Trimethyl orthoacetate continuous distillation equipment and distillation technology thereof

A trimethyl orthoacetate and rectification technology, which is applied in the field of trimethyl orthoacetate continuous rectification equipment and its rectification process, can solve the problems of large environmental pollution, large floor space, and difficult operation, and achieve a high purification rate The effect of high height, small equipment footprint and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The continuous rectification process of trimethyl orthoacetate in this embodiment, wherein, the mother liquor that needs to be distilled contains a small amount of methanol, a small amount of acetonitrile, a small amount of by-products, trimethyl orthoacetate, and solvent naphtha.

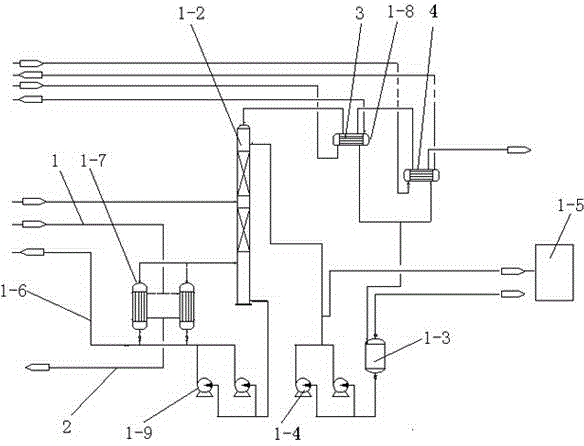

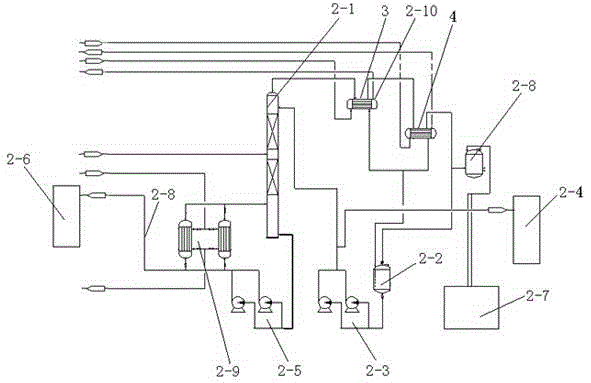

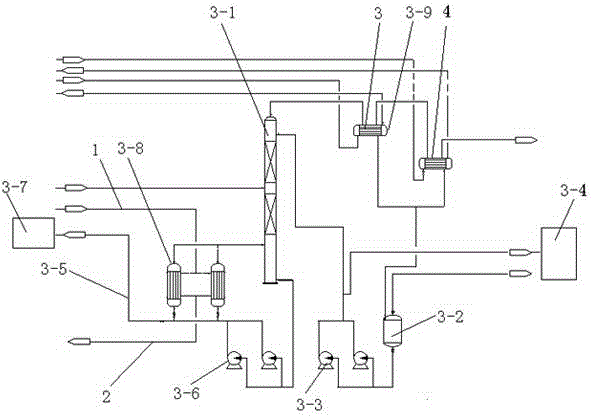

[0027] Equipment used: three-phase rectification device in series, which are respectively a primary rectification device for crude fractionation of light components and heavy components for mother liquor, a secondary rectification device for separating products and solvents, and a secondary rectification device for separating The three-stage rectification device for products and light components, the first-stage rectification device, the second-stage rectification device, and the third-stage rectification device are sequentially connected in series; wherein, the first-stage rectification device includes a first-stage separation tower 1-2, and a first-stage rectification device The bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com