Method for re-purifying and recovering liquid paraffin obtained after solvent extraction

A technology for liquid paraffin and a recovery method, which is applied in the petroleum industry, refined hydrocarbon oil and other directions, can solve the problems of oxidative discoloration of liquid paraffin and high energy consumption of the separation method, and achieves the effects of low cost, environmental protection and simple process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be described in detail below through the given implementation examples.

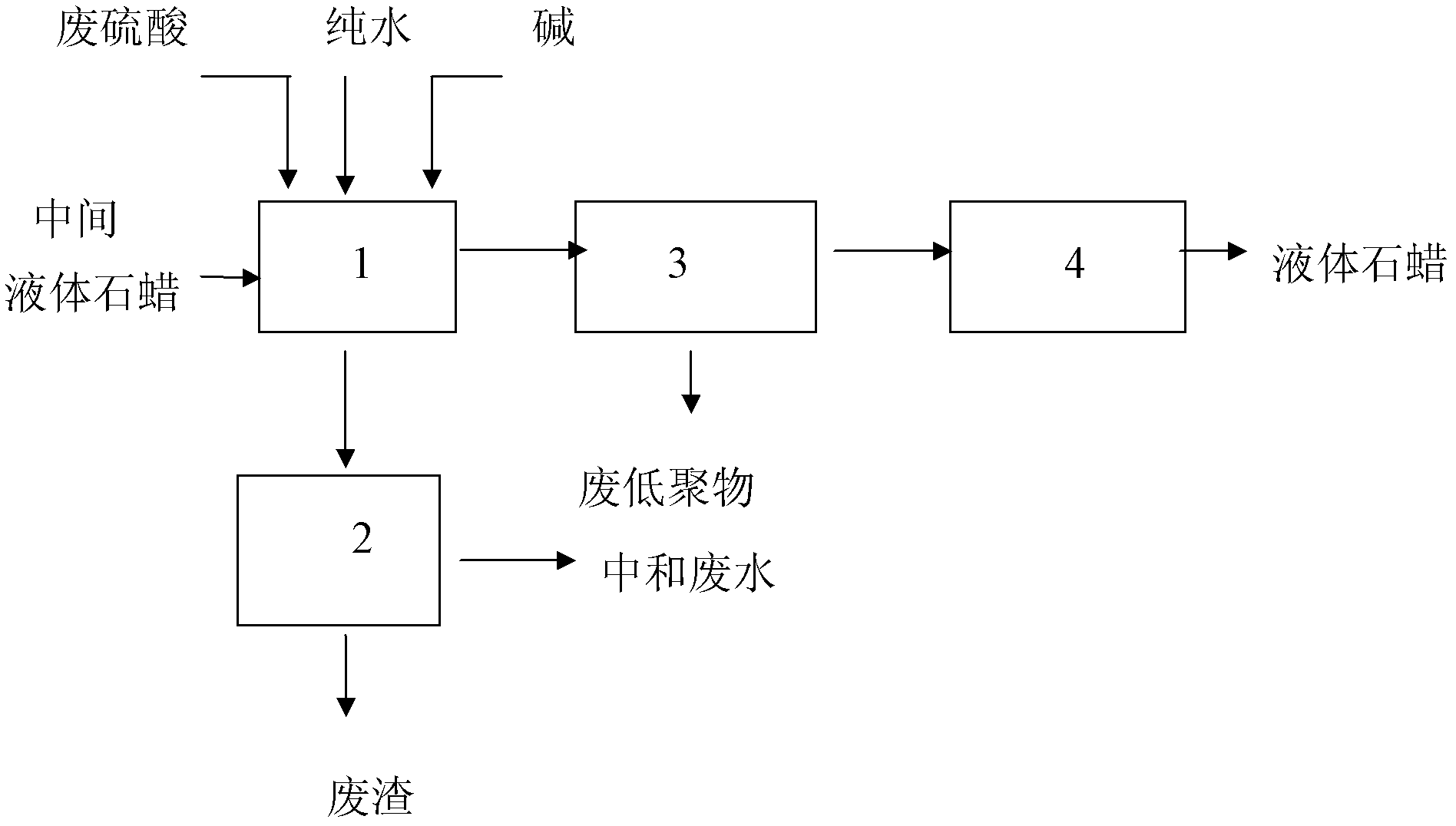

[0011] Get 1000kg of intermediate liquid paraffin, add it to a volume of 2000L reactor 1, start the stirring device, adjust the number of revolutions to 60 rpm, and slowly add 90kg of waste sulfuric acid with a concentration of 80%, which is used in the preparation of ion exchange resins. The waste sulfuric acid produced can of course be industrial sulfuric acid, stirred for 30 minutes, stopped for 5 hours, and after the upper and lower layers appeared, the lower layer of acid solution was discharged into the waste water and the tank 2; then stirred again, and added 2 % sodium carbonate solution or sodium hydroxide solution, and when the pH value is finally adjusted to 7, the neutralization process ends, and after standing for 1 hour to form the upper and lower layered liquids, a small amount of residual liquid in the lower layer is discharged t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com