Biomass biogas purification method

A purification method and biomass technology, applied in the field of resources and environment, can solve the problems of high cost, complex process, few uses, etc., and achieve the effects of low cost, simple operation and high purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

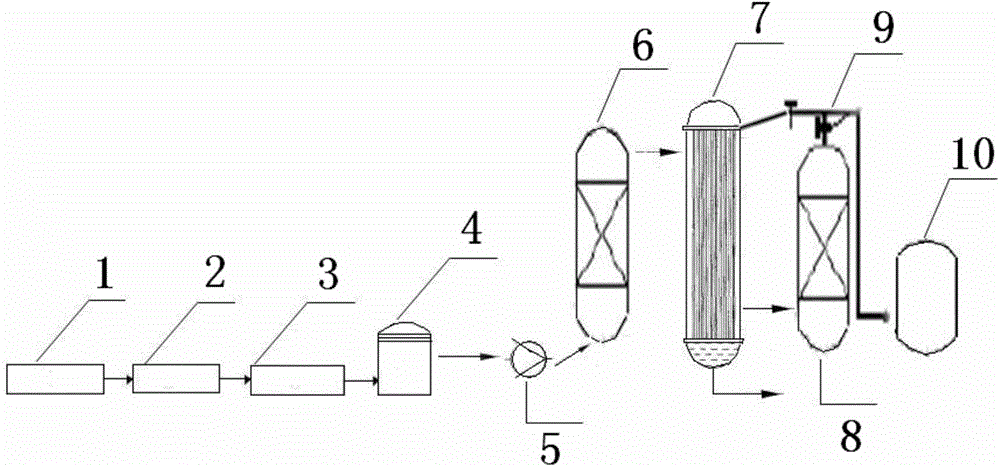

[0028] like figure 1 As shown, the untreated biogas 1 is passed through the particle filter 2 to decompose the particles and condensate in the gas flow, and then enters the drying tower 3, and the water is removed by drying, and then passes through the desulfurization tower 4, and is heated at normal temperature. The sulfide is removed under pressure, and the desulfurization process adopts the dry desulfurization continuous regeneration process, in which the desulfurizer uses iron oxide as the main active catalytic component, and adds various co-catalysts and carriers, and the desulfurization rate can reach more than 90%. The biogas passes through the compressor 5 and is compressed to 22MPa; then passes through the recooler 6 to reduce its temperature and then flows into the low-temperature purification tower 7, and controls the temperature in the low-temperature purification tower to -56°C so that the CO in the biogas 2 The liquefaction is precipitated from the lower part of ...

Embodiment 2

[0030] A method for purifying biomass methane, comprising the steps of:

[0031] The first step: the biogas 1 is passed through the particulate filter 2, and after the particles and condensate are separated, they are dried in the drying tower 3;

[0032] The second step: pass the dried biogas into the desulfurization tower 4 for desulfurization, then compress it to 21MPa through the compressor 5, and then cool down through the first recooler 6; the desulfurization is carried out continuously under normal temperature and pressure The regeneration process removes sulfide; the desulfurizer uses iron oxide as the main active catalytic component, and also includes a variety of co-catalysts and carriers. The desulfurization rate is above 90%.

[0033] Step 3: Pass the cooled biogas into the low-temperature purification tower 7, and the liquefied CO in the biogas 2 It is precipitated from the lower part of the low-temperature purification tower 7, and the pure methane gas flows int...

Embodiment 3

[0035] A method for purifying biomass methane, comprising the steps of:

[0036] The first step: the biogas 1 is passed through the particulate filter 2, and after the particles and condensate are separated, they are dried in the drying tower 3;

[0037] The second step: pass the dried biogas into the desulfurization tower 4 for desulfurization, then compress it to 24.5MPa through the compressor 5, and then cool down through the first recooler 6; the desulfurization is carried out under normal temperature and pressure by dry desulfurization The continuous regeneration process removes sulfide; the desulfurizer uses iron oxide as the main active catalytic component, and also includes a variety of co-catalysts and carriers. The desulfurization rate is above 90%.

[0038] The third step: the cooled biogas flows into the low-temperature purification tower 7, and the liquefied CO in the biogas 2 It is precipitated from the lower part of the low-temperature purification tower 7, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com