Cyclic utilization device for recycling, finely-steaming and purifying NMP in coating process of lithium ion battery

A lithium ion battery and coating technology, which is applied in the field of NMP recovery, distillation, purification and recycling devices in the coating process of lithium ion batteries, can solve the problems of consuming NMP solvent, unfavorable for energy saving and environmental protection, and large loss of NMP, and achieves high purification rate. , The effect of high liquid recycling recycling rate and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

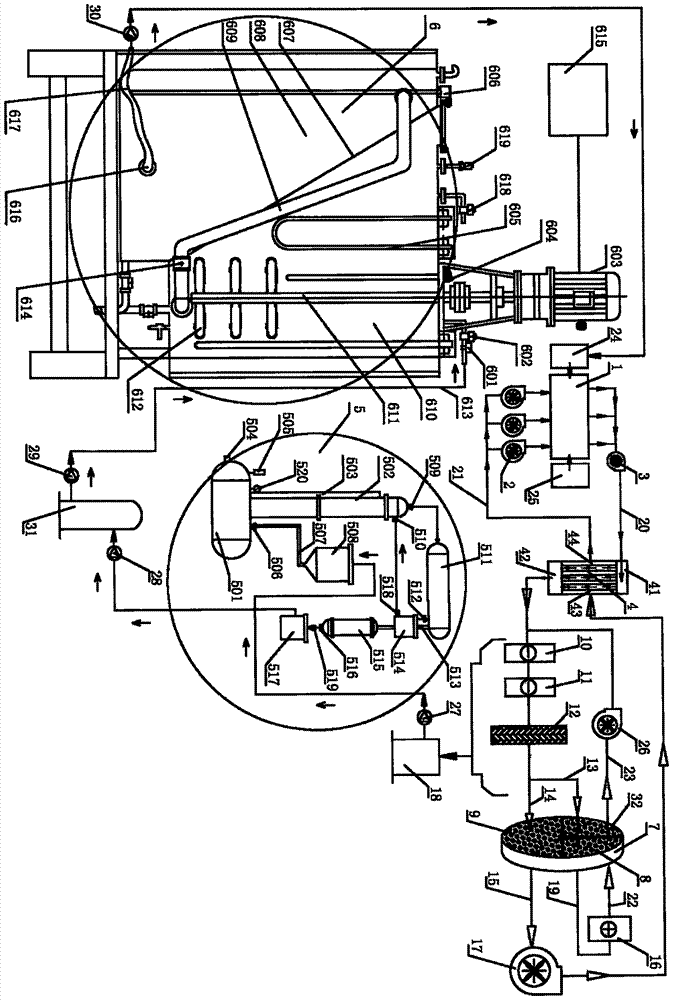

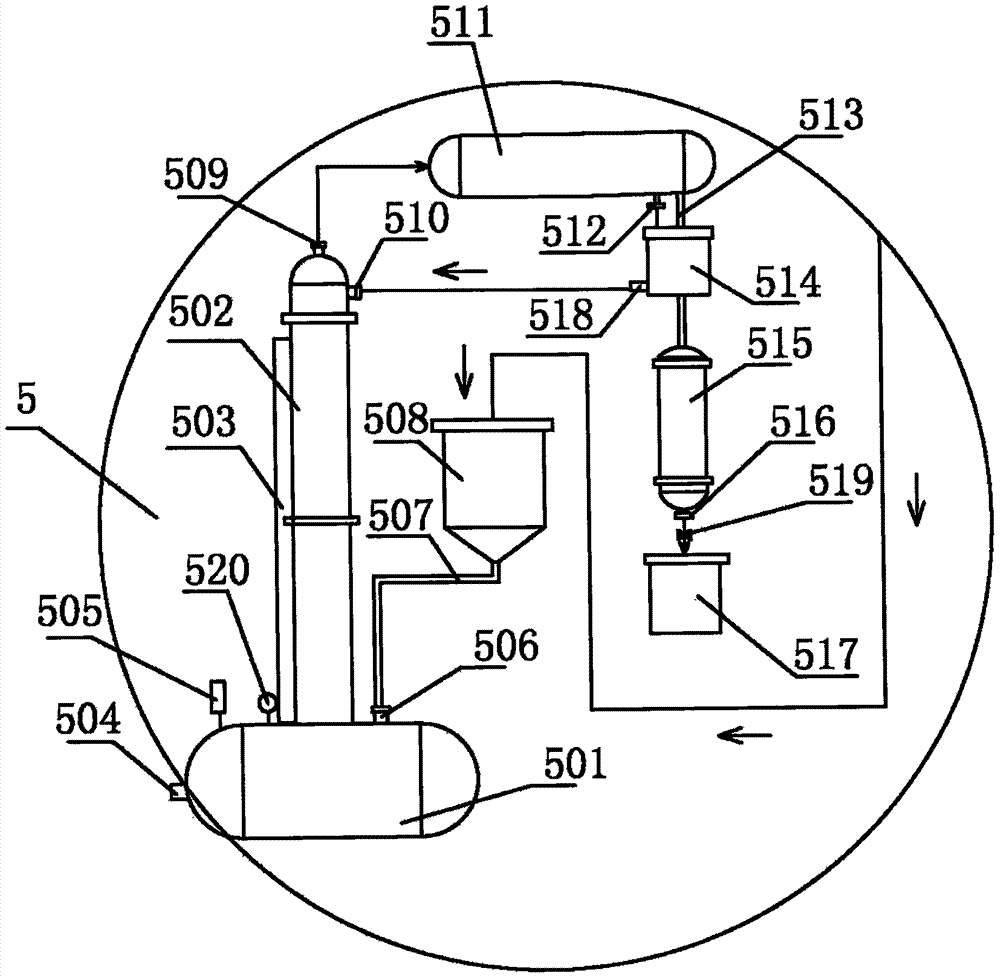

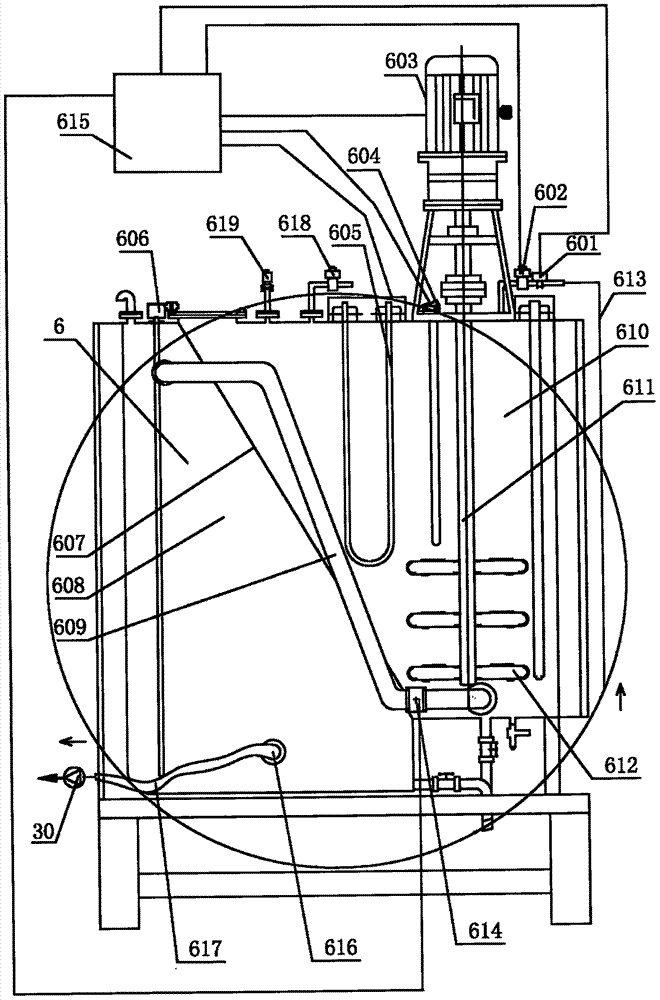

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 , image 3As shown, the present invention is a lithium-ion battery coating process NMP recovery fine steaming purification recycling device, including coating machine 1, heat exchanger 4, runner 7, fine steaming and purification equipment 5, waste liquid tank 18, automatic liquid addition Equipment 6, NMP solution storage tank 31, characterized in that: the heat exchanger 4 includes a heat exchanger high temperature inlet 41, a heat exchanger low temperature outlet 42, a heat exchanger dry air inlet 43, a heat exchanger dry air outlet 44, The left and right sides of the coating machine 1 are provided with a coating machine head 24 and a coating machine tail 25, and an exhaust duct 20 is arranged above the coating machine 1, and the exhaust duct 20 is connected to the exhaust fan 3, and the exhaust fan 3 passes through The air exha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com