Method for preparing high-content tuna anserine by adopting membrane separation and application of tuna anserine

A tuna, high-content technology, applied in the direction of semi-permeable membrane separation, application, material separation, etc., can solve the problems of high cost, unfavorable industrial production, obtaining high-purity tuna anserine, and many raw materials, etc., and achieve important social and economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

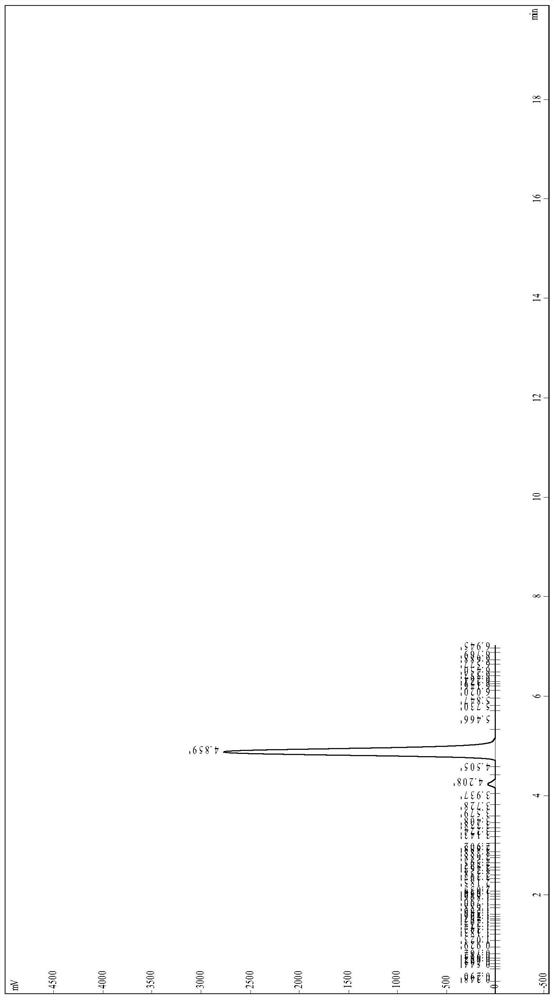

Embodiment 1

[0053] A kind of method adopting membrane separation to obtain high-content tuna anserine, concrete steps are as follows:

[0054] S1. Select 2.0kg of freshly frozen tuna meat.

[0055] S2. The raw materials are thawed by using ice water thawing method.

[0056] S3. The tuna meat is quickly crushed and beaten.

[0057] S4. Put the beaten tuna slurry in the boiling water prepared in advance (the first time the tuna common meat slurry is mixed with pure water at a mass ratio of 1:10), the temperature is controlled at 100°C, and the extraction time is 2h. 200 mesh sieves are sieved and filtered for the first time to obtain filtrate a, and the fish paste filtered by the first sieve continues to be dropped into boiling water for the second extraction (the second time tuna common meat fish paste and pure water are in a mass ratio of 1 : 10 mixing), the temperature is controlled at 100°C, the extraction time is 2h, and a 200-mesh sieve is used to sieve and filter for the second tim...

