Rotary station-changing type mechanical part cleaning and drying device

A technology for mechanical accessories and drying devices, applied in drying, drying machines, heating devices, etc., can solve the problems of manpower waste, reduce cleaning effect, and difficult to clean accessories, so as to reduce labor costs and improve cleaning The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

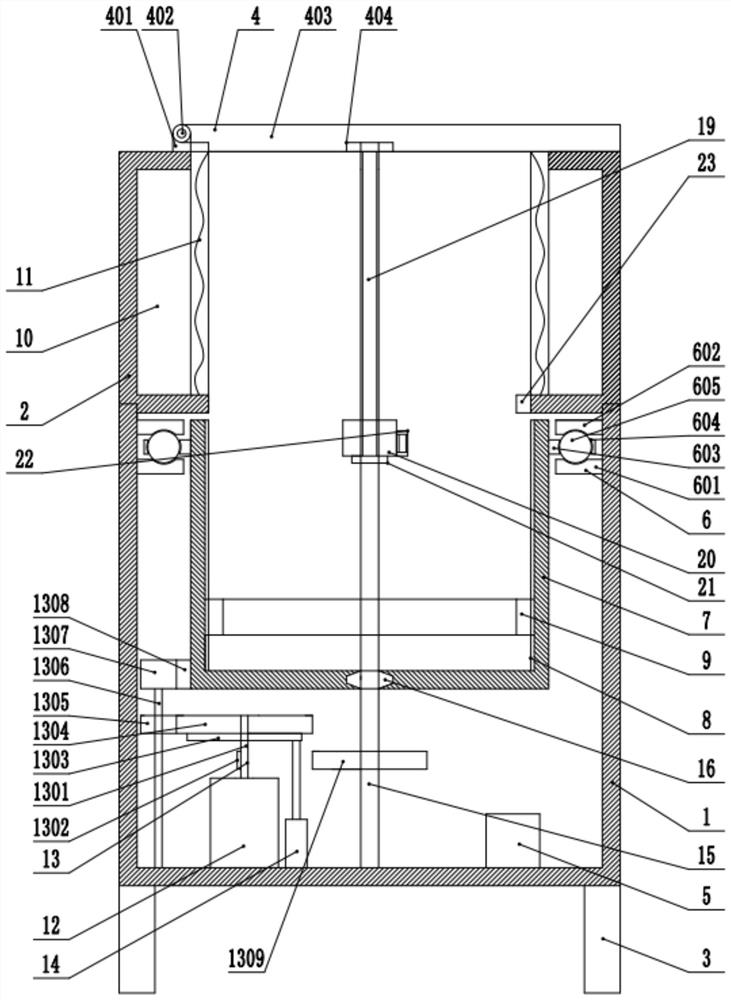

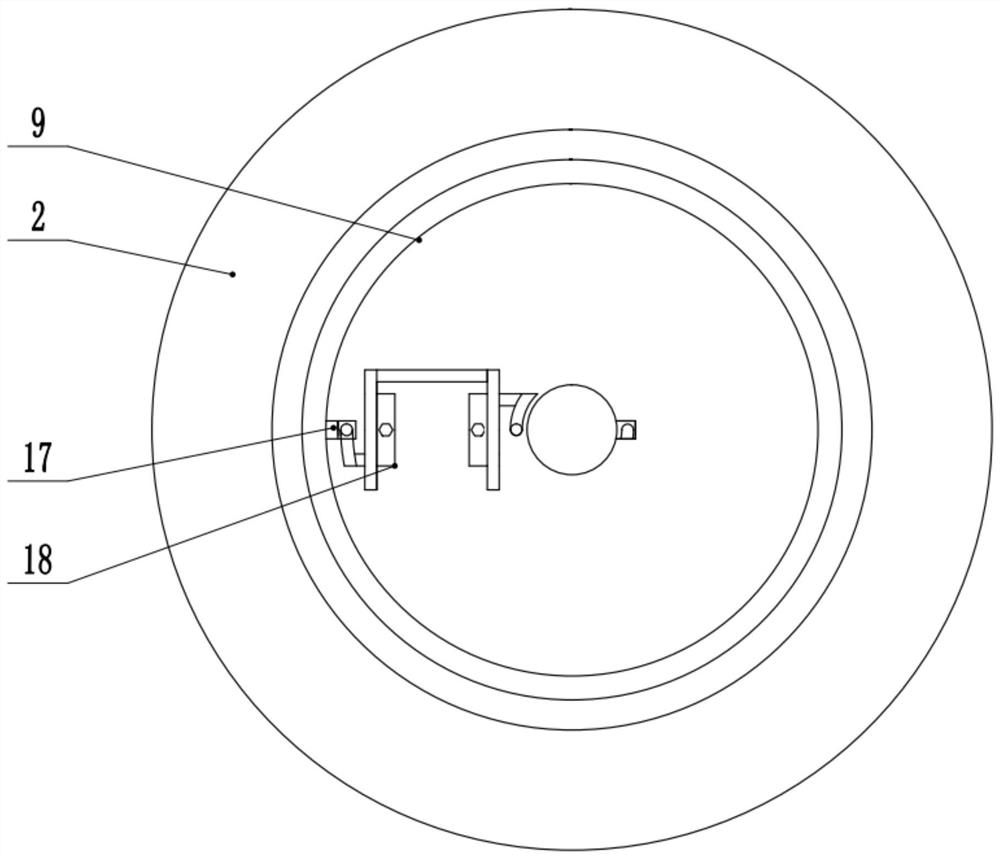

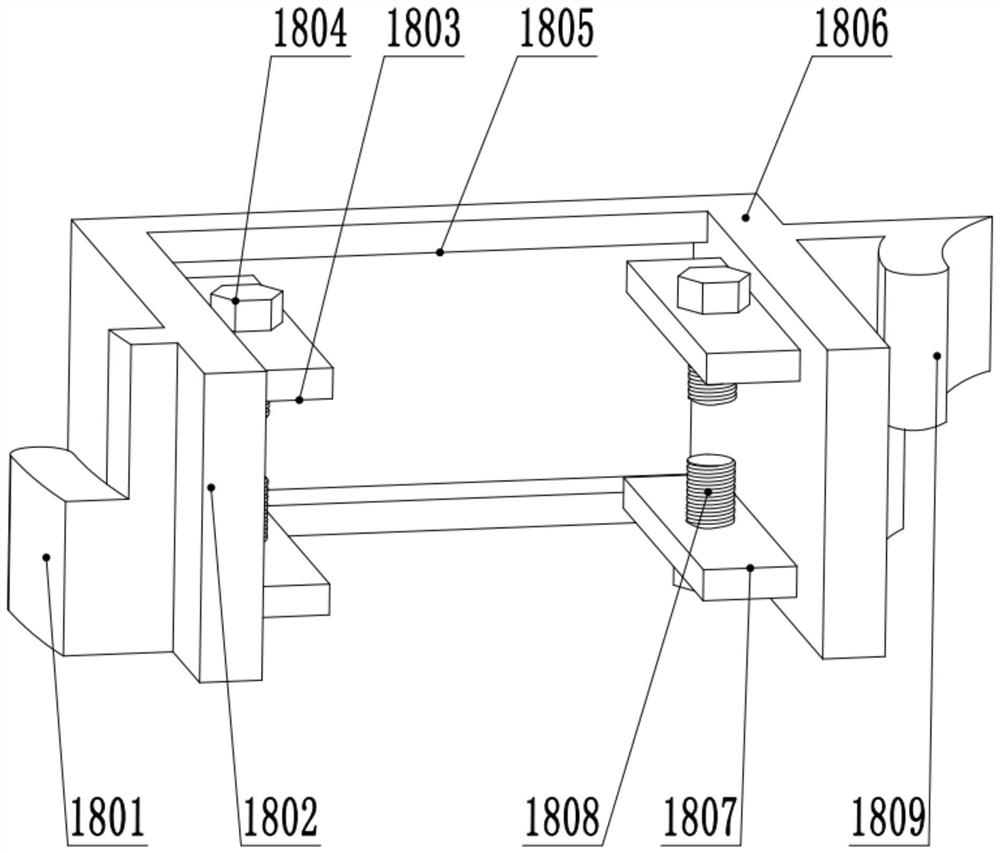

[0024] See Figure 1-5 , A rotary displacement type cleaning and drying device for mechanical parts, comprising a lower box body 1, including a lower box body 1, an upper box body 2 is provided on the upper part of the lower box body 1, and the lower surface of the lower box body 2 is fixedly connected with a supporting leg 3, The upper surface of the upper box 2 is fixedly connected with the cover mechanism 4, the bottom of the lower box 2 is fixedly connected with the controller 5, the inner wall of the lower box 1 is fixedly connected with four rotating mechanisms 6, and the rotating mechanism 6 is fixedly connected with the cleaning box 7, the cleaning box 7. The inner wall is fixedly connected with an internal threaded sleeve 8, the internally threaded sleeve 8 is threadedly connected with a threaded ring 9, and the inner wall of the threaded ring 9 is fixedly connected with an outer mounting seat 17, the outer mounting seat 17 is provided with a clamping mechanism 18, and ...

Embodiment 2

[0029] See Figure 1-5 The other content of this embodiment is the same as that of Embodiment 1, except that the bottom of the cleaning tank 7 is located outside the climbing shaft 15 and the sealing ring 16 is embedded.

[0030] The cover mechanism 4 includes a rotating shaft seat 401, the rotating shaft seat 401 is rotatably connected to the rotating shaft 402, the rotating shaft 402 is fixedly connected to the cover plate 403, and the bottom of the cover plate 403 is fixedly connected to the bearing 404.

[0031] During the implementation of the present invention, the accessories are first fixedly connected to the clamping mechanism 18. At this time, the controller 5 controls the first electromagnet 1703 to work, and the clamping mechanism 18 is firmly fixed on the outer mounting seat 17, and then the cleaning The tank 7 is filled with cleaning liquid, and the servo motor 12 is turned on. The servo motor 12 drives the cleaning tank 7 to rotate through the transmission mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com