Patents

Literature

86results about How to "High purification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing sodium copper chlorophyllin through supercritical purification

ActiveCN103965205AQuality improvementHigh selectivityOrganic chemistryNatural dyesChlorophyll derivativesSupercritical carbon dioxide

The invention belongs to the technical field of production of sodium copper chlorophyllin and in particular relates to a method for producing sodium copper chlorophyllin through supercritical purification. The method for producing sodium copper chlorophyllin through supercritical purification comprises the following steps: (1) saponifying; (2) washing; (3) copperizing; and (4) purifying, namely purifying copperized chlorophyll by adopting supercritical carbon dioxide; and (5) obtaining the finished product. According to the method, the copperized chlorophyll is purified by adopting a supercritical technology, the particularity of a molecular structure of chlorophyll derivatives is overcome, and the yield of the copperized chlorophyll is greatly improved, so that the process of producing the sodium copper chlorophyllin is efficient and friendly to the environment.

Owner:SHANDONG GUANGTONGBAO PHARMA

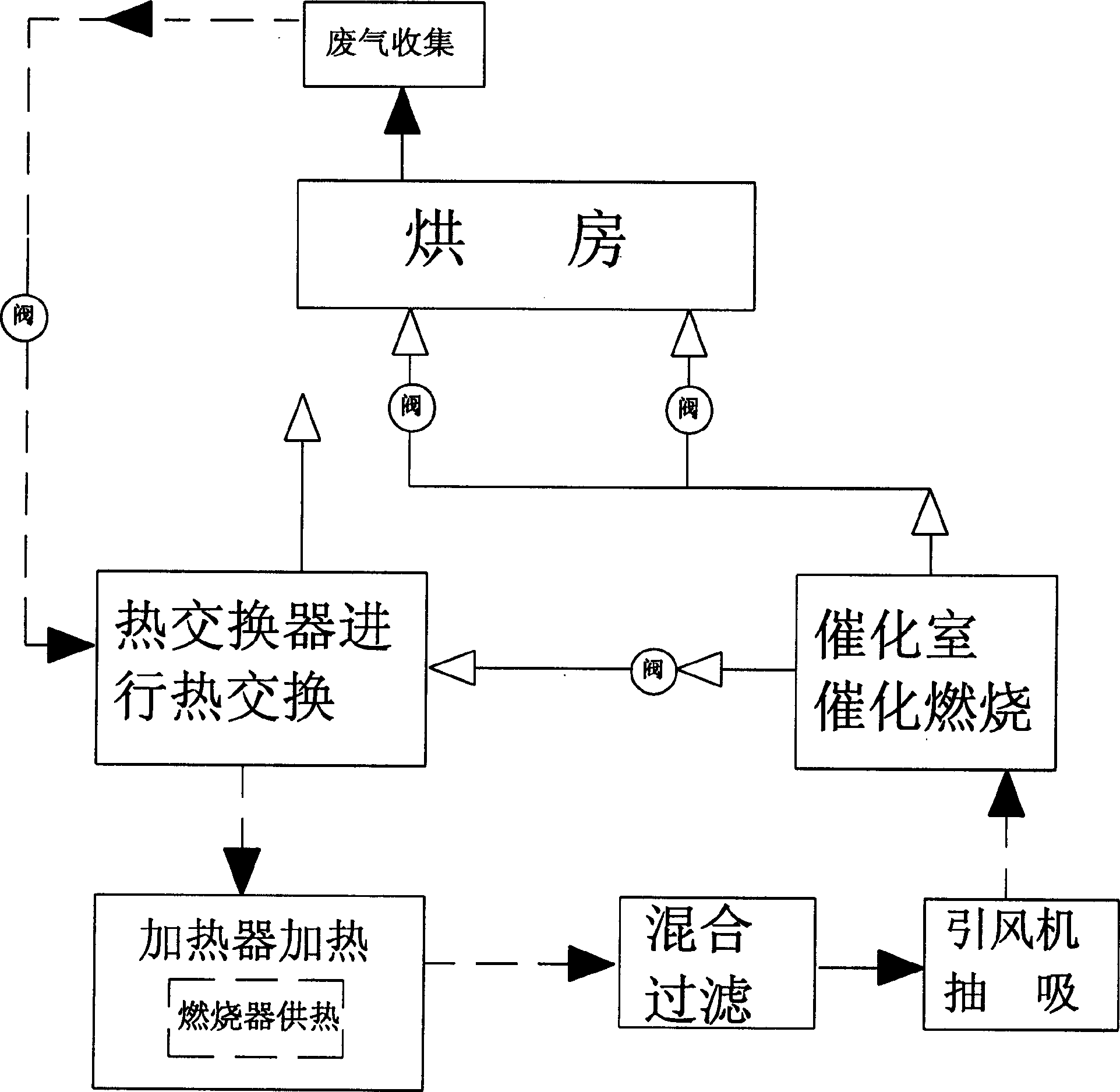

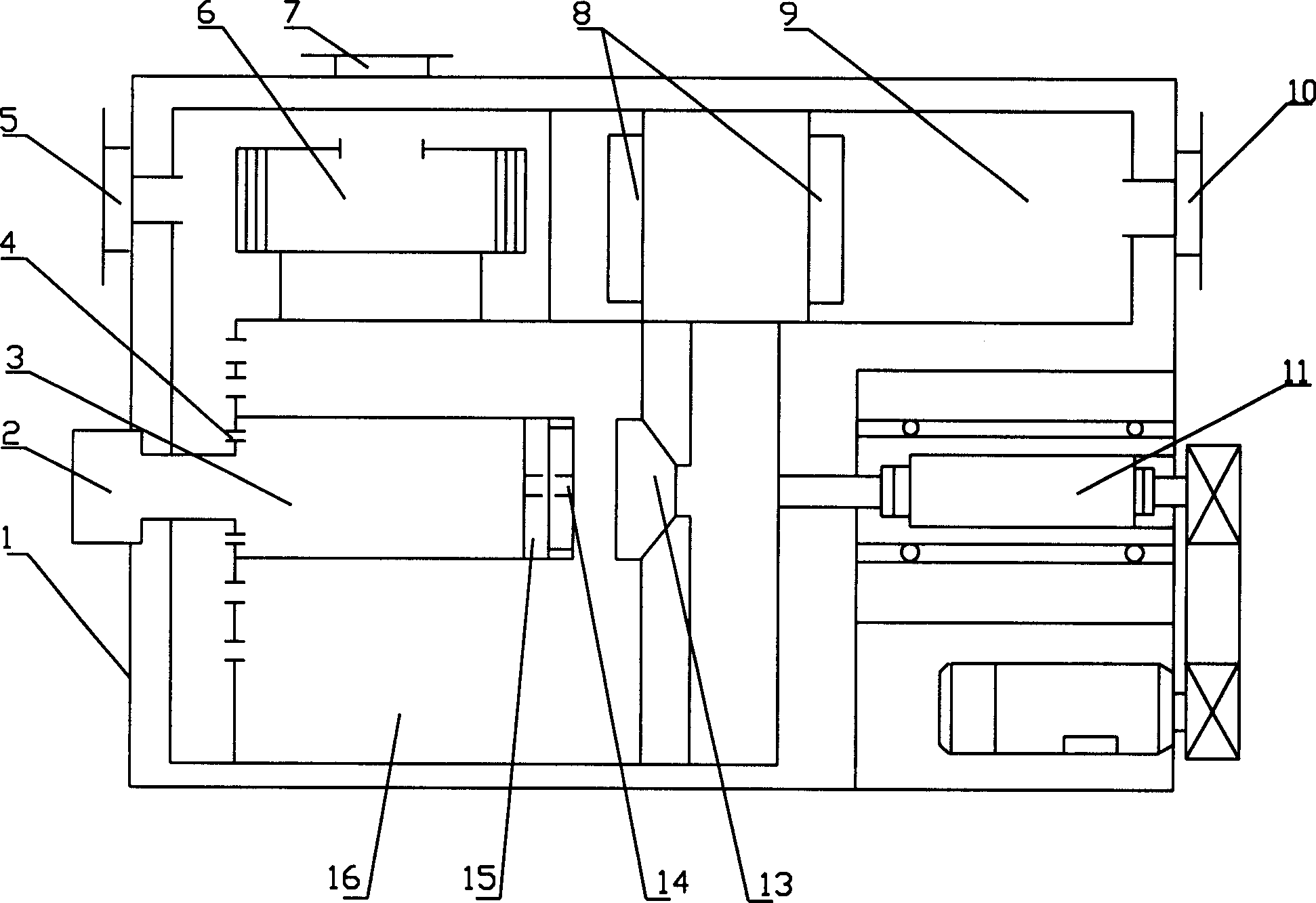

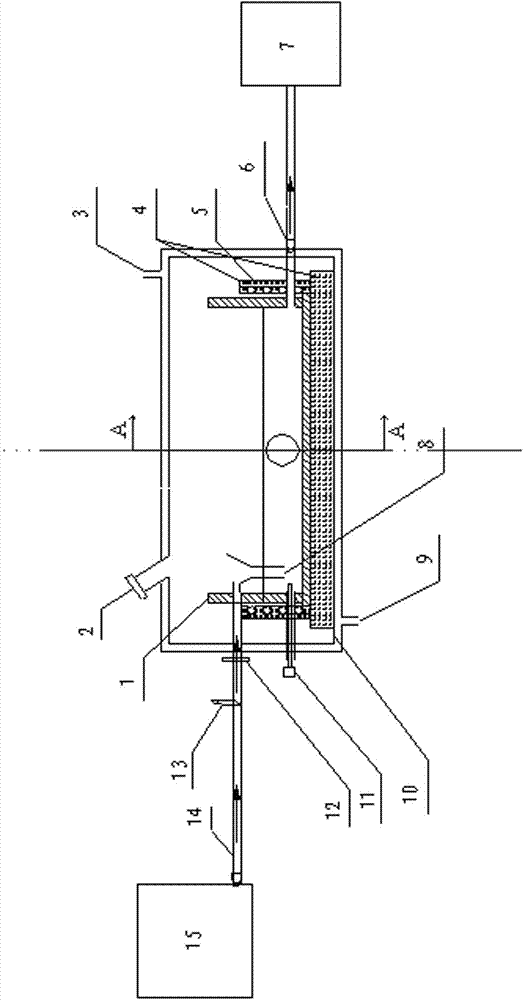

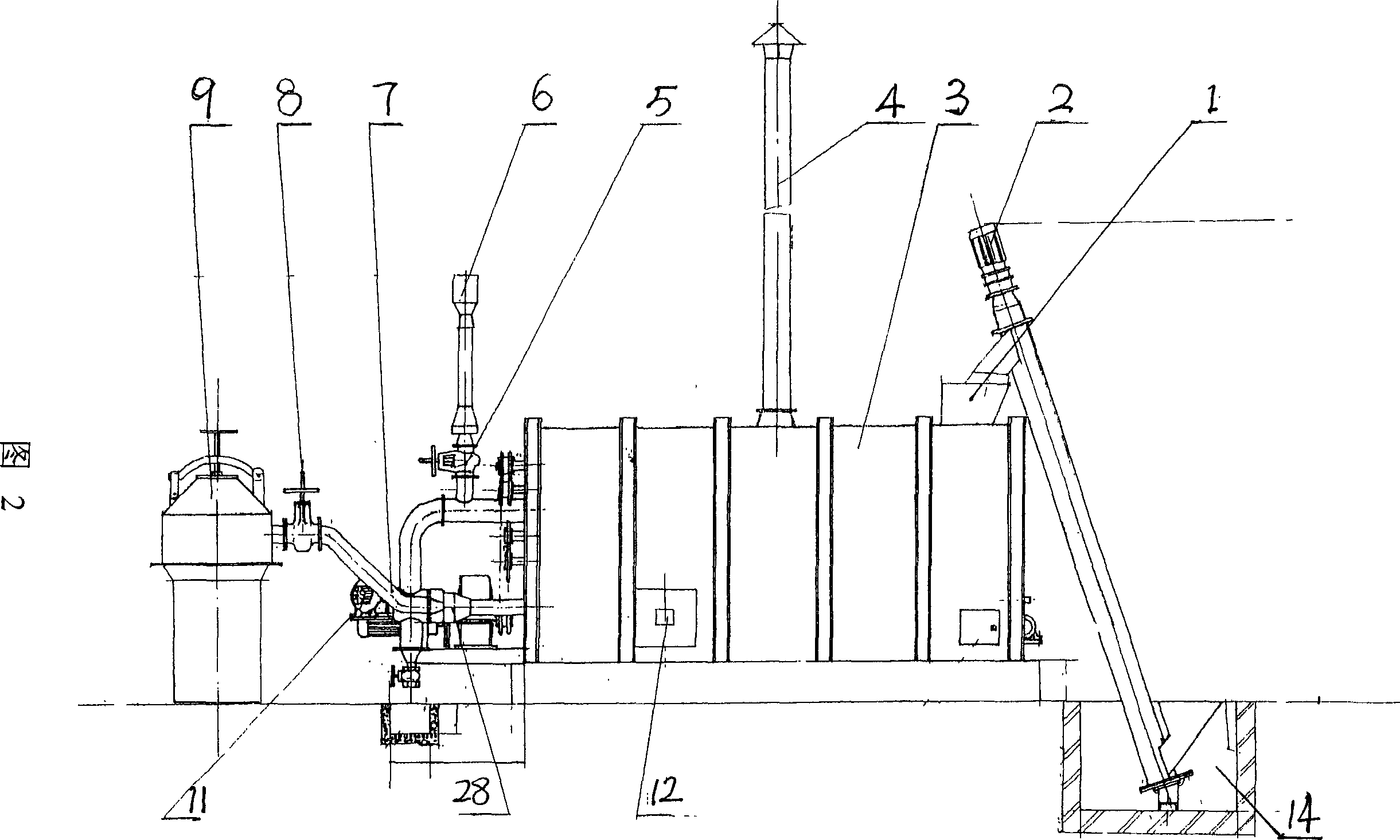

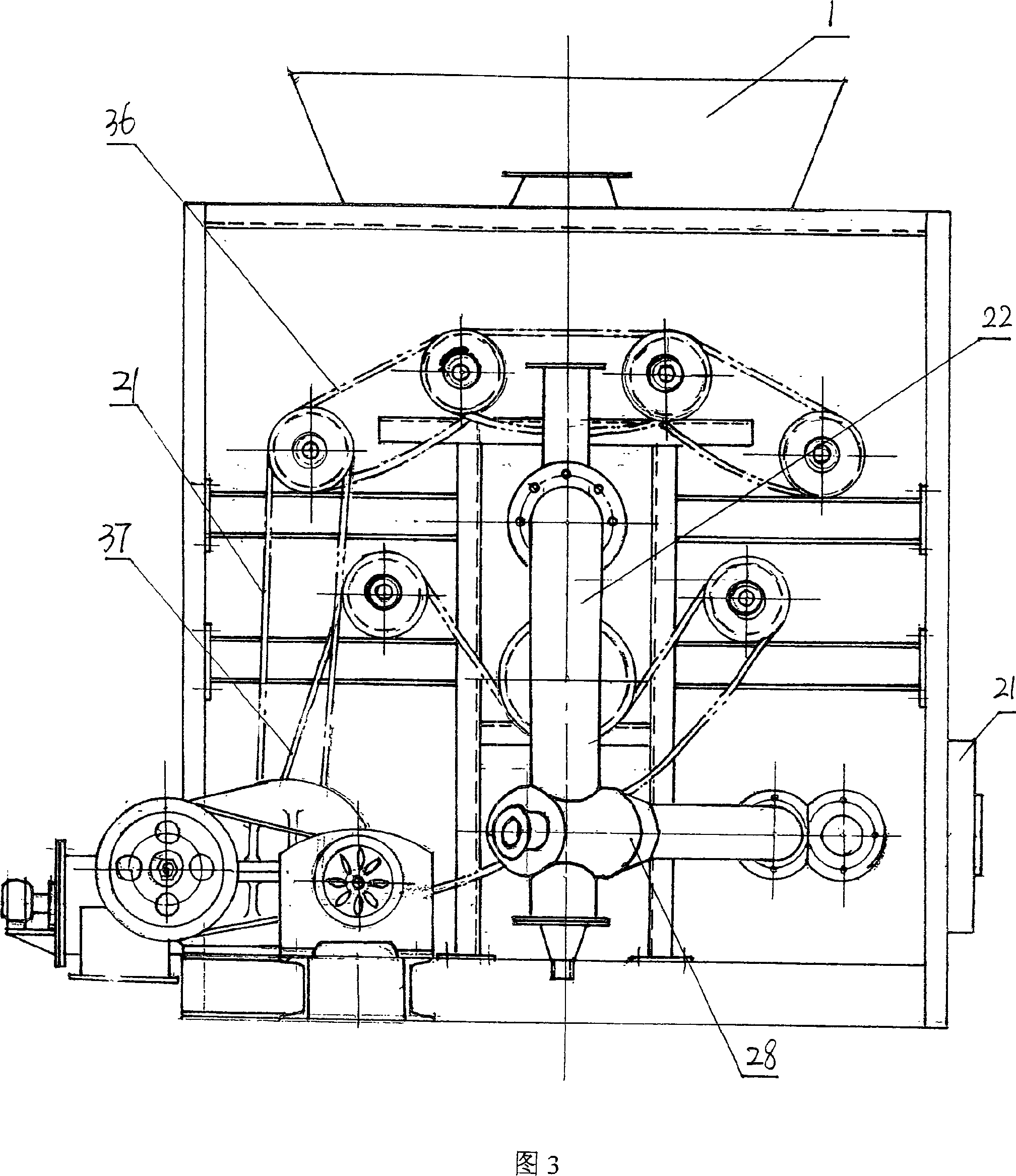

Drying room exhaust gas purification and energy recovery system and apparatus

InactiveCN1546211AHigh purification rateImprove purification rateDispersed particle separationProduct gasProcess engineering

