Water-cooled continuous dry distillation type stalk powdered carbon machine

A technology of straw charcoal and dry distillation, which is applied in special forms of dry distillation, petroleum industry, biofuel, etc., can solve the problems of unsuitable straw carbonization production and popularization, low single-machine production efficiency, complex device structure, etc., and avoid the harm of tar clogging , increase the working stability, the effect of high carbonization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

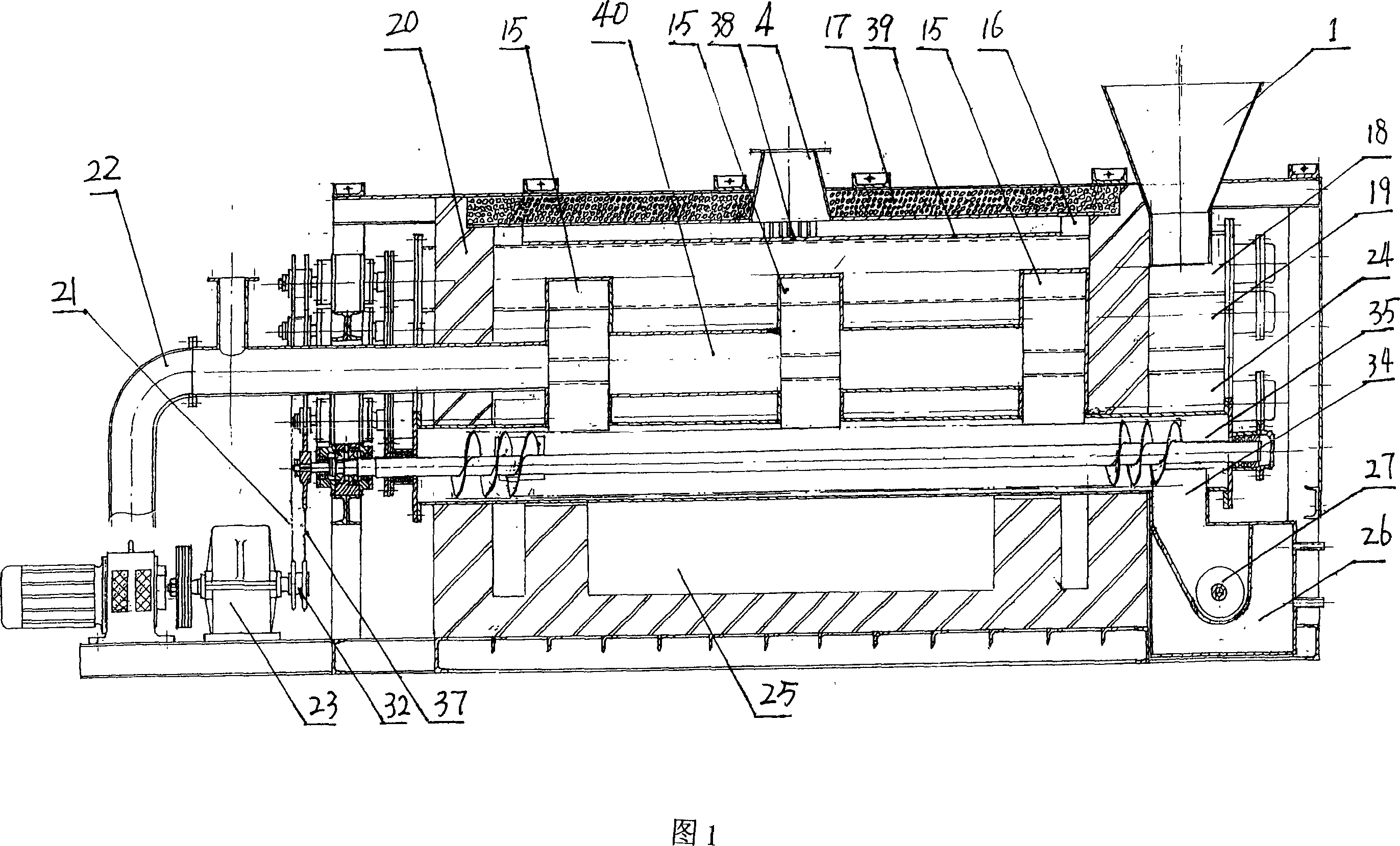

