Multi-station spraying cleaning and drying machine

A technology of spray cleaning and drying machine, which is applied in the direction of drying solid materials, drying solid materials without heating, drying, etc., to achieve the effect of improving cleaning and drying efficiency, reducing failure rate, and no bump damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

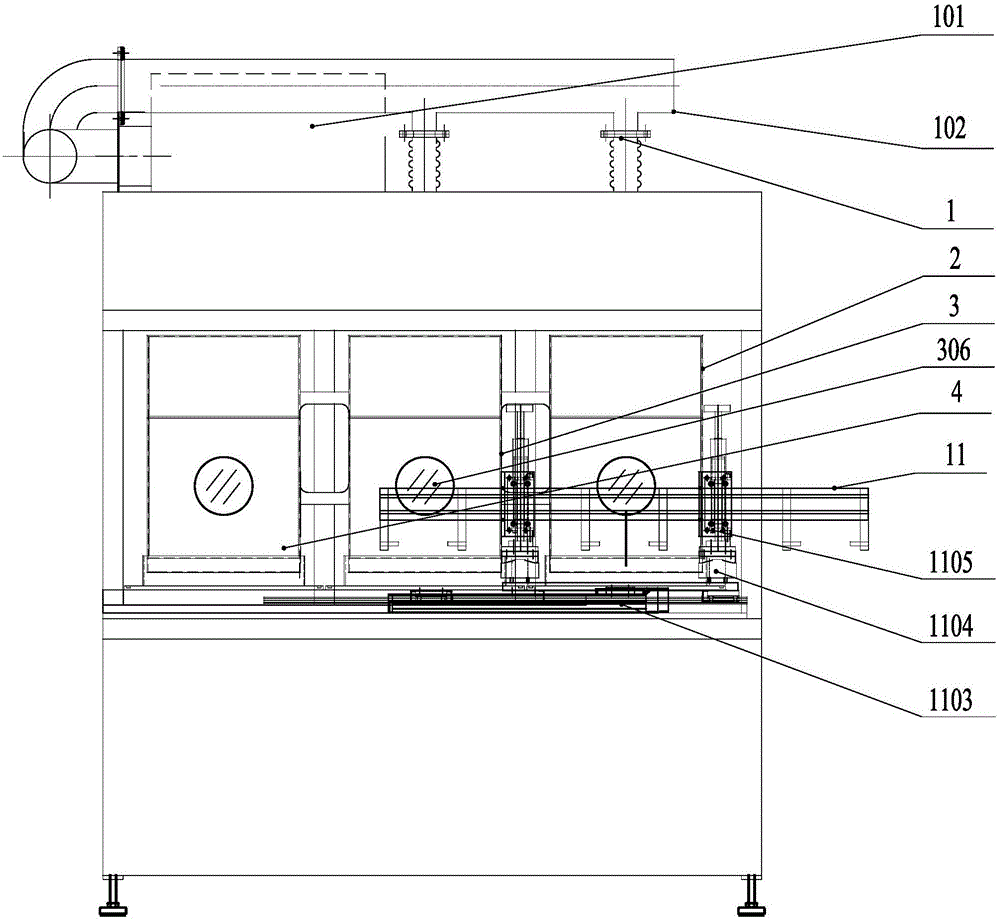

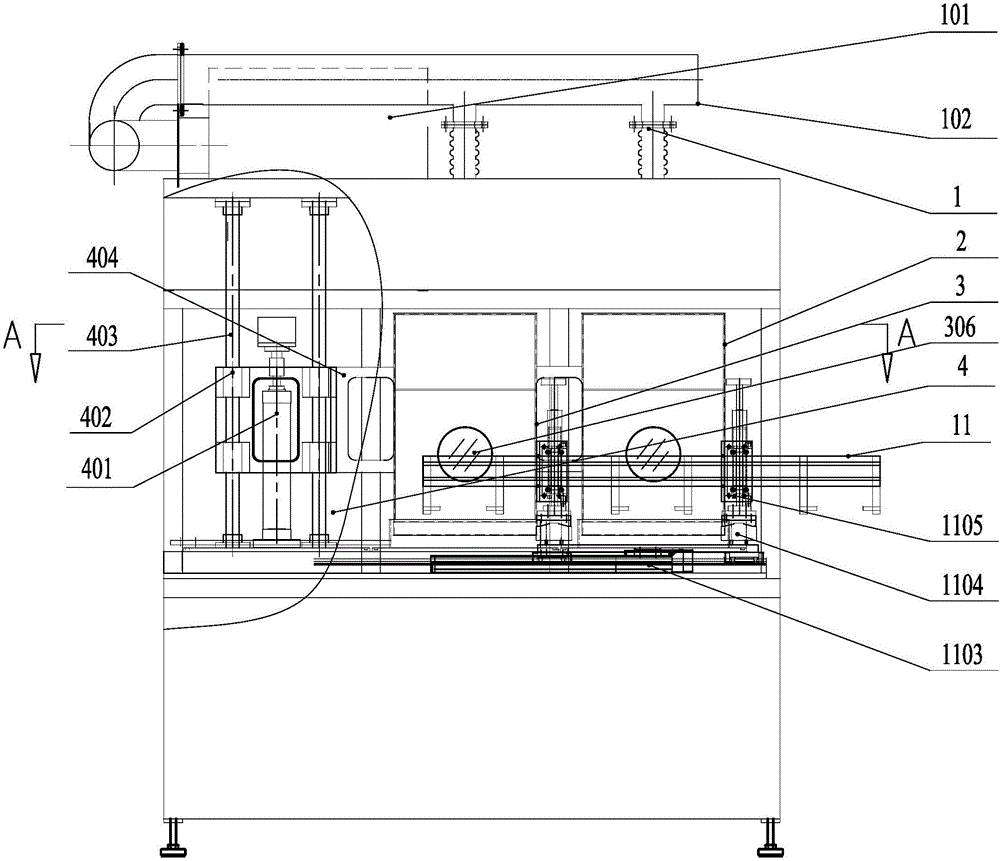

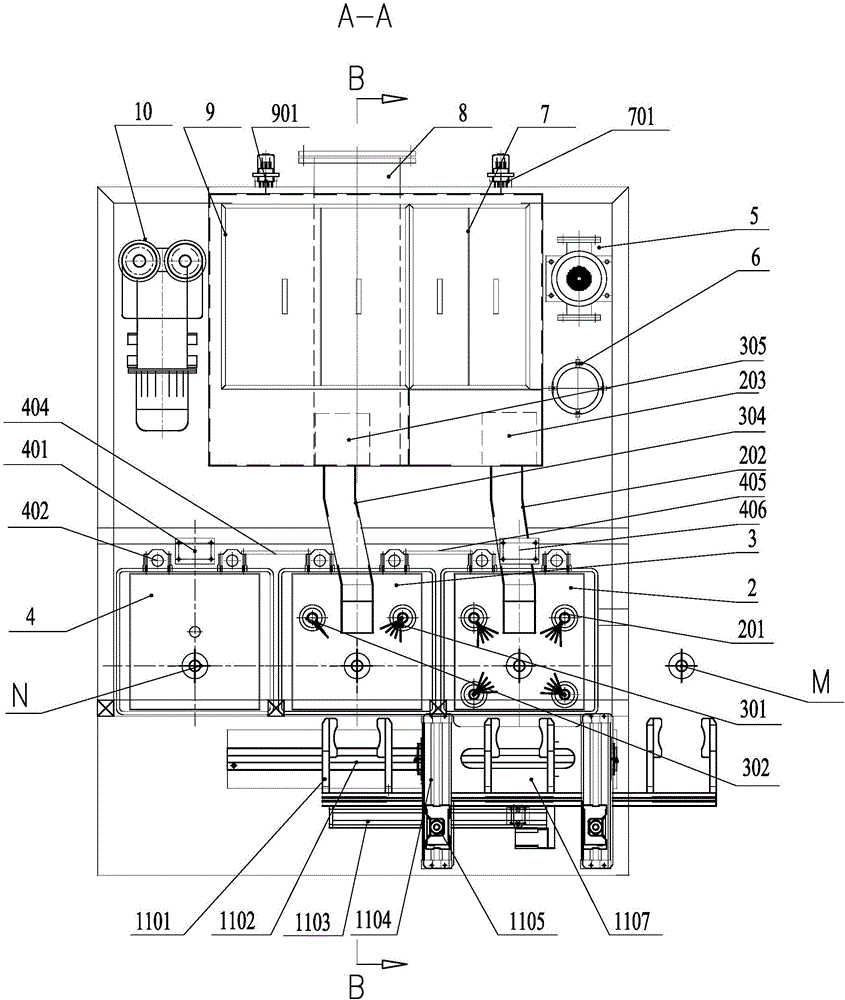

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] Figure 1~5 Among them, it includes a mist suction device 1, a mist suction fan 101, a mist suction pipeline 102, a fixed-point positioning spray cleaning chamber 2, a first spray pipeline 201, a first return pipeline 202, a rotary rinsing wind shear chamber 3, a second Two spray pipelines 301, wind shear pipeline 302, rotating mechanism 303, motor 303a, transmission belt 303b, rotating shaft 303c, second return pipeline 304, second filter basket 305, observation window 306, upper casing 307, vacuum Drying chamber 4, first cylinder 401, linear bearing 402, optical axis 403, second connecting plate 404, first connecting plate 405, second cylinder 406, spray pump 5, filter 6, cleaning liquid storage tank 7, the second A heater 701, a pressure tank 8, a rinse tank 9, a second heater 901, a vacuum pump 10, a mechanical arm 11, a manipula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com