The invention discloses a system and device for drying room waste gas processing and energy reclaiming, it uses circular system to combine heat conversion, heating and catalyzing combustion together, which includes: (1) the waste gas discharged form the drying room is preheated in the heat converter; (2) the preheated gas is heated in the heating room; (3) the waste gas is filtered and extracted into the catalyst room to be carried on catalyzing combustion; (4) the purified gas provides heat in the drying room; the residue gas enters the heat converter and provides heat for the waste gas and then they are discharged off. The structure is compact, the space if small, the assembly is convenient; the heat energy utilization efficiency is high.

Owner:杭州天人环保设备有限公司

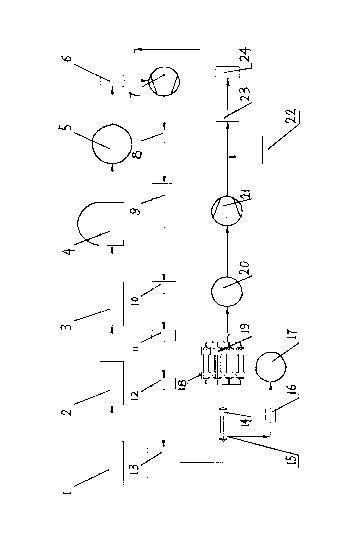

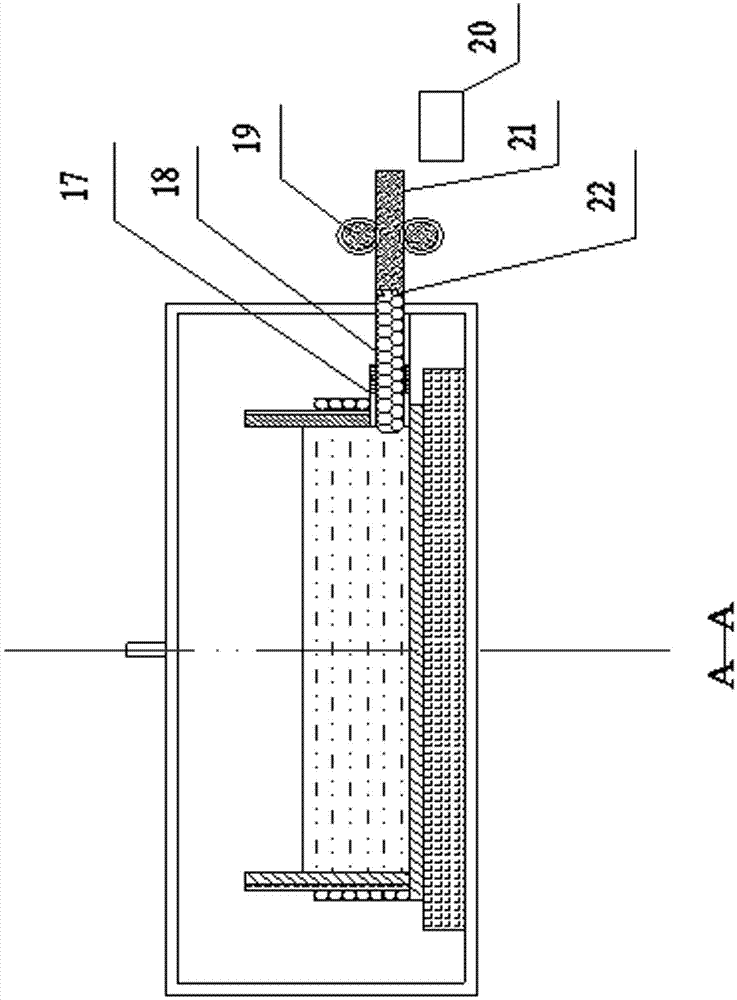

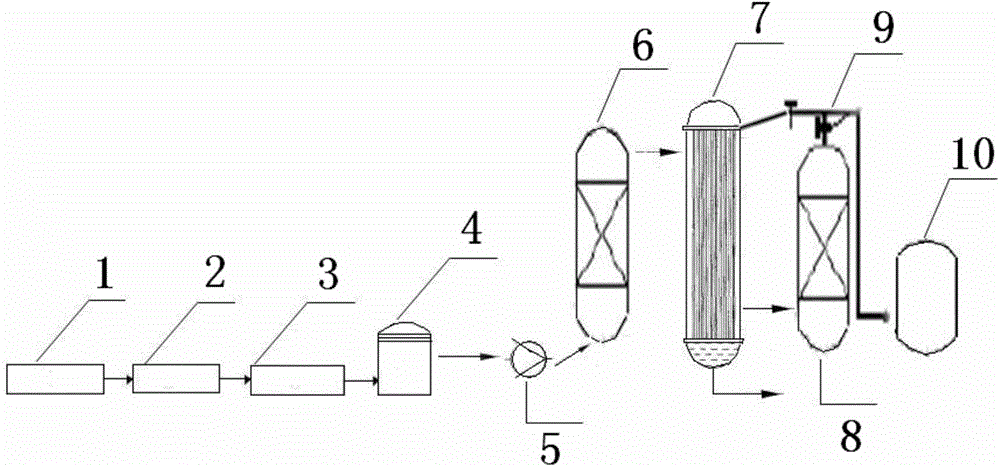

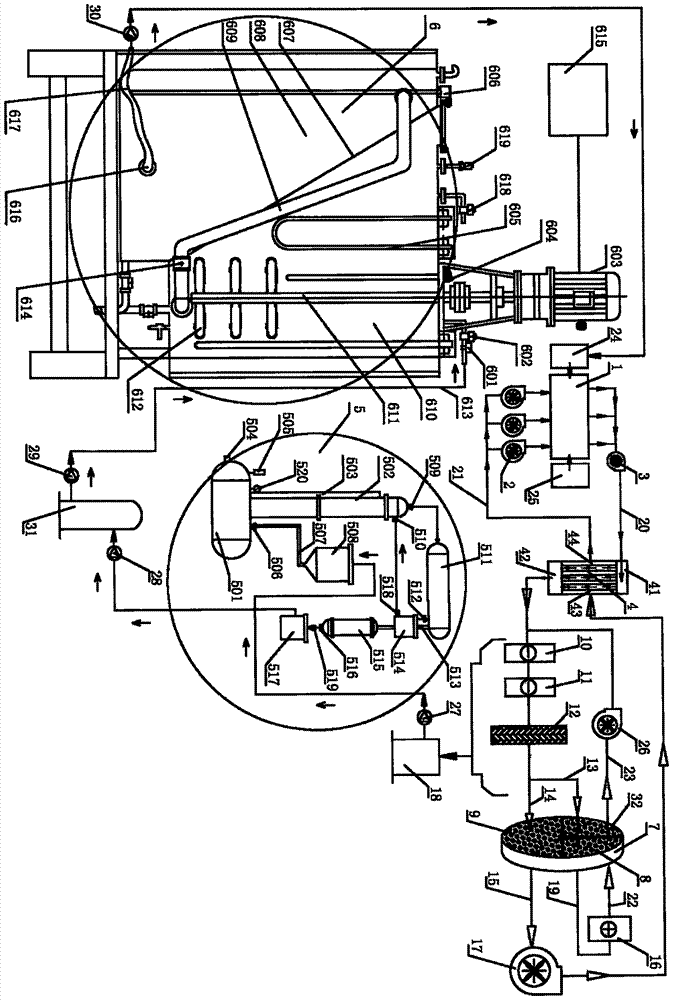

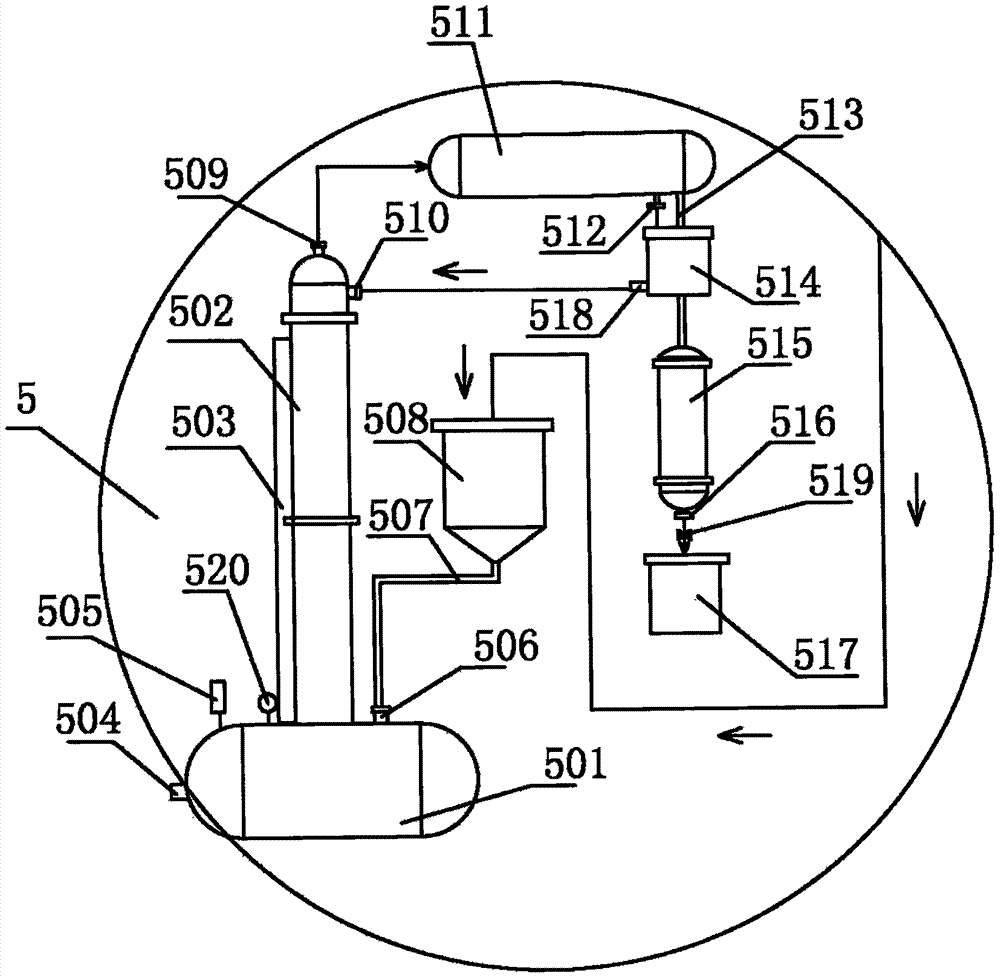

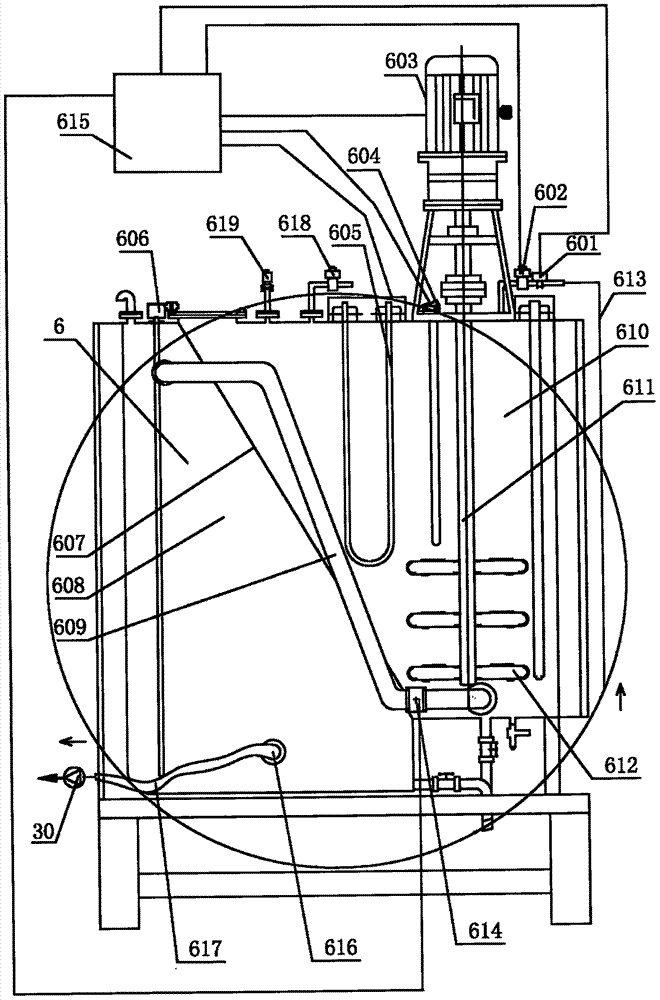

Methane purification system and methane purification technology thereof

InactiveCN103232871AHigh purification rateEfficient removalGaseous fuelsProcess engineeringOil water

The invention discloses a methane purification system and a methane purification technology thereof, solving problems of high investment cost, high operation cost, high fault rate and low purification purity of a conventional system. The system comprises an anaerobic tank (1), a particle filter (2), a drying tower (3), a desulfurizing tower (4), a gasometer (5), a steam-water separation device (6), a low-pressure methane compressor (7), an interception type prefilter (8), a refrigeration drying machine (9), an agglomeration type filter (10), an oil-water separation filter (11), a precise ultimate filter (12), a heater (13), a first CO2 / CH4 efficient separation membrane (14), a second CO2 / CH4 efficient separation membrane (19) and a methane storage tank (20), wherein a methane-enrichment port (15) of the first CO2 / CH4 efficient separation membrane (14) is communicated with a carbon dioxide purification device (16), and a carbon dioxide storage tank (17) is connected with the carbon dioxide purification device (16). The purification technology has high purification rate; and the whole set of technology can realize full-automatic operation.

