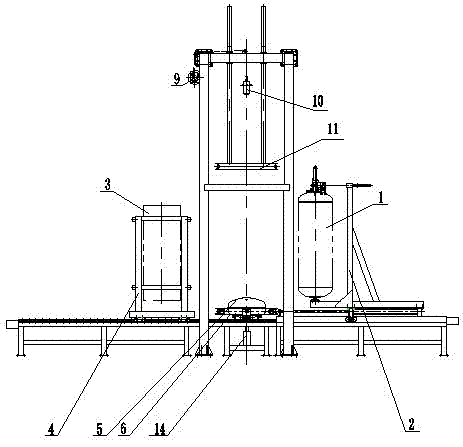

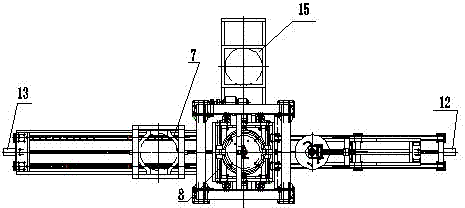

Vehicle-mounted LNG (liquefied natural gas) cylinder liner and outer cylinder sleeving device and method

A vehicle-mounted gas cylinder and outer cylinder technology, which is applied to the installation of vehicle-mounted gas cylinders and the field of vehicle-mounted gas cylinder equipment, can solve problems such as the center of the inner tank deviates from the center of the outer cylinder, the large diameter of the workpiece, and unfavorable large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] First, place the outer cylinder, lower head, upper head, and liner on each feeding mechanism, send the upper head into position, start the lifting motor, lift the upper head and inner liner down, and extend into the upper head. The tightening cylinder will tighten the upper head, the lifting motor will start to lift the upper head to the upper head holding device, the holding device will hold the upper head tightly, and the upper head and liner lifting device will loosen and separate from the upper seal Head, stepping motor screw auxiliary action, inner tank feeding inner tank feeding device feeds the inner tank, the upper head and the inner tank lifting device go down, the grasping cylinder moves to grasp the inner tank, and lifts the inner tank more than twice the height of the outer cylinder , the outer cylinder feeding device will hold the outer cylinder round, the stepping motor screw will move, the outer cylinder feeding device will feed the outer cylinder, the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com