Fruit picking manipulator

A technology for manipulators and fruits, which is applied in the direction of picking machines, manipulators, program-controlled manipulators, etc. It can solve the problems of small force-bearing area, fruit pinching, poor versatility of manipulators, etc., and achieve the effect of large force-bearing area and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

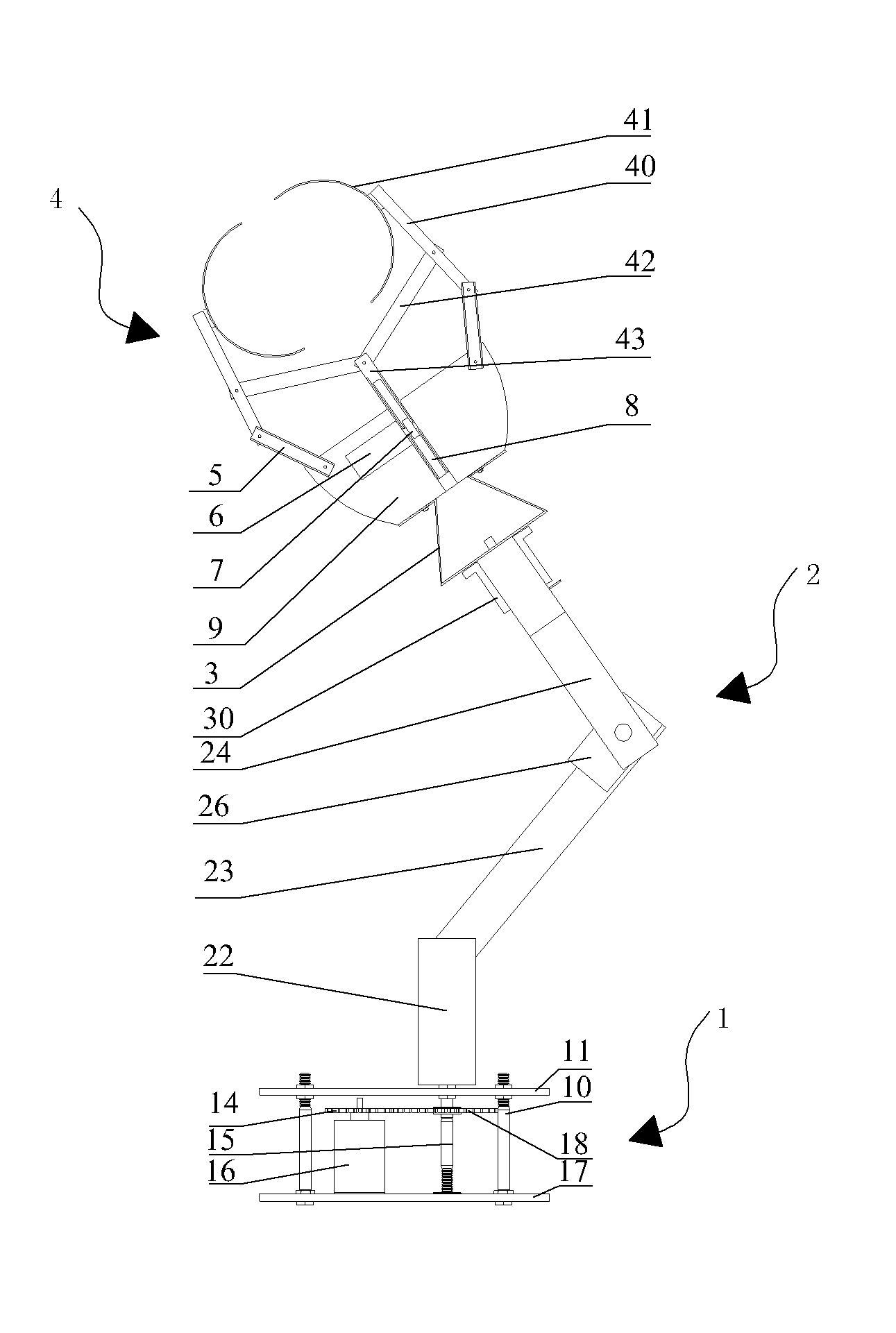

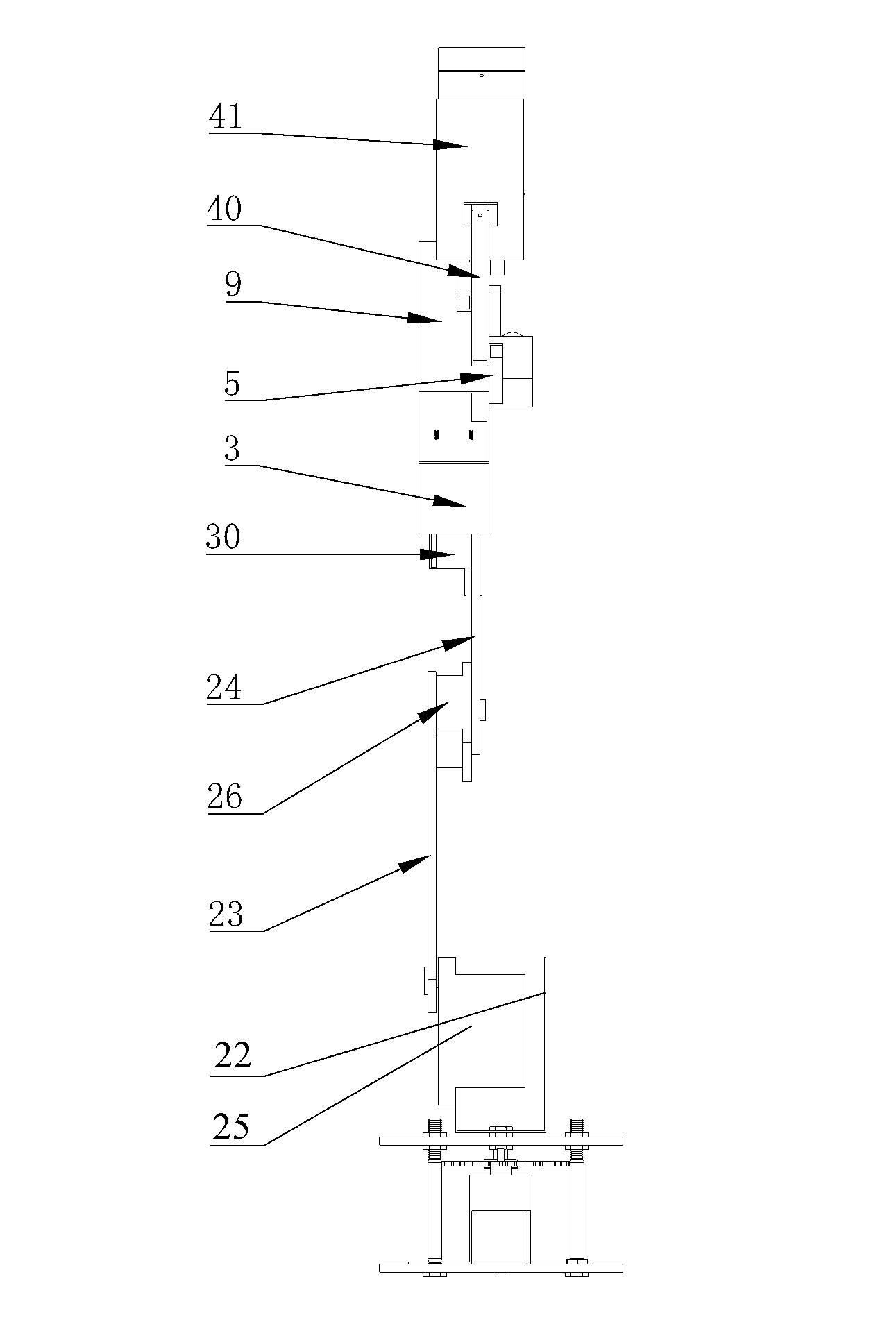

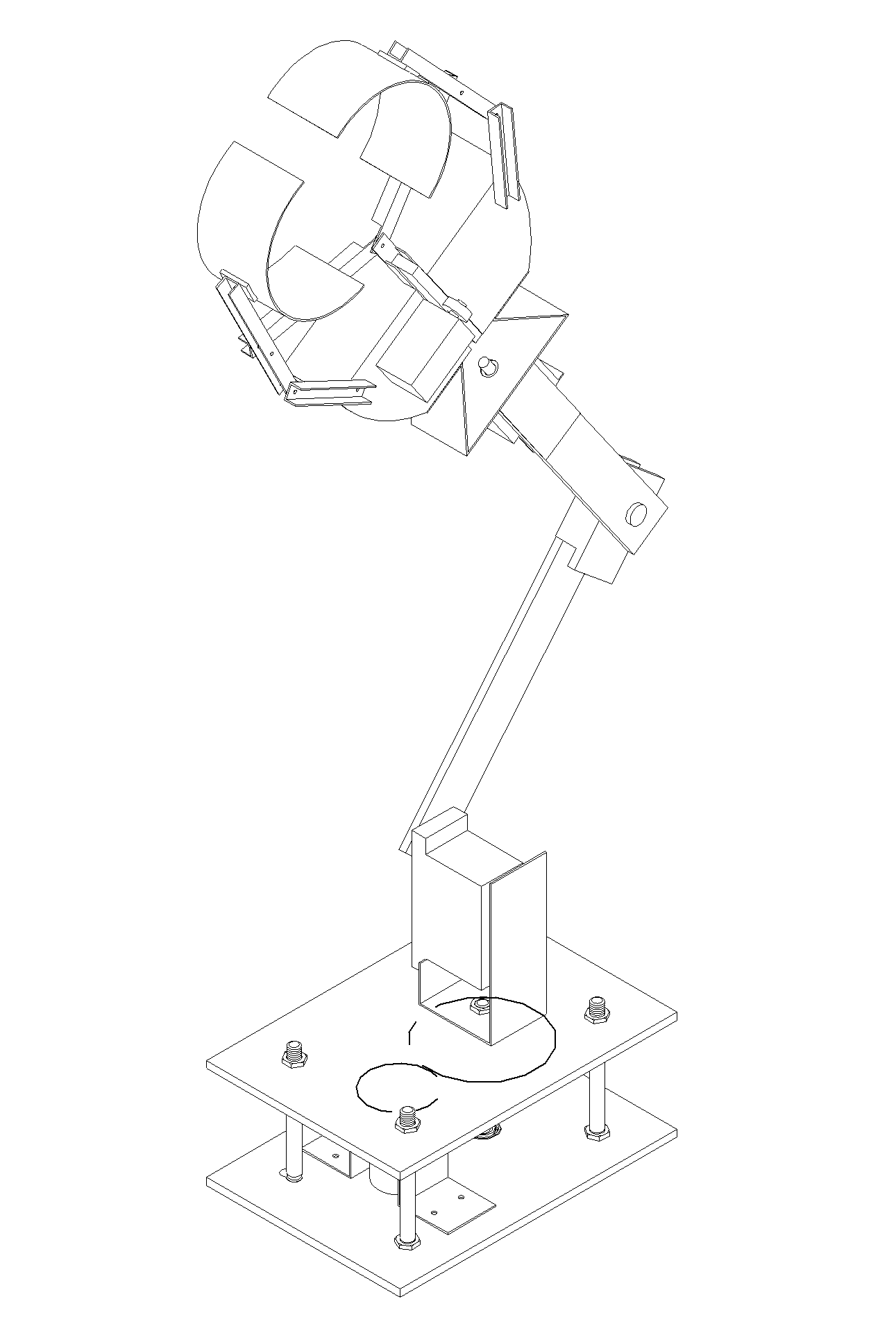

[0015] A kind of embodiment of fruit picking manipulator, as Figure 1-3 As shown, it includes base 1, arm 2, wrist 3, and hand 4. The hand 4 includes a support plate 9 arranged on the wrist 3. Finger connecting rods are respectively hinged on both sides of the front end of the support plate 9. 5. The upper ends of the finger connecting rods 5 are respectively hinged with fingers 40, and the inner sides of the front ends of the fingers 40 are respectively provided with arc-shaped splints 41 with notches facing the inside, and nylon (or rubber) is pasted on the inner wall of the arc-shaped splints 41 ), the middle part of the finger 40 is respectively hinged with a pull rod connecting rod 42, and the ends of the two pull rod connecting rods 42 are hinged with a pull rod 43 that pulls the pull rod connecting rod to drive the opening and closing of the finger 40. There is a pull rod drive mechanism that drives the pull rod 43 to move. The drive mechanism of the pull rod includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com