Owner:SHANXI FENXI ELECTROMECHANICAL

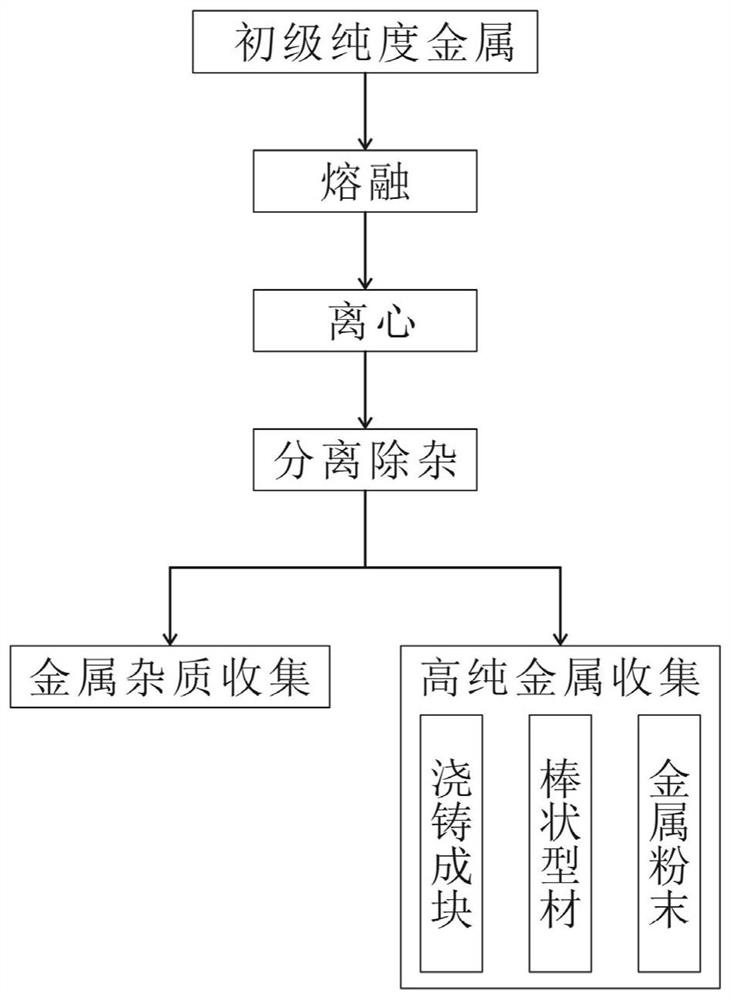

Method and device for purifying refined aluminum and high-purity aluminum through continuous segregation

ActiveCN102864314AGuaranteed stabilityTake away in timeProcess efficiency improvementProduction lineDirectional solidification

The invention relates to a method and a device for purifying refined aluminum and high-purity aluminum through continuous segregation and belongs to the field of casting metallurgy. The method and the device for purifying the refined aluminum and the high-purity aluminum through the continuous segregation are characterized in that crystallization of the refined aluminum and the high-purity aluminum is finished in flowing molten aluminum, the method and the device rely on a liquid supply system of production lines including a continuous casing production line, a continuous rolling production line and the like which need continuous liquid supply, the molten aluminum is from molten aluminum flowing out of a standing furnace, the flowing molten aluminum continuously provides a purification raw material, and continuous high-purity aluminum production is really achieved through the match of the method, the device and a rolling wheel crystal-pulling device. By means of the method, a stirring system is not required in the whole purification process, the energy consumption in the heat preservation process is reduced greatly, purified molten aluminum has no influence on follow-up production activities, the flowing molten aluminum enables the stability of purification raw material components to be ensured, and the uniformity of product components is ensured well under a certain process condition. The method greatly improves the production efficiency and simultaneously reduces the energy consumption, and a directional solidification and purification process is not influenced by the atmosphere environment inside a furnace.

Owner:KUNMING METALLURGY INST

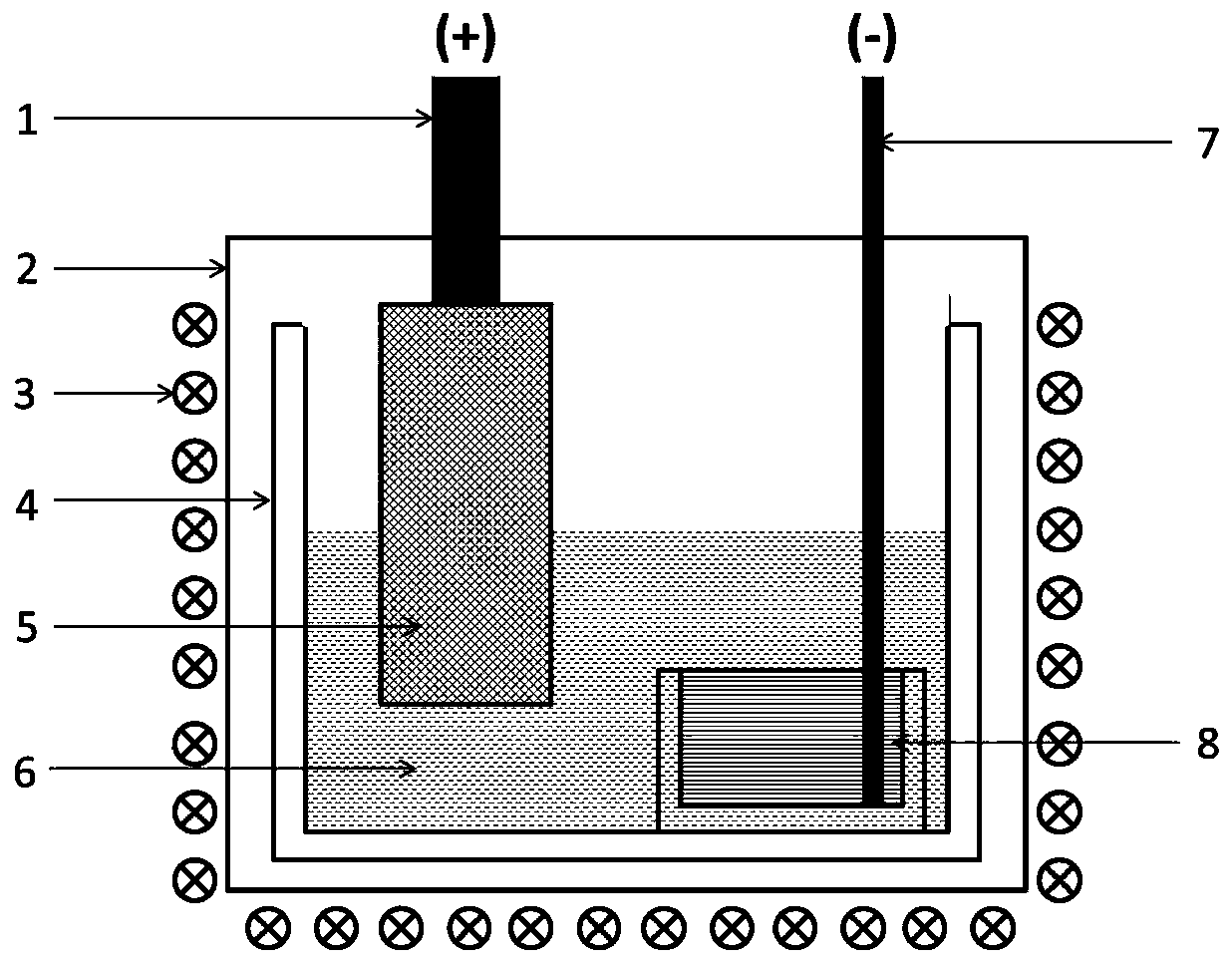

Device and method for preparing high-purity titanium metal through molten salt electrolysis-high-temperature distilling

InactiveCN109825854AReduce energy consumptionLower control costsProcess efficiency improvementElectrodesElectrolysisArgon atmosphere

The invention discloses a device and method for preparing high-purity titanium metal through molten salt electrolysis-high-temperature distilling, and belongs to the field of preparing high-purity titanium through an electrochemical method. The method comprises the following production steps that a titanium containing halide electrolyte is added in an electrolytic bath for premelting, and then, heat preservation is conducted under the argon atmosphere; liquid metal (bismuth, tin, lead and the like) serves as a cathode, titanium sponge or soluble titanium containing matter (titanium carbon oxygen solid solution and the like) serves as an anode, and electrolysis is conducted; and after electrolysis is finished, a cathode titanium alloy product is subjected to high-temperature distilling, andfinally, the high-purity titanium metal is obtained. The method has the characteristics that energy consumption is low, the equipment is simple, the production period is short, and the titanium yieldis high. Through the method, impurities in the anode can be effectively removed, the low-oxygen high-purity titanium metal is obtained, and the good application prospect is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

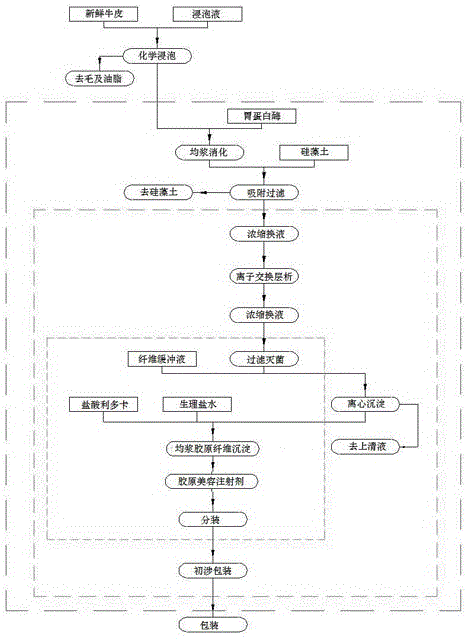

Method for preparing collagen

InactiveCN105063148ASimple processEasy to operatePeptide preparation methodsFermentationUltrafiltrationIon exchange

The invention belongs to the technical field of biological food, and aims to provide a method for preparing collagen with the skin of cattle as the main raw material. The method for preparing the collagen includes the steps of homogenization digestion, adsorption filtration, ultrafiltration concentration and buffer solution change, ion-exchange column chromatography, ultrafiltration concentration and preservation solution change, and filtration sterilization for preparation of a collagen stock solution, wherein the collagen is obtained after protein precipitation, centrifugation and fiber homogenization. The process is simple and easy to implement; by using serous fluid obtained after treatment of the skin of cattle for extracting the collagen through the process, the purification rate and purity of the collagen can be obviously increased.

Owner:FILLDERM (CHANGCHUN) MEDICINE BIOLOGY TECH CO LTD

Method for extracting active peptides from Qinzhou yellow pond turtle

The invention discloses a method for extracting active peptides from a Qinzhou yellow pond turtle. The method comprises the following steps of raw material treatment, hydrolysis, enzymolysis, freezing, melting, concentrating and spray drying to obtain a finished product. Compared with the traditional seed solution shaking table activation, inoculation, fermentation liquid culture and wall breaking technologies, the method has the advantage that the time is greatly shortened.

Owner:YANGXIN XINRUI DYEING & WEAVING

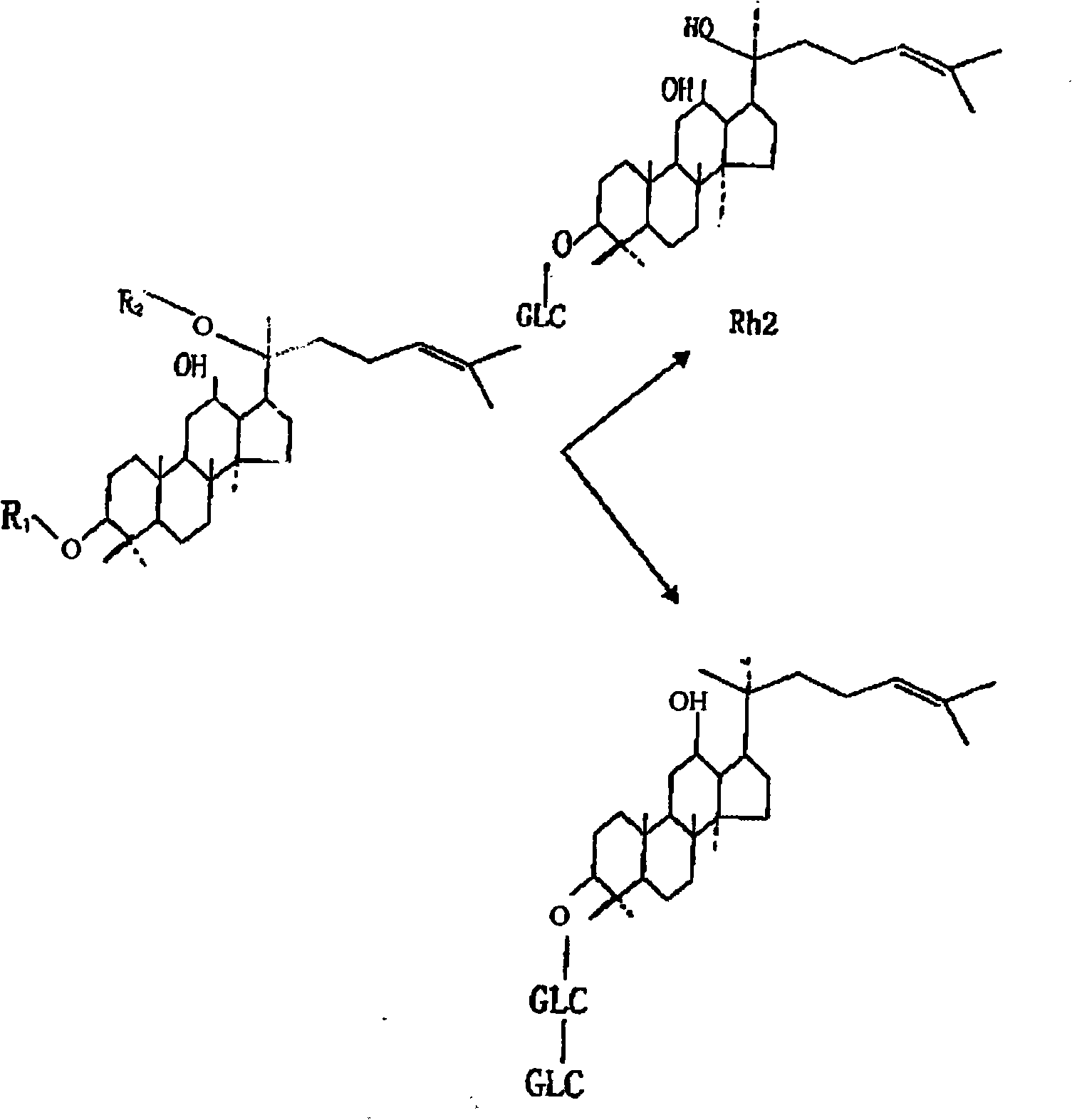

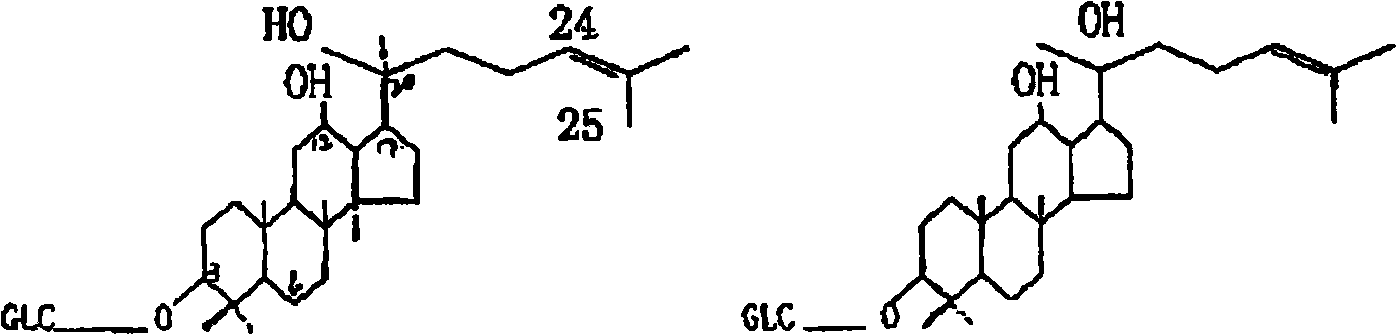

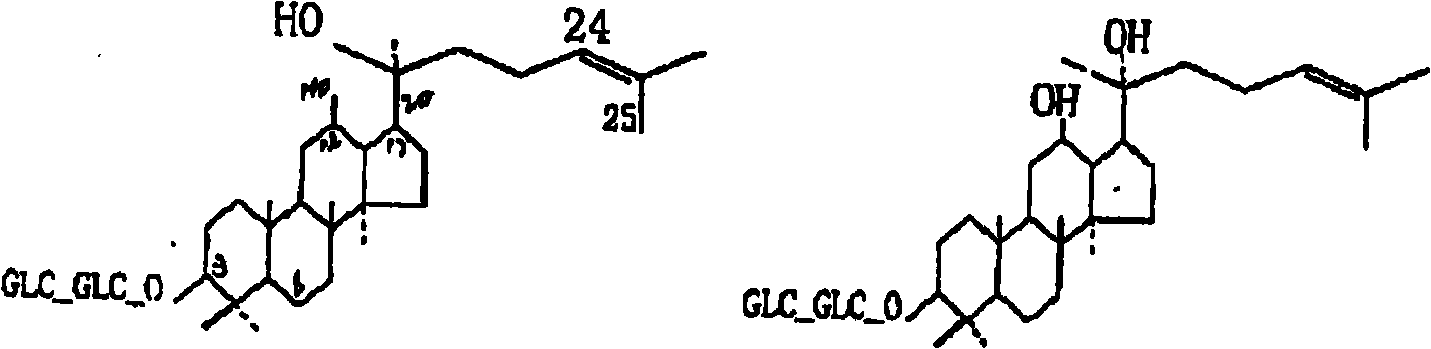

Process for preparing ginsenosides Rh2 and Rh3 from stems and leaves of pseudoginseng root

