Purification technology for waste liquor produced during sapphire grinding by aid of boron carbide

A technology of boron carbide and sapphire, applied in the field of waste liquid purification process, can solve the problems of increasing equipment investment, affecting alkali washing purification, unfavorable recycling, etc., and achieves high purification rate, short production cycle and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

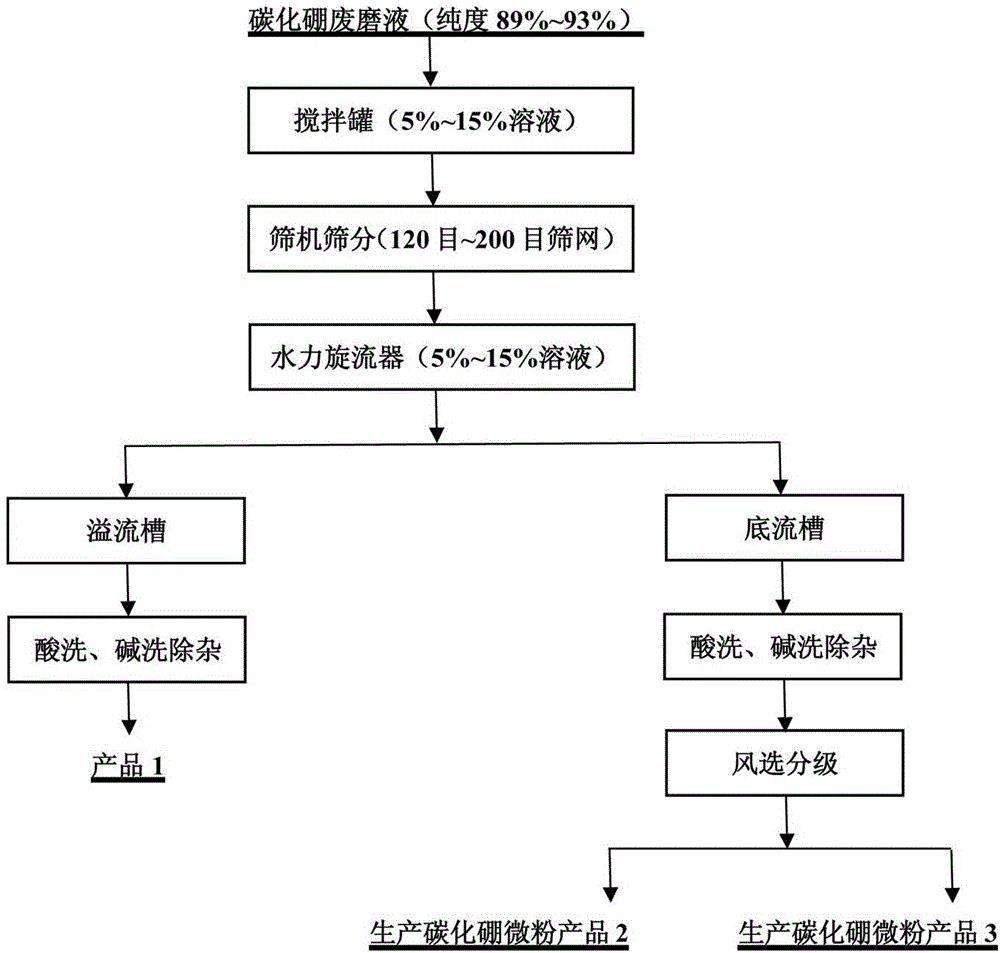

[0031] Such as figure 1 Shown, the purification process of the waste liquid that boron carbide grinds sapphire produces, specifically adopt following steps to carry out,

[0032] (1) Prepare the boron carbide waste grinding solution in the No. 1 stirring tank to make a solution with a concentration of 5%~15%;

[0033] (2) Pass the boron carbide waste grinding liquid through a sieve machine equipped with a 120-mesh screen, and the solution under the sieve enters the No. 2 mixing tank;

[0034] (3) Put the solution in the No. 2 stirring tank into the hydrocyclone with a feeding pressure of 0.2Mpa, and after the cyclone classification, the weight ratio of underflow and overflow material is 1.3:1;

[0035](4) Put the overflow material into pickling and alkali washing to remove impurities, the concentration of acid solution is 50%, stir for 4 hours after adding acid, wash with water 6 times until the solution is neutral; continue to add alkali to remove impurities, the concentrati...

Embodiment 2

[0042] Such as figure 1 Shown, the purification process of the waste liquid that boron carbide grinds sapphire produces, specifically adopt following steps to carry out,

[0043] (1) Dilution: Add water to the waste grinding liquid with a boron carbide particle size of 3µm~130µm, measure the concentration of the waste grinding liquid, weigh a certain weight of the boron carbide waste grinding liquid and put it into the batching tank, stir the batching tank, add water to the medium Prepare a solution with a mass concentration of 5% to 15%;

[0044] (2) Filtration: Pass the solution prepared in step (1) through a sieve machine equipped with a 200-mesh screen. The sieve machine screens out the large particles of impurities mixed in the boron carbide waste grinding liquid, and the solution under the sieve enters another stirring in the can.

[0045] (3) Cyclone classification: pump the solution stored in the stirring tank after step (2) into the hydrocyclone for cyclone classifi...

Embodiment 3

[0057] The purification process of the waste liquid produced by boron carbide grinding sapphire is carried out in the following steps,

[0058] (1) Dilution: Add water to the waste grinding liquid with a boron carbide particle size of 3µm~130µm, measure the concentration of the waste grinding liquid, weigh a certain weight of the boron carbide waste grinding liquid and put it into the batching tank, stir the batching tank, add water to the medium Prepare a solution with a mass concentration of 5% to 15%;

[0059] (2) Filtration: Pass the solution prepared in step (1) through a sieve machine equipped with a 150-mesh screen. The sieve machine screens out the large particles of impurities mixed in the boron carbide waste grinding liquid, and the solution under the sieve enters another stirring in the can.

[0060] (3) Cyclone classification: pump the solution stored in the stirring tank after step (2) into the hydrocyclone for cyclone classification. After the cyclone classifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com