricated coiled pipes, rolling and molding the pipe blanks to obtain prefabricated coiled pipes;

[0032] Step 2: Straightening treatment, introducing one end of the prefabricated coiled pipe into the straightening machine, and straightening the prefabricated coiled pipe through the straightening machine. The straightening machine is an existing technology;

[0033] Step 3: Continuous variab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com