InactiveCN101830957ASimple processing methodHigh purification rateNervous disorderDigestive systemS-ginsenoside rg3Acid hydrolysis

The invention relates to a process for preparing ginsenosides Rh2 and Rh3 by using stems and leaves of pseudoginseng root as raw materials, which comprises the following technical flows: (1), extracting saponin from the leaves of the pseudoginseng root, namely cooking the stems and leaves of the pseudoginseng root with water for extraction, absorbing, eluting and concentrating to obtain a thin extract of the ginsenosides of the pseudoginseng root; (2), preparing diol saponins, namely absorbing, eluting, concentrating, drying and crushing the thin extract of the ginsenosides of the pseudoginseng root to obtain the diol saponins; and (3), acid hydrolysis, namely, performing acid hydrolysis on the diol saponins, absorbing, washing with water, eluting, concentrating and drying to obtain a mixture which contains the ginsenosides Rh2 and Rh3. The process of the invention is simple and feasible, high in purification rate and good in quality, and reaches industry standards.

Owner:YUNNAN HEIYAO PLANT TECH DEV

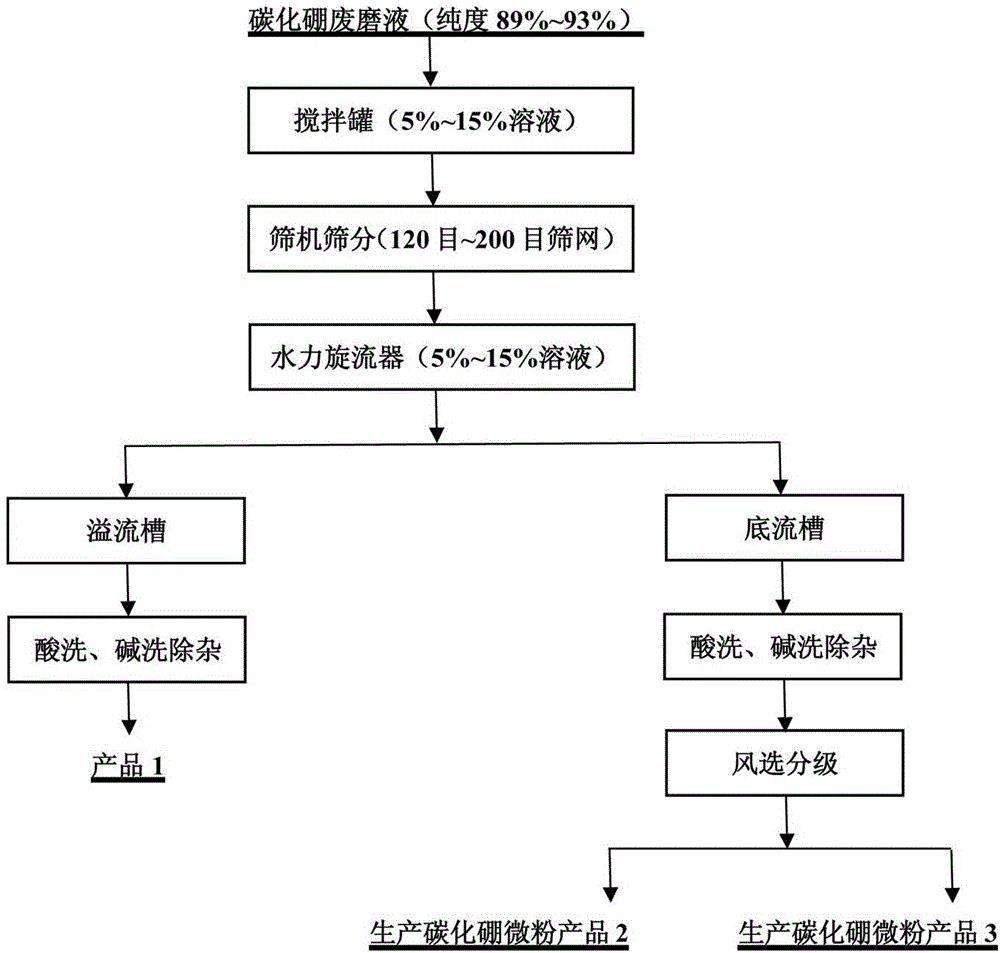

Purification technology for waste liquor produced during sapphire grinding by aid of boron carbide

ActiveCN106315585AEasy to handleReduce the difficulty of operationCarbon compoundsChemical industryFiltrationBoron carbide

The invention relates to recovery and purification technologies for boron carbide, in particular to a purification technology for waste liquor produced during sapphire grinding by the aid of boron carbide. The purification technology specifically comprises the following steps: (1) dilution; (2) filtration; (3) cyclone classification; (4) overflow slurry treatment; (5) alkali washing; (6) acid pickling; (7) drying: materials subjected to treatment and impurity removal in the step (6) are fed into an oven for drying, the temperature of the oven is regulated in the range of 120-150 DEG C, drying is performed for 18-24 h, and the dried materials are crushed into powder, the crushed materials are not caked, and the particle size of the crushed materials ranges from 7 mu m to 120 mu m; (8) air separation classification. The production process can be performed at the normal temperature and under the normal pressure, the production cycle is short, the classification efficiency is high, energy consumption in the production process is low, and influence on the environment is avoided.

Owner:玉溪恒宇科技有限公司

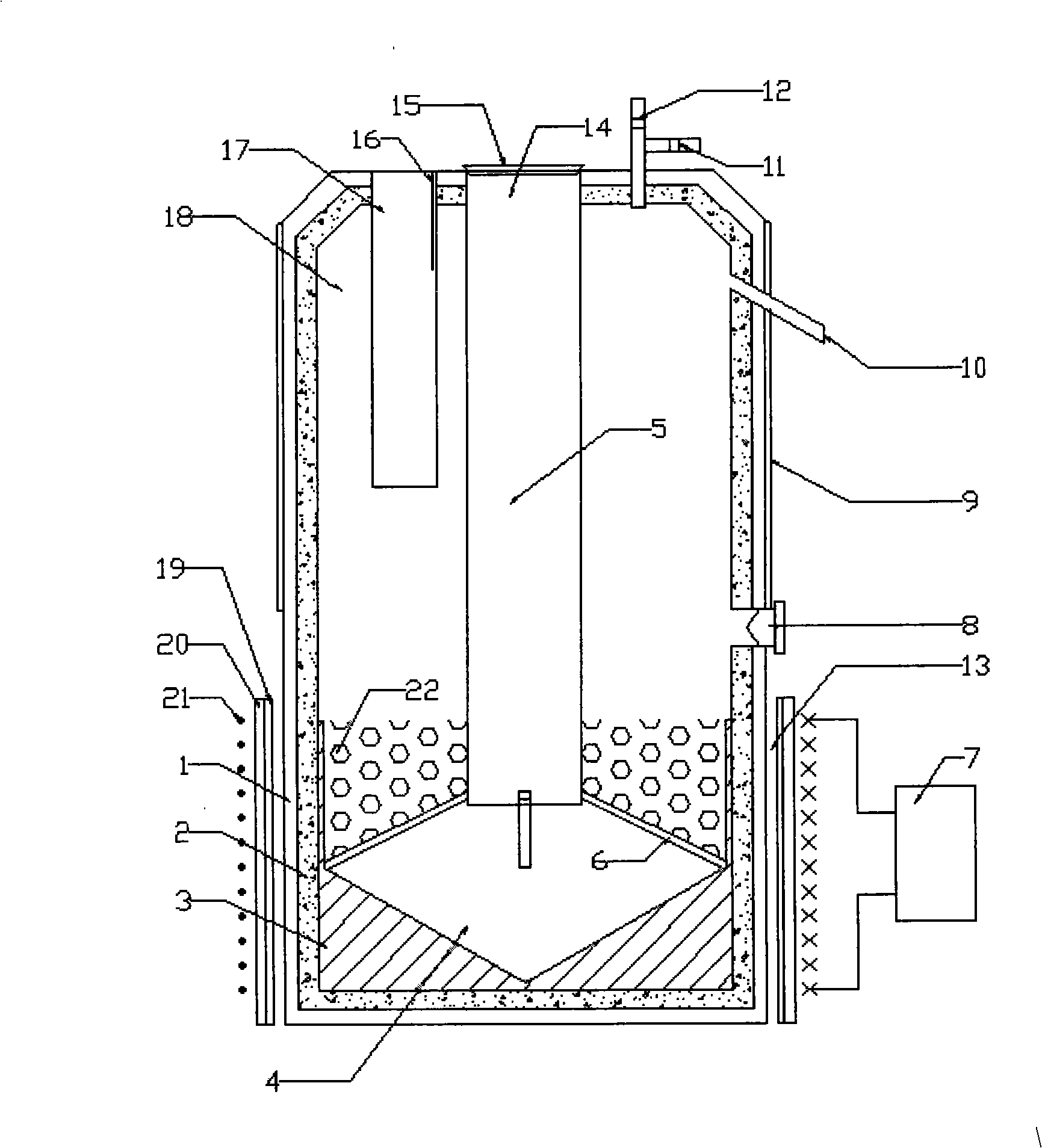

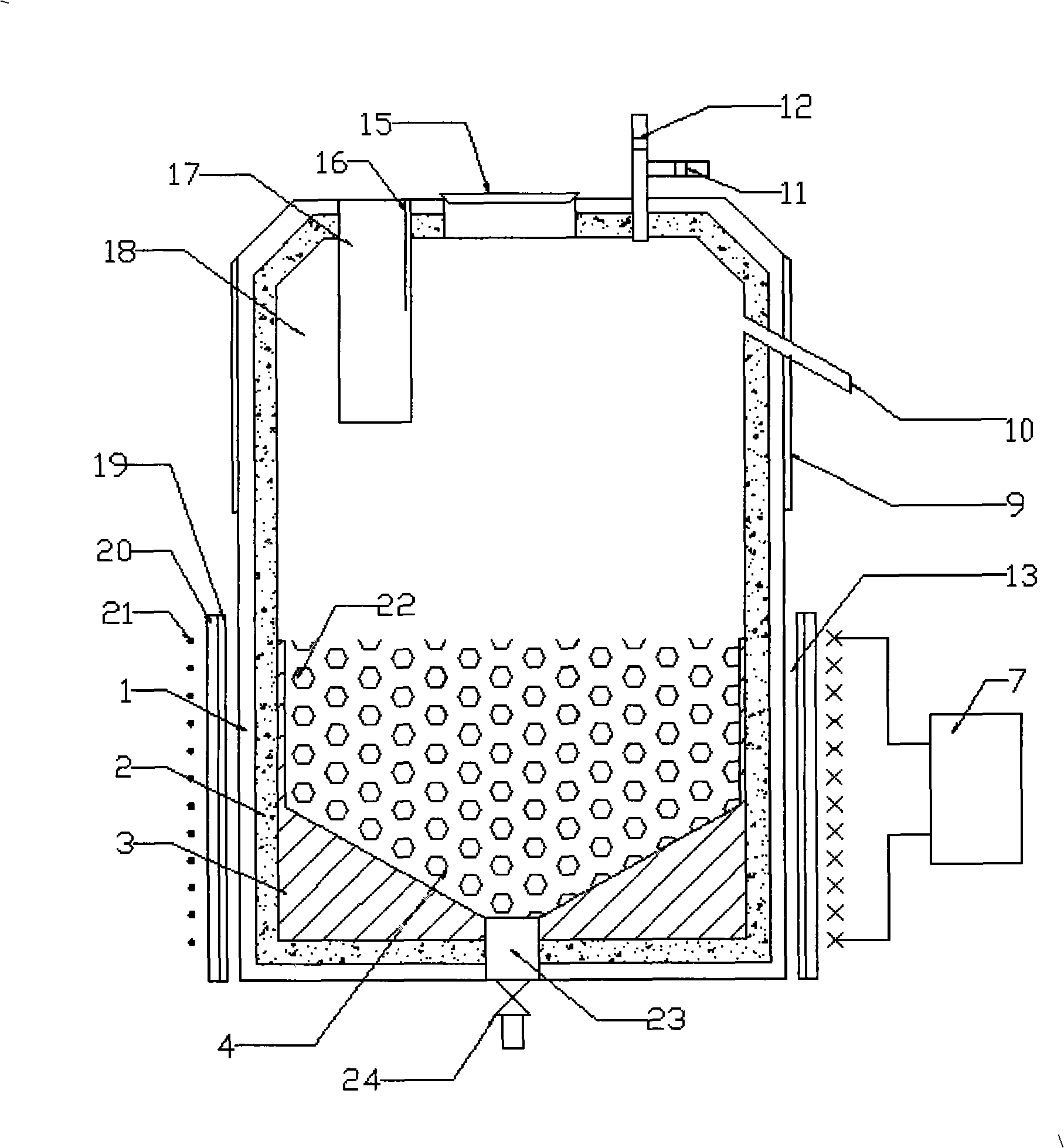

Furnace for abstracting high-purity magnesium metal by electromagnetic method

InactiveCN101285131ASolution to short lifeIncrease productionIncreasing energy efficiencyElectric heating for furnacesFurnace temperatureElectricity

The invention relates to a smelting furnace for extracting high-purity metallic magnesium, providing an electromagnetic method to extract the high-purity metallic magnesium furnace, which solves the technical problems of low pure magnesium yield, low purity and discontinuity of the production process of the prior art. The invention is a closed furnace body of which the outside is wound by an excitation coil; the excitation coil is connected electrically with a medium-high frequency power source; a furnace body are divided into a smelting area and a furnace slag area; the lower part of the smelting area is provided with a briquette; the bottom part of the furnace slag area is also provided with a magnetized body. The closed furnace for extracting the pure magnesium has the advantages of long service life, continuous production, high yield, non-pollution to environment, energy conversation, high purification rate and small floor area, and conveniently adjusts and controls the furnace temperature, thereby realizing the pure magnesium extraction by creatively using the electromagnetic method.

