Furnace for abstracting high-purity magnesium metal by electromagnetic method

A high-purity, metallic magnesium technology, applied in electric furnace heating, energy efficiency improvement, process efficiency improvement, etc., can solve the problems of high energy and raw material consumption, discontinuous production process, low purity of finished magnesium, etc., and achieve the purification rate High, small footprint, large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

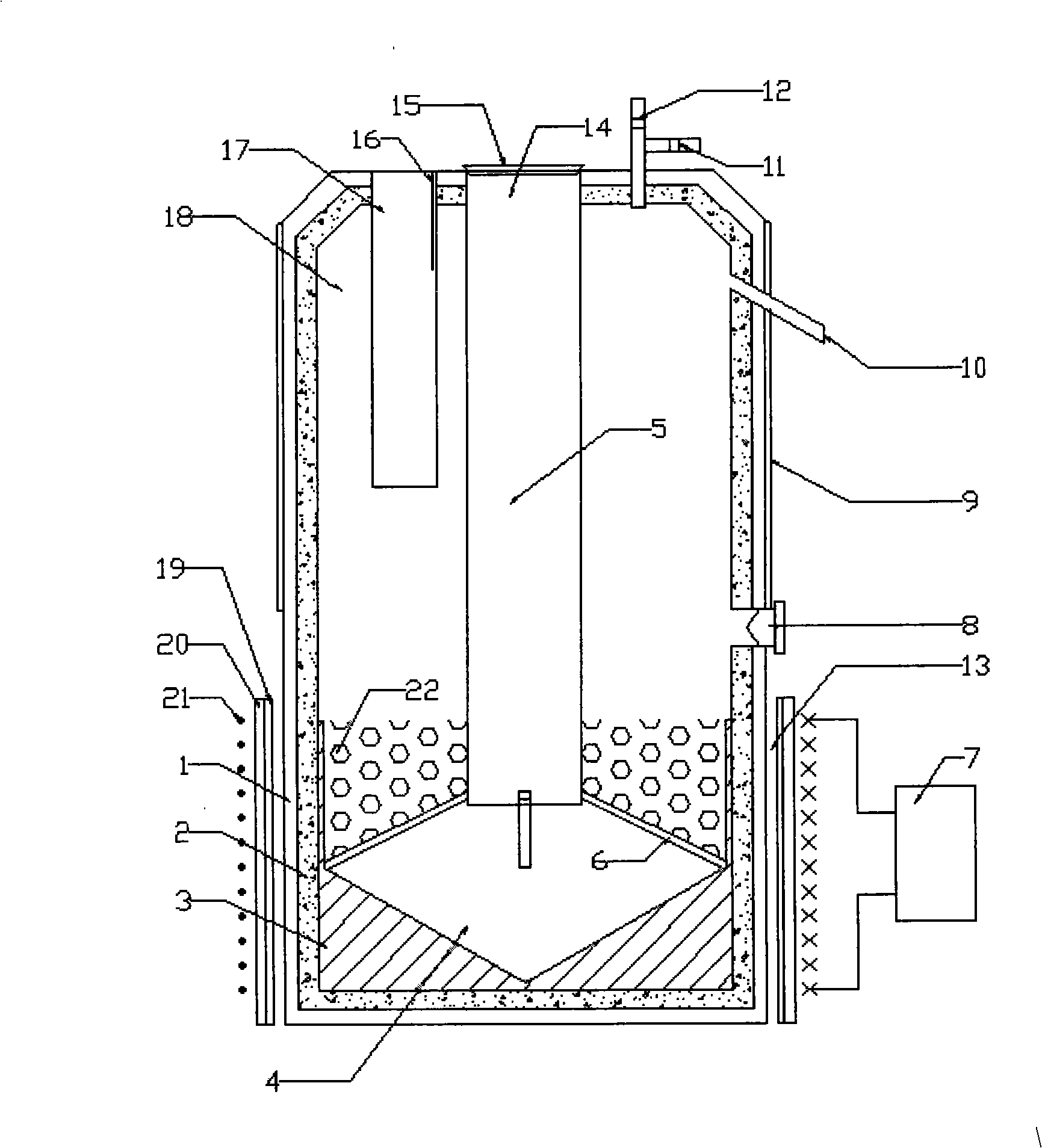

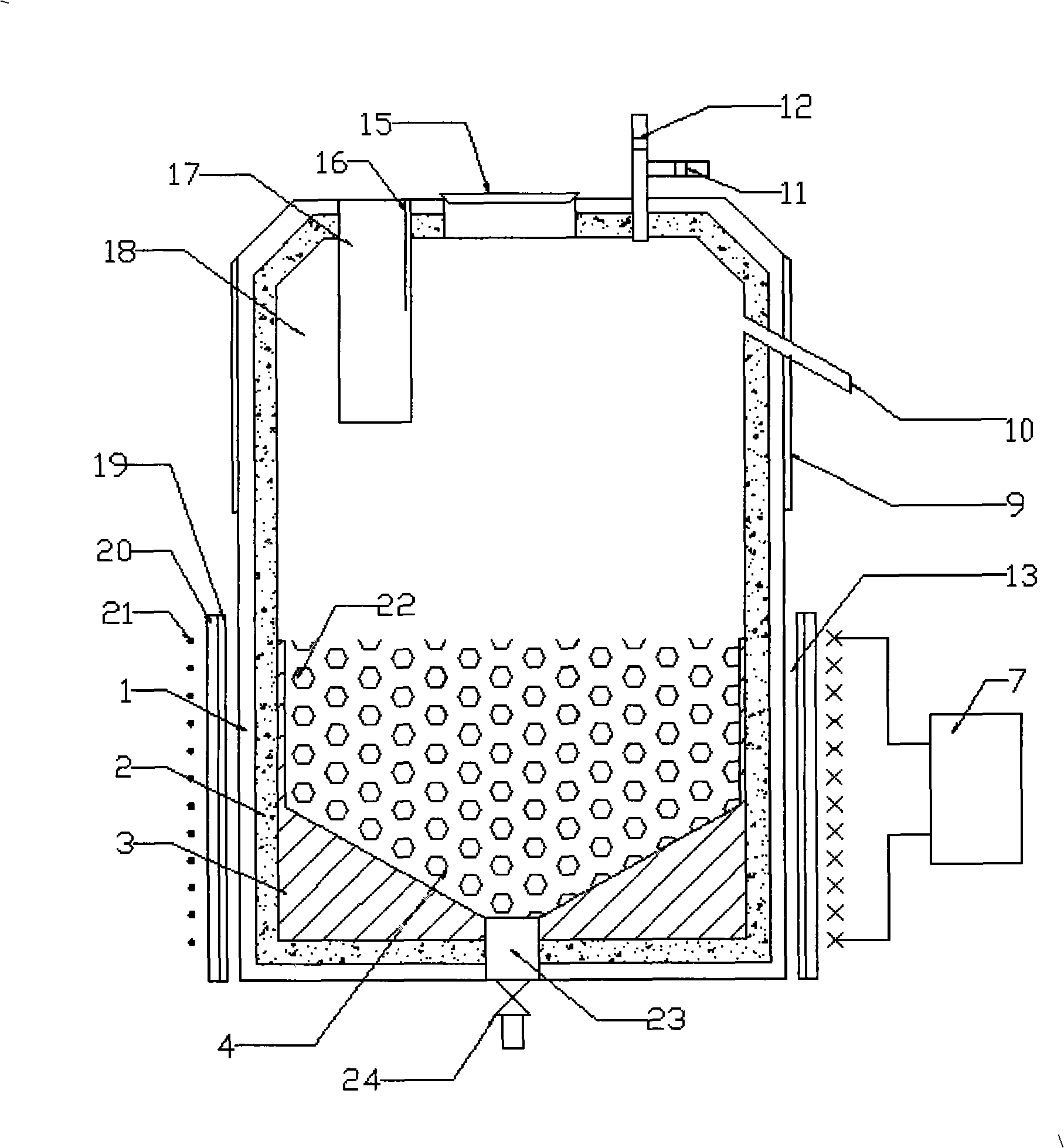

[0014] The furnace for extracting high-purity magnesium metal by electromagnetic method includes a closed furnace body 2, a raw material feeding barrel 17, a finished product discharge port 10, an emergency discharge port 8, an excitation coil 21 and a medium-high frequency power supply 7, and the furnace body 2 An excitation coil 21 is wound outside the lower half, and the excitation coil 21 is electrically connected to the medium and high frequency power supply 7 to generate a strong electromagnetic field in the furnace; a furnace bar support 6 is arranged above the bottom in the furnace body 2, and the middle part of the furnace bar support 6 is connected to the The bottom of a bottomless slag barrel 5 is fixedly connected together, the top of the bottomless slag barrel 5 is connected to the top of the furnace body 2, the top of the bottomless slag barrel 5 is provided with a cover 15, and the furnace The bar support 6 and the barrel body of the bottomless slag barrel 15 div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com