Rice processing, cleaning and drying integrated equipment

A rice processing and integrated technology, applied in the direction of lighting and heating equipment, drying, drying machine, etc., can solve the problems affecting the efficiency of rice production and processing, and achieve the effect of fast cleaning and drying, convenient removal and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

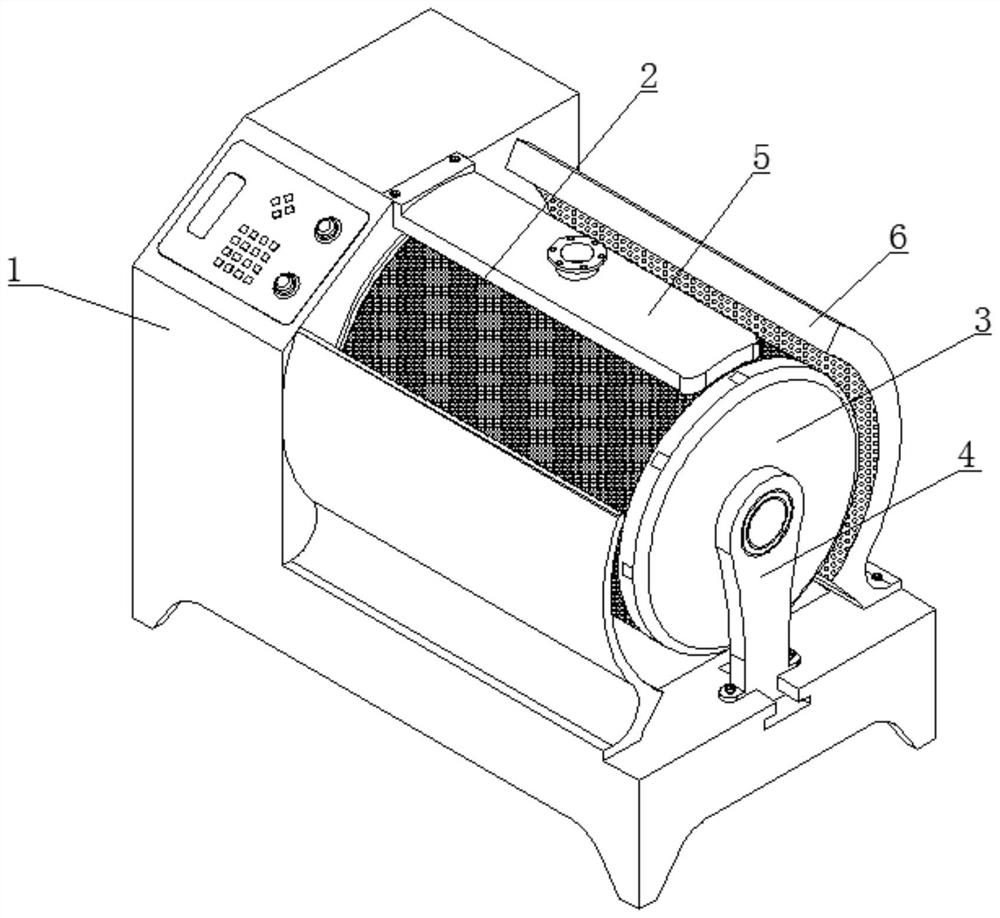

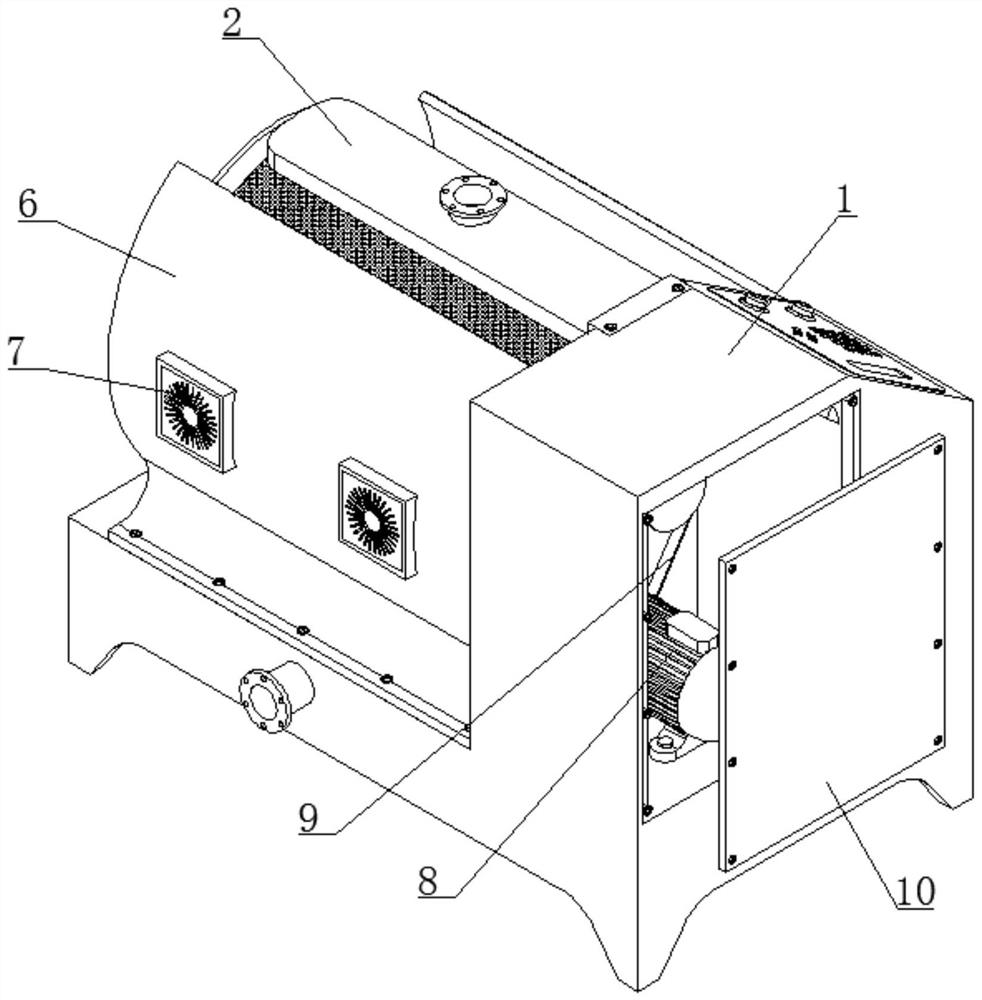

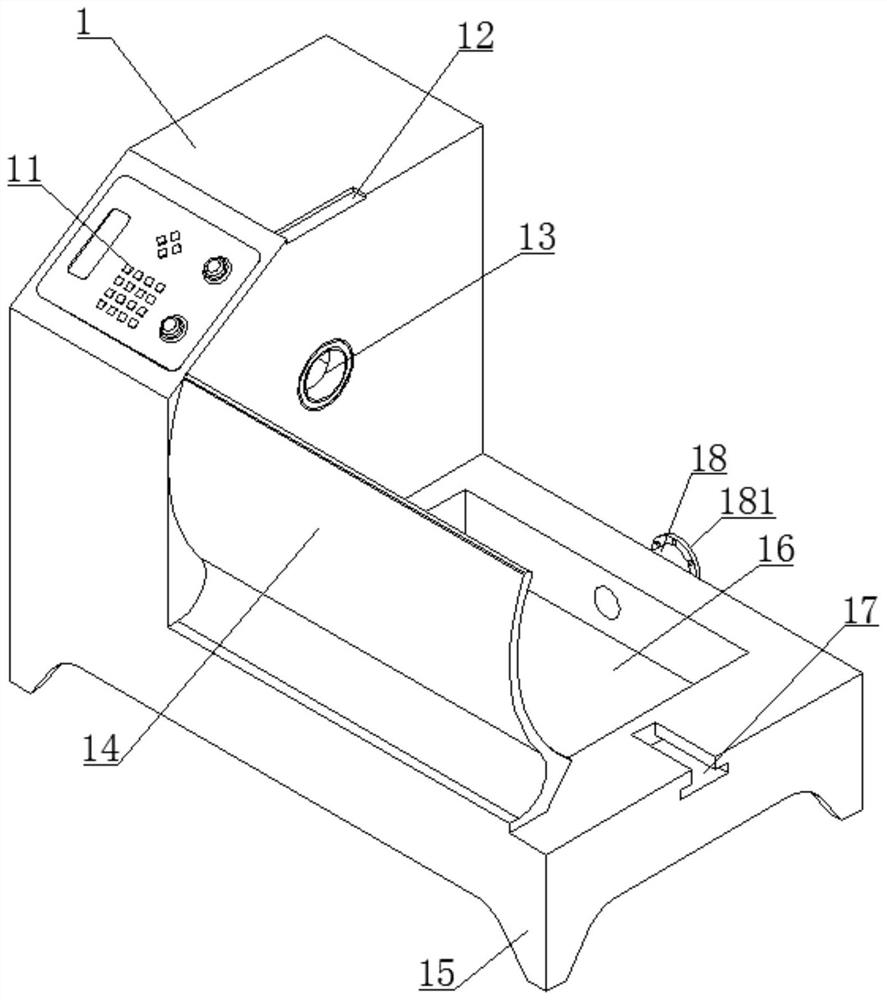

[0029] Example: refer to figure 1 and figure 2Shown: a rice processing, cleaning and drying integrated equipment, including a body 1, a drum 2 is provided on one side of the body 1, and a cover plate 3 is provided at one end of the drum 2 that is not connected to the body 1, and the end of the cover plate 3 facing the outside is provided. There is a support head 4, the cover plate 3 and the support head 4 are connected together, the top of the body 1 is provided with a water guide plate 5 along the top of the drum 2, the water guide plate 5 and the body 1 are connected together by bolts, and the body 1 is aligned with the drum 2. The position of the rear end is provided with a dryer 6, the back of the dryer 6 is symmetrically provided with two fans 7, the dryer 6 and the body 1 are connected together by bolts, the body 1 is provided with a motor 8, and the output end of the motor 8 is The end of the drum 2 inserted into the body 1 is connected together by the belt 9, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com