Owner:高源

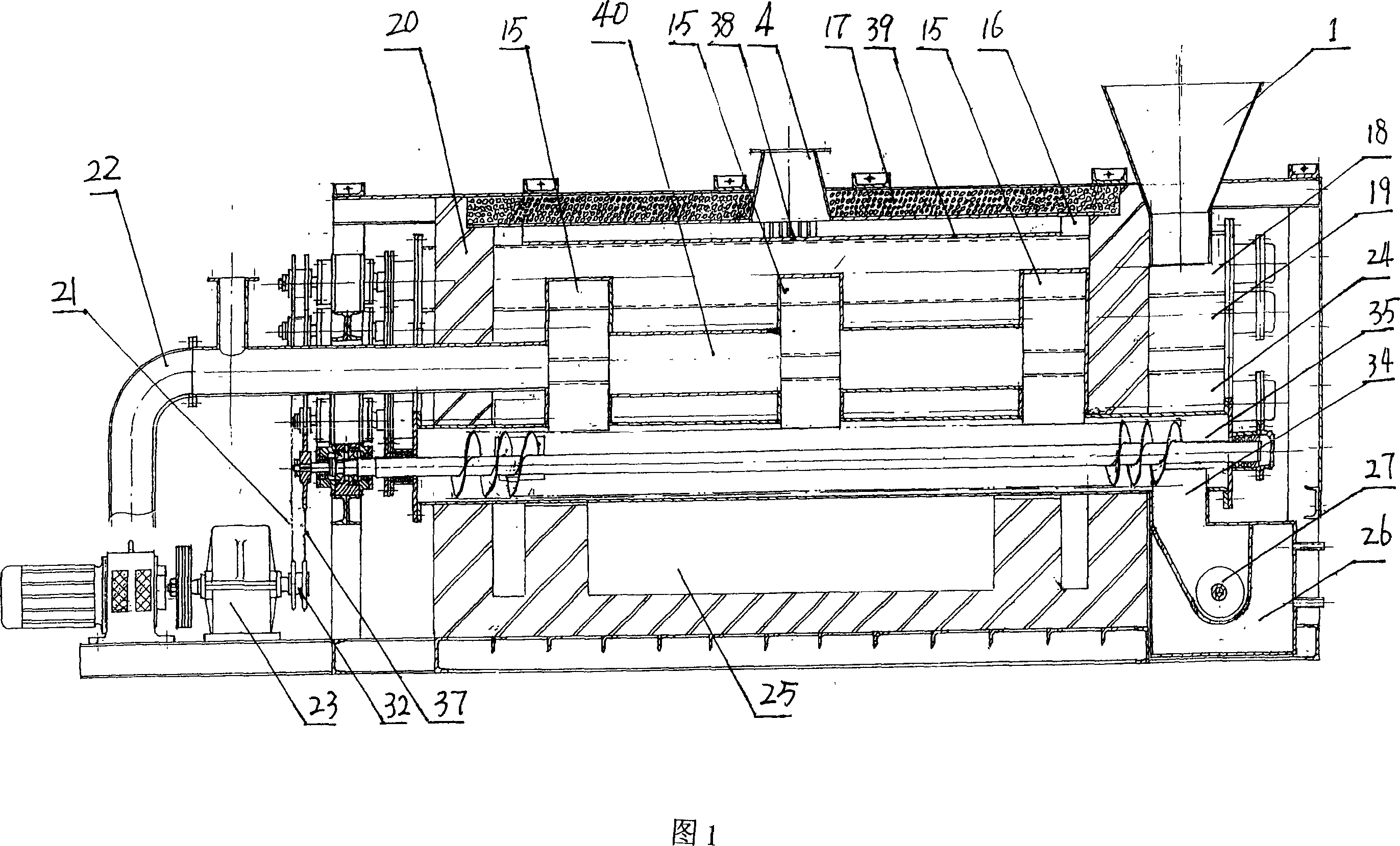

Water-cooled continuous dry distillation type stalk powdered carbon machine

InactiveCN101050370ARegulating pressureStable temperatureBiofuelsSpecial form destructive distillationHigh carbonEngineering

This invention relates to a water-cooling continuous carbonization machine for producing carbon powder from stalk. Multi-stage carbonization pipes are set in a carbonization chamber. A screw conveyer is set in each carbonization pipe. The screw conveyers are connected via double wheels and double chains. The screw conveyers in two carbonization pipes in upper and lower stages have reverse propelling directions. The propelling endpoint of the upper stage carbonization pipe and the propelling start point are through connected via a discharge passage. A gas collection chamber is set in the carbonization chamber to recover and recycle residual gas by an injection blower. An adjustment valve and a pressure reducer are set on the air return pipe. A discharge hopper is set in the circulating cooling water tank, and isolated from the circulating cooling water tank to realize dry cooling of carbon powder. The machine can ensure even speed continuous propelling of the raw material. The flue gas can be re-combusted, thus can avoid coal tar harm. The machine has such advantages as high carbonization temperature, no exhaust gas, low labor intensity, high production efficiency and high carbon powder quality.

Owner:赵陆凯

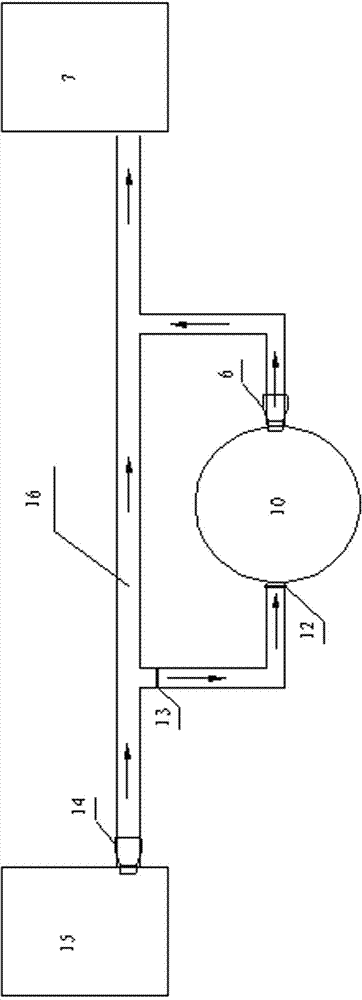

Biomass biogas purification method

InactiveCN104087355AEfficient removalHigh purification rateGaseous fuelsPurification methodsCompressed natural gas

A disclosed biomass biogas purification method comprises: introducing unprocessed biogas into a particle filter to separate particles and condensate in the gas flow, then drying to remove water by passing through a drying tower, then removing sulfides at normal temperature under normal pressure by passing through a desulfurization tower, and compressing desulfurized biogas to 21-24.5 MPa by passing through a compressor, then processing in a recooler to reduce the temperature of the biogas, then enabling the biogas to flow into a low-temperature purification tower, controlling the temperature in the low-temperature purification tower to be -56 DEG C, so as to liquidize CO2 in the biogas and separate out from the bottom of the low-temperature purification tower, and further to obtain purified methane gas; enabling purified methane gas to flow into the recooler through the upward side of the low-temperature purification tower, performing heat exchange in the recooler and controlling the temperature to be 11-14 DEG C, discharging through a control valve, and collecting by a CNG (compressed natural gas) storage tank, so as to obtain purified methane. The method is high in purification rate, is capable of effectively removing H2S, H2O, CO2, halogenated mixed gas and the like, and enables the concentration of methane to be 99% or more.

Owner:JILIN HUIZE GAS

Preparation method for resin used for antibiotics purification

The invention discloses a preparation method for resin used for antibiotics purification. The preparation method comprises the following steps that 1) an oil phase is prepared; 2) a water phase is prepared; 3) the oil phase reacts with the water phase to make mixed liquid gradually solidified into milk white particles, and white balls are obtained; 4) the obtained white balls are swelled by usingchloromethylation solvent, under the effect of a ferric chloride catalyst, the reaction lasts for 6 hours, after washing and drying, chlorine balls are obtained; 5) residual pore-foaming agent in thechlorine balls is eluted, and macropore cationic resin semi-finished products are prepared; 6) 100 ml of wet resin is added into 300 ml of caustic soda liquid with the concentration of 20-25%, the reaction lasts for 8-12 hours at 75-80 DEG C, after the reaction is finished, packing is conducted, the resin is washed with deionized water with the volume same with that of the resin, column chromatography isolation by using hydrochloric acid lasts for 4-5 hours, the resin is washed with deionized water to neutral, the macropore weakly acidic cation exchange resin is prepared, and by adopting the method, the purification rate of the prepared resin used for antibiotics purification is significantly improved.

Owner:安徽皖东树脂科技有限公司

Method for enriching germanium from lignite

ActiveCN104894399ALow costRelieve the pressure of enrichmentPhotography auxillary processesProcess efficiency improvementElectrolysisHydrolysis

A method for enriching germanium from lignite comprises the enrichment steps: (1) fire-method purification; (2) acid-liquid soaking; (3) electrolytic purification; and (4) purification and crystallization. The method has the beneficial effects that the germanium element is purified by adopting the method of fire method, hydrolysis and electrolysis, the purification rate of germanium is greatly improved, the amount of an acid liquid used in the hydrolysis process is greatly reduced, and the cost of the germanium element enrichment is reduced; and the obtained germanium enriched substance has relatively high germanium element content, eases the pressure of the germanium element enrichment, and is easy to popularize.

Owner:HEBEI UNIV OF ENG

Coking wastewater treatment method

InactiveCN101643299AHigh purification rateWith comprehensive utilizationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentDistillationUltrafiltration

The invention relates to a coking wastewater treatment method, which belongs to the technical field of wastewater treatment and is used for solving the problem that the coking wastewater treatment technology leads water quality to be difficult to achieve the standard. The coking wastewater treatment method comprises the steps of tar-ammonia water separation, ammonia distillation, biochemical treatment and the like, and wastewater after the biochemical treatment is treated according to the following steps after improvement: A. sequentially carrying out sand filtration, ultrafiltration and nanofiltration treatment on the wastewater treated biochemically, and carrying out secondary nanofiltration treatment on concentrated solution after the nanofiltration treatment; B. merging filtrate of twotimes of nanofiltration treatment, inputting into the step before the biochemical treatment step as biochemical diluted water or supplementary water of recycling water of a coking plant or being drained to outside; and C. inputting the concentrated solution of the secondary nanofiltration treatment into a tar-ammonia water separation slot in a coking gas purifying system or an ammonia water spraying system of a coke oven and mutually dissolving with tar ammonia water mixed solution. The method increases the membrane treatment based on the existing biochemical treatment for making up for congenital defects of biochemical treatment and is characterized by reasonable process, high purifying rate of wastewater treatment, comprehensive utilization of wastewater and the like.

Owner:KAILUAN ENERGY CHEM

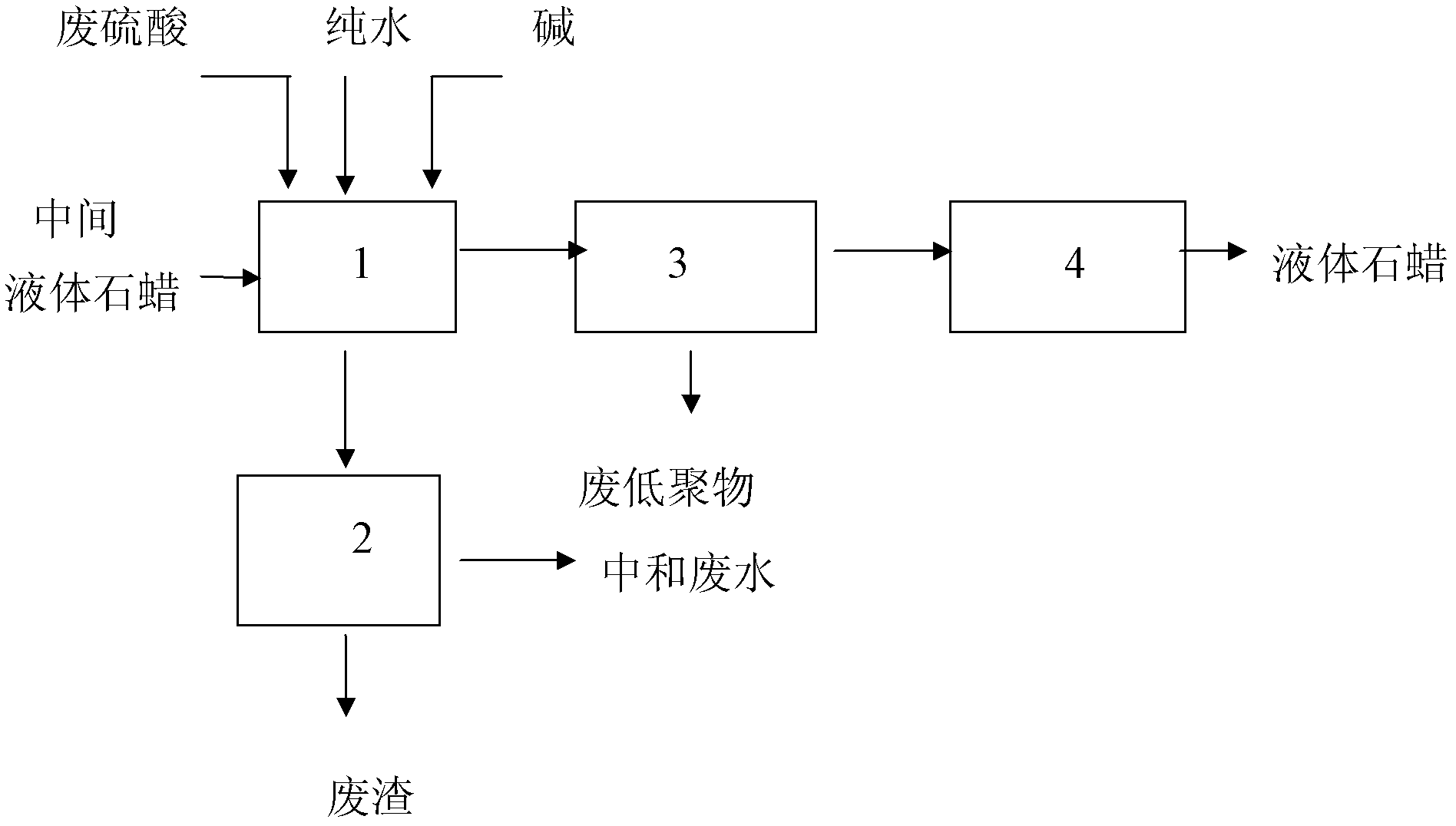

Method for re-purifying and recovering liquid paraffin obtained after solvent extraction

InactiveCN102585885AReduce energy consumptionLow costHydrocarbon oils refiningParaffin waxRecovery method

The invention provides a method for re-purifying and recovering liquid paraffin obtained after solvent extraction. By the recovery method, the liquid paraffin recovered after solvent extraction is performed and the solvent is removed is re-purified. The method mainly comprises the steps of acid washing, neutralizing, washing and settling; impurities such as inorganic salt, gelatin, and surfactant are removed, the heavy-component proportion of the obtained high-purity liquid paraffin is basically consistent with that of the unused industrial liquid paraffin, and the high-purity liquid paraffin can be applied to polymerization reaction of a macroporous ion exchange resin again. The technical scheme has the technical characteristics of simple and short process, and high purification rate.

