Drying room exhaust gas purification and energy recovery system and apparatus

A waste gas purification and energy recovery technology, which is applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large energy consumption, increased production costs, and high processing costs, and achieves high heat energy utilization and convenient device installation , the effect of small space volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

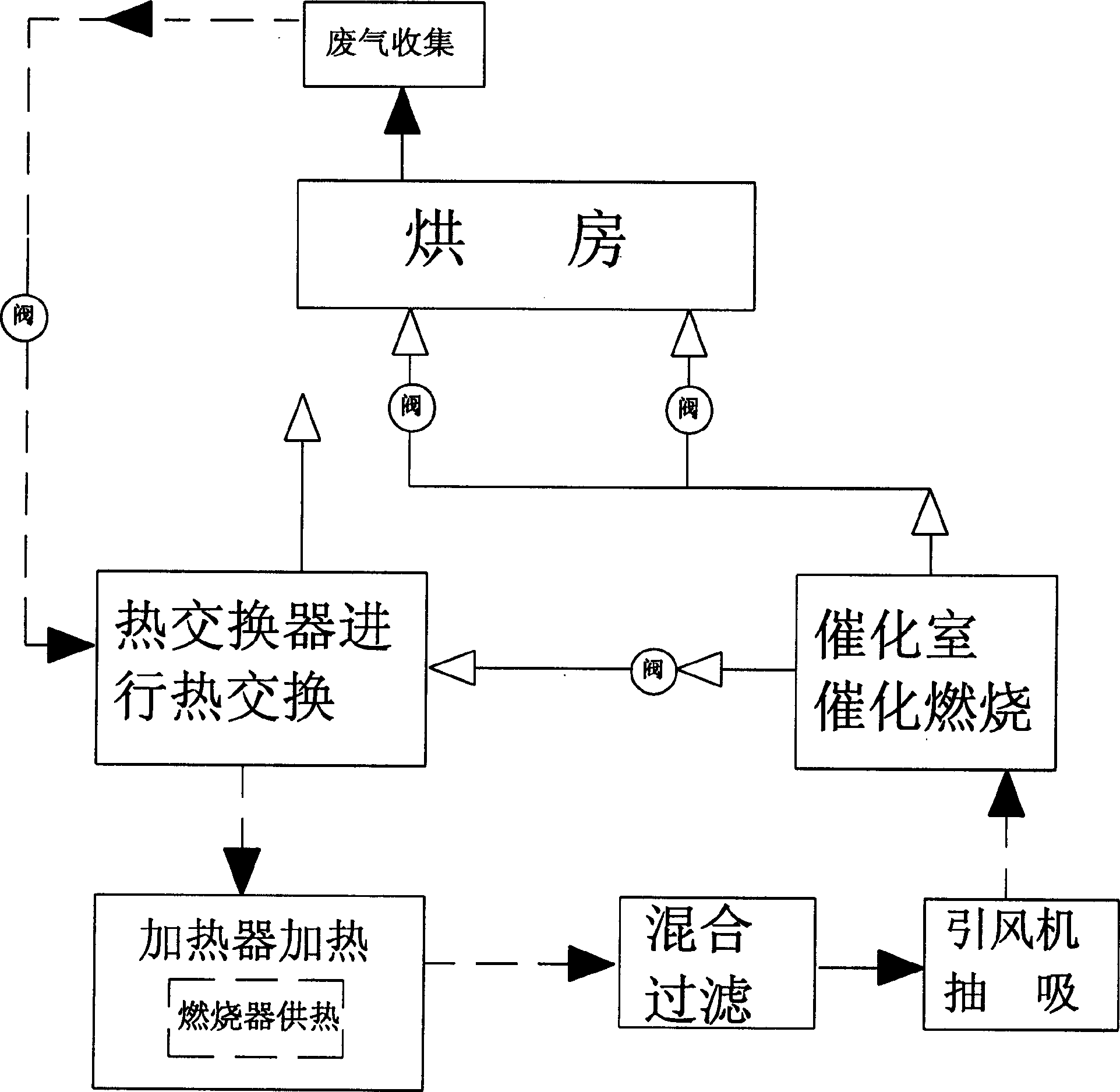

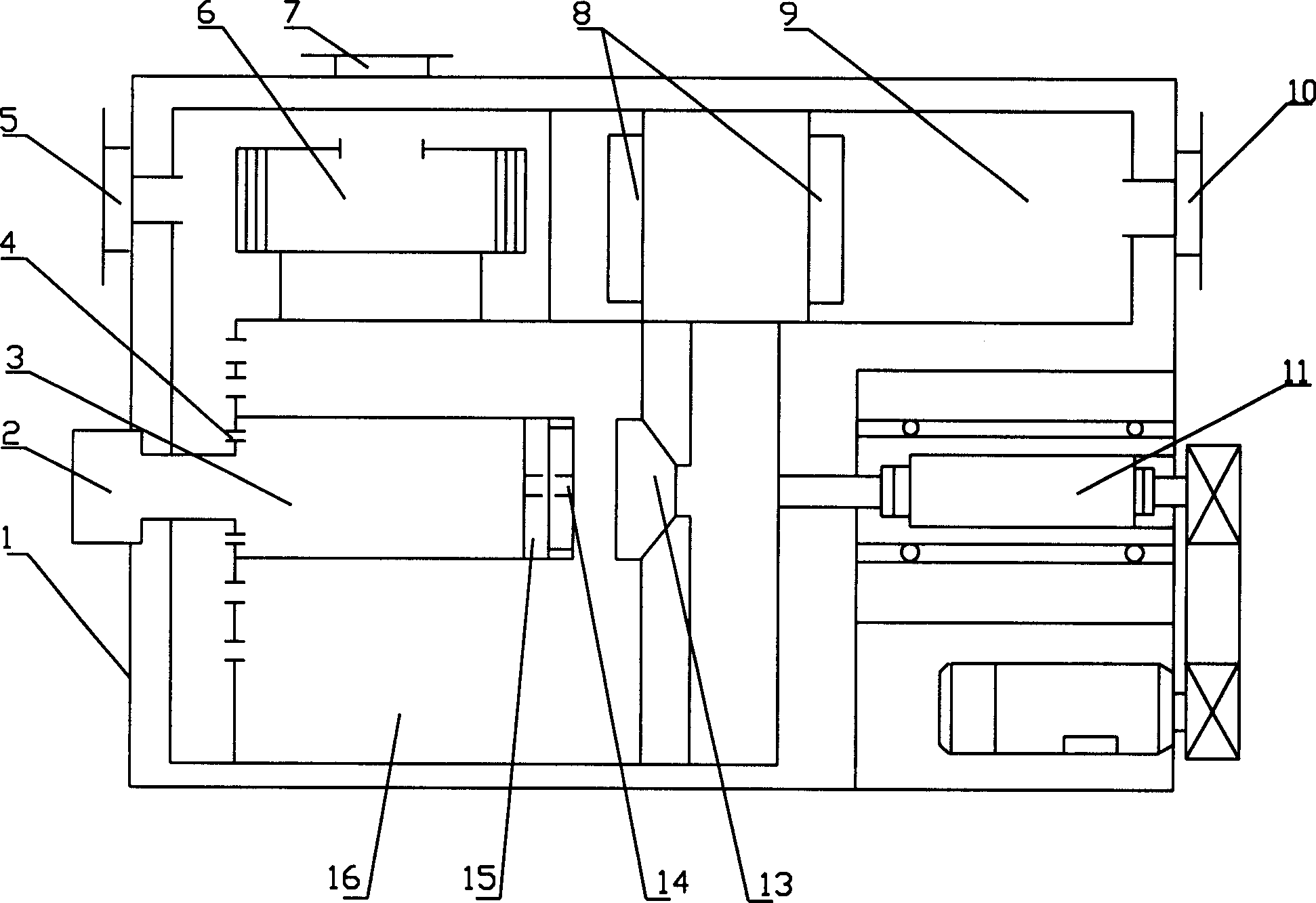

[0024] A system for purification of waste gas in a drying room and energy recovery and utilization, such as figure 1 As shown, the solid arrow in the figure indicates the flow direction of exhaust gas, and the hollow arrow indicates the flow direction of purified gas, forming a recycling system. After being collected, the exhaust gas discharged from the drying room enters the heat exchanger for heat exchange and pre-heating, and the pre-heated exhaust gas enters the heating chamber Heating, the heating chamber provides heat in the form of heat exchange through the burner set inside it, and a small part can also enter the burner to participate in combustion; after the heated exhaust gas is mixed with the exhaust gas burned by the burner, the temperature will reach 270-370 ℃, the filtered exhaust gas is extracted by the induced draft fan and enters the catalytic chamber for catalytic combustion; the temperature of the purified gas after combustion can reach 400-550 ℃, and most of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com