Combination device for testing large current aging and vacuum degree of a vacuum arc extinguish chamber

A technology of vacuum interrupter and combination device, which is applied in the direction of high-voltage/high-current switches, circuits, electric switches, etc., can solve the problems of low production efficiency, high labor intensity of operators, and long operation time, so as to improve production efficiency, Effect of reducing labor intensity and working time, reducing labor intensity and working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

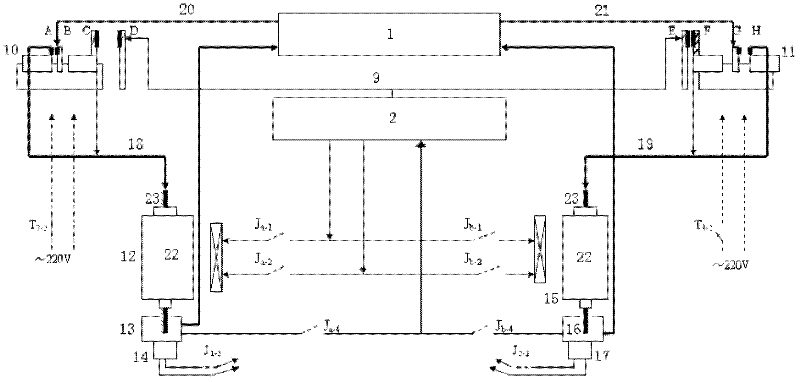

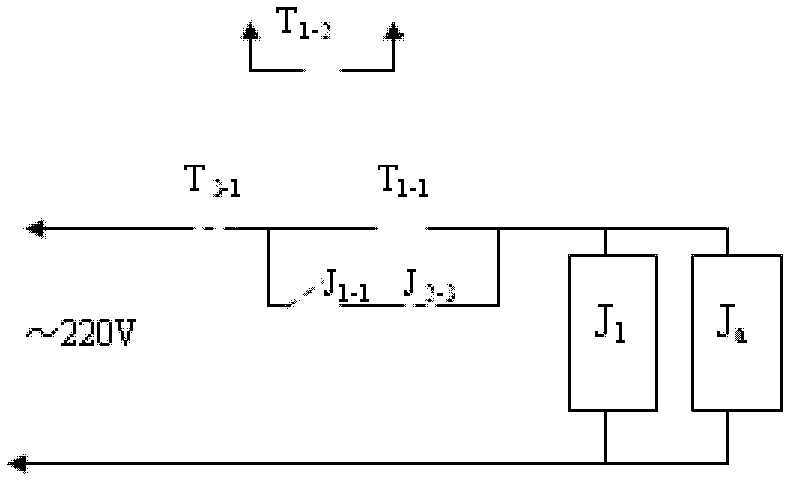

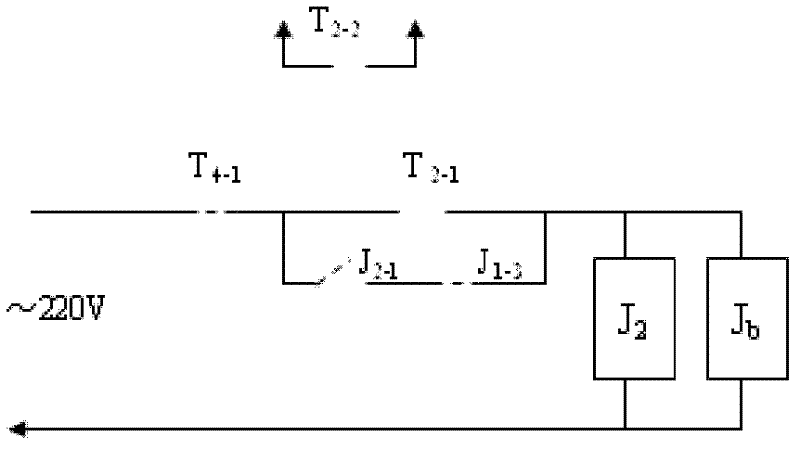

[0034] Example 1. Such as figure 1 As shown, it includes a high-current aging platform 1 and a magnetron vacuum gauge 2, with two stations, namely figure 1 No. 1 station 12 and No. 2 station 15 in. The aging switch of aging table 1 is respectively connected to No. 1 conversion cylinder 10 and No. 2 conversion cylinder 11, and the pneumatic switch of aging table 1 is respectively connected to clamping cylinder 13 and pull-down cylinder 14 of No. 1 station 12 and No. 2 station Clamping cylinder 16 and pull-down cylinder 17 of 15; A pair of conductive blocks A, B and another pair of conductive blocks C, D are housed on the No. 1 conversion cylinder 10, and a pair of conductive blocks E, F and D are housed on the No. 2 conversion cylinder 11. Another pair of conductive blocks G and H; conductive blocks A and C are connected to the aging clip line 18 of the first station 12, conductive blocks H and F are connected to the aging clip line 19 of the second station 15, and the conduc...

Embodiment 2

[0037] Example 2. Such as Figure 4As shown, it includes a high-current aging table 1 and a magnetron vacuum gauge 2. There is only one station 3, and a clamping cylinder 4 and a pull-down cylinder 5 are installed on the station 3. The aging switch of the aging table 1 is connected to the transfer cylinder 6, and the pneumatic switch of the aging table 1 is connected to the clamping cylinder 4 and the pull-down cylinder 5; a pair of conductive blocks A, B and another pair of conductive blocks C, D, conductive block A is connected to aging clip line 7, conductive block B is connected to aging table 1 through aging line 8, conductive block C is connected to aging clip line 7, conductive block D is connected to vacuum gauge 2 through high-voltage line 9; Gauge 2 respectively with AC contactor J a contact J a-1 , contact J a-2 and contact J a-4 connected. The burn-in switch adopts a self-locking switch with multiple sets of contacts, and the normally open contact T of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com