Owner:LIAONING GEOLOGY ENG VOCATIONAL COLLEGE

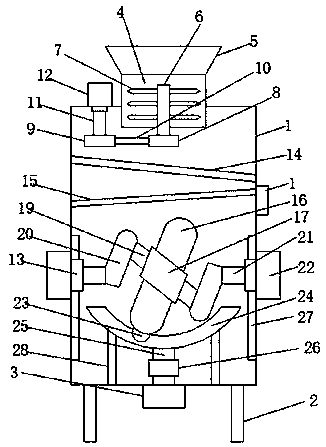

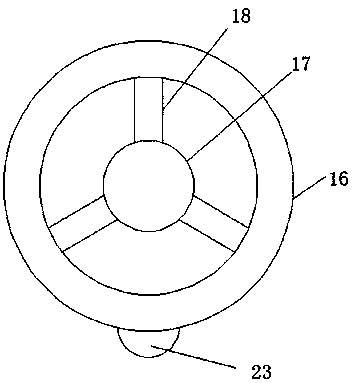

Device for extracting and grinding wormwood

InactiveCN108970780AGrinding effectAvoid the impact of normal workGrain treatmentsDrive wheelElectric machinery

The invention discloses a device for extracting and grinding wormwood. The device comprises a shell; a discharging port is formed on a middle position on the bottom of the shell; a feeding port is formed on the top of the shell; a first rotating shaft is arranged in the feeding port; multiple sets of smashing blades are arranged on the two sides of the first rotating shaft; a driven wheel is arranged on the bottom of the first rotating shaft; a driving wheel is arranged on one side of the driven wheel; the driving wheel is connected with the driven wheel through a belt; a second rotating shaftis penetrated through the middle of the driving wheel; the top of the second rotating shaft is penetrated through the shell and is connected with a first driving motor on one side of the top of the shell; a first filter screen is arranged on the inner top of the shell. The device disclosed by the invention has the beneficial effects of reasonable design, simple structure and convenience in use. Compared with the traditional extracting device, the device disclosed by the invention has the advantages that the sufficient grinding property is effectively promoted, so that the purifying rate can be effectively increased and the use ratio can be effectively increased.

Owner:安徽清山艾草制品有限公司

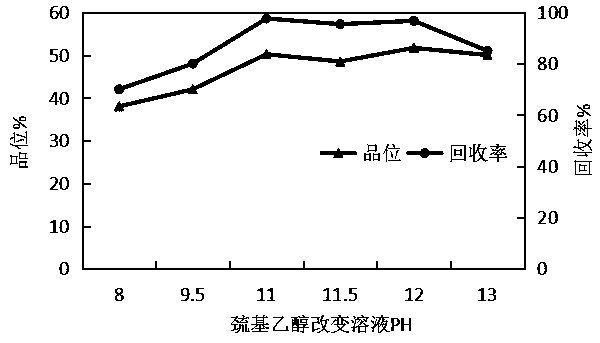

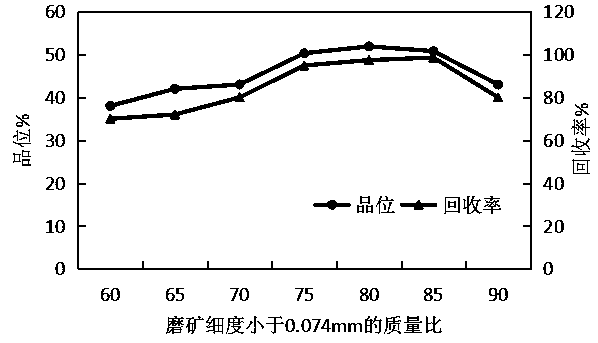

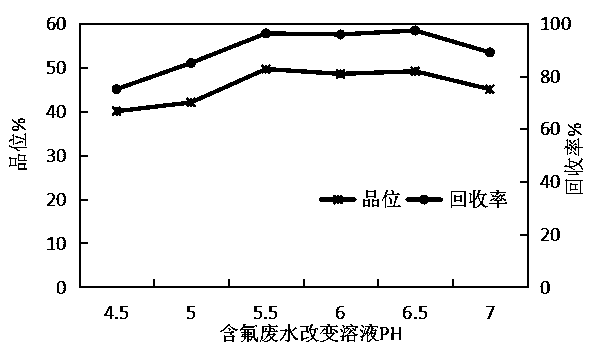

Ore dressing method of pyrite

ActiveCN109985732AReduce dosageHigh recovery rateFlotationGrain treatmentsResource developmentSulfur

The invention belongs to the technical field of metal mineral resources development, in particular to an ore dressing method of pyrite. The method comprises the following steps: taking pyrite, addingdepressant, adjusting PH, grinding; adding water to obtain raw ore slurry; roughing the slurry, adding butyl xanthate and No.2 oil, and performing ultrasonic treatment to obtain roughed sulfur ore andtailings; adding activator into tailings, carrying out secondary roughing, adding butyl xanthate and No.2 oil, and carrying out ultrasonic treatment to obtain roughed sulfur ore and tailings; treating the roughed sulphur ore by ultrasonic wave, and repeatedly cleaning the obtained tailings twice, and scavenging the tailings, adding butyl xanthate and No.2 oil to the tailings for ultrasonic wave treatment, and continuously roughing and scavenging the obtained tailings once. By this method, the production cost can be reduced and the recovery rate can be increased, a good application prospect can be obtained.

Owner:迁安市永德元工贸有限公司

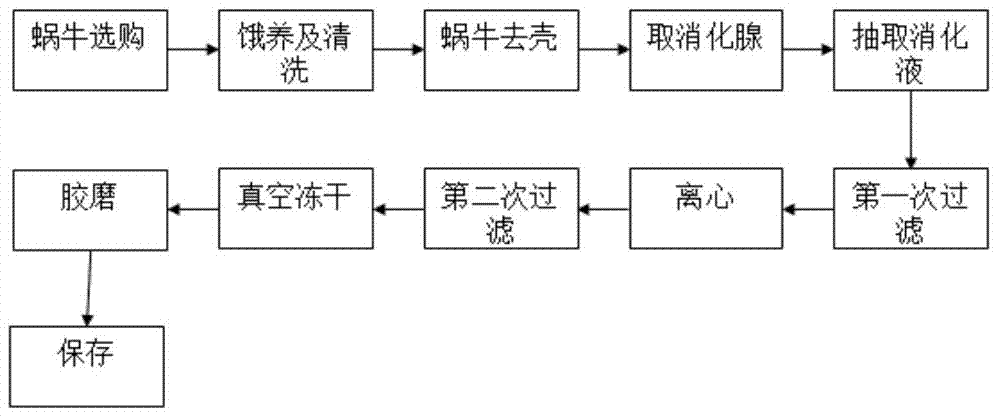

Snail enzyme preparation method

The invention relates to a snail enzyme preparation method and solves problems that an existing snail enzyme extraction method is complex in process, poor in operability, low in purification rate and high in cost. The snail enzyme preparation method includes the steps of selection of fresh achatina fulica, cleaning, shelling, digestive gland removal, digestive juice pumping, primary filtering, centrifuging, secondary filtering, vacuum freeze dehydration, glue milling and storage. The method is widely applicable to preparation of snail enzyme.

Owner:威海圣奥罗生物科技有限公司

Method for preparing high-content tuna anserine by adopting membrane separation and application of tuna anserine

ActiveCN112592315ASuitable for large-scale industrial productionImprove performanceOrganic chemistryComponent separationUltrafiltrationFishery

The invention provides a method for preparing high-content tuna anserine by adopting membrane separation and application of the tuna anserine, and belongs to the technical field of protein peptide extraction and purification. The method comprises the steps: smashing and pulping tuna meat, then placing tuna pulp in boiling water, performing screening and filtering twice, combining filtrates obtained twice, performing ultrafiltration membrane filtering three times, taking trapped fluid obtained in the third time, and performing concentration, smashing, heating, and reflux extraction to obtain the tuna anserine. According to the method, rich tuna fishery resources in China and the medical health care functions of the anserine contained in tuna meat are fully utilized, the industrial production and processing technology level and additional value of tuna anserine products are effectively improved, the production and preparation process is simplified, and the production efficiency is improved. Meanwhile, the pollution problem and the production cost for producing the product are reduced, and the varieties of tuna anserine products on the market are enriched, so that the high-content tuna anserine has a good practical application value.

Owner:SHANDONG RUIZHI BIOTECH +1

Nano-scale collagen purification method capable of reaching absorption rate of 96%

InactiveCN109486885ASmall molecular weightHigh purification rateConnective tissue peptidesPeptide preparation methodsEstriolMetabolite

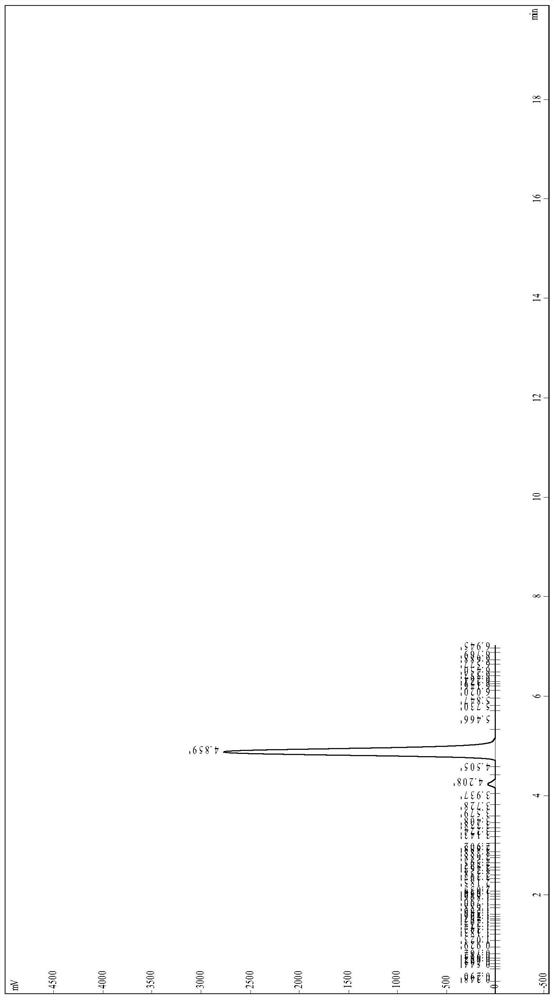

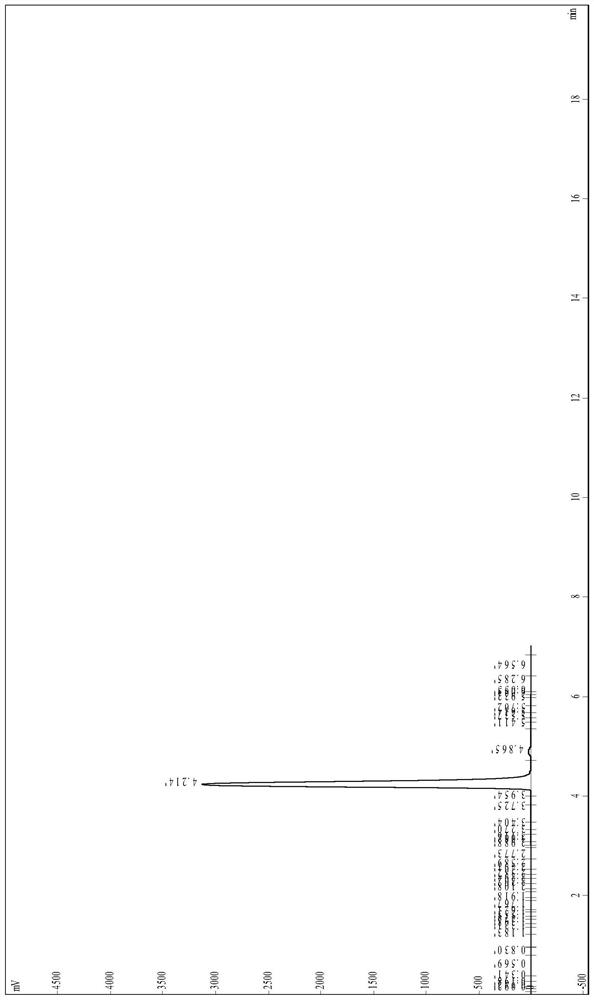

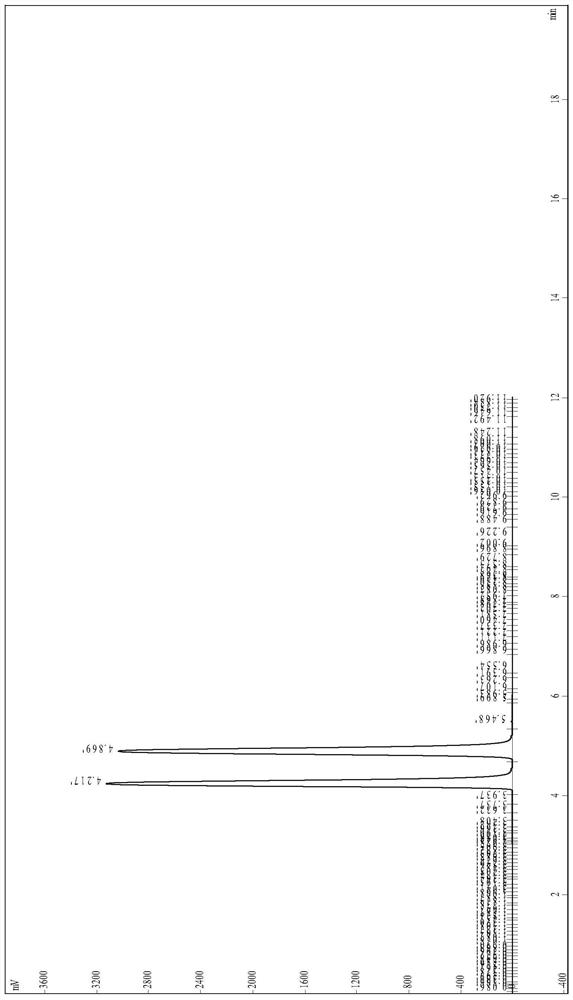

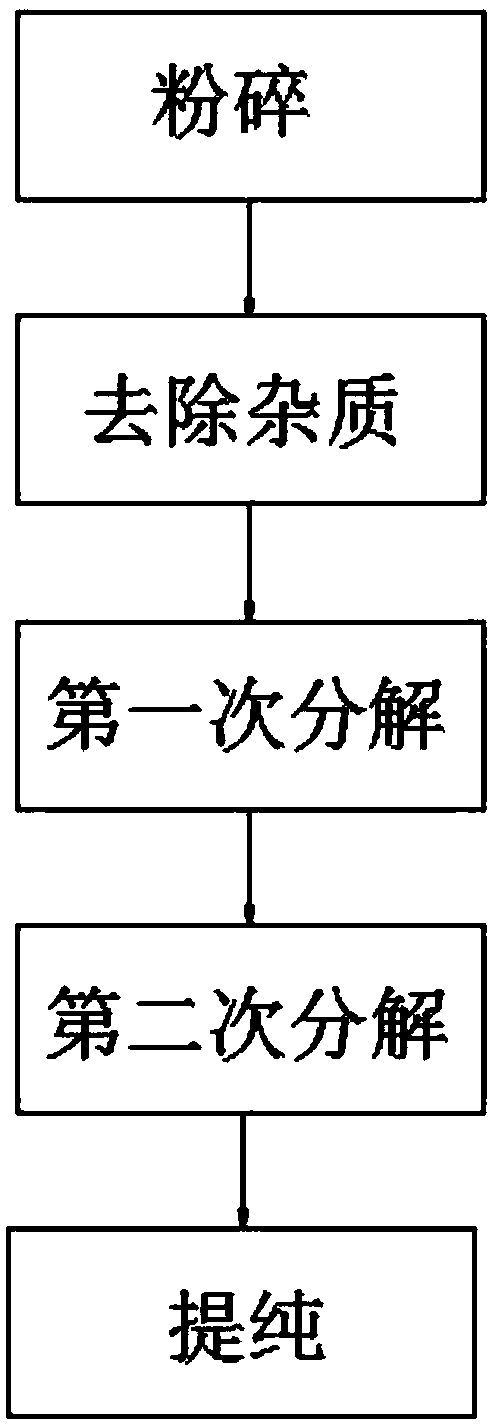

The invention discloses a nano-scale collagen purification method capable of reaching the absorption rate of 96%. The method includes the steps: crushing fish skins, and removing impurities; placing crushed materials into a low-temperature stirrer, stirring and mixing mixture for 30 minutes according to the volume ratio of the crushed materials to deionized water, standing for 10 minutes, removingupper floats, and placing mixture into a filter device to perform adsorption filtration; collecting filtered crushed materials, and performing first purification, second decomposition and third purification. The volume ratio of the crushed materials to deionized water is 1:3. Nano-scale collagen acquired through three purification steps and a particle collisions instrument is detected by SGS andPUNY, so that the nano-scale collagen is free from oestrone, chloramphenicol, progesterone, salmonella, methyltestosterone, macrodantin metabolite, fat, estradiol and estriol. According to the method,slurry acquired after treatment of the fish skins is used for extraction of the collagen, the purification rate and the purity of the collagen can be obviously increased, the slurry is purified by anano-scale collagen purification device to obtain nano-scale mixed powder, collision of the nano-scale mixed powder is implemented by the particle collisions instrument to obtain the nano-scale collagen with uniform molecular weight, and the absorption rate of the nano-scale collagen can reach 96%.

