Method for purifying tetrachloroisophthalonitrile crystal

A technology of tetrachloroisophthalonitrile and tetrachloroisophthalonitrile is applied in the field of tetrachloroisophthalonitrile crystallization and purification, and achieves the effects of simple operation, high purification rate and high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

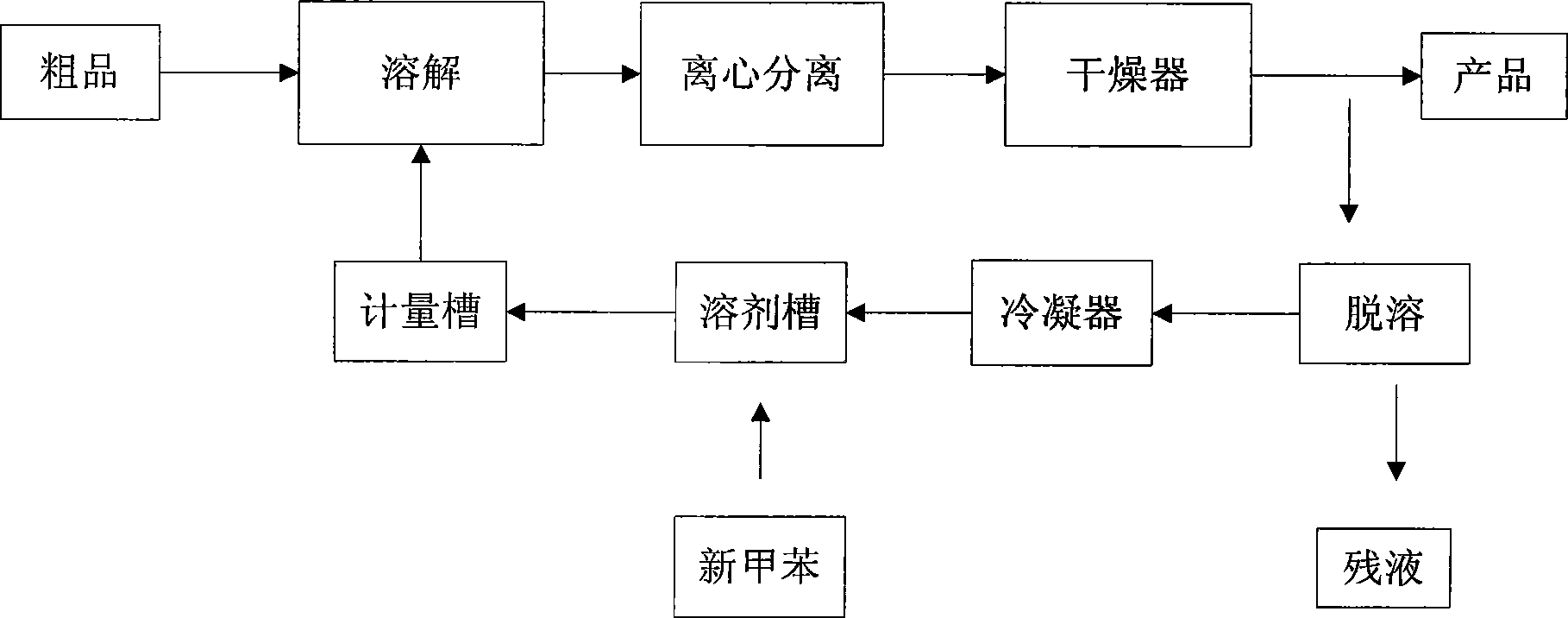

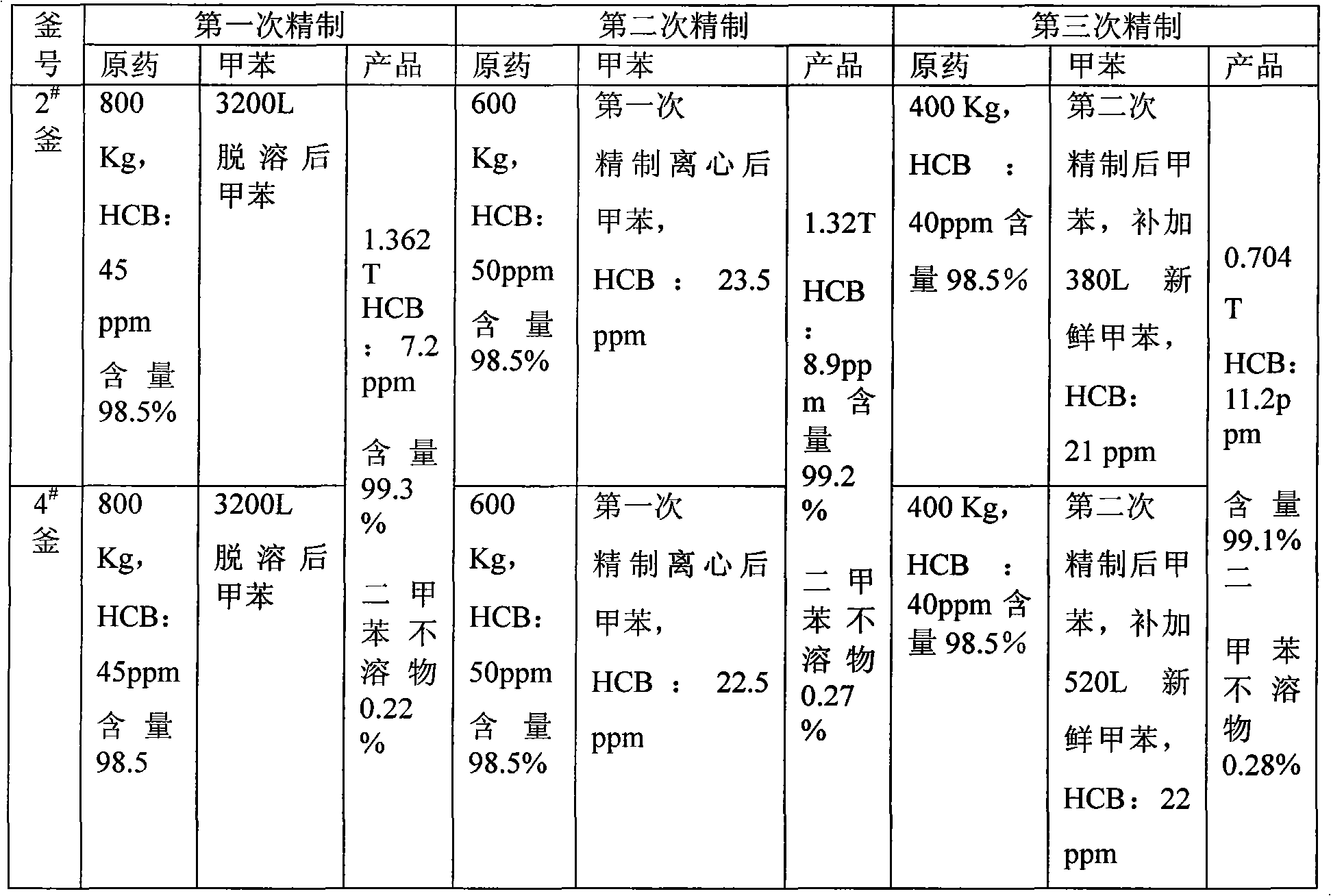

[0013] A method for tetrachloroisophthalonitrile crystallization purification, the flow chart of the method is as figure 1 Shown, comprise the following steps: the raw material tetrachloroisophthalonitrile that contains harmful substance hexachlorobenzene is placed in the dissolving kettle that toluene is housed, the weight percent concentration of tetrachloroisophthalonitrile is 90%, harmful substance The content of hexachlorobenzene is 40mg / kg, and the stirring device is turned on to stir and mix, then the temperature in the dissolution tank is raised to 85°C, and the heat preservation reaction is carried out for 1h, then the temperature of the dissolution tank is lowered to 20°C with cooling water, and finally separated by a centrifuge to obtain After the wet material is dried, the finished product tetrachloroisophthalonitrile is obtained. The centrifuged residual liquid is collected through precipitation, and the remaining part is condensed in a condenser, and then placed i...

Embodiment 2

