Use of plastic to produce automobile brake main cylinder piston and process

A technology of automobile braking and master cylinder piston, applied in the direction of piston, cylindrical piston, plunger, etc., can solve the problems of bumps, reduced machining accuracy, product failure, etc., and achieves improved service life, small friction coefficient and stable size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

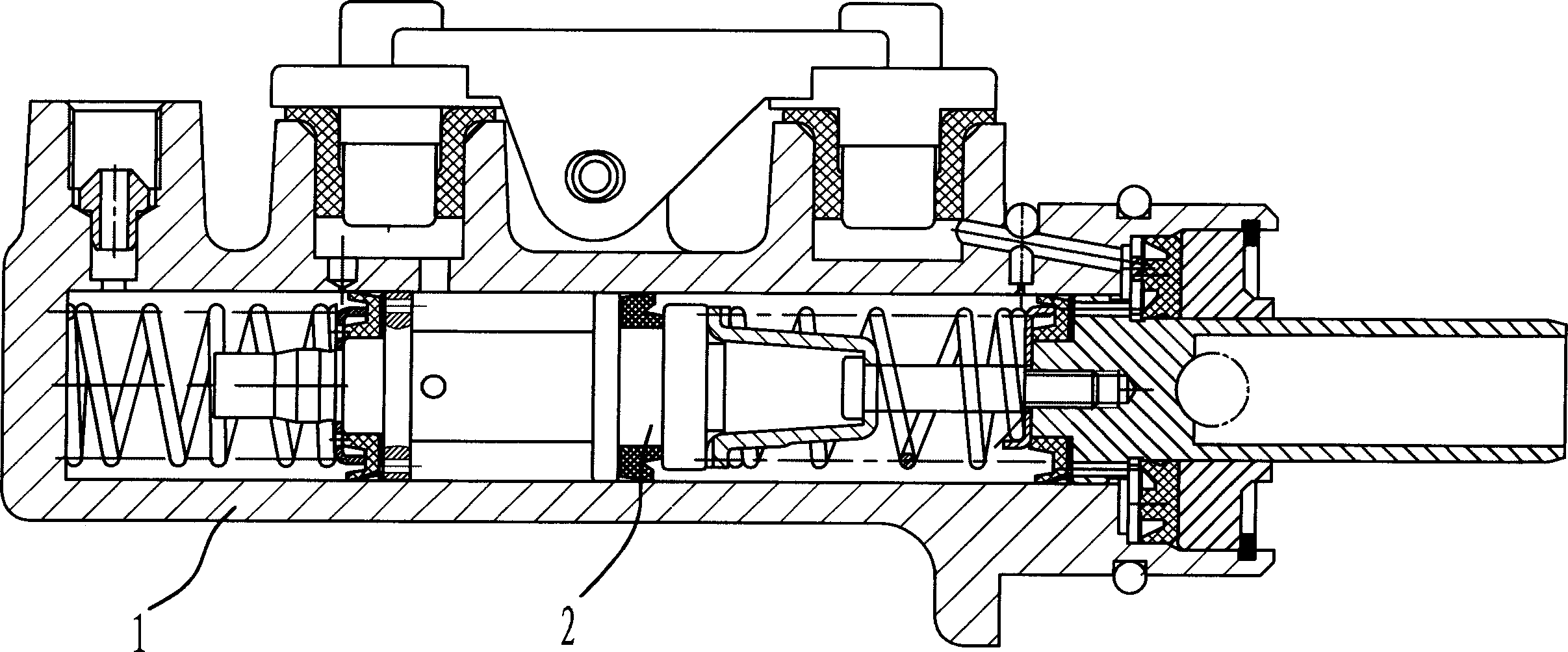

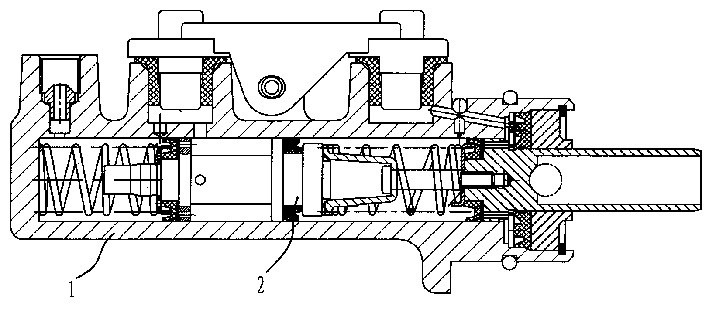

Image

Examples

Embodiment Construction

[0031] In this embodiment, PBTP plastic is used to make the piston. Mix PBTP and organic filler at a ratio of 1:0.08. The mixed raw materials were put into an oven for drying at a temperature of 102° C. for 1 hour. The drying time should also be adjusted according to the climate conditions, and the moisture content of the raw materials after drying should be below 0.2%. Put the dried raw materials into the injection machine and raise the temperature to 210°C. Injection machine for 20 seconds, high pressure for 2 seconds, cooling for 12 seconds. Then the shaped parts obtained were put into boiling water for 20 minutes. Finally, take it out and let it air dry at room temperature.

[0032] The piston made in this embodiment can be matched with various metal brake master cylinder blocks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com