Owner:티안지우안

Recovery process for palladium in alkaline palladium liquid

InactiveCN106086449AHigh purification rateSimple recycling processProcess efficiency improvementEconomic benefitsOrganic matter

The invention discloses a recovery process for palladium in alkaline palladium liquid. The recovery process comprises the following steps of a, oxidation, b, deposition, c, purification, d, drying and e, reduction. According to the recovery process for the palladium in the alkaline palladium liquid, pressurizing treatment is added before palladium recovery, so that other precious metal is removed to the greatest extent except the palladium, and the purification rate of the palladium is greatly increased; in addition, an organic matter attached to the surface of the palladium is removed with a washing method in the palladium recovery process; compared with a traditional roasting method, energy consumption is low, and industrial operation is convenient; moreover, the whole palladium recovery process is simple, the palladium recovery rate reaches up to 99.9%, and the content of other metal elements contained in tail liquid can be controlled; energy-saving emission-reduction environmentally-friendly effects are achieved, the production cost is reduced, and the economic benefits of an enterprise are increased.

Owner:KUNSHAN HONGFUTAI ENVIRONMENTAL PROTECTION TECH

Method for extracting bioactive peptide from black-bone chicken

InactiveCN105146566AUniform particle size distributionEasy to operateFood ingredient functionsFood preparationNutrientChemistry

The invention discloses a method for extracting bioactive peptide from a black-bone chicken. The method comprises the following steps: treating raw materials so as to obtain meat paste; hydrolyzing the obtained meat paste so as to obtain a solution; grinding the solution so as to obtain a pasty slurry; fermenting the pasty slurry and liquid spawn of lactic acid bacteria so as to obtain fermented liquor; performing enzymolysis on the fermented liquor and protease so as to obtain a solution on which the enzymolysis is performed; performing enzyme deactivation on the solution on which the enzymolysis is performed so as to obtain a solution on which the enzyme deactivation is performed; filtering a mixed solution after standing, of the solution on which the enzyme deactivation is performed, diatomite and / or active carbon so as to obtain filtrate, and concentrating the filtrate so as to obtain extracts; drying the extracts; and packaging the dried extracts so as to obtain finished products. According to the method disclosed by the invention, firstly a superfine grinding technology is utilized to treat hydrolysate of the black-bone chicken, then a lactic acid bacteria fermentation technology is utilized to treat the treated hydrolysate of the black-bone chicken so as to obtain solution particles of which the particle sizes are uniformly distributed, the decomposition of protein and monosaccharide and absorption of nutrient substances such as calcium and magnesium can be facilitated, and a large number of beneficial substances such as vitamin B can be generated; then the solution particles are treated into micro-molecular peptide substances through enzymolysis, and the micro-molecular peptide substances can be directly absorbed by a human body without gastrointestinal digestion, so that the problems of absorbing and utilizing macromolecular proteins by the human body are effectively solved. By the method disclosed by the invention, the extraction rate is higher than 20%, and the proportion of micro-molecular peptide is higher than 95%.

Owner:刘全生

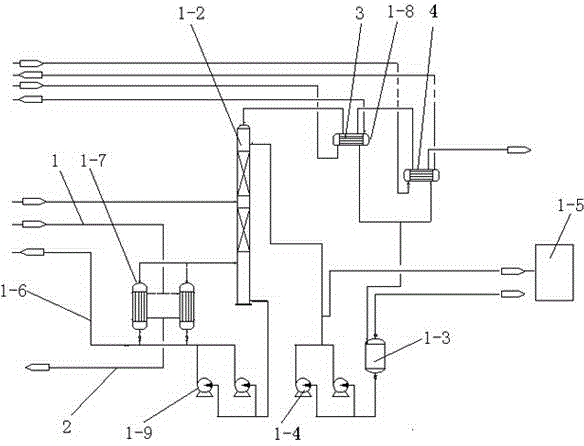

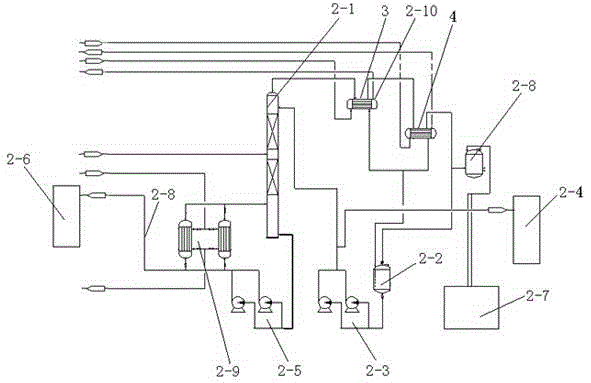

Cyclic utilization device for recycling, finely-steaming and purifying NMP in coating process of lithium ion battery

PendingCN107403960AImprove recycling efficiencyIncrease concentrationGas treatmentOrganic chemistryElectrical batteryProcess engineering

The invention relates to a cyclic utilization device for recycling, finely-steaming and purifying NMP in coating process of a lithium ion battery. The cyclic utilization device comprises a coating machine, a heat exchanger, a rotating wheel, finely-steaming and purifying equipment, a waste liquid tank, automatic liquid feeding equipment and an NMP solution storage tank. The device is characterized in that the heat exchanger comprises a heat exchanger high-temperature inlet, a heat exchanger low-temperature inlet, a heat exchanger dry air inlet and a heat exchanger dry air outlet; and a coating machine head and a coating machine tail are arranged on the left and right sides of the coating machine, respectively, an exhaust pipeline is arranged above the coating machine and is connected with an exhaust fan, the exhaust fan is connected with the heat exchanger high-temperature inlet through the exhaust pipeline, and an air supply pipeline is arranged below the coating machine. The cyclic utilization device is used for adsorbing NMP exhaust gas exhausted in a coating production process of the lithium ion battery and converting NMP in the exhaust gas into liquid to be recycled by virtue of a condenser so as to realize recycle and reuse, the concentration of NMP is high, and the purifying rate is high; and the automation degree of the device is high, and the recycling rate of liquid is high.

Owner:张建岗

Trimethyl orthoacetate continuous distillation equipment and distillation technology thereof

ActiveCN104399273AHigh purification rateReduce energy consumptionOrganic chemistryOrganic compound preparationRefluxAcetic acid

The invention relates to trimethyl orthoacetate continuous distillation equipment and a distillation technology thereof, and belongs to the technical field of the trimethyl orthoacetate continuous distillation equipment and the distillation technology thereof. The continuous distillation equipment comprises a first-level distillation device, a second-level distillation device and a third-level distillation device which are in series connection with one another, wherein the first-level distillation device comprises a first-level separation tower; first-level separation tower reboilers are communicated with the bottom of the first-level separation tower; first-level separation tower circulation pumps are mounted on a circulation pipeline I between the first-level separation tower and the first-level separation tower reboilers; the circulation pipeline I is communicated with the second-level distillation device; a discharging pipeline at the top of the first-level separation tower is communicated with a first-level separation tower condenser; the first-level separation tower condenser is communicated with a first-level separation tower receiving tank; the discharge opening of the first-level separation tower receiving tank is communicated with the first-level separation tower through a pipeline; first-level separation tower reflux pumps and a branch pipeline which is communicated with a low-boiling-point substance storing tank are mounted on the pipeline. The continuous distillation equipment is small in occupied area, low in energy consumption, simple and convenient to operate, high in distillation purity and less in environmental pollution.

Owner:烟台福川化工有限公司

Method for extracting active peptides from Qinzhou yellow pond turtle

Owner:YANGXIN XINRUI DYEING & WEAVING

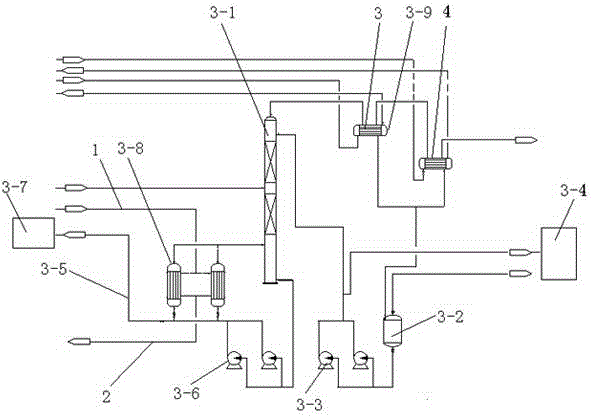

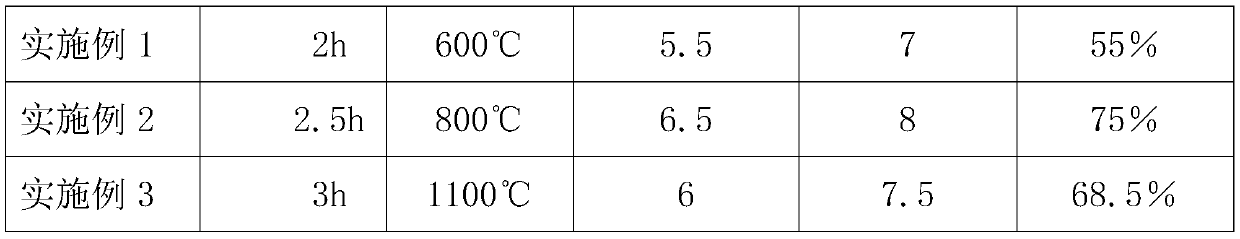

Recycling process and method for all metal elements in abandoned power lithium batteries

InactiveCN110592382AHigh purification rateSimple processWaste accumulators reclaimingProcess efficiency improvementOxidePrecipitation

The invention discloses a recycling process and method for all metal elements in abandoned power lithium batteries, and specifically relates to the field of recycling of metal in the lithium batteries. The recycling process and method specifically includes the following steps of raw material processing, high-temperature roasting, oxygen injection stirring, waste gas processing, acid pickling, precipitation and drying. In the raw material roasting process, internal raw materials are subjected to reduction of carbon powder in advance, the oxygen injection stirring step is then conducted, oxide formed by manganese, lithium and cobalt is independently taken out in batches within all temperature ranges of heating, and therefore the metal elements in the raw materials can be sufficiently oxidized, sufficient purification of the metal elements is ensured, and the purification rate of the metal elements is increased. Compared with the existing poor effect of recycling the metal elements in theabandoned lithium batteries, the method is simple in process, low in operation cost and high in recycling rate of metal elements in railings, the utilization rate of the device is greatly increased,and no secondary pollution is caused.

