Recycling process and method for all metal elements in abandoned power lithium batteries

A lithium battery and all-element technology, which is applied in the recycling process of all metal elements in waste power lithium batteries, can solve the problems of poor element recycling effect, inability to fully recycle metal elements, waste of metal resources, etc., and achieve good environmental quality , high protection effect, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

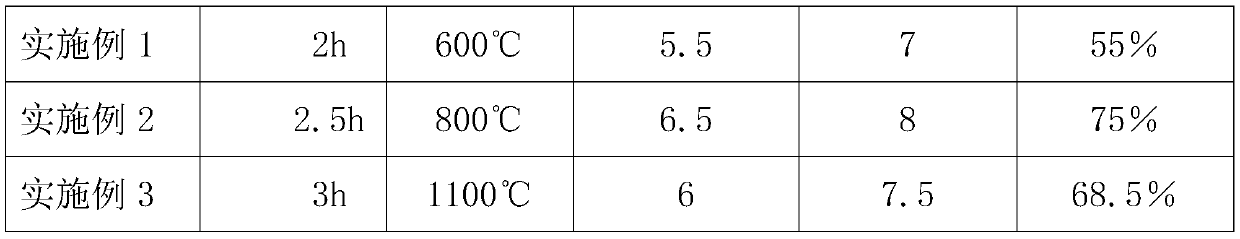

Embodiment 1

[0026] The invention provides a process and method for recovering all metal elements in a waste power lithium battery, which specifically includes the following steps:

[0027] Step 1: Process the raw materials, rinse the waste lithium battery, rinse it repeatedly with clean water three times, wipe it with a cotton cloth, then disassemble the waste lithium battery, dry the internal raw materials of the waste lithium battery at high temperature, and use grinding The machine grinds the internal raw materials of waste power lithium batteries, and screens the internal raw materials for many times to remove large particle raw materials;

[0028] Step 2: Roasting at high temperature, place the ground raw materials in the combustion furnace for combustion, and add an appropriate amount of carbon powder to the inside, when the reaction temperature in the combustion furnace is heated to 600 ° C, the reaction time is kept at 2 hours, so that the raw materials The internal metal elements...

Embodiment 2

[0035] The invention provides a process and method for recovering all metal elements in a waste power lithium battery, which specifically includes the following steps:

[0036] Step 1: Process the raw materials, rinse the waste lithium battery, rinse it repeatedly with clean water three times, wipe it with a cotton cloth, then disassemble the waste lithium battery, dry the internal raw materials of the waste lithium battery at high temperature, and use grinding The machine grinds the internal raw materials of waste power lithium batteries, and screens the internal raw materials for many times to remove large particle raw materials;

[0037]Step 2: Roasting at high temperature, place the ground raw materials in the combustion furnace for combustion, and add an appropriate amount of carbon powder inside, when the reaction temperature in the combustion furnace is heated to 800°C, the reaction time is kept at 2.5h, so that The metal elements inside the raw material form oxides wit...

Embodiment 3

[0044] The invention provides a process and method for recovering all metal elements in a waste power lithium battery, which specifically includes the following steps:

[0045] Step 1: Process the raw materials, rinse the waste lithium battery, rinse it repeatedly with clean water three times, wipe it with a cotton cloth, then disassemble the waste lithium battery, dry the internal raw materials of the waste lithium battery at high temperature, and use grinding The machine grinds the internal raw materials of waste power lithium batteries, and screens the internal raw materials for many times to remove large particle raw materials;

[0046] Step 2: Roasting at high temperature, place the ground raw material in the combustion furnace for combustion, and add an appropriate amount of carbon powder inside, when the reaction temperature in the combustion furnace is heated to 1100 ° C, the reaction time is kept at 3 hours, so that the raw material The internal metal elements form ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com