Nano-scale collagen purification method capable of reaching absorption rate of 96%

A collagen and purification method technology, which is applied in the preparation methods of peptides, chemical instruments and methods, animal/human proteins, etc., can solve the problems of affecting the quality of collagen, many impurities in collagen, and insufficient purification accuracy, and achieves increased purification. The effect of yield and purity, small molecular weight, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

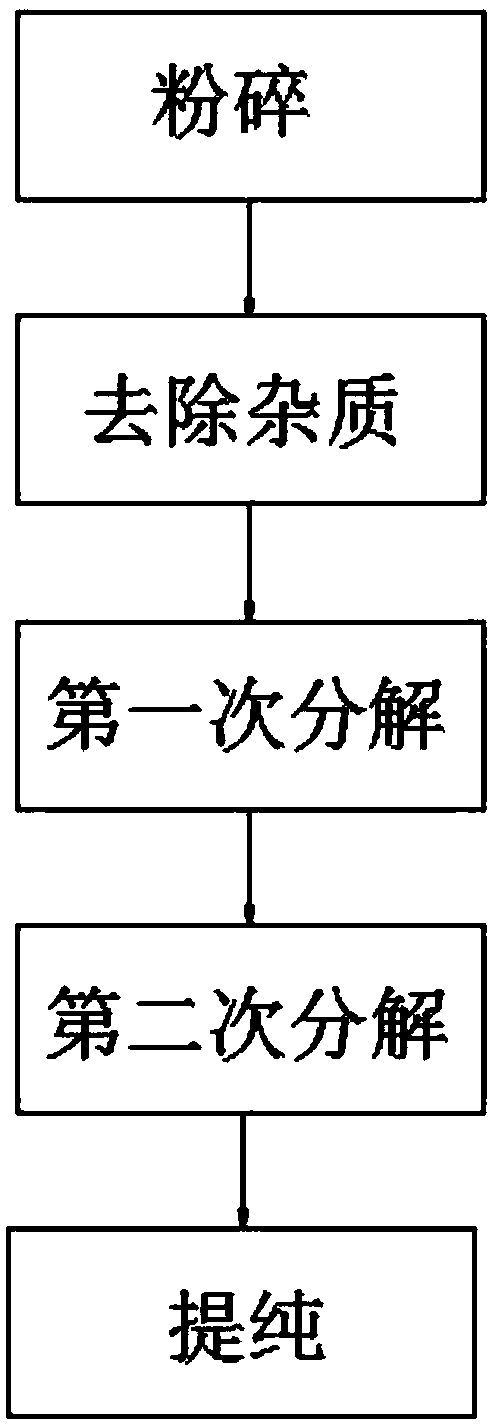

[0026] Example: such as figure 1 As shown, the present invention provides a nanoscale collagen purification method with an absorption rate of 96%, comprising the steps of:

[0027] 1) Crushing: Firstly, the fish skin is subjected to essence detection, which is divided into antibiotic detection, heavy metal residue detection, estrogen detection and animal-derived toxin residue detection, and then the fish skin is soaked in ultra-pure water until the raw material containing collagen is frozen. Stir the loose tissue particles evenly with a glass rod to form a paste; add 10 times the volume of ultrapure water to the pasty tissue particles, and homogenize 3 times according to the operating procedures of the tissue masher until completely suspended; After the particles are crushed evenly, add ultrapure water until the tissue content is 25 g / L, and mix well; add glacial acetic acid to the tissue suspension, and adjust the solution concentration to 0.5 mg / ml; digestion: weigh pepsin, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com