Owner:NANCHANG HANGKONG UNIVERSITY

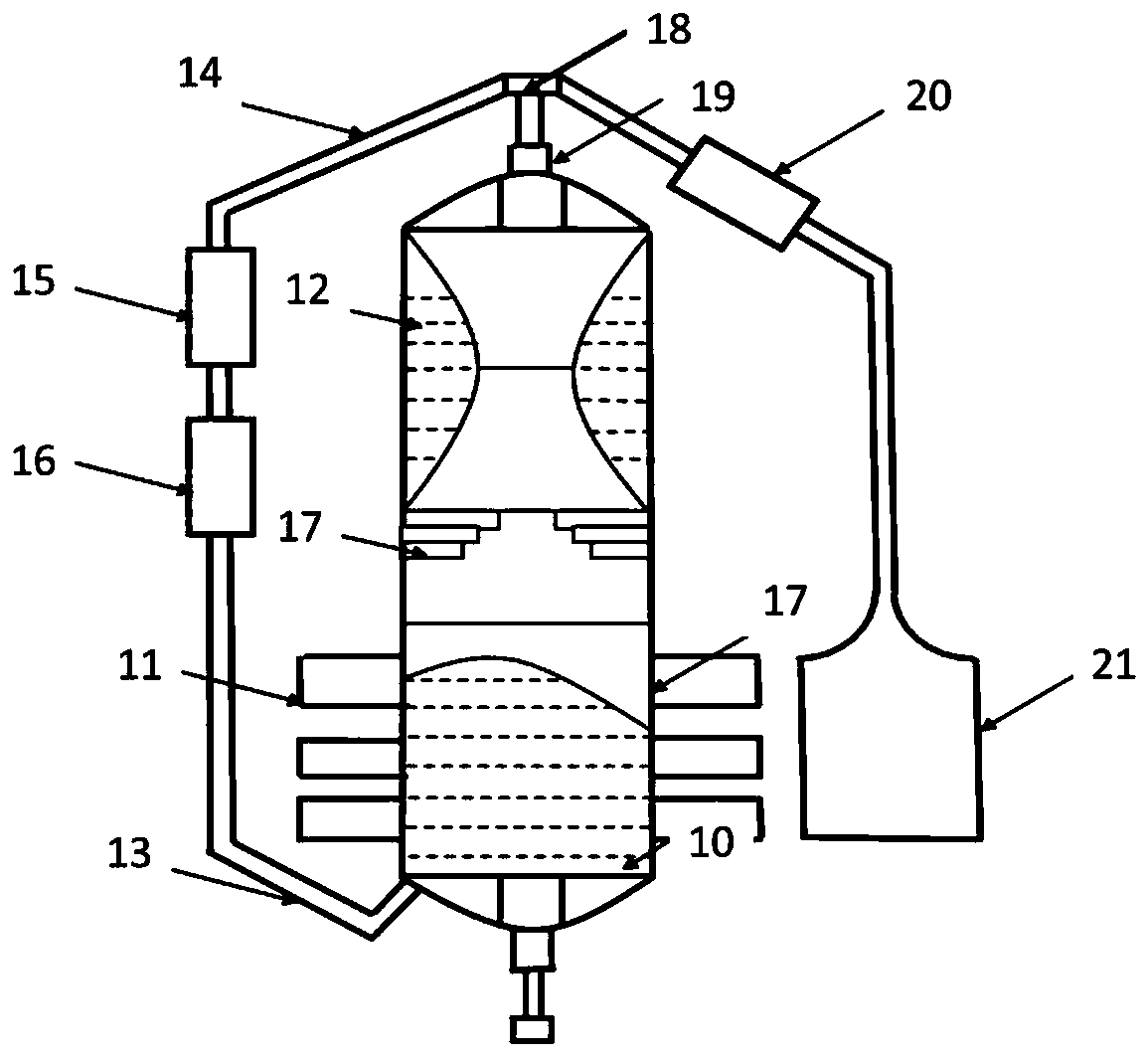

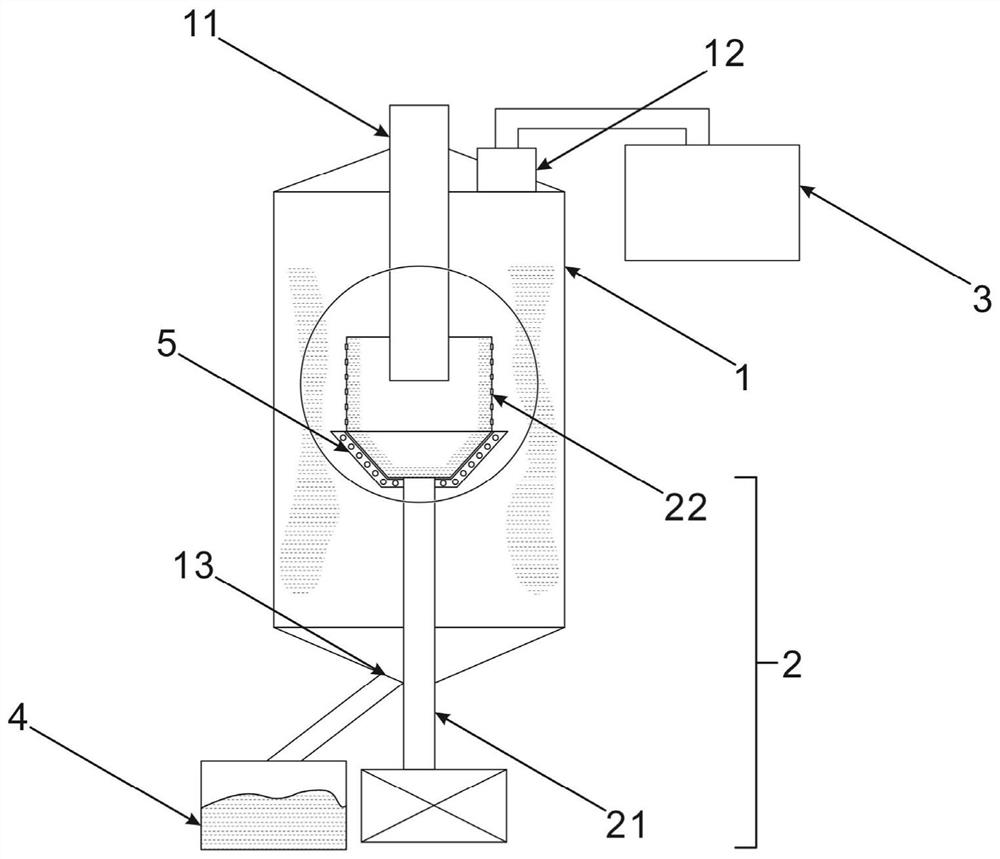

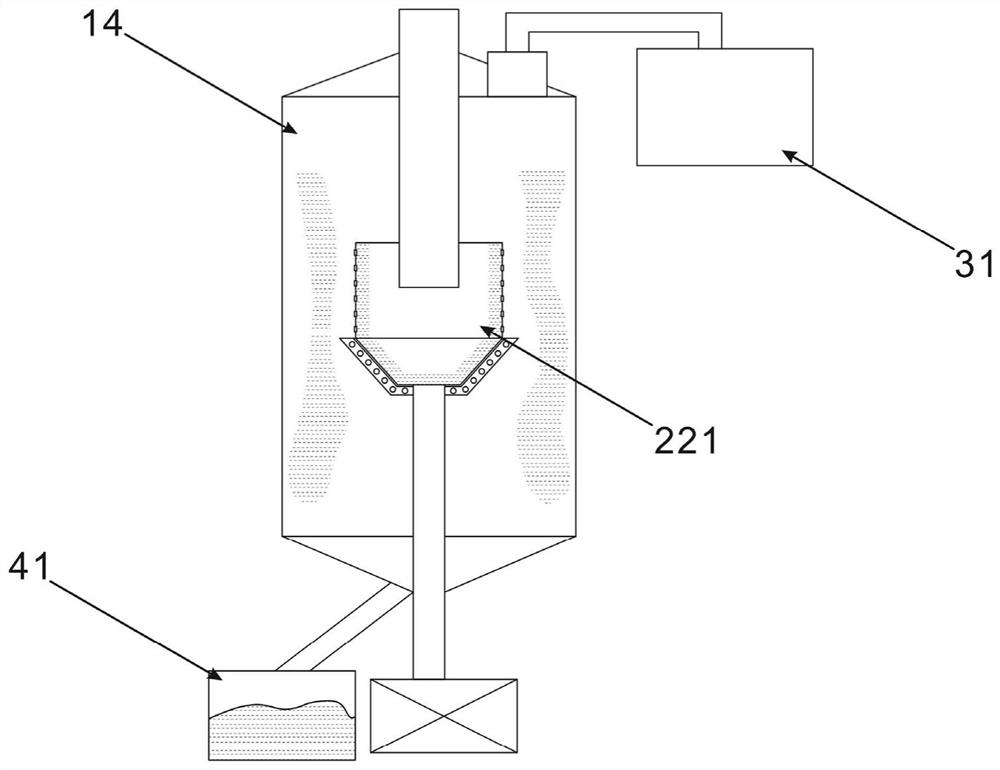

Method and device for preparing high purity metal or alloy through efficient distillation method

ActiveCN113621823AImprove vaporization efficiencyImprove efficiencyProcess efficiency improvementAlloyDistillation method

The invention provides a method and a device for preparing high purity metal or alloy through an efficient distillation method, relates to the technical field of metal or alloy purification, and solves the technical problem that in the prior art, the efficiency of purifying metal or alloy through an existing distillation method is low. The device comprises a purifying plant body provided with a distillation chamber and a centrifugal cavity provided with a centrifugal chamber, wherein the centrifugal chamber is communicated with the distillation chamber; and a to-be-purified metal or alloy inlet, a metal or alloy vapor outlet and a metal or alloy discharging port are formed in the purifying plant body. The method and the device are suitable for metal or alloy with the melting point below 1500 DEG C, purification is achieved by means of different boiling points and saturation vapor pressures of impurity elements contained in the metal or alloy, a gas-liquid interface is improved by conducting droplet formation and atomization on the molten metal or alloy, the vaporization efficiency is improved, and the purification efficiency is high on the basis that the purification effect is guaranteed.

Owner:XI AN JIAOTONG UNIV

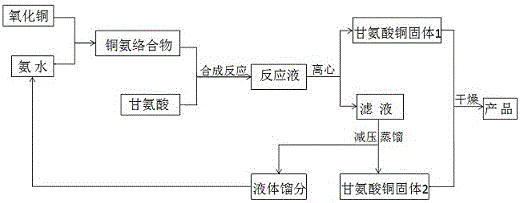

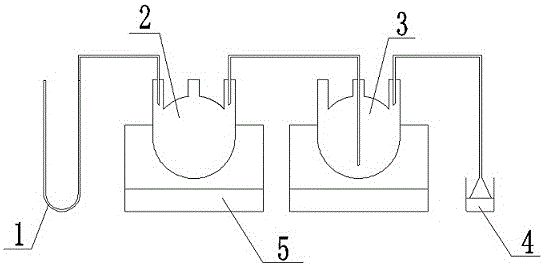

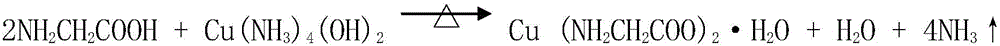

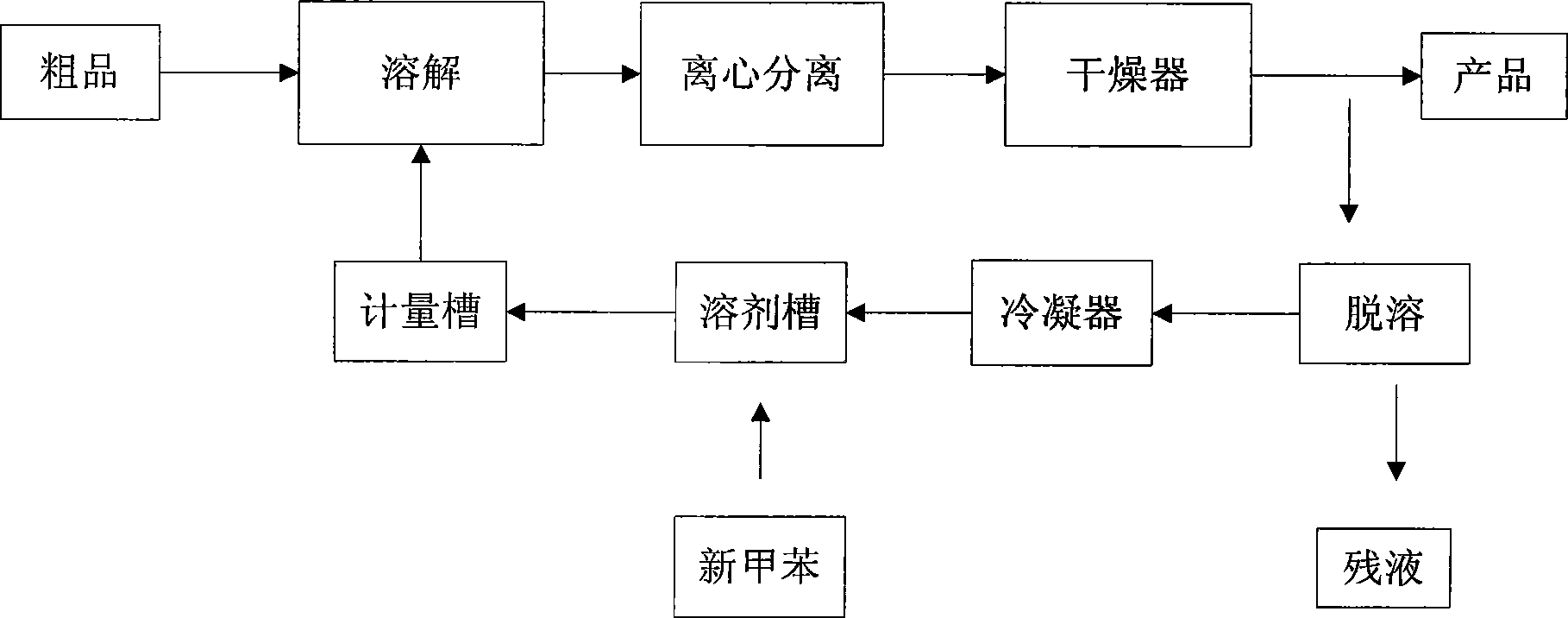

Preparation method of copper glycinate

ActiveCN106278916ADoes not increase interfering ionsReduce manufacturing costOrganic compound preparationAmino-carboxyl compound preparationGlycineCopper oxide

The invention discloses a preparation method of copper glycinate. The preparation method comprises the following steps: (1) dissolving copper oxide: dissolving the copper oxide into ammonia water to form a copper-ammonia complex; (2) carrying out a synthetic reaction: adding glycine and the copper-ammonia complex into a reaction kettle according to a certain ratio and reacting; heating and reacting for a period of time to obtain reaction liquid; (3) purifying a product: cooling the reaction liquid and centrifuging to obtain a copper glycinate solid 1 and filtrate; decompressing and distilling the filtrate to obtain a copper glycinate solid 2 and a liquid fraction; drying the copper glycinate solid 1 and the copper glycinate solid 2 to obtain a product; (4) recycling ammonia: absorbing ammonia gas generated in a reaction process by an absorbent, so as to obtain recycling liquid; using the recycling liquid to the step (1) to replace ammonia water for dissolving copper oxide. The invention provides the preparation method of the copper glycinate, which can avoid interference of foreign ions and can also improve the reaction speed.

Owner:HEBEI DONGHUA JIHENG CHEM

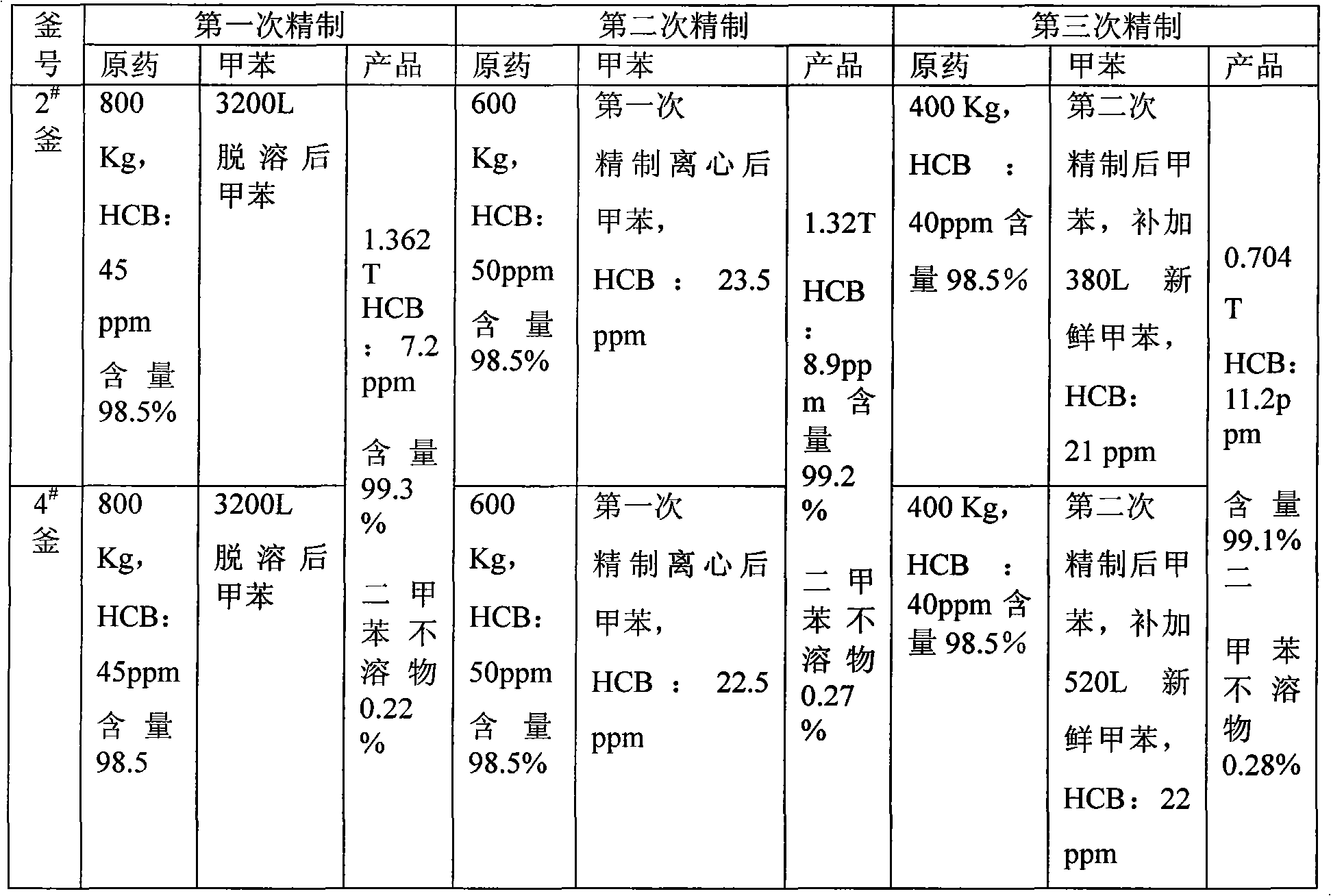

Method for purifying tetrachloroisophthalonitrile crystal

ActiveCN101962344BEasy to operateHigh purification rateBiocideFungicidesOrganic solventHazardous substance

Owner:JIANGSU XINHE AGROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com