[0026] A method for crystallization and purification of tetrachloroisophthalonitrile, the method comprises the following steps: placing the raw material tetrachloroisophthalonitrile containing the harmful substance hexachlorobenzene in a dissolution tank equipped with toluene, and tetrachloroisophthalonitrile The weight percent concentration of dinitrile is 95%, the harmful substance hexachlorobenzene content is 200mg / kg, and the stirring device is turned on to stir and mix, then the temperature in the dissolving tank is raised to 90°C, and the heat preservation reaction is carried out for 1.5h, and then cooled with cooling water. The temperature of the dissolution kettle is lowered to 30°C, and finally separated by a centrifuge, and the obtained wet material is dried to obtain the finished tetrachloroisophthalonitrile.

Embodiment 3

[0028] A method for crystallization and purification of tetrachloroisophthalonitrile, the method comprises the following steps: placing the raw material tetrachloroisophthalonitrile containing the harmful substance hexachlorobenzene in a dissolution tank equipped with toluene, and tetrachloroisophthalonitrile The weight percent concentration of dinitrile is 92%, and the content of harmful substance hexachlorobenzene is 150 mg / kg. Turn on the stirring device to stir and mix, then raise the temperature in the dissolution tank to 88 ° C, keep the temperature for 1.5 hours, and then use cooling water to dissolve The temperature of the dissolution kettle was lowered to 25°C, and finally separated by a centrifuge, and the obtained wet material was dried to obtain the finished tetrachloroisophthalonitrile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com