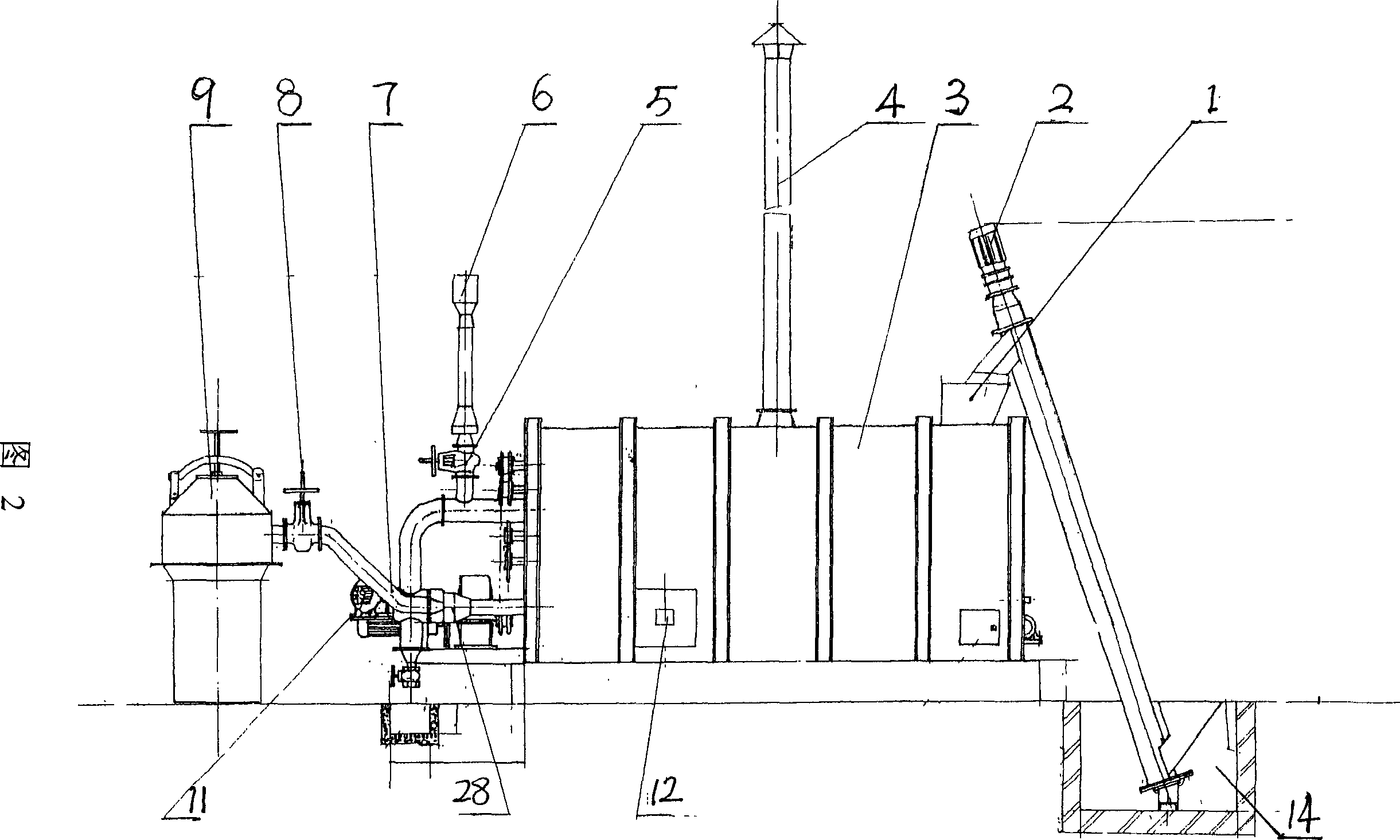

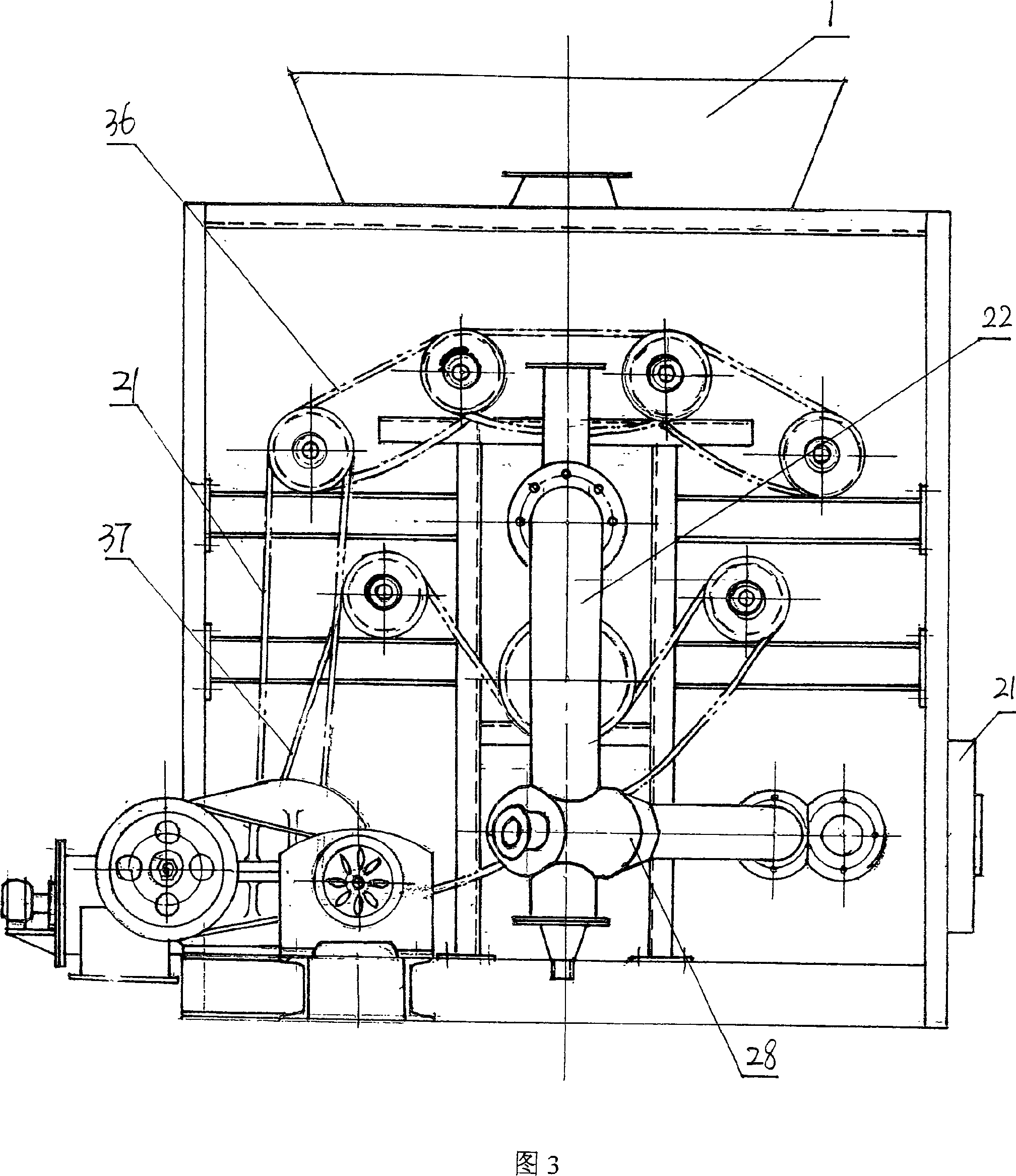

[0022] As shown in Figure 1, Figure 2, Figure 3, Figure 4, and Figure 5. The water-cooled continuous dry distillation straw charcoal powder machine of the present invention includes a combustion chamber 25, a carbonization chamber 16, a feeder 2, a gasification furnace 9, and an unloader 27. The combustion chamber communicates with the carbonization chamber through a heat transfer port on the top. There are four levels of carbonization tubes from top to bottom in the carbonization chamber: first level carbonization tube 18, second level carbonization tube 19, third level carbonization tube 24 and fourth level carbonization tube 35, first level carbonization tube and The second-stage carbonization pipes, between the second-stage carbonization pipes and the third-stage carbonization pipes, and between the third-stage carbonization pipes and the fourth-stage carbonization pipes are communicated by feeding passages. A screw conveyor is respectively provided in each tube body of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com