Methane purification system and methane purification technology thereof

A technology of biogas and gas cabinets, which is applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of high operating cost, high investment cost, and low purification purity, and achieve low operating cost, low failure rate, and high purification rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

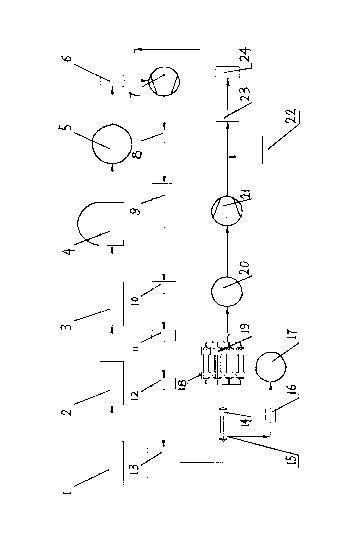

[0017] A biogas purification system, comprising an anaerobic tank 1, a particle filter 2 is connected to the anaerobic tank 1, a drying tower 3 is connected to the particle filter 2, a desulfurization tower 4 is connected to the drying tower 3, and the desulfurization A gas cabinet 5 is connected to the tower 4, a steam-water separator 6 is connected to the gas cabinet 5, a low-pressure biogas compressor 7 is connected to the steam-water separator 6, and an interception pre-filter 8 is connected to the low-pressure biogas compressor 7 , the interception pre-filter 8 is connected with a refrigerated dryer 9, a coalescing filter 10 is connected with the refrigerated dryer 9, and an oil-water separation filter 11 is connected with the coalescing filter 10. The oil-water separation filter 11 is connected with a precision terminal filter 12, and a heater 13 is connected with the precision terminal filter 12, and the gas output port of the heater 13 is connected with the first CO 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com