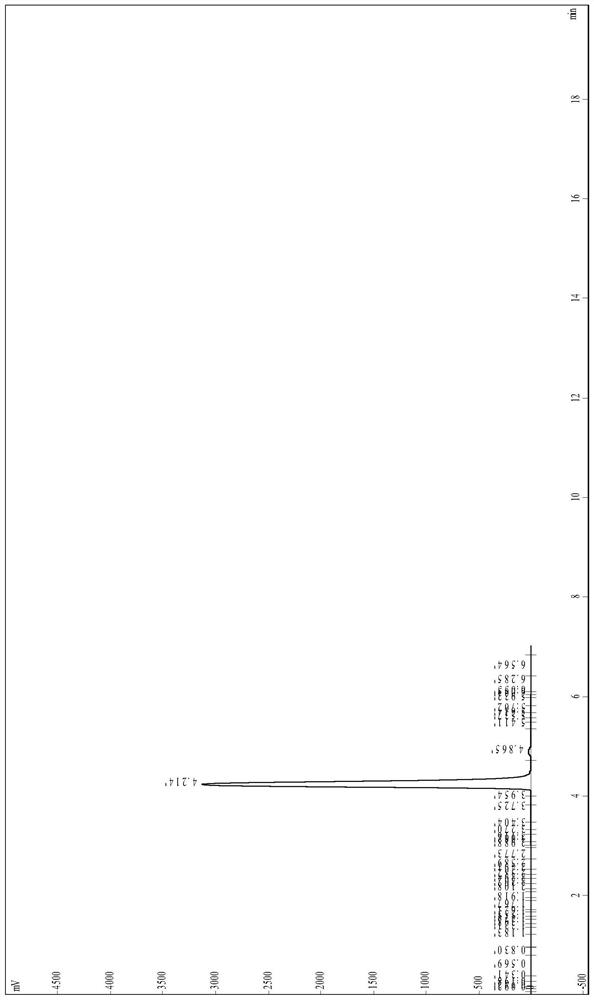

Embodiment 2

[0065] A kind of method adopting membrane separation to obtain high-content tuna anserine, concrete steps are as follows:

[0066] S1. Select 2.0kg of freshly frozen tuna meat.

[0067] S2. The raw materials are thawed by using ice water thawing method.

[0068] S3. The tuna meat is quickly crushed and beaten.

[0069] S4. Put the beaten tuna slurry in the boiling water prepared in advance (the first time the tuna common meat slurry is mixed with pure water at a mass ratio of 1:10), the temperature is controlled at 100°C, and the extraction time is 2h. 200 mesh sieves are sieved and filtered for the first time to obtain filtrate a, and the fish paste filtered by the first sieve continues to be dropped into boiling water for the second extraction (the second time tuna common meat fish paste and pure water are in a mass ratio of 1 : 10 mixing), the temperature is controlled at 100°C, the extraction time is 2h, and a 200-mesh sieve is used to sieve and filter for the second tim...

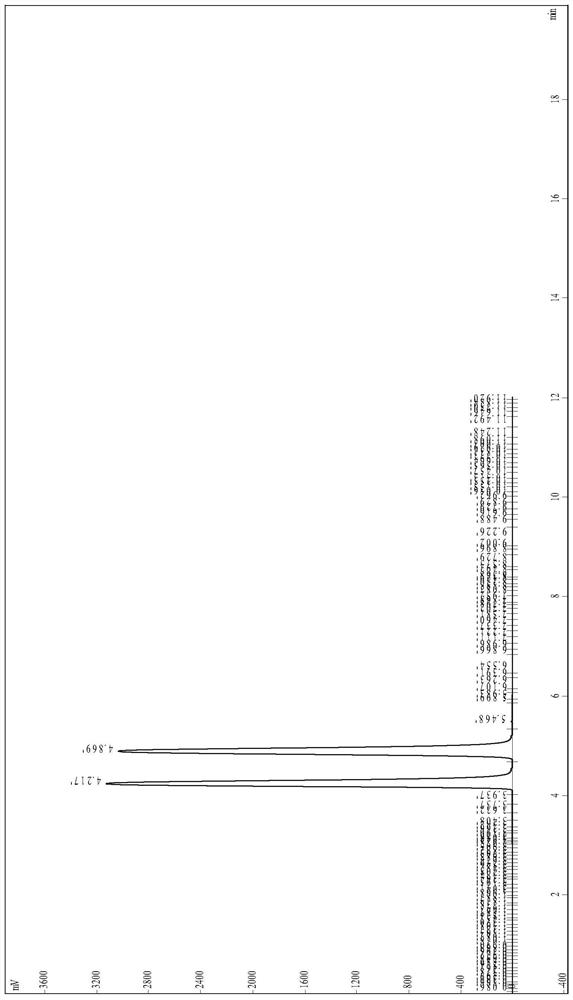

Embodiment 3

[0077] A kind of method adopting membrane separation to obtain high-content tuna anserine, concrete steps are as follows:

[0078] S1. Select 2.0kg of freshly frozen tuna meat.

[0079] S2. The raw materials are thawed by using ice water thawing method.

[0080] S3. The tuna meat is quickly crushed and beaten.

[0081] S4. Put the beaten tuna slurry in the boiling water prepared in advance (the first time the tuna common meat slurry is mixed with pure water at a mass ratio of 1:10), the temperature is controlled at 100°C, and the extraction time is 2h. The 200-mesh sieve is sieved and filtered for the first time to obtain filtrate a, and the remaining fish paste is continuously put into boiling water for the second extraction (the second time tuna common meat fish paste is mixed with pure water at a mass ratio of 1:10), the temperature The temperature was controlled at 100°C, the extraction time was 2 hours, and a second sieve was performed with a 200-mesh sieve to obtain th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com